TWO MARK QUESTIONS AND ANWERS 1. What are the important

advertisement

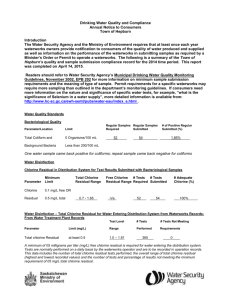

TWO MARK QUESTIONS AND ANWERS 1. What are the important unit operations? 1. Gas transfer: aeration 2. Ion transfer: a. chemical coagulation b. chemical precipitation c. ion exchange d. adsorption 3. Solute stabilization a. chlorination b. liming c. re-carbonation d. super-chlorination 2. What are the types of aerators? i) Gravity aerators ii) Spray aerators iii) Diffusers iv) Mechanical aerators 3. Write the example of chemical precipitation? i) Flocculation of iron in water, by addition of lime ii) Precipitation of carbonate hardness by addition of lime. iii) Precipitation of non-carbonate hardness by addition of soda-ash 4. What are the common forms of solute stabilization? i) Chlorination: by chlorination, hydrogen sulfide in water is oxidized in to sulfate. ii)liming : by passing the water through chips of marble ,lime stone or dolomites ,carbon dioxide in excess of equilibrium requirements is converted in to soluble bicarbonate. iii) Re-carbonation .by re-carbonation of water softened by excess time treatment, excess lime is converted in to bicarbonate. 5. What are the purposes of water treatment? i) To remove color, dissolved gas and murkiness of water. ii) To remove objectionable tastes and odour. iii) To remove the disease producing micro0roganisms so that water is safe for drinking purpose. iv) To remove hardness. 6. Write about objectives of aeration i) It removes tastes and odour caused by gases due to organic decomposition. ii) It increases the dissolved oxygen content of the water. iii) It removes hydrogen sulphide, and hence odour due to this is also removed. iv) Due to agitation of water during aeration, bacteria may be killed to some extent. 7. What are the factors affecting the hydraulic performance of fixed –spray pressure aerators? i) Orifice and nozzle behavior. ii) Orifice effects. iii) Pipe friction associated with multiple take-off. 8. Write on limitations of aeration? i. it is not efficient method of removal of reduction of tastes and odours caused by relatively non-volatile substances such as oils of algae. ii. odour removal is 50 % only when symura was causative organism. iii. Tastes and odours causes by chemicals due to industrial wastes discharged in to receiving waters are not satisfactory. 9. What are the types of sedimentation? Discrete settling Hindered settling Zone settling Compression settling. 10 .what is plain sedimentation? When the impurities are separate from suspending fluid by action natural forces alone by gravity and natural aggregation of the settling particles, the operation is called plain sedimentation. 11. What is chemical precipitation? When chemicals are added to throw dissolved impurities out of solution, the operation is called chemical precipitation. 12. What are the assumptions are made in horizontal sedimentation tank? i. within the settling or sedimentation zone , the particles settle exactly I the same manner as they do in a quiescent tank of equal depth. ii. The flow is horizontal and steady and velocity is uniform in all parts of the settling zone for a time equal to the detention time. 13. What are the elements of sedimentation? i. detention period and displacement ii. Overflow rate and surface loading iii. Basin dimension iv. in-let and out-let arrangement. v. sludge removal devices. 14. What are the factors affecting coagulation? i) Types of coagulant ii) Quantity or dose of coagulant iii) Characteristic of water such as a. type and quantity of suspended matter b. temperature of water c. pH of water iv) Time, violence and method of mixing. 15. Write about common coagulants 1. Alumnium sulphate or alum 2. Chlorinated copperas 3. Ferrous sulphate and lime 4. Magnesium carbonate 5. Polyelectoreds 6. Sodium acuminate. 16. What are the types of filtration? i) Mechanical straining ii) Sedimentation iii) Biological action iv) Electrolytic action 17 .write about the mechanism of disinfections? i) Damage to cell wall of micro-organism ii) Alteration of cell permeability iii) Changing the colloidal nature of the cell protoplasm iv) In-activation of critical enzyme systems responsible for metabolic activities. 18. Write notes on break point chlorination. When chlorine is applied to water, two actions take place one after the other. i) it kills bacteria and disinfections is effected ii) It oxidizes the organic matter .when chlorine is added to pure water which has no chlorine demand, a curve, such as line A. From figure, is obtained between the applied and residual chorine relationship. The chlorine first performs the functions of removing bacteria .during the disinfections process ,the amount of residual chlorine will be less in the beginning, during which various chemicals such as ions of ferrious iron ,sulphides or nitares present in water , will be oxides ,while during stage II ,the combined residual chorine will gradually increase as the demand of disinfections is satisfied ,till a point C is reached where the ammonia of combined residual chlorine will be maximum. 