respirators in construction script

advertisement

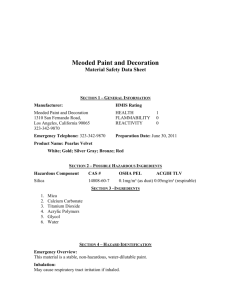

WHITE CAP Course 11 Script Respirators in Construction Slide 1: Welcome Thank you for your interest in respirators in construction. This course provides an introduction to common health hazards encountered on the jobsite and the conditions that necessitate use of respiratory safety equipment. Under the Department of Occupational Safety and Health Administration (OSHA) OSH Act, employers are responsible for providing employees with exposure control plans (ECP) that guarantee working conditions free of known hazards. This course will review sources of exposure that require contractors to use respiratory protection equipment, the types of equipment required for specific jobsite conditions, the safety regulations that govern respiratory protection and products, and respiratory protection programs that address the proper use and maintenance of respirators. Slide 2: Instructions Before we begin, let me point out a few features. On the left, you’ll see two tabs. Use the Notes tab to follow this narration. Click on the Outline tab to track your progress through this course. You can click on a section or page to navigate back to it. On the top right, you’ll see Attachments and Exit. Click on Attachments to download additional resources for this program. Click on Exit to leave this program at any time. Your progress through the course will be saved. When you open the course again, you’ll start at the slide you last completed. On the bottom, there are three buttons: the Play/Pause button and the Forward and Backward buttons. Use the Play or Forward buttons to advance to the next page. Use the Backward button to go back to a previous page. Use the Pause button to pause the program briefly (for instance if you need to stop to take a note). Click Pause again to resume the program. Please note that you cannot skip sections of this program. You must view them in order. You will not be able to advance until you have completed each page. Click the Play or Forward button to advance to the next page. As you progress through the course, you’ll know you can advance when the Play/Pause button blinks light blue and the narration ends. Slide 3: Connection Recommendation To ensure a successful connection as you complete the course, we recommend the following: Use a recommended Web browser: Microsoft Internet Explorer 7 or Microsoft Internet Explorer 8. Use a wired broadband connection. Keep ALL windows associated with the course open while completing the course. If a window opens in your browser as you’re starting the course, leave it open. Close all other programs. Slide 4: Course Progress PLEASE NOTE: This program tracks your course progress so that you can save your session and return at a later time. If you are presented with an error message while completing or exiting the course, or if you believe that you have completed a course but do not see the course list on the “My Training” page under “Your Courses Completed,” please email KeolaniRobles@whitecap.net. The TRADE Center will still record your progress, which will be used to confirm course completions. Slide 5: Course Agenda This course is separated into three sections: hazardous jobsites, respiratory protection equipment, and respirator safety and maintenance. We recommend that you take notes while viewing this presentation to help you learn the information presented. After each section, there will be a short learning check, or assessment. You’ll have to pass the assessment before advancing to the next section. Slide 6: Learning Objectives After completing this course, you will be able to properly answer customer questions about the need for and uses of different respiratory protection equipment. By the end of this course, you will be familiar with: • Respiratory hazards on construction sites. • Different jobsite activities that create hazardous conditions. • Common respiratory equipment and their use and maintenance. • OSHA regulations that govern respiratory protection. • Respiratory protection programs companies must implement. SECTION 1: HAZARDOUS JOBSITES Slide 7 Section 1 will describe the different respiratory hazards and jobsite conditions that necessitate use of respiratory protection. When construction workers drill, grind, cut, or crush construction materials such as concrete, masonry, rock, and tile, they produce particulates, a mixture of extremely small particles and liquid droplets. Particle pollution is made up of a number of components, including acids (such as nitrates and sulfates), organic chemicals, metals, soil, and dust. Particles 10 micrometers in diameter or smaller generally pass through the throat and nose and enter the lungs. Once inhaled, they can affect the heart and lungs and cause serious health problems. Slide 8 The Department of Occupational Safety and Health Administration (OSHA) Regulation 29 CFR 1926.55 provides safety standards specific to gases, vapors, fumes, dusts, and mists, all of which can