Defects in Multiple InGaN/GaN Quantum Wells and

advertisement

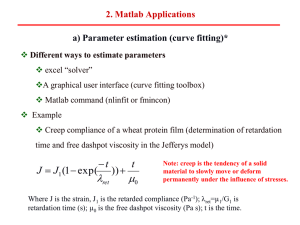

Book of Abstract of The 8th ASEAN Microscopy Conference & 32nd Microscopy Society of Thailand Annual Conference 28-30 January 2015, Nakhon Pathom, Thailand The effect of microstructure obtained after sintering on the Creep of SiAlON Dilek Turan1*, Serkan Ulukut 2 1 Department of Airframe and Powerplant Maintenance, Anadolu University, 26480, Eskisehir, Turkey 2 Department of Materials Science and Engineering, Anadolu University, 26480, Eskisehir, Turkey *Corresponding author, e-mail: dtetik@anadolu.edu.tr Abstract Silicon nitride (Si3N4) based materials are used in high temperature applications due to their high strength, toughness and low density [1-3]. The mechanical and chemical properties of Si3N4 based materials can be tailored further with the addition of aluminum and oxygen into the structure, which are called SiAlON materials. Creep rupture is the major damage form for SiAlON ceramics when used at high temperatures. Creep properties of SiAlON ceramics are determined by the state of secondary phases, i,e. whether it is amorphous or crystalline. The steady state creep mechanisms of SiAlON ceramics containing amorphous intergranular phase has been attributed to viscous flow, grain boundary sliding, diffusion and cavities. In this work, the effect of microstructure obtained after sintering on the creep resistance of SiAlON ceramics was studied. SiAlON was densified with the multi cation sintering additive system containing Er-SmCa and 10wt% SiC as a secondary phase [4]. After sintering, mass loss during sintering process and the bulk density of the samples were measured by using the Archimedes method. Then, the creep tests of the samples were carried out under four-point bending test in air at the temperature of 1390°C and 100 MPa flexural stress for 72 hours. Creep test samples were selected from different bulk densities after sintering. The characterization of existing phases and microstructure of the specimens before and after creep tests were studied with X-ray diffraction (XRD-Rigaku Rint 2000) and scanning electron microscope (SEM-Zeiss Supra 50VP) attached with an energy dispersive x-ray spectrometer (EDX). Density measurement results of non-heat treated samples were given in Table 1. Creep rate and strain of the samples having different densities are given in Fig. 1. According to this figure, the creep strain and flexural creep rates of the samples were observed to increase with increasing density. The average creep rate of high density sample is 4.26x10-8s-1, whereas the average creep rate of low density sample is measured as 4.96x10-9s-1. Microstructures of the samples were examined with SEM and given in Fig. 2. First of all, the density difference can be seen very easily (Fig. 2). Additionally, there are three different regions in these images: (i) oxide layer formed at the surface since the creep tests have been performed in air, (ii) sintering additive rich region (which appears in white and light gray portions) formed by diffusion of additional sintering silicate glassy phase under the top layer and (iii) sintering additive depleted region. The layer below the oxide layer are affected by creep. These layers were different for high density and low density of the samples (Fig. 2). Low density materials contain less sintering additives after sintering due to the evaporation during sintering (Fig. 2). Therefore, as long as the strength of the materials are good enough for the application, slightly less dense material have a better creep strain and creep rate. This also shows that grain boundary sliding is more important than cavities for these ceramics. The relationship between the microstructure after sintering and after creep and the creep behaviour of SiAlON ceramics will be discussed in detail with the help of detailed SEM-EDX analysis. References [1] S. M. Wiederhorn, B.J. Hockey and J.D. French, “Mechanisms of Deformation of Silicon Nitride And Silicon Carbide at High Temperature”, J. Am. Ceram. Soc., 19,2273-84 (1999) [2] A. Carman, E.V. Pereloma and Y. B. Cheng, “Grain Boundary Evolution in Sm-and Nd-SiAlONs during Post Heat Treatment”, J. Austr. Ceram. Soc. 45, 27-34 (2009). [3] M.T. Lin, L. Wang, D.Y. Jiang, G.Q. Zhu and J.L. Shi, “High Temperature Bending Creep of a Sm-- SiAlON Composite” J. Mat. Sci., 37, 655-62 (2002). [1-3] A. Uludag and D. Turan, “High Temperature bending creep behavior of a multi-cation doped -- SiAlON Composite” Ceramics International, 37, 921-26 (2011). Book of Abstract of The 8th ASEAN Microscopy Conference & 32nd Microscopy Society of Thailand Annual Conference 28-30 January 2015, Nakhon Pathom, Thailand Table 1. Densities of the samples after sintering Sample Code ER-1 ER-3 ER-5 ER-71 ER-74 Er-75 Density(gr/cm3) 3,29 3,29 3,29 3,29 3,23 3,20 Figure 1. Creep behavior of non-heat-treated samples for 72 hours at 1390 ° C and under 100 MPa. Figure 2. The microstructure of crept samples with a density of a) 3.29 g/cm3 and b) 3.20 g/cm3.