Structural behavior of confined R

advertisement

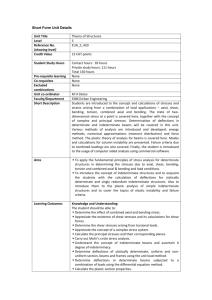

Shear Strength Response of HSRC deep beams without Stirrups Part II Beam characteristics Ahmed I. Ramadan*; Aly G. Abd-Elshafy; Mahmoud H. Ahmed and Atif M. Abdel-Hafez Civil Engineering Department, Faculty of Engineering, Assiut University, Assiut, Egypt *Corresponding email: a.i.h.r1978@gmail.com Abstract: ACI code specifies the shear strength of deep beams based on the strength at the first diagonal crack of NSC beams without the consideration of beam size effect. Therefore, it is necessary to evaluate if the ACI design equation for deep beams is applicable to high strength reinforced concrete (HSRC) deep beams with main reinforcement ratio less and more than 1% with considering size effect or not. This paper is considered a supplement to the companion paper (Part I Comparison of Design Equations). Eighteen simple span HSRC deep beams without stirrups were tested to examine various parameters on the shear capacity; f’cu=50 MPa, three values of main reinforcement, (ρs%), (0.73%,1.21% &1.83%) and four values of shear span to overall depth ratio, (a/h), ( 0.84,1.3,1.7&2.3) were selected to mainly study the characteristics of deep beams. The increase in overall depth (h) under the same a/h=1.3&1.7, led to more brittle failure with wide diagonal cracks and high energy release rate related to size effects. HSRC deep beams exhibited more remarkable size effects with regard to brittle behavior. It was also shown that the ACI code gives similar safety factors on the shear strength at the first diagonal crack of HSRC deep beams, but do not specify a high enough safety factor on their ultimate strength due to the size effects. Keywords: deep beams, high strength concrete, first diagonal crack, ultimate strength, Beam characteristics. 1. INTRODUCTION Deep beams are structural elements loaded as beams but having small shear span to effective depth ratios. These have useful applications in many structures, such as tall buildings, foundations, offshore structures, and several others. Many formulas in concrete design codes can of course be developed purely empirically because it is possible to obtain sufficient test data for the entire range of practical interest, and to sample that range statistically uniformly, without alignment; an example is the ratio of tensile and compressive strengths, or the effect of reinforcement ratio in various code specifications. Unfortunately, the size effect is not a problem of that kind. Thus, it is necessary to investigate the shear behavior of deep beams according to various variables including beam size. Based on the strength at the first diagonal cracks of NSC normal beams without the consideration of size effects, the ACI code [1,2] specifies the shear strength of beams. The design code has been developed from experimental results obtained from concrete beams without shear reinforcements, and with concrete strength less than 40 MPa, an average overall depth of 340 mm, and an average reinforcement ratio of 2%. Thus, it is necessary to investigate the validity of the ACI code when applied to concrete deep beam in other ranges. A number of papers reporting on the shear strength of normal beams have concluded that the ACI code tends to overestimate the shear strength as concrete strength and overall depth increase. Collins and Kuchma [3] showed experimentally that the ACI code overestimated the shear capacity of reinforced concrete beams having large sections and small reinforcement ratios. Smith and Vantsiotis [4] compared between test data obtained from an experimental investigation of 52 simply supported deep beams and mathematical model. They reported that considerable increase in loadcarrying capacity occurs with increasing concrete strength and decreasing shear span to depth ratio. The shear strength of deep beams is closely related to the beam size. There have been many studies to investigate the size effects of normal beams with test variables like shear span to depth ratio (a/h) and maximum diameter of aggregates by Kani [5], Taylor [6], Walraven and Lehwalter [7]. However, these experiments were confined to concrete strengths less than 40 MPa and the size effects according to overall depth under the same shear span/depth ratio were investigated. Taylor [6] reported that size effects diminish if the maximum diameter of aggregates increases in proportion to the increase in overall section depth. Tan and Lu [8] made a study of size effects of deep beams having a/h=1.0, concrete strength of 40 MPa, and reinforcement ratio of 2.6 %, and evaluated and compared the shear behavior of deep beams as the overall depth increases. They reported that the ACI code predictions are generally conservative for all sizes of beams even though the conservatism decreases with increasing h and a/h, the CIRIA [9] predictions are unsafe for large beams with h exceeding 1000 mm, and the Canadian CSA code [10] predictions provide uniform safety margin for the beam specimens. The experimental variables to investigate size effects on the shear behavior of deep beams have been limited to aggregates less than 10 mm and concrete strength of 40 MPa. Thus, it is difficult to apply the experimental results to members having HSC greater than 40 MPa and other aggregate sizes. The shear behavior of HSC deep beams with reinforcement ratios less and more than 1% should be evaluated according to the change of overall depth and the validity of the ACI code should be examined. The objective of this paper is to evaluate the shear strength as an index to predict the load carrying capacity and behavior of 18 HSRC deep beams without web reinforcement and to investigate the validity of the ACI code involving beam size effects. Test variables include compressive concrete strength f’cu=50 MPa, tensile reinforcement ratio (0.73%, 1.21% &1.83%), the shear span to effective depth ratio-(a/d)-(1, 1.5 &2), shear span to overall depth ratio-(a/h)-(0.84, 1.26, 1.3, 1.7 & 1.75), and overall depth (h=400 & 700 mm). 2. EXPRIMENTAL PROGRAM 2-1 Test Specimens This paper consist of eighteen HSRC deep beams, two groups; nine deep beams each, without stirrups, summarized in Table 1 and dimension details shown in Fig. 1, was tested. The anchorage of the longitudinal bars was maintained according to ACI (318-11)-Section (12.5). The width of the bearing plate at the two loading points, two support points and development length of main steel bars were calculated, Fig. 2. Only the two support points were reinforced by three web reinforcements to avoid bearing failure. The clear thickness of cover concrete was selected as 40 mm to prevent a splitting failure of concrete. Strain gages were used to measure the strain of the longitudinal bars in the specimens. All the beams were tested to failure under two point symmetric loading. The distance between the two loading points for the specimens (ah) were varied according to a/h. However, the distance between the two loading points for the specimens of h = 600 mm was chosen according to two a/h