19. What are the factors affecting bacterial efficiency of chlorine? i) Turbidity ii) Presence of metabolic compounds iii) Ammonia compounds iv) pH of water v) Temperature. 20. What are the advantages of Ozonation? 1. It is more powerful disinfectant over a wide temperature. 2. There is no danger of over treatment since ozone decomposes to oxygen. 3. The oxidation products of ozone are non-poisonous and bio degradable. 16 MARK QUESTIONS AND ANSEWRS 1. Explain about the water treatment process? Screening This is adopted to remove all the floating matter from surface waters. It is generally provide at the intake points. Aeration This is adopted to remove objectionable tastes and odour and also to remove the dissolved gases such as carbon dioxide, hydrogen sulphide etc. the iron and manganese present in water are also oxidize d to some extent .the process is optional and is not adopted in cases where water does not contain objectionable taste and odour. Sedimentation The purpose of sedimentation is to remove the suspended impurities .with the help of plain sedimentation, silt, sand etc can be removed. However, with help of sedimentation with coagulants, very fine suspended particles and some bacteria can be removed. Filtration The process of filtration forms very most important stage in the purification of water .filtration removes very fine suspended impurities and colloidal that may have escaped the sedimentation tanks. in addition to this, the micro-organisms present in water are largely removed. Disinfections It is carried out to eliminate or reduce to safe minimum limit, the remaining microorganisms, and to prevent the contamination of water during its transit from the treatment plant to the place of its consumption. Miscellaneous process These include water softening, desalination, removal of iron manganese and other harmful constituents. 2. What are Types of screens? Coarse screens Coarse screens or bar screens are intended to intercept only grosser floating material. They are mostly in the form of bar grill. Then bars are generally of 25 mm size and are spaced at 75 to 100 mm centers. Mostly, bars are kept inclined so that they can be cleaned easily with a rake. Trash tracks are often included in dams and other intake structures. For the purpose of cleaning, they are placed on a slope of 3 to 6 vertical to a horizontal. from figure, the vertical screen is constructed of vertical wires or bars .the strained water enters the screen box, leaving behind leaves and other debris which drops below as sediment .the inclined screen can be lifted onto vertical position from cleaning .in most cases, the common arrangement is to slide a pair of removable screens on to vertical grooves I the walls and bottom of the inlet channel. Fine screens Fine screen are used at surface water intakes, sometimes alone some times following a bar screen .in order that fine screens does not get clogged up, some device is set up to clean it continuously .due to this reason, fine screens are usually arranged as end less band or drums of material perforated with hole of about 6mm diameter .The process is therefore known as ‘automatic straining ‘. Automatic strainers are self cleaning and they work continuously, eliminating solids from the liquid flowing through and disposing of these solids, also continuously. In automatic strainers, appear straining fabric is submerged in water to be strained while the remained of ht fabric remains above the water. 3. Write briefly about the Types of aerators. Cascade aerators: Cascade aerators are the simplest of free fall aerator. Weirs and waterfalls of any kind are cascade aerators. a simple cascade consists of a series of three or four steps of concrete or metal .water is allowed to fall through a height of 1 to 3 meters, and due to this it come into close contact with air .the case cades can be louvered air inlet. The reduction of CO2 is usually in the range of 50 % to 60%. Inclined apron aerator with riffle plates: In this type of aerator, water is allowed to fall along an inclined plane which is usually studded with riffle plates in hearing bone fashion .the breaking –up to the sheet of water will cause agitation of water and consequent. Slat tray aerators. This is most commonly used .it consist of a closed round or square structure containing a series of closed structure containing a series of closely stacked superimposed wood- slat trays .water enters the top of the aerator and is evenly distributed over the topmost tray. the salts in the trays are staggered so that the films of water raining over the edges of the slat in one tray fall on the center of he slats in the slats in the tray just below. Air supplied to the bottom of the aerator with help of a blower, which blows it upward. A ventilator ids provided at the top, which discharge air and gases to the atmosphere .water is collected in the collector pan at the bottom, from where it flows to attach basin or reservoir. Gravel bed