Detailed Design Workshop - Department of Mechanical Engineering

advertisement

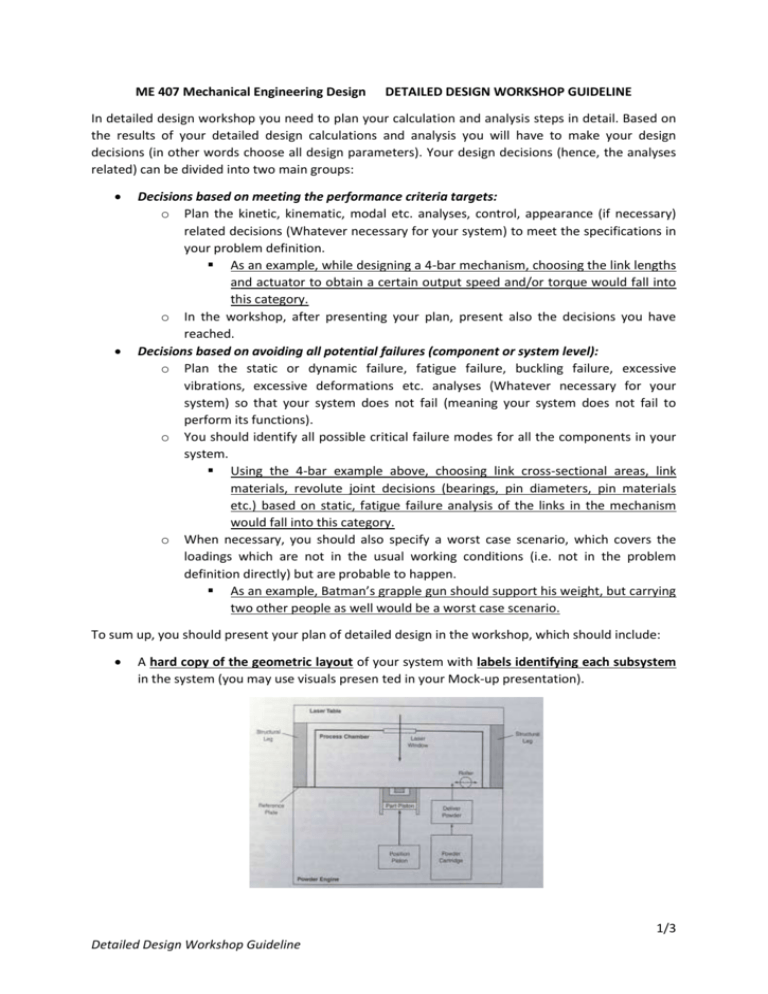

ME 407 Mechanical Engineering Design DETAILED DESIGN WORKSHOP GUIDELINE In detailed design workshop you need to plan your calculation and analysis steps in detail. Based on the results of your detailed design calculations and analysis you will have to make your design decisions (in other words choose all design parameters). Your design decisions (hence, the analyses related) can be divided into two main groups: Decisions based on meeting the performance criteria targets: o Plan the kinetic, kinematic, modal etc. analyses, control, appearance (if necessary) related decisions (Whatever necessary for your system) to meet the specifications in your problem definition. As an example, while designing a 4-bar mechanism, choosing the link lengths and actuator to obtain a certain output speed and/or torque would fall into this category. o In the workshop, after presenting your plan, present also the decisions you have reached. Decisions based on avoiding all potential failures (component or system level): o Plan the static or dynamic failure, fatigue failure, buckling failure, excessive vibrations, excessive deformations etc. analyses (Whatever necessary for your system) so that your system does not fail (meaning your system does not fail to perform its functions). o You should identify all possible critical failure modes for all the components in your system. Using the 4-bar example above, choosing link cross-sectional areas, link materials, revolute joint decisions (bearings, pin diameters, pin materials etc.) based on static, fatigue failure analysis of the links in the mechanism would fall into this category. o When necessary, you should also specify a worst case scenario, which covers the loadings which are not in the usual working conditions (i.e. not in the problem definition directly) but are probable to happen. As an example, Batman’s grapple gun should support his weight, but carrying two other people as well would be a worst case scenario. To sum up, you should present your plan of detailed design in the workshop, which should include: A hard copy of the geometric layout of your system with labels identifying each subsystem in the system (you may use visuals presen ted in your Mock-up presentation). 1/3 Detailed Design Workshop Guideline A table that includes the following: o Modeling/analysis/tests that you plan to build/perform/conduct to check if your system is meeting the performance based design criteria: Present only the types of models/analysis/tests and on which component/subsystem you plan to perform these. Results and details of these models/analysis/tests should be available separately in case instructors need to go through them. For each model/analysis/test, mention all assumptions, any commercial software that use for the implementation. o Modeling/analysis/tests that you plan to build/perform/conduct to check if your system will avoid any failure during its operation Present only the types of models/analysis/tests and on which component/subsystem you plan to perform these. Results and details of these models/analysis/tests should be available separately in case instructors need to go through them. For each model/analysis/test, mention all assumptions, any commercial software that is used for the implementation. A table that lists all your design decisions you will have to make and how these decisions are related to results of modeling/analysis/test that you plan to perform. o For example: material selection; geometrical dimensions and shapes of components in your system; specifics of off-the shelf components you have chosen to use in your system i.e. actuators, sensors, etc. geometric tolerances; standard parts like bolts/nuts; heat treatment; etc. A final table showing the final values of design decisions you have made o For example: material selection; geometrical dimensions and shapes of components in your system; specifics of off-the shelf components you have chosen to use in your system i.e. actuators, sensors, etc.; geometric tolerances; standard parts like bolts/nuts; heat treatment; etc. Table 1 Decisions based on meeting the performance criteria targets Modeling/analysis/test Component/Subsystem/Whole Design system Parameters to be Decided Explanation (State assumptions, any commercial software that use for the implementation, etc.) 2/3 Detailed Design Workshop Guideline Table 2 Decisions based on avoiding all potential failures (component or system level) Modeling/analysis/test Component/Subsystem/Whole Design system Parameters to be Decided Explanation (State assumptions, any commercial software that use for the implementation, etc.) Table 3 List of design decisions and parameters Design Decision or Parameter Relevant Component/Subsystem (material selection; geometrical dimensions and shapes of components in your system; specifics of off-the shelf components you have chosen to use in your system i.e. actuators, sensors, etc.; geometric tolerances; standard parts like bolts/nuts; heat treatment, etc.) Which Modeling/analysis/test were used for the decision Table 4 List of final values of design decisions and parameters Final Results for Design Decision or Parameter Relevant Component/Subsystem (material selection; geometrical dimensions and shapes of components in your system; specifics of off-the shelf components you have chosen to use in your system i.e. actuators, sensors, etc.; geometric tolerances; standard parts like bolts/nuts; heat treatment, etc.) 3/3 Detailed Design Workshop Guideline