ratios of 0.5 and 1.0. Based on the study by Tan et al. [11] that (L/h) does not affect the ultimate shear strength of deep beams, this study did not consider the effects of (L/h). Table 1. Specimen Details a ar a/h a/d S mm mm mm s 1224 1.7 2 326 200 1224 1.7 2 326 200 1224 1.7 2 326 200 918 1.3 1.5 332 800 918 1.3 1.5 332 800 918 1.3 1.5 332 800 1600 2.3 1 326 1000 1600 2.3 1 326 1000 1600 2.3 1 326 1000 10 11 12 13 14 15 16 17 18 h mm B700-2-50-r1 700 B700-2-50-r2 700 B700-2-50-r3 700 B700-1.5-50-r1 700 B700-1.5-50-r2 700 B700-1.5-50-r3 700 B700-1-50-r1 700 B700-1-50-r2 700 B700-1-50-r3 700 d mm 660 660 660 660 660 660 660 660 660 28 29 30 31 32 33 34 35 36 B400-2-50-r1 B400-2-50-r2 B400-2-50-r3 B400-1.5-50-r1 B400-1.5-50-r2 B400-1.5-50-r3 B400-1-50-r1 B400-1-50-r2 B400-1-50-r3 360 670 1.7 2 330 360 670 1.7 2 330 360 670 1.7 2 330 360 502.5 1.3 1.5 348 360 502.5 1.3 1.5 348 360 502.5 1.3 1.5 348 360 335 0.84 1 365 360 335 0.84 1 365 360 335 0.84 1 365 Beam Name 400 400 400 400 400 400 400 400 400 P/2 800 800 800 1000 1000 1000 1000 1000 1000 Leff ρs (%) Pu(test) KN mm 2948 0.73 562.0 2948 1.21 997.0 2948 1.83 939.8 2936 0.73 1007.0 2936 1.21 1399.9 2936 1.83 1288.3 2948 0.73 1443.5 2948 1.21 1949.0 2948 1.83 2492.4 2340 2340 2340 2305 2305 2305 2270 2270 2270 0.73 1.21 1.83 0.73 1.21 1.83 0.73 1.21 1.83 P/2 CS 400&700mm No. Ss Strain Gauge Varies LVDT ar a 2 LVDT ah LVDT a Fig. 1 Details of Specimen ar 416.2 451.3 744.5 560.8 886.0 1075.4 862.7 1176.1 1530.4 Fig. 2 Development length calculations for Beam 10 & 28 2-2 Materials The beams are constructed using HSC (50 MPa) provided by a local ready-mix supplier. The strength of the concrete ranged from 48 MPa to 52 MPa with an average value of 50 MPa at the age of 28 days. Four diameters of high strength deformed bars 10, 12, 14, 18, and 20 mm and of 765, 650, 670, 670, and 670 MPa proof strengths respectively were used for longitudinal reinforcement, Fig. 3. 2-3 Test Procedure Each specimen was tested at 28 days as a simply supported beam under four point bending, Fig. 4. Two point loads were applied at constant rate by hydraulic jacks in a load frame. To monitor the behavior of the tested beams, the crack widths, strains in the reinforcement and at the concrete surface, and displacements are measured using different instruments. Instrumentation of the beams includes electrical resistance strain gauges for strain measurements and two of linear variable displacement transducers (LVDTs) for deflection and crack width measurements at middle of span and one at each of middle of shear span. Fig. 3 Stress-Strain of used steel bars Fig. 4 Test Setup of test Specimens 3. RESULTS AND DISCUSSION 3-1 Results All specimens exhibited similar overall behavior, which was characterized by a nearly bilinear response. The measured load, deflection, crack development and failure of each of the eighteen tested specimens were recorded. The tests results for the experimental program are summarized in the companion paper. 3-2 Mode of Failures Initial flexural cracks occurred at the mid-span of the specimen, (10–35%) of maximum load, and then diagonal cracks were propagated, in range 25-85% of maximum load, to the mid-height of beam rapidly. The specimen showed brittle failure mechanism with the appearance of the diagonal crack carrying capacity by strut region. Regardless of the tensile reinforcement ratio, the crack development and failure modes influence the shear span to overall depth ratio (a/h) and overall depth of specimens (h). As in the companion paper, crack patterns of specimens with (a/h = 1.26&1.3) exhibited the combined failure modes of diagonal shear cracks and shear compression. It is logically that the rigidity of tested beams decreased once the diagonal cracks started appear and remarkably decrease with the increase in (a/h), . This can be explained as with increasing overall depth, the beams behave more brittle and more energy release at the diagonal crack. Fig. 5 represents the strain values of the longitudinal bars along hall span for some tested beams, almost symmetric with increasing strains towards mid-span of the beam. It can be shown that the longitudinal bars did not reach the yield strain value, according to steel tension test, (0.46%) at the maximum load. It was observed a sudden reduction in strain values of main reinforcement between the inner edge of the support plate and the back side of the plate. Before failure occurs, strains in excess of yield were recorded near the face of the bearing plate of support. a) Beam 10 b) Beam 11 a) Beam 18 b) Beam 33 a) Beam 35 b) Beam 36 Fig. 5 Strain distribution of lower layer of reinforcement steel Japanese electrical strain gages were used to measure concrete strains in the mid-span region and at the middle of inclination line between load plate and bearing support plate (εST). Fig.5 (a-f) illustrate the progression of surface concrete strains (εc), at failure in the flexural compression zone ranged between 0.001 and 0.0035, and at the strut region, which simulates the main load-carrying strut assumed in the STM design, with increasing the applied load for two locations. 3000 2500 Load (kN) 2000 Relationship between applied load & strains of concrete & SG of strut for B16 & 17 & 18 1500 1000 500 CS1 B16 CS2 B16 0 Strain ε-750 (μm) -2250-2000-1750-1500-1250-1000 -500 -250 0 250 a) Beams 10, 11 & 12 Load (kN) 1100 Relationship between applied load & 1000 strains of concrete & SG of strut for 900 800 B10 & 11 & 12 700 600 500 400 300 200 100 CS1 B10 CS2 B10 0 (μm) -2900 -2650 -2400 -2150 -1900 -Strain 1650 -1400 -ε1150 -900-650-400-150 100 b) Beams 13, 14& 15 Load (kN) 1000 c) Beams 16, Relationship between applied load & strains of concrete & SG of strut for B28 & 29 & 30 CS1 B28 CS2 B28 0 ε (μm) -2000 -1750 -1500 -1250Strain -1000 -750 -500 -250 0 250 17& 18 1500 1250 Load (kN) 1000 Relationship between applied load & strains of concrete & SG of strut for B13 & 14 & 15 750 500 250 CS1 B13 CS2 B13 0 Strain (μm) -250 -1750 -1500 -1250 -1000 -750 ε-500 0 250 d) Beams 28, 29& 30 Load (kN) 2000 Relationship between applied load & strains of concrete & SG of strut for B31 & 32 & 33 CS1 B31 CS2 B31 0 ε (μm) -2000 -1750 -1500 -1250Strain -1000 -750 -500 -250 0 250 e) Beams 31, 32& 33 Load (kN) 2000 Relationship between applied load & strains of concrete & SG of strut for B34 & 35 & 36 CS1 B34 CS2 B34 0 Strain ε (μm)-500 -250 0 250 -2500-2250-2000-1750-1500 -1250-1000-750 f) Beams 34, 35& 36 Fig. 6 (a-f) Relationship of (Papp.- εc & εST) 3-2 Vision on Diagonal crack and ultimate strength Stresses After the first diagonal crack, the tested beams exhibited much load-resisting capacity by compressive strut action. The difference between the ultimate strength (Vu) and the diagonal crack load (Vcr) is defined as reserve strength which was analyzed according to the experimental variables. This study considered Vu/Vcr as a way to measure the reserve strength. At Table 3, the values of Vu/Vcr are within the range of 2.2–4.7 at the specimens of a/h = 1.3 and 1.6–5.7 for a/h = 1.7. It can be understood that the