aerators. Cascading through beds of coke, lime –stone or other anthracite is to have more efficient CO2 removal than other methods .From figure, a typical gravel bed aerator in which water is applied at the top and trickles down while air is blown upwards. The thickness of gravel bed may be from 1 to 1.5 m. Spray aerators Spray aerators divide the water flow into fine streams and small droplets which come into intimate contact with air in their trajectory .water is sprinkled in the fine jets through nozzles. It requires considerable head, but it reduces carbon dioxide by 70 to 90% or more. Air diffusion In this method, perforated pipe net work installed at the bottom of the aeration tank, and compressed air is blown through theses pipes .the air bubbles travel upward through warter, thus causing aeration. Air diffuser basins have retention period of about 15 minutes and a depth of 3 to 5m. Alternatively, compressed air may inject into the flows of water in a pipe, or air at atmosphere pressure may be drawn in the pipe where a constriction, such as the throat of a venture tube reduces the water pressure below atmospheric. However, aeration under pressure does not remove CO2. 4. Write the details of plain sedimentation tanks. Rectangular tanks In many of these tanks, baffles are provided with the object of preventing shot circuiting. From figure, a rectangular tank, with out baffles, but with a sludge hopper, and sloping floor. Such a tank has high settling efficiency .it is provided with mechanical sludge –removal equipment. The sludge, scrapped by the sludge scrapers is collected in the hopper from where it is removed through the sludge withdrawal pipe connected ti a sludge pump. Circular tank with radial or spiral flow: Though circular tanks are costlier to install, they are convenient for installing mechanical sludge scrapers. The circular tank may have radial or spiral flow. The path of water in such case s is generally from a distributor at the center to canting weir at the circumference. Influent enters through a central pipe and rises up to the baffle box or influent well from where it flows radial towards the circumference .the outlet channels is provided at the circumference. The racking arms move slowly to scrap the sludge which is removed through the sludge pipe connected to a sludge pump. In case of circular ,a spiral –flow tank, the inlet is provide at the circumference and directed at an angle between a radius and a tangent .the outlet ,provided in the form of a submerged weir, is also provided in the form of a submerged weir, is also provide at the outer circumference ,but is of relatively short length. The effect of the inlet velocity is ti rotate the water in the tank and to induce a spiral path for the water from inlet to outlet. Hopper bottom tank with vertical flow: From the figure, a hopper bottom tank, water enters through the centrally placed inlet pipe and is deflected towards by the action of deflector box. Water travels vertically downwards. the sludge settles at the bottom of the hopper, from where it is removed with the help of a sludge pipe connected to a sludge pump. 5. Explain about of mixing devices. Centrifugal pump: In most of cases, centrifugal pump is used to raise the raw water to the settling tank. The required dose of the chemical therefore can be added to the section line of the pump .when water fed with the coagulant passes through the impeller of the pump, mixing is complied by the agitation .however ,after the water comes out ,some gentle agitation is required to get good results, and to accelerate coagulation and sedimentation. Compressed air agitation: In this method the are water fed with coagulant is agitated vigorously by diffusing compressed air from the bottom of the mixing basins. Narrow mixing channel with flume From the figure, a narrow mixing channel with vertical baffles. The coagulant is fed from the feeding tank. The turbulence caused by vertical baffles mixes the chemical toughly .a flume is some times provided to develop the hydraulic jump for causing turbulence ,and also to measure the flow. Mixing basins with baffle walls: From figure, two types of mixing basins with baffles. in the horizontal or round the end type .The water flows horizontally for a short distance makes a complete turn , and continues back and forth around the ends of the baffles .this causes turbulence ,and hence the mixing .another type ,known as vertical or “ over and under type’. Mixing basins with baffle walls are not used now because of high head losses and variations in the velocities. Mixing basins with mechanical devices Most of the modern water treatment plants now have mixing basin with mechanical devices. From the figure, a typical ‘flash mixer ‘in which the raw water and coagulant are agitated vigorously by a paddle operated by a variable speed motor. The intensity of mixing is dependent upon the temporal mean velocity gradient. The turbulence and resultant intensity of mixing is based on the rate of power input to the water. Propeller type impellers, commonly employed in flash mixers, have revolving speeds ranging from 400 to 1400 rpm. The usual ratio of impeller diameter to the tank diameter is 0.2 to 0.4..the shaft speed of propeller is so kept that tangential velocity of greater than 3 m/s, is imparted at the tip of the blades. 