give rise to severe health disorders, such as poisoning, asphyxiation, and cancer. OSHA sets enforceable permissible exposure limits (PELs) to protect workers against the adverse health effects of exposure to hazardous substances. PELs regulate the amount or concentration of a substance in the air. OSHA’s respiratory protection program details how to detect jobsite hazards; the amount of protection workers will need; and procedures for selecting, wearing, operating, and maintaining respiratory protective equipment. Wearing the wrong respirator can be fatal. Slide 9 OSHA’s respiratory protection program contains provisions for hazard communication training for workers exposed to crystalline silica. Crystalline silica is a basic component of soil, sand, granite, and minerals such as quartz, cristobalite, and tridymite. When workers drill, grind, cut, or chip objects that contain crystalline silica, they may become exposed to respirable crystalline silica, which is associated with the development of silicosis, lung cancer, pulmonary tuberculosis, and airways diseases. Slide 10 INTERACTION: Respiratory Hazards (TAB INTERACTION) Instructions: Click on the tab on the left to hear a description of different types of respiratory hazards. Please note that the narration will provide additional information to the text that is presented on the screen. This additional information is available to download by using the Attachments link at the top right. Respiratory hazards may be present on the jobsite as dusts, fibers, and fumes; mists; gases and vapors; and biological hazards. Dusts, Fibers, and Fumes Dusts and fibers are solid particles formed or generated from solid materials through mechanical processes such as crushing, grinding, drilling, abrading, or blasting. Examples are silica, asbestos, wood, gypsum, and stone. Fumes are airborne particles formed when a metal, which is solid at room temperature, is melted, vaporizes into the atmosphere, and then condenses to a solid again. Examples are metal fumes from welding or cutting. Mists Mists are tiny droplets of liquid suspended in the air. The most common examples are oil mists produced in metal cutting operations and spray paint mist from spraying operations. Gases and Vapors Gases are materials that exist as individual molecules in the air at room temperature. Examples are welding gases, such as acetylene and nitrogen, and carbon monoxide, which may be produced by welding and cutting. Vapors are the gaseous form of substances that are normally in a solid or liquid state at room temperature and pressure, and are formed by evaporation. Most solvents produce vapors. Examples include toluene and methylene chloride. Biological Hazards Biological hazards include bacteria (soil, water), viruses, fungi (mold), and other living organisms that are respirable and can cause acute and chronic infections. Slide 11 INTERACTION: Hazardous Jobsites (Flipbook) Instructions: We'll discuss activities such as demolition, drilling, cutting, grinding, welding, sanding, mixing, and mold removal that can create health hazards on the jobsite. Please note that the narration will provide additional information to the text that is presented on the screen. This additional information is available to download by using the Attachments link at the top right. Click Next to flip the page. Demolition Before the start of any demolition job, the contractor must safeguard the health and safety of workers at the jobsite. Activities such as abrasive blasting, sandblasting, and demolition of concrete and masonry structures can potentially expose workers to hazards posed by dusts. During the pre-job survey, the contractor determines if any hazardous chemicals, gases, explosives, flammable material, or similar dangerous substances have been used or stored on the site. Demolition (2) The contractor determines all safety equipment needs during the planning stage of the job, to include the required number and type of respirators, warning signs, special face and eye protection, and any other dust containment procedures. If the jobsite has an underground location such as a manhole or sewer, the contractor also completes a comprehensive plan for any confined-space entry. The hazards encountered when entering and working in confined spaces are capable of causing bodily injury, illness, and death. Demolition (3) Control measures the contractor would implement on the jobsite might include using safer abrasive blast media containing no or low silica, using local exhaust ventilation, blasting cabinets, dust collection shrouds, water sprays, and wet drilling methods. Workers would wear an N95 or higher rated NIOSHcertified respirator, and a Type CE abrasive-blasting respirator for abrasive blasting. Drilling To protect from harmful dust exposure during drilling, contractors use hammer drills with attached dust removal systems that draw the dust down into a HEPA filter. Placing a HEPA-equipped vacuum near the location of the drill also effectively captures dust. Wet control methods such as spraying dusty surfaces with water also keep dust levels down. When using a dust-removal system, a disposable N95 respirator or a half-face respirator equipped with a 100 series (HEPA) filter is recommended. A full-face respirator with a 100 series (HEPA) filter is recommended when drilling many holes and using dust controls are impractical. Cutting During cutting, workers usually wear respirators to protect themselves from dusts and mists. To control dust, a number of tool manufacturers are designing saws equipped with vacuum shrouds or water attachments. A tight-fitting negative pressure half-face respirator with HEPA filters is the minimum protection recommended. If, for example, concrete is being cut dry, then a full face respirator should be used. Grinding Workers might experience adverse health effects caused by the dust produced during grinding operations and by galvanized coating metals that become airborne during metal grinding activities. Grinding (2) Dust can be suppressed by the use of water, specialty dust filters on grinders, and improved exhaust ventilation systems. Local exhaust ventilation (LEV) systems can be attached to concrete grinders to reduce respirable dust exposures. The P95 and N95 respirators, which filter out 95 percent of particles 0.3 microns and larger, are best suited for general dusts when grinding concrete or metal. Welding Welding can produce hazards such as sparks, spatter, radiation, slag, heat, hot metal, and fumes and gases. The filler, base metal, and base metal coating used during welding operations and the subsequent gases formed during the welding process release small, solid particles into the air creating a plume. This plume is called welding fume. Welding fumes are a mixture of metallic oxides, silicates, and fluorides. All welding processes produce these fumes, but most fumes are produced during arc welding. Welding (2) When electrode coatings, fluxes, shielding gases, and surface coatings are burned or exposed to ultraviolet arc rays, they can generate potentially harmful gases such as carbon monoxide, ozone, nitrogen oxides, gaseous fluoride, and phosgene. Welding (3) Because each component of welding fume has unique toxic effects and varying exposure limits, the exposure level of each component must be measured independently to ascertain selection of the appropriate respirator. The solid particles in welding fume can only be captured with particulate filters. For most welding operations, N95 class filters are recommended because welding fume is relatively easy to filter and oil mist is seldom a factor. Welding (4) Exposure to lead or cadmium requires the use of 100 class filters. Since gases and vapors cannot be removed by particulate filters, they require adsorption in a bed of activated carbon. Certain vapors require specially treated carbon. It is important to select a NIOSH-approved cartridge for the specific vapors present. Each cartridge lists the approved contaminants. In welding operations, the most common cartridges are organic vapor (black label), acid gas (white label), and organic vapor/acid gas (yellow label). Sanding Hazardous amounts of wood dust may be generated by jobs like floor sanding. The main hazards occur where there is poor natural or mechanical ventilation, especially in indoor workplaces with inadequate dust extraction systems. Dusts from hardwoods are usually finer and, therefore, more easily inhaled. Workers exposed to wood dust are at risk of developing nose, throat, lung, and skin conditions. Sanding (2) Reducing wood dust at the jobsite is best handled by using machines enclosed or fitted with local exhaust ventilation systems. Machines with a single cutting, grinding, or sanding face may have several sources of dust blown from different parts of the machine. Ideally, the LEV system should control each dust source. Sanding (3) While most wood dust is generally from machines, hand sanding also can necessitate the use of respiratory protection. NIOSH-approved particulate respirators provide a high level of dust and particle filtration for sanding operations. Mixing Portland cement, one of the most widely used materials in construction, is the basic ingredient of concrete, mortar, stucco, and most non-specialty grout. Cement mixed with other materials can adversely affect health if improperly handled. These additional materials may include alkaline compounds (such as lime) that are corrosive to human tissue, small amounts of crystalline silica, or small amounts of chromium that can cause allergic reactions. Inhaling cement dust may occur when workers empty bags of cement to make concrete and other cement-based materials. When mixing dry cement, control measures include mixing the cement in well-ventilated areas, working upwind from dust sources, and wearing a P-, an N-, or an R-95 respirator to minimize cement dust inhalation. Mold Removal Exposure to mold can cause asthma attacks in addition to eye, skin, nose, and throat irritations. While it is impossible to