Essential Information Required for Changes to/or New Module

advertisement

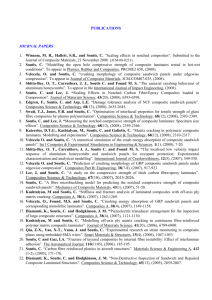

New Module Form Essential Information Required for Module Manager ACADEMIC YEAR ___________ Module Detail Title Composite Materials (maximum 50 characters) Description Introduction to polymer composites, anisotropic elasticity, composite laminated plate theory, anisotropic coupling modes, anisotropic strength theories, experimental testing techniques, plate and shell theory, micromechanics of composite materials, use of numerical software for composite structural design including analytical and finite element analysis codes, manufacturing and experimental testing of composite laminates and coupons. (brief description of the content of the module between 75 – 150 words) *Note Field to indicate taught through Irish/English/Erasmus Module version number and date approved xx/xx/2012 * Course Instances (s) 1SPE, 2SPE, 3SPE, 4SPE ME Mechanical Eng. 1SPD, 2SPD, 3SPD, 4SPD xx/xx/2012 xx/xx/2012 Date Retired Module Owner / Lecturer Module Administrator Details Dr. Conchúr Ó Brádaigh Jane Bowman Please specify main contact person(s) for exam related queries and contact number /email Module Code ( Office use only) Module Type ECTS Core= Student must take the module Optional = Choice for Student Multiple of 5 ects Optional for Core for ME 5 ects Mechanical Eng. Course Requirement (i.e. where a module has to be passed at 40%) Semester Taught Semester Examined Year Long Summer Requisite(s) Co-Req. Modules If they take module X they must take module Y Pre-Req Modules The student must have taken and passed a module in previous year Excl.Req. Modules If they take module X they CANNOT take module Y Module Assessment st 1 Sitting Assessment Type Exam Session Duration Written Paper Semester 2 2 Hours Continuous Assessment Semester 2 Not Applicable 2nd Sitting Bonded Modules (modules which are to be examined at the same date and Draft Created by Syllabus Team as part of Academic Simplification 2012/2013 Page 1 time) Draft Created by Syllabus Team as part of Academic Simplification 2012/2013 Page 2 PART B Workload: ECTS credits represent the student workload for the programme of study, i.e. the total time the student spends engaged in learning activities. This includes formal teaching, homework, self-directed study and assessment. Modules are assigned credits that are whole number multiples of 5. One credit is equivalent to 20-25 hours of work. An undergraduate year’s work of 60 credits is equivalent to 1200 to 1500 hours or 40 to 50 hours of work per week for two 15 week semesters (12 weeks of teaching, 3 weeks study and formal examinations). Module Schedule No. of Lectures Hours 24 No. of Tutorials Hours 6 No. of Labs Hours 20 Recommended No. of self study hours 75 Other educational activities(Describe) and hours allocated Lecture Duration Tutorial Duration Lab Duration Placement(s) hours 1 hr 1 hr 1 hr *Total range of hours to be automatically totalled (min amount to be hit) Module Learning Outcomes (CAN BE EXPANDED) On successful completion of this module the learner should be able to: 1 State the various applications and mechanical properties of fibre reinforced composite materials, as well as the production processes used with same 2 Develop and use anisotropic constitutive models, such as transverse isotropy, in representing the thermo-mechanical behaviour or fibre-reinforced composites 3 Employ thin plate and beam assumptions and derive the Composite Laminated Plate Theory (CLPT) equations for laminates 4 Perform engineering design calculation on composite laminates, and predict stresses and strains in each ply for various loading conditions (mechanical and thermal) 5 Use CLPT modules in software (e.g. CDS software from U. of Delaware) for prediction of laminate stress and strain 6 Use Finite Element Analysis software to model thermomechanical loading of composite plates and shells 7 Understand the manufacturing of composite laminates, coupon extraction and mechanical testing. 8 Compare the predicted strength of composite laminates with the measured strengths in the experiments. Explain the discrepancies between model and experimental results. Module Learning, Coursework and Assessment Learning Outcomes at module level should be capable of being assessed. Please indicate assessment methods and the outcomes they will assess Assessment type, eg. End of year exam, group project Outcomes assessed Draft Created by Syllabus Team as part of Academic Simplification 2012/2013 % weighting Page 3 Written Paper Continuous Assessment 1-4 50 5-8 50 Indicative Content (Marketing Description and content) This module involves the design and testing of fibre-reinforced composite laminates and structures. Mathematical modelling techniques are used in conjunction with numerical software to design composite laminates constructed of anisotropic materials. Significant laboratory work including laminate manufacture, coupon extraction and coupon testing is carried out to compare to the design results. Module Resources Suggested Reading Lists Library Physical (e.g. AV’s) B. D. Agarwal and L. J. Broutman, Analysis and Performance of Fiber Composites, 2nd ed. WileyInterscience; Experimental Characterization of Advanced Composite Materials, D.F. Adams, L.A. Carlsson, R.B. Pipes, CRC Press. Journal IT (e.g. software + version) ABAQUS, CDS Admin FOR COLLEGE USE ONLY Student Quota Quota (where applicable only) (identify number per module where applicable only) Module: Number: Discipline involved in Teaching Share of FTE *(drop down for disciplines within school) Mechanical *(% out of 1) 100 RGAM NB: Notes on some fields are for the technical side when considering which software company to use. Draft Created by Syllabus Team as part of Academic Simplification 2012/2013 Page 4