increase in overall depth of beam section led to the decrease in load-carrying capacity after the diagonal crack, [12]. Based on (a/h), Vu and Vcr were investigated according to tensile steel ratio (ρs%); where r1,r2 and r3 indicate to 0.78%, 1.21% and 1.83% respectively, and is illustrated in Fig. 7,8,9&10. With, at constant f’c =50MPa for all tested beams, increasing (ρs%), 0.78%, 1.21% & 1.83%, for same (a/h) and the overall depth increases from 400 to 700 mm, ѵcr which is the shear stress at the first diagonal crack increase about 40,52&60% respectively at a/h=1.3 and 40,70&90% respectively at a/h=1.7. While on the contrary, with increasing (ρs%), 0.78%, 1.21% & 1.83%, for same (a/h) and the overall depth increases from 400 to 700 mm, the ultimate shear stress ѵu reduced about 5,16&53% respectively at a/h=1.3 and 35,40&45% respectively at a/h=1.7. The increase in overall depth led to the reduction of the resisting capacity. The reduction of the resisting capacity with increasing overall depth is caused by the decreased aggregate interlocking action due to large crack widths and high energy release rate due to a number of cracks at the concrete strut. The specimens of 700 mm overall depth showed several flexural cracks but did not show much diagonal cracks. In the specimens of 400 mm overall depth, flexural cracks gradually extended to compression region of beam section, and diagonal cracks were considerably developed at the concrete strut. It can be understood that deep beams after the first diagonal crack resist the load by compressive strut action and the crack width gradually increases with higher energy release rate due to the reduction of reserve strength. r1,h400 r2,h400 r3,h400 1.00 r1,h700 0.00 r2,h700 0.00 0.50 1.00 1.50 2.00 2.50 Fig. 7 (ѵcr - a/h) a 10.00 Fig. 8 ѵu a/h 5.00 MPa MPa ѵcr 2.00 ѵcr a/h ѵu 3.00 r1,h400 r2,h400 r3,h400 r1,h700 0.00 r2,h700 0.00 0.50 1.00 1.50 2.00 2.50 a (ѵu - a/h) r2,ѵcr a r2,ѵu r3,ѵcr 2.00 6.00 ѵcr , ѵu - a/h , h=700 mm r1,ѵcr r1,ѵu 4.00 MPa r1,ѵu 8.00 ѵcr, ѵu r1,ѵcr MPa ѵcr, ѵu 10.00 ѵcr , ѵu - a/h , 8.00 h=400 mm 6.00 4.00 2.00 0.00 0.00 1.00 r2,ѵcr 0.00 r3,ѵcr 0.0 0.5 1.0 1.5 2.0 2.5 2.00 r2,ѵu a Fig. 9 (ѵcr ,ѵu - a/h) for h=400 mm (ѵcr ,ѵu - a/h) for h=700 mm Fig. 10 It can be observed that the increase in (ρs%) cause good development in ultimate strength of deep beams. Comparing results of a/h=0.84,1.3,1.7& 2.3, it can be observed that the specimens of a/h=0.84&1.3, which show high energy release rate, are less sensitive than that of a/h=1.7&2.3. 3-3 Comparison between ACI 318-11 code and experimental shear strength results According to ACI code specification, the shear strength is the sum of the shear strength of concrete contribution and those of the stirrups. The ultimate shear strength of deep beams without stirrups is expressed by multiplying the diagonal crack strength of concrete beams (Vcr)test by the reserve strength factor (Vu)test /(Vcr)test. According to the specification of ACI code, there is a restriction on material properties in shear design equation, as concrete strength < 40 MPa, the overall depth in range of (300–500) mm, and 2.2% for the main reinforcement ratio. Therefore, it is necessary to investigate the validity of the ACI code on HSRC deep beams without stirrups with considering the size effect and the reserve strength. Table 2 compares experimental results and analytical results calculated by ACI eqs. (1),(2) for shear design code of deep beams: (Vcr)ACI = [0.156 √f’c +17.96ρ (Vu d/Mu ] bwd (1) (Vc)ACI = [3.5-2.5 Mu/Vu d ] [ 0.156 √f’c +17.96ρ (Vu d/Mu) bwd (2) ;where; [3.5-2.5 Mu/Vu d ]≤2.5 , (Vc)ACI ≤ 0.5 √f’c bwd (Vcr)ACI denotes the shear strength at the first diagonal crack, and (Vc)ACI the shear strength contributed by concrete. a/h Pcr (KN) (Vcr)test (KN) (Vu)test (KN) (Vu)R (KN) 1.7 1.7 1.7 1.3 1.3 1.3 2.3 2.3 2.3 1.7 1.7 1.7 1.3 1.3 1.3 0.84 0.84 0.84 122.5 125 130 137.5 175 245 200 200 260 34.63 37.17 37.84 35.76 38.81 35.91 31.82 34.49 33.07 175 200 240 175 265 300 300 325 450 50 65 65 60 75 110 120 115 150 281.0 498.5 469.9 503.5 699.9 644.1 721.8 974.5 1246.2 208.1 225.7 372.3 280.4 443.0 537.7 431.4 588.0 765.2 106.0 298.5 229.9 328.5 434.9 344.1 421.8 649.5 796.2 158.1 160.7 307.3 220.4 368.0 427.7 311.4 473.0 615.2 ACI (318-11) code Values (Vu)tes t /(Vcr)te st 1.6 2.5 2.0 2.9 2.6 2.2 2.4 3.0 2.8 4.2 3.5 5.7 4.7 5.9 4.9 3.6 5.1 5.1 ValueTest /ValueACI ѵu/√f'c (Vcr)ACI (KN) (Vu)ACI (KN) (Vu)test /(Vu)ACI 10 11 12 13 14 15 16 17 18 28 29 30 31 32 33 34 35 36 Experimental Values (Vcr)test /(Vcr)ACI Beam No. Table 2. Test results and ACI values of Vcr ,Vu & ѵu/√f'c 0.2 0.4 0.4 0.4 0.6 0.6 0.6 0.8 1.1 0.3 0.2 0.6 0.4 0.7 0.8 0.9 1.2 1.2 193.7 201.3 211.3 197.6 207.8 221.0 190.9 196.8 204.4 105.6 109.8 115.2 107.7 113.3 120.5 112.0 120.3 131.1 197.7 205.0 214.4 201.4 211.1 223.6 195.1 200.7 207.9 107.8 111.8 116.9 109.8 115.1 121.9 113.8 121.7 131.9 0.9 1.0 1.1 0.9 1.3 1.4 1.6 1.7 2.2 0.5 0.6 0.6 0.6 0.7 0.9 1.1 1.0 1.1 1.4 2.4 2.2 2.5 3.3 2.9 3.7 4.9 6.0 1.9 2.0 3.2 2.6 3.8 4.4 3.8 4.8 5.8 3-4 Shear strength at the first diagonal crack & Ultimate shear strength Fig. 11 illustrates the relation of (Vcr)test / (Vcr)ACI and a/h according to ρs% & h. It can be shown, the experimental result is (1.3-1.4) & (1.6-2.2) times as large as the ACI code in case of h=400 mm and a/h=1.3& 2.3 respectively. However, the safety factor decreases with the increase in the depth, the specimens of overall depth 700 mm exhibit an inadequate safety factor. It can be concluded that the calculation of predicted load at the diagonal crack according to ACI 318-11 for HSRC tested deep beams, 700 mm, should include the size effects. Fig. 12 shows the variation of (Vu)test / (Vu)ACI to compare the ACI code 318-11 and the experimental results with variation of (h). The safety factor represents a tendency to abruptly decrease with the increase in the overall depth of beam. Based on this experimental study, it can be observed that the ACI code prediction 318-11 overestimates the ultimate shear strength of HSRC deep beams with overall depth 700 mm. Thus, it can be expected that the ACI code prediction regarding the ultimate shear strength of deep beam is conservative for HSRC deep beams with (Vcr)test /(Vcr)ACI 2.00 (Vcr)test /(Vcr)ACI a/h r1,h400 r2,h400 r3,h400 r1,h700 1.00 (Vu)test /(Vu)ACI - a/h 1.50 r1,h400 r2,h400 1.00 (Vu)test /(Vu)ACI 3.00 r3,h400 r1,h700 0.50 r2,h700 0.00 0.00 1.00 a 2.00 r3,h700 3.00 r2,h700 0.00 0.00 1.00 a 2.00 r3,h700 3.00 overall depth 400 & 700 mm. Fig. 11 ( ѵcr,test/ ѵcr,ACI - a/h) Fig. 12 ( ѵu,test/ѵu,ACI - a/h) 7. CONCLUSIONS This experimental study investigated the shear strength response of HSRC deep beams by studying the beam characteristics as size effects and evaluated the validity of the ACI code 318-11. As a conclusion of the experimental results, it was observed that: 1) The tested beams of a/h =0.84&1.3 show less sensitive size effects than the ones of a/h=1.7&2.3, with more brittle failure at strut region and higher energy release rate as the results of size effects with the decrease in a/h. 2) At constant f’c =50MPa, increasing (ρs%) 0.78%, 1.21% & 1.83%, for same (a/h) and (h) increases from 400 to 700 mm, ѵcr increase about 40,52&60% respectively at a/h=1.3 and 40,70&90% respectively at a/h=1.7. 