6. Explain the components of slow sand filters. A slow sand filters filter unit consists of the following parts. Enclosure tank: The traditional slow sand filter is an open basin, usually rectangular in size, built below finished ground level. The water tight basin or tank is constructed either in stone or brick masonry, with a coatings of water proof material .the floor has a bed slope of 1 in 100 to 1 in 200 towards the central drains. The surface area of the tank varies between 50 square m. to 1000 m 2. And is found on the basis of filtration rate which varies between 100 to 200 lit. Of the water per square meter. The depth of the tank from 2.5 m top 4 m. Filter media The filter media consist of sand layer, 90 to 110 cm thick .the effective size of sand varies from 0,2 to 0.35 ,with common value of 0.3. The coefficient of uniformity varies from 2 to 3, the common value being 2.5 the finer the sand better will be bacterial efficiency, but slower will be filtration rate. Fine sand is suitable when pretreatment is poor, high bacteria and turbidity removal efficiency is desired and saving of wash water is not an important factor. However, if the pretreatment is good and water to be treated is not highly polluted, coarse sand is suitable. The sand should be also containing not more than 2% of calcium magnesium computed as carbonates. Base material The filter media is supported on the base material consisting of 30 to 75 cm thick gravel bed. The gravel base is graded, and laid in layers of 15 cm with topmost layer of the finer size and bottom most layer of coarse of coarse size. Under drainage system The filter media and base material are supported over the under drainage which eventually collect the filter water and delivers it to clean water with the water reservoir. From the figure .the plan of slow sand filter with under drainage system consisting of central drain collecting water from a number of lateral drains .the lateral drains are either earth ware pipes or perforated pipes of 7.5 to 10 cm dia. They may also be open jointed tiles. Appurtenances The various appurtenances that are generally installed for efficiency working are the devices for (i) measuring loss of head through filter media (ii) Controlling depth of water above the filter media. (iii) Maintaining constant rate of flow through the filter. When a newly constructed or newly washed filter unit is put on operation, the filter head is only 10 to 15 cm. but as the upper portion of filter sand gets clogged due to impurities of the water, the filter head increase .in order terminating a constant discharge, the telescopic tube is adjusted manually. 7. Explain about the forms of chlorination? Plain chlorination Plain chlorination is the application of chlorine to plain or raw water supply as it enters distributions systems. It is also includes the chlorination of raw waters in tanks or reservoirs to check the growth of weeds, organic matter, algae, and bacteria. It is also removes color and odour from water. Plain chlorination to untreated water is resorted to when water is relatively clear, water turbidities less than 20 – 30 ppm. The normal dose between 0.5 to 1 p.p.m Pre-chlorination It is the application of the chlorine to water before its treatment –especially before filtration .sometimes, chlorination is done before the raw water enters the sedimentation tanks. This helps in reducing in the amount of coagulates required because of eth oxidations of organic matter. In alkaline water, chlorination may precede aeration. The dose of chlorine residual of 0.1 – 0.5 p.p.m .when it enters the filter plant. Post chlorination It is the application of chlorine top water after its treatment. this is the standard form of chlorination in which chlorine is added to water as leaves the rapid filters and before it enters the distribution systems .the dose of the chlorine should be adjusted that residual chlorine is about 0.21 – 0.2 p.p.m before water enters the distribution systems .it is useful for protection against contamination from cross0connections. Double or multiple chlorination Double or multiple chlorination refers to the application of chorine at two or more points in the purifications .Generally, double chlorination is resorted to, in which chlorine is applied just before water enters the sedimentation tanks and after it leaves the filter plant. These large amounts of bacteria life and other organic matter. Break point chlorination When chlorine is applied to water, two actions take place one after the other. iii) it kills bacteria and disinfections is effected iv) It oxidizes the organic matter .when chlorine is added to pure water which has no chlorine demand, a curve, such as line A. From figure, is