eliminate all molds, moisture control can help prevent indoor mold growth since mold requires water to grow. OSHA Safety and Health Information Bulletin (SHIB), (2003, October 10), provides recommendations for the prevention of mold growth and describes measures to protect the health of workers involved in mold cleanup and prevention. Mold Removal (2) The cleanup method depends on the type of material affected. Methods include wet vacuum, damp wipe, HEPA vacuum, and disposal of damaged materials in sealed impermeable bags or closed containers. Killing mold with biocide is not enough since the elements that cause reactions in humans are present in dead mold. To remove fungal particulate matter from the air, contractors should wear a P100 or an N95 particulate respirator, possibly with a VOC filter attached for organic compounds. Slide 12: Section 1 Summary This section discussed respiratory hazards and hazardous jobsites. We learned about various respiratory hazards on the jobsite, such as dusts, fibers, fumes, mists, gases, vapors, and biological hazards, and about the activities that can create these health hazards, such as demolition, drilling, cutting, grinding, welding, sanding, mixing, and mold removal. Slide 13: Section 1 Assessment This short assessment will test your knowledge of respiratory hazards and hazardous jobsite conditions. You must correctly answer at least six of the eight questions to advance to Section 2. You will receive feedback after answering each question. If you do not pass on your first attempt, that’s OK. You will be directed to the beginning of the section where you can review the concepts before re-attempting the assessment. Click Next to begin. SECTION 2: RESPIRATORY PROTECTION EQUIPMENT Slide 14 Section 2 will review various types of respiratory protection equipment and the appropriate choice of respirator given specific jobsite conditions. Slide 15 OSHA regulations require contractors to develop and implement a written respiratory protection program for their employees. The program needs to detail how to detect jobsite hazards, explain how much protection workers will need, and describe the proper procedures for selecting, wearing, operating, and maintaining NIOSHcertified respiratory protective equipment. Slide 16 OSHA’s respiratory protection standard provides for an assigned protection factor (APF), which is the workplace level of respiratory protection a respirator or class of respirators is expected to provide to employees under the employer’s respiratory protection program. The standard also assigns a maximum use concentration (MUC), which is the maximum atmospheric concentration of a hazardous substance from which an employee can expect to be protected when wearing a respirator. MUC is determined by the assigned protection factor of the respirator or class of respirators and the exposure limit of the hazardous substance. When no OSHA exposure limit is available for a hazardous substance, the MUC is determined by the employer. Slide 17 The basic parts of a typical half-facepiece respirator include the facepiece body, yolk, and headband, a particulate filter or combination gas and particulate cartridge, cartridge or filter holder, inhalation valve behind holder, an exhalation valve and cover, and a gasket, if applicable. Slide 18 There are primarily two kinds of respirators: air purifying (APRs) and supplied air (SARs). Air-purifying respirators remove contaminants in the air by filtering out particulates (dusts, metal fumes, mists). Air-purifying respirators can also absorb gases or vapors on a sorbent in a cartridge or canister. They are tight-fitting and available in several forms: Mouth bit respirator (fits in the mouth and comes with a nose clip to hold nostrils closed, for escape purposes only). Quarter-mask (covering the nose and mouth). Half-facepiece (covering the face from the nose to below the chin). Full facepiece (covering the face from above the eyes to below the chin). Slide 19 Supplied-air respirators (SARs) supply clean air from a compressed air tank or through an airline, not from ambient air on the jobsite. The air supplied in tanks or from compressors must meet standards for purity and moisture content (e.g., CSA Standard Z180.1-00 (R2010): Compressed Breathing Air and Systems). Slide 20 Supplied-air respirators may have either tight-fitting or loose-fitting respiratory inlets. Respirators with tight-fitting respiratory inlets have half or full facepieces. Respirators with loose-fitting respiratory inlets can be hoods or helmets that cover the head and neck, or loose-fitting facepieces with rubber or fabric side shields. These are supplied with air-through airlines. Slide 21 Examples of air-purifying respirators include: Particulate respirators (dust, fume, and mist respirators or masks). Chemical cartridge respirators that can have a combination of chemical cartridges, along with a dust pre-filter. This combination provides protection against different kinds of contaminants in the air. Gas masks (are more