Student Proposal

advertisement

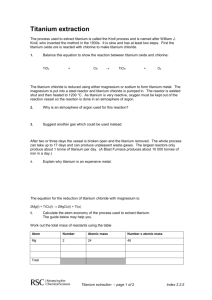

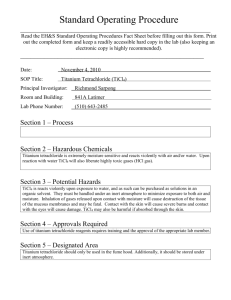

CAREY, SEAN and RUSSELL’S MAJOR PROJECT PROPOSAL TEAM: Carey Arthurson, Sean Sharmon and Russell Smith TEAM FOCUS: Titanium- TiRO/KROLL method of Titanium production and 3D printing of Titanium MENTOR: Andrew Urban and Chad Henry at CSIRO, Clayton MATERIAL SAMPLES: 3D printed part/sample from CSIRO : 8mm thick x 10cm long x 4cm wide PLANNED TESTING and TEAM FOCUS We have obtained two different samples of Titanium, one being a 3D printed part/piece from CSIRO, and the other being a small piece of Titanium sheet measuring 8mm thick x 10cm long x 4cm wide. The exact grade of Titanium is unknown at this stage. From the Titanium sheet, 8mm thick, we plan to section it and obtain two tensile test pieces, one piece for initial testing and the other for ‘Double Loop’ testing. The test pieces need machining to obtain the correct profile and thickness. As we are limited to a maximum tensile force of 24kN, research of previous Tensile Testing of Titanium will be needed to find the thickness needed of the test pieces, so that our testing will not exceed the limits of the INSTRON Tensile Testing machine. Standards will be referred to and a correct gauge length will be obtained and then machined to the required dimensions. Also from the 8mm thick sample we will section two ‘Hardness testing’ samples, one for the initial test and the second for the ‘Double Loop’ test. For microscopy we will section/cut approximately eight to ten test pieces. Two or three test pieces will be used for the initial testing and two or three samples will be used for the ‘Double Loop’ testing. After mounting of these test pieces, polishing and etching is required for viewing under the microscope. After some research it has become apparent that Titanium is a difficult material to prepare. To obtain clear and deformation/scratch free microscopy the etching required is that of the etchant known as WECK’S REAGENT, which is also a dye, and requires a polarised light filter for clear microstructure analysis. The microscope available to use does not have polarised light . The other etchant that can be used is known as KROLL’S REAGENT which contains HYDROFLUORIC ACID. (Weck’s reagent also contains HF acid) We are unable to use Hydrofluoric Acid in the Laboratory. So, we are unable to etch the mounted samples in the on-site laboratory. We are hoping to approach a business or person that can do Kroll’s Reagent etching for us, and try to get them to do this for us free of charge. Page | 1 The other three or four samples are to try a formula found researching these etchants. This etchant formula does not contain HF acid, but uses NITRIC ACID and HYDROGEN PYROXIDE. The results of this etchant are not to the standard of the Kroll’s reagent, thus they recommend using the Kroll’s Reagent on another batch of samples. If the unnamed etchant does not produce a finish of a standard needed, hopefully we will have had another batch of samples done off-site using the Kroll’s Reagent. The results of these two etchants will also be looked at and analysed. The 3D printed sample can only be cut for microscopy, as the piece is wave shaped and rather small. A flat piece for hardness testing is probably not achievable. As described above, eight to ten samples for microscopy will be prepared along the same method as previously described. From the testing we shall do, we may be able to determine the exact grade of Titanium, in reference to relevant Standards. We will also address the TiRO and KROLL methods of Titanium production. All Titanium is produced using the Kroll method, with the TiRO method being an improvement on the original Kroll method. The TiRO production method is a highly involved and intricate process that starts with the raw material, being ORE, and ending with a highly pure form of titanium. Several chemicals are used in the processing steps from ore to metal, all of which will be examined and discussed. Testing of the ore, such as purity, and testing of the final product, oxygen and nitrogen content are performed. We will research these testing methods, such as X-RAY INFLUORESENCE (XMF), the LECO method, and several others, and describe and discuss these testing methods. OH&S will also be discussed. Page | 2