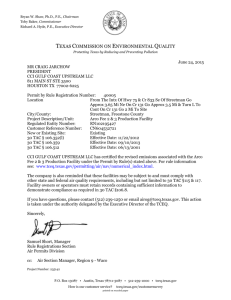

Permit Application Form for a Class I Injection Well

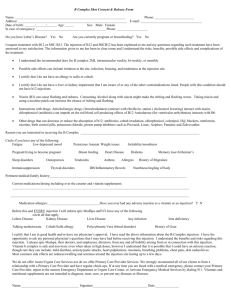

advertisement