3) On contrary, at constant f’c =50MPa, increasing (ρs%) 0.78%, 1.21% & 1.83%, for same (a/h) and (h) increases from 400 to 700 mm, ѵu reduced about 5,16&53% respectively at a/h=1.3 and 35,40&45% respectively at a/h=1.7. 4) a/h=0.84 show high energy release rate, it can be concluded that the specimens represent more brittle failure of concrete strut and higher energy release rate as the results of size effects with the decrease in a/h. 5) Depending on the results of size effect, the safety factor decreases with increasing in the overall depth, especially 700 mm depth exhibit an inadequate safety factor. 6) The ACI code prediction overestimates the ultimate shear strength of deep beams with overall depth 700 mm. Thus, it can be concluded that the calculation of predicted load at the diagonal crack according to ACI 318-11 for HSRC tested deep beams, 700 mm, should include the size effects. REFERENCES [1] ACI Committee (318-11), Building code requirements for structural concrete (318-11) and commentary-(318R-11). Detroit, Michigan: American Concrete Institute, 2011. [2] ACI-ASCE Committee 426. Shear strength of reinforced concrete members. Proceedings, ASCE 1973;99(6):1091–1187. [3] Collins MP, Kuchma D. How safe are our large, lightly reinforced concrete beams, slabs and footings? ACI Struct J 1999;96(4):482–90. [4] Smith KN, Vantsiotis AS. Deep beams test results compared with present building code models. ACI J 1982;79(3):280–7. [5] Kani GNJ. How safe are our large reinforced concrete beams? ACI J Pro 1967;64(3):128–41. [6] Taylor HPJ. Shear strength of large beams. J Struct Division, ASCE 1972;98(11):2473–90. [7] Walraven J, Lehwalter N. Size effects in short beams loaded in shear. ACI Struct J 1994;91(5):585–93. [8] Tan KH, Lu HY. Shear behavior of large reinforced concrete deep beams and code comparisons. ACI Struct J 1999;96(5):836–45. [9] CIRIA. CIRIA Guide 2. The design of deep beams in reinforced concrete. Ove Arup and Partners. Construction Industry Research and Information Association, 1984. [10] Canadian Standards Association. In: Design of concrete structures for buildings. Rexdale, Ontario: CSA; 1984. p. 281. [11] Tan KH, Kong FK, Teng S, Guan L. High-strength concrete deep beams with effective span and shear span variations. ACI Struct J 1995;92(4):395–405. [12] Keun-Hyeok Yang, Heon-Soo Chung, Eun-Taik Lee, Hee-Chang Eun Shear characteristics of high-strength concrete deep beams without shear reinforcements, Engineering Structures, Volume 25, Issue 10, August 2003, Pages 1343-1352. NOTATIONS a = Shear span, distance between concentrated load and face of support, in mm ah = distance between two concentrated loads , in mm ar = distance between end of beam and face of support, in mm b = Beam width, in mm d = Effective beam depth, in mm do = maximum aggregate size, in mm a/h = shear span to overall depth ratio f’c = Cylindrical compressive strength of concrete, in MPa ρs = Ratio of Longitudinal reinforcement ratio; = As /bd Ss = distance between two stirrups under concentrated loads, in mm Vu = the ultimate strength load Vcr = the diagonal crack load (Vcr)ACI = the shear strength at the first diagonal crack according to ACI code (Vc)ACI = the shear strength contributed by concrete according to ACI code ѵcr = the shear stress at the first diagonal crack ѵu = the ultimate shear stress