aic14040-sup-0001-suppinfo01

advertisement

Supplementary material

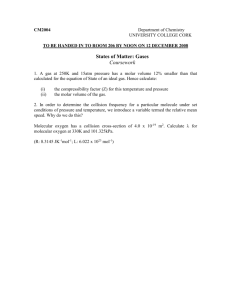

Structures of the interconnection matrix M and the perturbation block Δ

The two key blocks in μ-analysis problem ( Δ M ) shown in equation (5) are the

interconnection matrix M and the perturbation block Δ. The interconnection matrix M is defined

as follows:

0 yˆ p M13

0

M yˆ p I

0

0

M

0

31 M 32

(A.1)

where ŷ p is a real scalar parameter that represents the unknown element in equation (5) and I is

an identity matrix of size N 1 N 1 . The three additional matrices shown in (A.1) are

defined as follows:

M13 d1K,, d nd K

T

M31 h0,1,, hN ,1,, h0,q ,, hN ,q ,, h0,nd ,, hN ,nd

(A.2)

M 32 h0,1 ,, hN ,1 ,, h0,q ,, hN ,q ,, h0,nd ,, hN ,nd

(A.3)

(A.4)

where K is a row vector of length N+1. As shown in (A.2)-(A.4), the key entries to build M are

the coefficients of the each of the uncertain impulse response models that describe the response

in output p due to changes in the process disturbances, i.e., ŷ p , and the maximal change of each

process disturbance considered in the analysis, i.e., δd (see definition (2)). The perturbation

block Δ included in the mixed structured singular value problem presented in (5) is defined as

follows:

Δ diag Δ d , Δ h , p

(A.5)

(A.6)

(A.7)

Δ d d d 1 ; Δ d nd N 1

Δ h h h 1 ; Δ h nd N 1

1

p 1; p C

(A.8)

where Δ d is norm-bounded block that accounts for the uncertainty in the process disturbances at

specific sampling instants. Likewise, the norm-bounded block Δ h represents the uncertainty in

the impulse response coefficients at a particular sampling interval. Each of the elements in Δ d

and Δ h are assumed to be independent real scalars. Moreover, δp is a complex scalar that

measures the system’s dynamic performance. Upper and lower bounds for the Δ M problem

can be estimated using numerical subroutines available in standard engineering software, e.g.,

the mussv built-in function MATLAB®.

Remarks on the worst-case performance tool

The use of uncertain impulse response models as an approximation to the actual nonlinear

process model may add conservatism in the computation of *yˆ , d*p and ywc,p since each of the

p

model coefficients in (3) is bounded by lower and upper limits. Thus, the optimal process and

control design obtained by the present method may be conservative. However, tight bounds are

expected for each model coefficient included the uncertain models because the identification test

is performed in closed-loop. Accordingly, it is expected that the feedback loops and the

controller actions will reduce the process nonlinearities in the presence of fluctuations in the

process disturbances, which will subsequently reduce the conservatism in the computation of

* , d*p and ywc,p, respectively. Moreover, the bound * can be used as a metric of the worstyˆ p

yˆ p

case performance of the output p. That is, *yˆ can be used to evaluate the dynamic performance

p

and the process constraints considered in the optimal process and control design formulation.

Although the use of *yˆ reduces the computational costs, it also adds conservatism in the

p

solution because of the use of a bound ( *yˆ ) for the evaluation of the complete optimization

p

function. However, a preliminary process design analysis using only *yˆ may return educated

p

starting points in a short period of time. