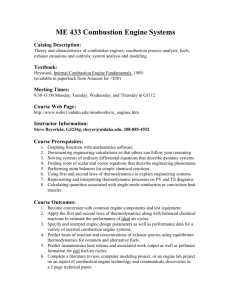

Spring Conference Paper: Annotated Outline

advertisement

Session C6 Paper #2308 ENGINE EFFICIENCY: THE ECOMOTORS SOLUTION Joey Daubert (jsd31@pitt.edu), Andy Lawniczak (ajl73@pitt.edu) Abstract—As the world’s demand for energy continues to increase, people look to new technologies to make energy consumption efficient and environmentally friendly. The inefficient use of fossil fuels, particularly by four stroke internal combustion engines used in today’s automobiles, has taken precedence in the discussion of energy efficiency. A suitable solution to this issue is a new engine design that maximizes energy efficiency and minimizes harmful emissions. The progressive engine company EcoMotors has accomplished this with the design of their two-stroke opposed-piston opposed-cylinder (OPOC) engine. This paper will explain and critique how the cutting-edge OPOC engine meets the energy efficiency criteria in a compact, reliable package. It will also clarify any ethical concerns associated with the OPOC engine and how it will avoid these concerns with its innovative design. The technicalities of each separate part of the OPOC engine will be discussed at length, and they will be compared to the parts of conventional internal combustion engines to show why the OPOC engine displays significant improvement in energy efficiency and emissions. The OPOC engine is the proper solution to today’s automobile energy needs due to its direct gas exchange operation. This type of gas exchange provides the OPOC with emissions benefits comparable to that of the four stroke engine. Additionally, the compact design allows for two pistons per combustion chamber, thereby doubling the energy output of the engine [Technology]. With its emissions benefits and high energy efficiency, the OPOC will epitomize power density in internal combustion engines. Key Words—direct gas exchange, Ecomotors, four stroke, OPOC engine, power density, two stroke. TODAY’S ENERGY CRISIS As the world’s very limited supply of fossil fuels continues to be depleted by society, the demand for energy efficient and environmentally friendly technologies grows ever more apparent. With no definitive replacement for fossil fuels in the immediate future, the most plausible course of action is to improve upon the current technologies that are the primary consumers of these fuel sources. One of the leading culprits of fuel consumption is the automobile industry. In 2011 in the United States, automobile fuel use alone accounted for 8.75 million barrels of fuel consumption. When combined with the inefficiency of the conventional internal combustion engine, these substantial amounts of Twelfth Annual Freshman Conference 1 fuel consumption amount to a considerable waste of energy. The primary concerns with automobiles involve efficiency – particularly engine efficiency – and harmful gas emissions. In the typical automobile, only about 14%-26% of the energy from the fuel put in the tank gets used to move the car down the road. The majority of the remaining energy is lost through the engine: 60% is lost as heat exhaust and a combined 10% is lost through combustion, pumping, and friction. With more cars appearing on the road every day, the consumption of fuel will continue to increase at an alarming rate unless a solution to fuel efficiency is discovered [5]. FIGURE 1 U.S. FUEL CONSUMPTION The conventional internal combustion engines are no longer able to meet the requirements that allow them to keep pace with the rapidly changing efficiency and emission standards. The optimal solution to this issue is to develop a new engine design that maximizes energy efficiency and minimizes harmful emissions. However, today’s most common internal combustion engine, the four stroke engine, provides little room in its design for adjustments. Previous attempts to redesign the four stroke engine have fallen short because they were unable to meet the strict criteria demanded by automobiles today. Current four stroke engines are limited to certain amount of efficiency with little variation. When it comes to this type of engine, the consumer must choose between having high engine power or clean fuel emissions. Today’s consumer demands an engine powerful enough to drive around a full cab of people and hit top speeds of around 80 miles an hour or more. In order to achieve this, the engine must have a substantial size to it. However, this requires higher amounts of inefficient fuel consumption and ultimately leads to more harmful emissions. The emission standards of the four stroke engine are met February 10, 2012 Session C6 Paper #2308 in two ways. The first way is to limit the amount of fuel that gets injected into the cylinder for combustion. Less combusted fuel means less harmful gases leave the car as exhaust. However, this also means the engine will have less power and won’t be able to hit the high speeds that the consumer demands. The other way automobile manufacturers reduce emissions is by recycling noncombusted gasoline in the exhaust tank back into the cylinder and burning it again. Regardless, with the four stroke engine, limited efficiency means there will always be a trade-off between engine power and clean exhaust emissions. CONVENTIONAL MODELS OF THE INTERNAL COMBUSTION ENGINE Internal combustion engines power many different types of machines used today. The two most commonly used types of internal combustion engines used are four stroke and two stroke engines. Although these two types of engines work through similar thermodynamic processes, they have a few differences that allow them to have different applications. They both work by combusting fuel, which causes gases to expand in the cylinder of the engine. This in turn creates enough pressure to push down a piston which is connected to a camshaft. This causes the camshaft to turn, which creates a rotational energy that is then converted into usable kinetic energy that can be harnessed and transformed into motion by the machine. Each of these engines has different strengths and downfalls which make them useful for specific applications. four stroke engine uses a carefully calibrated timing belt to open the intake valve while keeping the exhaust valve closed. This allows an air/fuel mixture to be drawn in as the piston slides down the cylinder, thus completing the first stroke. The cams on the camshaft provide a counter weight that pushes the piston back up after it takes in fuel. As the piston moves up, it compresses the cold fuel gas and increases pressure. Near the top of this second stroke, a spark plug ignites the air/fuel mixture and causes it to expand. The gases expand for two reasons: one reason is the heat produced by combustion causes the gases to expand. This expansion process is proven by the Ideal Gas Law PV=nRT (where P=pressure, V=volume of gas, n=number of moles of gas, R is a constant equal to 0.08205 liter atm / mol*kelvin, and T=temperature). If this equation is rearranged to in terms of the volume (V=nRT/P), it can be shown that as T increases, so does volume. The other reason for the expansion of gas is that burning gasoline produces more gas molecules. This can be shown by the basic balanced chemical equation for combustion of gasoline C8H18 + 12.5O2 → 9H2O + 8CO2. Again, this is the basic formula and does not take into account other fuel additives or additional carbon dioxide caused by a lack of a sufficient amount of O2 during the combustion process. Prior to combustion, the air/fuel mixture contains 13.5 moles of gas, and after combustion there are 17 moles of gas. The Ideal Gas Law (V=nRT/P) can again be used to show that as the number of moles (n) increases, so does the volume of the gas [8]. These expanding gases push the piston back down, which turns the camshaft, resulting in the third stroke. This stroke is called the power stroke because it is what allows the machine to do work. Finally, during the fourth stroke of the engine, the cams rotate and force the piston back up. As the piston goes up, the timing belt opens the exhaust valve and allows the hot, combusted gas to leave the cylinder. Then the process repeats [10]. FIGURE 2 SIMPLE DESIGN OF INTERNAL COMBUSTION ENGINE The four stroke internal combustion engine is the larger of the two types of engines. Four stroke engines have a pair of valves for each cylinder. One valve controls intake, and the other controls exhaust. The first part of the power producing cycle for any internal combustion is intake. A Twelfth Annual Freshman Conference 2 FIGURE 3 FOUR STROKE ENGINE DESIGN February 10, 2012 Session C6 Paper #2308 FIGURE 5 TWO STROKE ENGINE DESIGN FIGURE 4 TYPICAL TIMING BELT IN A FOUR STROKE Two stroke internal combustion engines use the same thermodynamic principles as four strokes to push the piston and produce power. However, they are designed to do this in only two strokes of the piston, as the name implies (a compression stroke and combustion stroke). During the compression stroke, the counter weighted cams on the camshaft push the piston up, compressing the air/fuel mixture. Then the spark plug ignites the mixture and the combustion pressure pushes the piston back down, producing power. During this power stroke, the engine will simultaneously intake and exhaust gas. It does this by using open ports on the side of the cylinder wall. The crankcase that contains the camshaft pressurizes the air/fuel mixture as the camshaft rotates. Initially, as the piston goes down, gas is exhausted through the exhaust port. Then, as it goes down further, the intake port is opened to the combustion chamber, allowing the pressurized air/fuel mixture to enter. As the cams drive the piston back up, the ports are closed and more air/fuel mixture is accepted into the crankcase. Then the process is repeated. Twelfth Annual Freshman Conference 3 Four stroke internal combustion engines are the standard engine for automobiles, mostly due to their ability to carefully control the intake and exhaust of fuel. This allows them to meet government emission standards relatively easily. Also, the precise timing ability of the four stroke engine makes it reliable. Two strokes, on the other hand, have a difficult time meeting emission standards. The type of fuel and air mixture that is compatible with two strokes also needs lubricants to be mixed with them so the crankcase can be lubricated enough to ensure that the engine functions properly. These extra chemicals, as well as a sloppy control of intake and exhaust gases, generally cause two strokes to be dirty engines that aren’t meant to be run for a long amount of time. This is why they are usually used in smaller applications such as weed whackers, lawnmowers, and dirt bikes. However, if two strokes were redesigned to perform in a cleaner manner, they would be preferred over four strokes due to their compact size. As two strokes lack the extra bulk of the timing belts and the valves, the overall weight of the engine is significantly less than the four stroke and thus contributes to a reduction in energy lost to friction. Since they produce power every other stroke instead of every four strokes, the two stroke engine is more efficient (in terms of power) compared to the four stroke engine [3]. THE ECOMOTORS SOLUTION The four stroke engine and the two stroke engine each contain multiple strengths in their designs. Naturally, the ideal engine would combine the best features of both of these engines: the clean emissions and reliability of the four stroke, with the compact size and efficiency of the two stroke. However, this feat is not easily accomplished and many previous attempts have not produced a design sufficient enough to survive in today’s strict consumer market. However, after years of research and design, Prof. Peter Hofbauer (Founder, Chairman, and Chief Technical Officer of EcoMotors International) seems to have found the optimal solution to automobile power. The solution, called the OPOC engine, uses an ingenious engine design to combine the efficiency of a two stroke engine with the clean emissions of a four stroke. The OPOC (opposed-piston opposed-cylinder) is considered a two stroke engine because it produces power every other stroke. It uses advanced exhaust gas recycling methods to minimize gas emissions with the efficiency of a four stroke. It works by having two horizontally positioned pistons face each other on each side of the camshaft. When one side is ignited and begins expanding, the other side is exhausting gas and taking in new fuel. An electronic turbo (a turbo is a compressor driven by the engine’s exhaust) allows the car’s internal computer to control proper compression February 10, 2012 Session C6 Paper #2308 and exhaust depending on engine rotations per minute (rpms). This turbo also controls the flow of exhaust gas. Unlike standard two strokes, the OPOC does not need oil or other chemical additives to be mixed with its fuel because the crankcase and outer piston housing have ports for engine oil. This eliminates the dirty environment of the typical two stroke engine and therefore extends its lifespan and broadens its range of application. The OPOC also has an electronically controlled clutch that allows multiple engines to be connected or disengaged to reduce fuel consumption. These parts of the OPOC engine are essential to its design and they contribute substantially to its overall efficiency [9]. THE BENEFITS OF A DUAL PISTON CYLINDER Although the OPOC works off of the same thermodynamic principles as other internal combustion engines, its unique architecture allows it to reduce the amount of energy lost to friction and achieve unprecedented levels of efficiency. The OPOC reduces friction in two ways. The main way is through a process in which the center pushrods are almost always forced in, causing them to experience a force in the form of compression, while the outside pull rods are always experiencing tension. These opposing forces cancel out leaving a resultant force of almost zero on the crankshaft. Since there is little force on the crankshaft, there is little friction opposing its rotating motion. The balance of the OPOC can be demonstrated by the equation r1*m1 = r2*m2, where r1= 45 mm and r2= 35 mm are the inner and outer throws, respectively, and m1 and m2 are the corresponding, adjusted reciprocating masses that make both sides equal to each other. between the OPOC and the standard four stroke internal combustion engines. Lincoln Hill, public liaison of EcoMotors International, says the problem with friction in standard internal combustion engines is “Primarily a result of the balanced crank shaft. In a typical engine configuration, there is always something exerting pressure on the crank in a counterproductive direction, something the engine block is designed to contain” [9]. Since there is less force on the OPOC crankshaft the engine block can be made smaller and lighter, providing the OPOC with greater power density. Unlike standard four stroke engines, which on average produce about 1 horsepower for every 3 pounds of engine weight, the OPOC engine averages an output of about 1.1 horsepower per pound. The power density of the OPOC engine is one of the most crucial keys to its success and efficiency [3]. However, there are more friction problems EcoMotors had to overcome. Specifically, rubbing occurred on the side of the outer pistons where they meet the pull rods. Although there is a small amount of friction here, it was important that EcoMotors addressed this problem because it could have easily led to wear and tear issues after a lot of usage. This wear is at two locations: the piston skirt and the piston pin. The piston skirt is the bottom part of the piston head that extends the lowest, opposite the combustion bowl. When the piston reaches the bottom of its stroke, it rocks some in the cylinder; this rocking is what causes wear. The OPOC uses cross head type linear bearings to prevent these side forces from acting on the piston skirt. Another problem with two stroke pistons is friction at the piston pin. Because forces are always acting in the same direction on the piston head, oil has a tough time getting between the bearing surface and the pin. The linear bearings cause a significant deficiency of relative motion between the rocking surfaces and therefore eliminate most friction in this area. When designing this part of the engine, the EcoMotors engineers took particular care in making sure the radius of curvature at this point was selected to ensure that pressure at this contact point was less than the Hertzian pressure. Hertzian pressure is the maximum pressure allowed between two objects that are touching before they start to deform to each other and wear [10]. It is an important concept of contact mechanics that the engineers must adhere to in order to develop the optimal engine design. By keeping contact pressure of these bearings below Hertzian pressure, the OPOC engine prevents wear in the piston pin. KEY FEATURES OF THE FUEL INTAKE PROCESS FIGURE 6 MODEL OF OPPOSING PISTONS This process of rendering friction to be almost nonexistent within the engine exemplifies a key difference Twelfth Annual Freshman Conference 4 One of the main features of the OPOC intake is the direct gas exchange operation. This means that the OPOC has fuel injectors that spray the proper amount of fuel directly into the combustion cylinder for optimum operation. This is common in today's four stroke engines and helps them achieve low fuel emissions. However, this is an advanced feature for two stroke engines, because two strokes must February 10, 2012 Session C6 Paper #2308 typically rely on an air/fuel mixture coming up from the crankcase, which is a sloppier and less fuel efficient way to run an engine. This direct fuel injection is also why the OPOC can run on virtually any liquid fuel and does not require a fuel/oil mix like standard two strokes. Another key feature of the OPOC’s intake and exhaust system is its electronically controlled turbo. The turbos for regular four stroke engines work by using the pressure from exhaust gas to turn a turbine that forces more air into the combustion cylinder. The high intake air pressure increases the compression between the cylinder and the piston, which translates into more power produced by the engine at certain rpms. However, turbos have some difficulty producing high power when going from low or idling rpms to high rpms. The problem occurs because the exhaust gas pressure must first build up in order for the turbo to be properly wound up. The lack of power due to the turbo winding is called turbo lag in the auto industry. The electric motor in the OPOC’s turbo allows it to spin up the turbo even when exhaust pressure is low, thereby eliminating turbo lag. This turbo was designed to dissipate heat around the electric motor and be able to withstand the high temperatures of the engine. This turbo also can be used as a generator that uses excess exhaust gas to make electricity for the car rather than letting that energy go to waste like standard turbos. Basically, the electronic turbo allows the OPOC to control the optimum intake and exhaust pressures for certain rpms of the engine [5, 7]. FIGURE 7 ELECTRONICALLY CONTROLLED TURBO DIAGRAM ADVANCED EXHAUST SCAVENGING SYSTEM The OPOC engine contains a few unique features that allow it to achieve unprecedented efficiency. The designers of the Twelfth Annual Freshman Conference 5 OPOC at EcoMotors International have claimed that the engine can achieve 90% cylinder scavenging. Cylinder scavenging is a process that recycles fuel from the exhaust that did not fully combust and puts it back into the combustion chamber to be burned again. This leads to less harmful chemicals being produced by the engine and drastically reduces that amount of harmful emissions. The OPOC boasts three key features that allow it to achieve such a significant reduction of fuel emissions. These features are the electronically controlled turbo, asymmetric port timing, and circumferential ports [1, 3]. The electronically controlled turbo supports cylinder scavenging by producing a resistance to exhaust gas pressure. This resistance causes some combusted fuel to reenter the cylinder while the exhaust port is still open. Asymmetric ports refer to the ideal locations of the intake and exhaust ports in the cylinder. Since the inner pistons have a shorter distance to travel than the outer pistons, the exhaust port is on their side. This allows the exhaust port to open before the intake as well as close after it. Additionally, the intake port is on the outer piston side. This allows the OPOC to let some of the exhaust gas in before it enters the turbo to blow back into the cylinder to be burned again. Circumferential ports refer to the intake and exhaust ports on the engine. The ports are circumferential because they wrap around the whole combustion cylinder. This allows for even gas flow around the cylinder. Even gas flow is important to the fluid dynamics of the engine because it allows it to efficiently move intake and exhaust gases without causing turbulence that leads to inefficient air flow. The design and placement of these ports does much more for the engine than what can be initially observed. As said before, it is important that the exhaust ports allow some backflow for combusted fuel scavenging. This port has more advantages: the design of the exhaust and intake ports allow the backflow of exhaust gas to hit the fresh fuel coming in from the intake ports at a tangential angle. Using fluid dynamics, EcoMotors engineers were able to make the exhaust gas hit the intake gas at a tangential angle, causing the gas to tumble in a manner similar to an ocean wave crashing. This tumble effect promotes swirl in the cylinder. By having proper swirl of fuel gases in the cylinder, there is a more homogenous mixture of fresh fuel and recycled fuel. Therefore, when the mixture is ignited during combustion, it explodes better and therefore produces more power and increases fuel efficiency. These features all combine to contribute to a reduction of harmful emissions that meet the Environmental Protection Agency 2010 standards for heavy duty commercial trucks with a Selective Catalytic Reduction (SCR). SCR is a chemical converter on the exhaust end of the engine that uses a chemical reaction to convert harmful NOx gas into nonhazardous N2 and H2O. EcoMotors International, as well as multiple independent engineering firms, confirmed that February 10, 2012 Session C6 Paper #2308 the OPOC engine meets these requirements; however, the engine is still being updated and small changes to its design are continuously being made in an effort to meet the EPA standards of converting NOx into nonhazardous compounds without the use of SCR [4]. MODULAR DESIGN OF THE OPOC ENGINE A unique feature of the OPOC engine is its modular design. Since the OPOC is extremely well balanced, it can easily be connected to another OPOC engine next to it for added power. EcoMotors has designed an electronically controlled clutch that can engage and disengage multiple engines. The ability to simply add more OPOC engines to a vehicle’s drivetrain greatly increases fuel efficiency. EcoMotors claims that a single OPOC engine is able to achieve 15% better fuel economy than a standard four stroke internal combustion engine. When two OPOCs are coupled using the electronically controlled clutch, this is called a Dual Module. In this case, the fuel efficiency of the pair increases to 45% better than that of a standard four stroke. Furthermore, EcoMotors claims that the addition of a third engine, called a Dual Module Tribrid can achieve 55% better fuel economy [4]. This is much more efficient than current forms of flex fuel engines (flex fuel engines are engines that are designed to run on gasoline or a blend of up to 85% ethanol) such as those found in the typical car today. Normally, cars that shut off part of their engine when they aren’t under high load just stop combustion in a few chambers of the engine. However, since these pistons are still connected to the camshaft, they still move up and down as the other pistons still fire. This leads to natural parasitic losses (parasitic loss comes from any device that takes energy away from the engine in order to enhance the engine’s ability to create more energy) in energy from friction in the pistons that aren’t producing power. The EcoMotors OPOC engine, however, completely disengages the other module when under low engine load, which results in no parasitic energy loss. With the OPOC, EcoMotors solved the other potential problem of starting the second module through the use of the electronically controlled clutch. Normally, an electric starter motor is needed to start the engine. Although the first module needs one, the second module does not because when the clutch engages it, the power of the running modules turns and starts the engine by starting the compression process. In the auto industry, this is referred to as bump starting [5]. The electronically controlled clutch is the essential piece that maintains the OPOC’s well-balanced characteristics. It achieves this by making sure the forces of each module cancel each other out. EcoMotors says it does this by using a “two-position lockup element” that generates a phase angle of ninety degrees between each module. This effectively cancels out opposing forces and produces an even firing order similar to a powerful V8 engine without sacrificing Twelfth Annual Freshman Conference 6 performance [9]. INTEGRATION INTO THE MANUFACTURING INFRASTRUCTURE One of the major ethical concerns of any new technology is ease and cost of production. These factors are important because if a product requires rare materials or parts that are hard to make or obtain, it will be more expensive to produce. With the current condition of the United States consumer market, an expensive automobile will never replace the standard cars used every day. However, the versatility of the OPOC falls perfectly into the strict demands of the consumer market. Since the OPOC engine works off of the same principles as standard internal combustion engines, many of its parts are very similar to those of its predecessors. This means that the current automobile production infrastructure today can easily be converted to begin the production of OPOC engines. Additionally, because the OPOC doesn’t need a valve train like that of the standard four stroke, it doesn’t require the contributing timing parts, thereby eliminating the extra costs that the typical four stroke engine brings with it. The EM100 model of the OPOC only has 62 parts, while a four stroke engine with comparable has 385 parts [7, 9]. This means that the OPOC engine is not only more efficient than standard four stroke engines, but it is also cheaper to produce. All of these factors amount to a 20% lower cost of production. Additionally, the long term investment in the OPOC will be more than 30% lower than the investment needed for conventional internal combustion engines. The OPOC is projected to have a much longer lifespan than most standard engines and with less glitches and failures, which means the costs of repairs will also be decreased. The OPOC could not only be an ethical solution to automobile power, but also a solution to creating new jobs and pulling out of the global recession [7, 9]. CLOSING THE DEAL Although clearly an innovative design with the ability to produce unprecedented efficiency and emissions results, the EcoMotors OPOC engine is not currently in mass production because no single company has agreed to buy the design and begin producing them to be sold on the market. As in the case with hybrid vehicles, which were researched for many years before they were put into production, significant research and development must still be conducted before this engine becomes standard in vehicles. However, it has been developed for some military uses with a DARPA (Defense Advanced Research Projects Agency) contract. There are also several private company customers: Navistar, Generac, and Anhui Zhongding Holding Group Co. have all agreed to development and commercialization contracts [9]. February 10, 2012 Session C6 Paper #2308 EFFICIENCY FOR THE FUTURE The implementation of the OPOC engine into automobiles is driven by the need to develop suitable new technologies that will make energy consumption efficient and environmentally friendly. The conventional internal combustion engines are no longer able to keep pace with rapidly changing consumer demands and emission standards. A new engine design as innovative and efficient as the EcoMotors OPOC engine is precisely what is needed in order to maximize the available fuel sources that we have remaining, and minimize the harmful effects that they have on the environment. Since the OPOC possess the best strengths of both the two stroke and four stroke engines, it is the ideal engine that has the capability of accomplishing this. Not only is the OPOC a clean, lightweight, and power dense engine that can be used in a variety of applications, it also has the proper dimensions that allow it to be integrated directly into the current manufacturing facilities and assembly lines. This ease of production eliminates the need for any ethical concerns regarding excessive manufacturing costs as well as any concerns of being able to produce the engine on a large scale. The OPOC engine will eventually render all conventional internal combustion engines obsolete. With its high energy efficiency and clean emissions, the OPOC engine is the proper solution to today’s automobile energy needs. (OPOC).” Popular Mechanics. [Online]. Available: http://www.popularmechanics.com/cars/news/fuel-economy/6-prototypeengines-to-get-your-brain-firing#fbIndex1 [12] Xu, H.-J. (September 2009). “Simulation on in-cylinder flow on mixture formation and combustion in OPOC engine.” Neiranji Xuebao, 27(5), 395-400. ACKNOWLEDGMENTS We would like to thank the Engineering Library for providing us with the useful information on how to find the sources necessary for writing this paper. We would also like to thank Lincoln Hill and the engineers at Ecomotors for assisting us in our research. REFERENCES [1] Aston, A. (21 March 2008). “Diesel Design by EcoMotors.” Bloomberg Businessweek. [Online]. Available: http://www.businessweek.com/bwdaily/dnflash/content/mar2008/db200803 21_874119.htm [2] (July 2010). “Ecomotors receives funding for OPOC engine.” The Engineer, July Volume, 2. [3] Ellzey, C. (1 July 2008). “Opposed Piston Opposed Cylinder Engine.” EngineeringTV. [Online]. Available: http://www.engineeringtv.com/video/Opposed-Piston-Opposed-Cylinder [4] (20 April 2011). “Greenhouse Gas Emissions.” U.S. Environmental Protection Agency. [Online]. Available: http://epa.gov/climatechange/emissions/index.html [5] (28 February 2012). “New Electronic Turbo.” RSE Innovators. [Online]. Available: http://www.rse.co.uk/images/turbo2.jpg [6] Ping, H. (February 2011). “Analysis of Self-Balance Characteristics of OPOC Engine.” Advanced Materials Research, 211-212, 93-96. [7] Runkle, D. (16 June 2010). “Tribrid Power System.” Automotive News Green Car Conference. [Online]. Available: http://www.autonews.com/Assets/html/10_angc/pdf/pres_runkle.pdf [8] Skipor, A. (May 2006). “Liquid to Gas Combustion.” Newton – Ask a Scientist.” [Online]. Available: http://www.newton.dep.anl.gov/askasci/chem03/chem03768.htm [9] (2012). “Technology.” EcoMotors International. [Online]. Available: http://www.ecomotors.com/technology [10] Walker, J. R. (1981). Exploring Power Technology. South Holland: The Goodheart-Willcox Co., Inc. [11] Wojdyla, B. (2012). “Ecomotors Opposed Piston Opposed Cylinder Twelfth Annual Freshman Conference 7 February 10, 2012 Session C6 Twelfth Annual Freshman Conference Paper #2308 8 February 10, 2012