absorbent than cartridge-type respirators and can provide a higher level of protection than chemical cartridge respirators). Powered air-purifying respirators (PAPRs). Slide 22 Air-purifying respirators can be further subdivided into: Filtering facepiece respirators (FFRs), sometimes referred to as disposable particulate respirators because the entire respirator is discarded when it becomes unsuitable for further use due to considerations of hygiene, excessive resistance, or physical damage. These are also commonly referred to as “N95s.” Elastomeric facepiece respirators, sometimes referred to as reusable respirators because the facepiece is cleaned and reused while the filter cartridges and canisters are discarded and replaced when they become unsuitable for further use. Slide 23 Examples of supplied-air respirators include: Self-contained breathing apparatus (SCBA) – an atmosphere-supplying respirator for which the breathing air source is designed to be carried by the user. Airline supplied-air respirators: Continuous flow respirator – an atmosphere-supplying respirator that provides a continuous flow of breathable air to the respirator facepiece. Demand respirator – an atmosphere-supplying respirator that admits breathing air to the facepiece only when a negative pressure is created inside the facepiece by inhalation. Pressure demand respirator – an atmosphere-supplying respirator that admits breathing air to the facepiece when the positive pressure is reduced inside the facepiece by inhalation. Protective suits that totally encapsulate the wearer's body and incorporate a life-support system. Slide 24 Respirators must be NIOSH (National Institute for Occupational Safety and Health) certified and adequate to protect workers from the respiratory hazards that have been identified. Many respirators can be fitted with different filters to protect against different contaminants. Slide 25 Respirators, whether disposable or permanent, are graded with a series of letters and numbers -- N. R, and P, and 95, 99 and 100 -- that relate to the filtering capabilities. The numbers designate how much particulate matter a filter removes from the air. The efficiency levels 95, 99, and 100 mean a filter removes 95 percent, 99 percent, and 100 percent of the contaminants, respectively. Slide 26 The letters designate whether or not filter performance will suffer when oil particles are in the air. Filters marked N offer no oil resistance, those marked Rare oil-resistant, and those marked P are oil-proof. Oil can break down certain types of filters, therefore, it is important to know the materials one is working with at all times in order to select the right filter. Slide 27 Many filtering facepiece respirators have an N95 class filter and many people refer to them as N95 respirators. The NIOSH respiratory protection approval regulation (42 CFR 84), however, defines the term “N95” to refer to a filter class, not a respirator. A filtering facepiece respirator that filters out at least 95 percent of airborne particles (the minimal filtration level NIOSH will approve) is given a 95 rating. There are nine classes of NIOSH-approved particulate filtering respirators currently available. Slide 28 INTERACTION: Types of Respirators (TAB INTERACTION) Instructions: Click on the tab on the left to hear a description of different types of respirators for specific airborne hazards. Please note that the narration will provide additional information to the text that is presented on the screen. This additional information is available to download by using the Attachments link at the top right. There are five common respirators used for specific jobsite activities: dust/mist, particulate, particulate filter-assembled, multi gas/vapor-assembled, half facepiece, and full facepiece. Dust/Mist Respirators Dust/mist respirators are approved for non-toxic dusts and vapor mists having a PEL not less than 0.5mg/m3. They provide N95-level protection against non-oil based particles, and can also be used to reduce inhalation of certain airborne biological particles including mold and bacteria. Particulate Respirators Particulate respirators are suited for heat, humidity, and long periods of wear. Workplace applications include hot, humid, and dusty environments such as welding, soldering and brazing, grinding, sanding, sweeping, bagging, stone quarrying, metal machining, and cement. For areas with oils present, an R or P respirator is recommended. Particulate Filter-Assembled Respirators Particulate filter- assembled respirators come with a dual cartridge respirator, and are certified under NIOSH 42 CFR 84 to have a filter efficiency level of 99.97 percent or greater against oil and non-oil based particulate aerosols. These respirators are suitable for contaminants requiring a HEPA filter, such as asbestos, lead, inorganic arsenic, and cadmium. Multi Gas/Vapor-Assembled Respirators Multi gas/vapor-assembled respirators have multiple gas/vapor cartridges and are approved for ten gas/vapors and for use against multiple hazards in the same workplace. These respirators can provide protection against certain organic vapors, chlorine, hydrogen chloride, sulfur dioxide, chlorine dioxide, hydrogen sulfide (escape only), ammonia, methylamine, formaldehyde or hydrogen fluoride at concentrations of up to 10 times the PEL. Half Facepiece Respirators Half facepiece respirators are commonly used with various filters and cartridges against a variety of gases, vapors, and particulate hazards. Workplace applications include grinding, masonry, pouring/casting, sanding, sawing, and welding. Full Facepiece Respirators Full facepiece respirators with replaceable filter and cartridges combine half and full facepieces with a variety of filters and cartridges for a wide range of respirator protections. Some are NIOSH approved for negative pressure air purifying and positive pressure dual airline applications. Workplace applications include mold remediation, asbestos abatement, construction renovations in old buildings, welding, and painting where workers are exposed to mold, lead dust, and asbestos. Slide 29 Filters are made of material designed to trap particles as one breathes. Cartridges, on the other hand, contain a material that absorbs gases and vapors. The type of filter and cartridge selected depends on whether dusts, fumes, mists, vapors, or gases are present on the jobsite. It is important to use the right filter or cartridge for the substances present on the jobsite. Since filters capture particles, always check that filters are not clogged as it makes it harder for air to pass through and increases the likelihood of contaminated air entering the mask. Cartridges can also become "full" or saturated and gases or vapors can leak through the cartridge. Both filters and cartridges must be replaced on a regular basis according to the manufacturer’s recommendations. Slide 30 INTERACTION: Types of Filters and Cartridges (TAB INTERACTION) Instructions: Click on the tab on the left to hear a description of different types of filters and cartridges. There are five common filters and cartridges used for specific jobsite activities: particulate, flexi-filter pads, organic vapor cartridges, paint and pesticide cartridges, and multiple-gas/vapor smart cartridges. Particulate Filters Particulate filters protect against oil and non-oil, certain dusts, fumes, mists, radionuclides, and asbestoscontaining dusts and mists. Flexi-Filter Pads Flexi-filter, low profile, flexible pads act as a high-efficiency filter (99.7 percent) against 0.3 micron particulates and fit well under welding hoods. Organic Vapor Cartridges Organic vapor cartridges provide respiratory protection from certain organic vapors as well as non-oil and oil particulates. Paint and Pesticide Cartridges Paint and pesticide cartridges protect against paint or pesticide organic vapors. Multi-Gas/Vapor Smart Cartridges Multiple-gas/vapor smart cartridges are approved for nine common gas/vapors and are used for multiple hazards in the workplace. Slide 31: Section 2 Summary This section discussed respiratory protection equipment. We learned that respirators protect workers in two basic ways. The first is by the removal of contaminants from the air. Air-purifying respirators include particulate respirators, which filter out airborne particles, and respirators with cartridges/canisters, which filter out chemicals and gases. Other respirators protect workers by supplying clean respirable air from another source. Supplied air respirators include airline respirators, which use compressed air from a remote source, and self-contained breathing apparatus (SCBA), which include their own air supply. We also learned about the use of various filters and cartridges. Slide 32: Section 2 Assessment This short assessment will test your knowledge of respiratory protection equipment. You must correctly answer at least six of the eight questions to advance to Section 3. You will receive feedback after answering each question. If you do not pass on your first attempt, that’s OK. You will be directed to the beginning of the section where you can review the concepts before re-attempting the assessment. Click Next to begin. SECTION 3: RESPIRATOR SAFETY AND MAINTENANCE Slide 33 Section 3 will review the common elements in a respiratory protection program and respirator safety and maintenance. Slide 34 OSHA’s Respiratory Protection Standard (29 CFR 1910.134) highlights the most commonly used OSHA directives and standards related to respiratory protection, and to the procedures for maintaining and cleaning respirators. OSHA Bulletin: General Respiratory Protection Guidance for Employers and Workers provides basic information on what respirators are, how they work, and what is needed for a respirator to provide protection. OSHA eTool: Respiratory Protection provides employers instruction on the proper selection of respiratory protection and change schedules for gas/vapor cartridges. Slide 35 Employers whose workers wear respirators are required to develop and