The Characterization and Novel Synthesis of Acid Terminated Poly

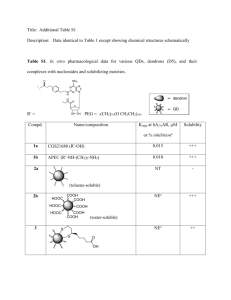

advertisement

NOVEL SYNTHESIS OF (CARBOXYLIC ACID)-TELECHELIC POLY(-CAPROLACTONE) Robson F. Storey and John W. Sherman Department of Polymer Science University of Southern Mississippi Southern Station Box 10076 Hattiesburg, MS 39406-0076 polymerization (Figure 2) clearly show that conversion of the monomer was complete by 3.5 h. However, the final molecular weight (2700 g/mol) was higher than theoretical (2,000 g/mol), which was attributed to the condensation polymerization of the -hydroxyl--(carboxylic acid) oligomers. Additional evidence for the occurrence of condensation polymerization was the appearance of water vapor on the walls of the flask during the quenching process. O Introduction There has been recent interest in using end functionalized low molecular weight polyester prepolymers for the synthesis of biodegradable networks. 1,2,3 These syntheses involve the initial ring-opening polymerization of a cyclic ester, such as lactide, glycolide and/or -caprolactone, with a polyol initiator to produce hydroxyl-telechelic polyesters. The latter have been used in various post-polymerization reactions to produce a variety of polymers containing end groups suitable for cross-linking. In particular, it has been reported that (carboxylic acid)-telechelic polyesters can be synthesized using a two step synthesis4 consisting of isolation of the hydroxyl-telechelic prepolymer followed by reaction with succinic anhydride. The focus of this paper is the synthesis of (carboxylic acid)-telechelic poly(-caprolactone) polymers using a new, one-step method that eliminates isolation of the hydroxyl-telechelic prepolymer intermediate. Experimental Materials. All reagents were used without further purification. Glycolic acid (99%), and succinic anhydride (97%) were purchased from the Aldrich Chemical Co. Stannous 2-ethyl-hexanoate (stannous octoate, 95%) was purchased from Sigma Chemical Co. -Caprolactone (high purity) was donated by Union Carbide Co. Instrumentation. Gel permeation chromatography (GPC) was used to determine molecular weights and molecular weight distributions, M w/Mn, of polymer samples with respect to polystyrene standards (Polysciences Corporation). The system configuration has been described previously.4 13C NMR spectra of the polymers were obtained on a Bruker AC-200 spectrometer using 5 mm o.d. tubes. Sample concentrations were about 25% (w/v) in CDCL3 containing 1% TMS as an internal reference. Synthesis of -Hydroxyl--(Carboxylic Acid) Poly(-Caprolactone). Glassware and stir bar were dried at 145-155C for 24 h, fitted with rubber septa, and cooled under a flow of dry nitrogen. To a 40mL test tube equipped with a 24/40 ground glass joint and magnetic stir-bar were added glycolic acid (5.1 x 10-3 mol, 0.39g), -caprolactone (8.8 x 10-2 mol, 10g) and stannous octoate catalyst (1.4 x 10 -4 mol/mol monomer). The tube was purged with dry N2 gas, sealed with a glass stopper, and placed in a 140C constant temperature oil bath. The polymerization was carried out for 3.5 h with continuous stirring, and then quenched by immersing the tube in an icewater bath. The product was characterized by 13C NMR with no purification. Synthesis of (Carboxylic Acid)-Telechelic Poly(-Caprolactone). To a 40mL test tube equipped with a 24/40 ground glass joint and magnetic stirbar were added glycolic acid (5.4 x 10 -3 mol, 0.41g), -caprolactone (8.8 x 102 mol, 10g), succinic anhydride endcapper (5.4 x 10 -3 mol, 0.55g), and stannous octoate catalyst (1.4 x 10-4 mol/mol monomer). The tube was then purged with dry nitrogen gas, sealed, and placed in a 140C constant temperature oil bath. The polymerization was carried out for 12 h with continuous stirring, and then quenched by immersing the tube in an ice-water bath. The product was characterized by 13C NMR with no purification Results and Discussion -Hydroxyl--(Carboxylic Acid) Poly(-Caprolactone). The synthesis of -hydroxyl--(carboxylic acid) poly(-caprolactone) depicted in Figure 1, involved the reaction of glycolic acid with -caprolactone in the presence of stannous octoate catalyst. In view of the reported role of hydroxyl groups as initiators of the ring-opening polymerization,5,6 this reaction was expected to produce an oligomer (A) containing a carboxylic acid group on one end, derived from a single, terminal unit of glycolic acid, and n units of caprolactone, and terminating in a primary hydroxyl group at the other end of the chain. GPC chromatograms of aliquots taken at various times from the O O n O + SnOct HO OH HO O H O 140 C A O n Figure 1. Synthesis of -Hydroxy--(Carboxylic Acid) End Functional Poly(-Caprolactone). 