obtained between the applied and residual chorine relationship. The chlorine first performs the functions of removing bacteria .during the disinfections process ,the amount of residual chlorine will be less in the beginning, during which various chemicals such as ions of ferrious iron ,sulphides or nitares present in water , will be oxides ,while during stage II ,the combined residual chorine will gradually increase as the demand of disinfections is satisfied ,till a point C is reached where the ammonia of combined residual chlorine will be maximum. This stage of point C is sometimes accompanied by bad taste and odour .Stage II reflects the forming of combined residuals as the ammonia or amines react with HOCL that has formed .further increase in the applied chlorine will result increase in the residual chlorine ,indicating the beginning of eh second action. During this, action, the relation between applied breaks down choramtes changing them to nitrogen compounds while the chlorine residual actually drops. At point D, the bad smell and taste suddenly disappear and the oxidation of organic matter is also complete .the residual chlorine has it minimum value .further addition of applied chlorine result in increase in the residual chlorine as represented by line E. the slope of which will be 45 o .point D on the curve represents break point since further addition of chlorine break through water and appears as residual chlorine .actually, up to point C. In curve B, chloramines have been recorded has residual chorine while at point D (break point) true residual free chorine is revolved. The break point in the chlorination of water may be defined as the point on applied residual chorine curve at which all, or nearly all, the residuals chorine is free chlorine. Free chorine residual is part if the total residuals remaining in water (after a specified contact period) that will react chemically or biologically as hypochlorous acid or hypho chlorite ion. Super chlorination Super chlorination is the application of chorine beyond a stage break point .the addition chlorine sufficient to give a residual chlorine content of 1 to 3 p.p.m. has provide useful to destroy odours and tastes resulting from chlorine products formed between the decomposition product from vegetable matter and algae. Excess chlorine may be added at any points or points of chlorination, though it is usually applied after flirtation. Super chlorination followed by retention of contact period of 30 -60 min. when residual is discharge by means de-chlorination against. De-chlorination It is the process pf excessive chorine from water before distribution to consumer to avoid chlorine tastes. As stated above, de-chlorination should do in such away in that some residual chorine remains in water. De-chlorination is achieved either by aeration or by uses of chemicals such as sodium thio-sulphate, sodium bio-sulphate, activated carbon, KMnO4.. Sodium dioxide gas is applied practically in the same manner, as chlorine, with a contact period of de-chlorination has not less than 10-15 min. Generally 0.3 to 0.6 p.p.m of sulphur dioxide may be required by filtering super chlorinated water through beds of granular activated carbon, excessive chlorine oxidize the carbon to CO2. Due to which odour, taste, the color is removed. 8. What are the Methods available for water distribution systems? Gravity systems In the gravity system, source of water supply is so located with respect to the area of distribution that water is available with sufficient pressure at various points of the area. No pumping normally required. However the purification units air located on hill, and sources of water supply (lake of reservoir) is also located behind hill, pumping may be required to covey water from the raw water source to the purification work. The purified water then follows entirely under gravity this is most reliable and economical distribution system. Combined gravity and pumping system This is the most common system adopted in most of the case, generally, water purification work air located almost at the same level as the area of distribution –specifically when sure of ear water supply is river or a reservoir formed behind a dam. In order to sufficient distribution pressure, filtered water is pumped into clear water reservoir (C.W.R) located either on a higher ground or elevated on tower. The water from elevated from reservoir then flows under gravity as in figure Pumping systems In this systems water is pumped directly in to the distribution of system to achieve the required pressure, as shown in figure. Such as system, is not desirable .generally double pumping is required first to pump raw water from the source to the treatment work and then to pump purified water direct in to the distribution mains. The pumps have to be run at varying speeds according to the variations in the consumption .in case of power failure ,the entire water distribution systems of the locality is distributed .then systems as requires constant attendance.