implement a respirator protection program that covers the following items: Why the respirator is necessary. The respirator’s capabilities and limitations. How to properly inspect, put on, seal check, use, and remove the respirator. How to clean, repair, and store the respirator. How to use a respirator in an emergency situation or when it fails. Medical symptoms that may limit or prevent respirator use. Slide 36 All respirators need to be inspected before and after every use and during cleaning. In addition, emergency respirators and self-contained tank-type supplied air respirators in storage need to be inspected monthly. Respirators need to be inspected for damage, deterioration, or improper functioning, and repaired or replaced as needed. Supplied air respirators need to be checked for proper functioning of regulator and warning devices and amount of air in tanks when used. Any needed repairs or adjustments on supplied air respirators should be done by the manufacturer or technician trained by the manufacturer. On respirators with vapor or gas cartridges, the cartridges should be replaced on a regular schedule. Slide 37 Respirators need to be regularly cleaned and sanitized. This does not apply to paper dust masks, which are disposed of daily. Respirators are cleaned according to either the manufacturers’ instructions or the Respirators Rule cleaning procedures. Products used to clean, disinfect, and dry respirators include industrial respirator washers, respirator dryers, and respirator cleaning chemicals. Cleaning requires that filters, cartridges, or canisters be removed and that facepieces be disassembled by removing speaking diaphragms, demand and pressuredemand valve assemblies, hoses, or any components recommended by the manufacturer. Any defective parts should be discarded or repaired. Slide 38: Section 3 Summary This section discussed the OSHA standard that governs respiratory protection, and common elements in a respirator protection program. We also learned that all respirators need to be inspected before and after every use and during cleaning; and that respirators need to be regularly cleaned and sanitized. Slide 39: Learning Game: Respirator Safety and Maintenance Instead of a formal assessment, we will complete a learning game on respirator safety and maintenance. You must reveal the hidden answer one letter at a time, before time runs out. You will have 1 minute to answer each question. You will be given 2 attempts before you can advance to the next question. Slide 40: Congratulations Congratulations! You have completed Respirators in Construction. Before you go, there are a few things we’d like to share with you. Slide 41: Course Summary You learned about different respiratory hazards and hazardous jobsites. You are now familiar with various respirators and the filters and cartridges they use. You also learned that OSHA governs respiratory protection and products, and the common elements in a respirator protection program that address respirator use and maintenance. Slide 42: Recap You should now be able to: • Identify respiratory hazards on construction sites that require respiratory equipment. • Be more knowledgeable about the appropriate respiratory equipment contractors need for specific jobsite conditions. • Better understand how OSHA regulates respiratory protection, and the respiratory protection programs employers are required to implement. • Advise on the proper maintenance of respirators. Slide 43: Resources Thank you for your time. White Cap’s core value is customer service. By improving our overall understanding of the businesses in which our customers work, we can better help them achieve success. Look for additional programs and resources, such as the items listed here, on the TRADE Center. Look for these additional programs and resources: Additional programs: Identifying Surface Defects on Concrete Slabs Selecting the Right Concrete Repair Materials Anchors and Fasteners Used in Concrete and Masonry Construction The Elements of Design and Construction of a Concrete Slab on Ground Concrete Polishing: Tools, Equipment, and Chemicals Erosion Control for Jobsites Resources: International Safety Equipment Association (ISEA) – www.safetyequipment.org The American Concrete Institute (ACI) – www.concrete.org International Concrete Repair Institute (ICRI) – www.icri.org CONCRETE CONSTRUCTION Magazine – www.concreteconstruction.net White Cap’s TRADE Center Resources – www.hanleywooduniversity.com/whitecaplearning/ Slide 44: Last Slide Close this program by clicking Exit at the top right. Look for these blue buttons on the page for your next action. The Course Exit button will close the course launch page. The Course Forward button will take you to a course feedback form, where you can rate this course. Clicking the Course Forward button after filling out the feedback form will take you to your certificate of completion. You will also be able to find your certificate of completion under the My Training tab on the main TRADE Center page.