1h 754 g/mol toluene flow marker -caprolactone 2h 2259 g/mol 3.5 h 2754 g/mol 800 1000 1200 Time (seconds) Figure 2. GPC traces showing the incorporation of -caprolactone during the synthesis of oligomer (A). Figure 3 shows the 13C NMR spectrum of oligomer (A) with structural assignments. The spectrum shows evidence of a mechanism involving the ring-opening polymerization of -caprolactone initiated by glycolic acid followed by condensation polymerization and transesterification. This combination of reactions created a polymer structure containing slightly more than one glycolic acid unit per chain, one at the head of the chain and an occasional additional unit at some random position along the rest of the chain. In the carbonyl carbon region of the spectrum are six peaks designated 1-6. The largest (1) at 173.6 ppm was attributed to the ester carbonyl carbons derived from internal -caprolactone repeat units that are adjacent to other caprolactone units. Only one peak, at 177.2 ppm (2), has a chemical shift characteristic of carboxylic acid carbonyl carbons, and this peak was logically assigned to the carboxylic acid end groups derived from glycolic acid. Peaks 3 and 5 were identified according to the assignments for caprolactone/glycolide copolymers given by Kricheldorf and coworkers, 7 and peak 6, barely discernible as a shoulder on the downfield side of peak 1, was attributed to the carbonyl carbons of -caprolactone units at the hydroxyl end of the chain.5 Peak 4 was assigned to the carbonyl carbons of terminal glycolic acid units at the hydroxyl end of the chain, i.e., (glycolic acid)/hydroxyl end groups. Condensation polymerization alone cannot produce such end groups; however, it was reasoned that in-chain ester linkages of the type ~Gly-O-CO-Capro~ are particularly susceptible to transesterification under the conditions employed in the polymerization, and this reaction resulted in the creation of the observed end groups. In Figure 3, the methylene carbons of -caprolactone are defined as , , , , and , moving away from the carbonyl carbon, while the glycolic acid methylene carbon is defined as g. In the region, there are five peaks of interest: , , OH, g, and g. The largest peak at 64.1 ppm () was assigned to the -carbons of internal caprolactone units that are adjacent to other caprolactone units. The smaller companion peaks at 65.2 ppm () and 62.5 ppm (OH) were attributed to -carbons of caprolactone units adjacent to glycolic acid units and terminal caprolactone units at the hydroxyl end of the chain, respectively. Two peaks due to glycolic acid methylene residues were observed at 60.2 (g) and 60.5 ppm (g). The former was assigned to glycolic acid units surrounded on both sides by caprolactone units. 7 The g peak was assigned to the methylene carbons of terminal glycolic acid units at the carboxylic acid end of the chain. However, a third peak was expected in this region due to the methylene carbon of glycolic acid/hydroxyl end groups. It must be assumed that this peak (gOH) is coincident with either g or g. Later, it will be seen that gOH becomes resolved into a separate peak when the terminal hydroxyl end groups are esterified. In the -carbon region of Figure 3, the main internal caprolactone peak () is flanked on the upfield side by a smaller peak at 33.6 ppm. This peak was attributed to -carbons of -caprolactone adjacent to glycolic acid units. The small peak located at 32.2 ppm, OH, was attributed to the -carbon located at the hydroxyl endgroup.5 The remainder of the , , and regions were insensitive to the presence of adjacent glycolic acid residues. 7 Capro O C CH2 CH2 CH2 CH2 CH2 O Capro O Capro '' O O C CH2 CH2 CH2 CH2 CH2 O HO 3 O Capro caprolactone succinic anhydride toluene flow marker 2h 1397 g/mol 3.5 h 2496 g/mol gOH C CH2 OH 5h 2508 g/mol 9h 2611 g/mol 4 1 Gly attributed to the ultimate -carbon adjacent to the terminal succinyl group. The ultimate methylene carbon of the succinyl end groups () was observed at 29.0 ppm. The penultimate succinyl methylene carbons, () and (), were assigned to peaks at 28.8 and 29.1 ppm, respectively. The existence of two, distinct -methylene carbon peaks lent additional support for the presence of the two types of end groups depicted in Figure 6. C g' O CH2 O C ' CH2 CH2 CH2 CH2 CH2 O 12 h 2538 g/mol 2 g O C C CH2 O Capro 6 5 800 CH2 CH2 CH2 CH2 CH2 OH Time (seconds) '' O Capro OH 180 ', '' g' ' 2 345 60 CH2 O C 40 O 30 20 O OH O ' 7 O CH2 CH2 C OH 9 7 O SnOct 50 ppm 1 39 (Carboxylic Acid)-Telechelic Poly(-Caprolactone). The synthesis of (carboxylic acid)-telechelic poly(-caprolactone) is depicted in Figure 4. This polymerization involved ring-opening of -caprolactone initiated by glycolic acid, with termination by reaction with succinic anhydride. O + O HO O O O 140 C O B OH nO Figure 4. The Synthesis of (Carboxylic Acid)-Telechelic Poly(Caprolactone). GPC was used to monitor the conversion of -caprolactone and the incorporation of succinic anhydride onto the polymer chain end. Figure 5 depicts the GPC chromatograms of aliquots taken at various times, and it clearly shows that by 12 h there is complete conversion of monomer and incorporation of succinic anhydride into the polymer. Figure 6 shows the 13C NMR spectrum of oligomer (B) and suggests that succinic anhydride has been incorporated onto the chain-end and perhaps occasionally into the interior of the chain as a result of condensation reactions. The spectrum revealed a pattern of disappearance and appearance of certain peaks consistent with the reaction of succinic anhydride with the hydroxyl chain ends. For example, two new peaks arose at 178.0 and 172.2 ppm which were attributed to the succinyl carbonyls, 7 and 8, respectively. Closer inspection revealed that peak 8 actually consists of two peaks. This third carbonyl peak at 172.4 ppm (9) and a new peak in the g-region at 60.9 ppm (g) were assigned to succinyl units formed by reaction of succinic anhydride with glycolic acid/hydroxyl end groups. Additional strong evidence of succincic acid incorporation was observed in the - and -carbon regions of the spectrum. The two peaks associated with the hydroxy/caprolactone endgroup, depicted in Figure 3 as OH at 62.5 ppm and OH at 32.2 ppm were absent in Figure 6. The incorporation of the succinyl group caused these carbons to fall in line with the other main-chain caprolactone carbons. The peak at 64.6 ppm () was '' 8 5 72 180 O CH2 CH2 C OH g 70 + HO C g'' Figure 3. NMR spectrum and structural assignments of -hydroxy-(carboxylic acid) end functional poly(-caprolactone). O O 13C n O OH 1 O C CH2 CH2 CH2 CH2 CH2 O C 8 Capro 6 1200 Figure 5. GPC traces showing the incorporation of both -caprolactone and succinic anhydride during the synthesis of oligomer (B). OH 1000 170 ' 70 g'' ' g' 60 ppm ', '' g 50 40 30 20 Figure 6. 13C NMR spectrum and additional structural assignments of (carboxylic acid)-telechelic poly(-caprolactone). Conclusions Initiation of -caprolactone with glycolic acid yields a polymer structure with carboxylic acid head groups derived from glycolic acid and occasional additional glycolic acid units placed randomly along a poly(-caprolactone) chain terminating with a hydroxyl tail. This structure was attributed to initiation by glycolic acid, followed by condensation polymerization and transesterification reactions. When the same polymerization was carried out in the presence of sufficient succinic anhydride to cap the hydroxyl ends of the chains, a (carboxylic acid)-telechelic polymer was produced via a one step synthesis. This method demonstrated good incorporation of the monomer into the polymer in a reasonable amount of time and enabled the elimination of a separate reaction of the polymer with succinic anhydride. Acknowledgements. The authors of this paper would like to thank Boehringer-Mannheim for financial support of this research. References (1) Storey, R.F.; Wiggins, J.S.; Puckett, A.D. J. Polym. Sci. 1994, 32, 2345. (2) Storey, R.F.; Hickey, T.P. Polymer 1994, 35, 830. (3) Storey, R.F.; Warren, S.C.; Allison, C.J.; Wiggins, J.S.; Puckett, A.D. Polymer 1993, 34, 4365. (4) Storey, R.F.; Hickey, T.P. J. Polym. Sci. 1993, 31, 1825. (5) Storey, R.F; Taylor, A.E. J. Macromol. Sci., Chem. 1996, A33(1), 77. (6) Nijenhuis, A.J.; Grijpma, D.W.; Pennings, A.J. Macromolecules 1992, 25, 6419. (7)Kricheldorf, H.R.; Mang, T.; Jonte, F.M. Macromolecules 1984, 17, 2173.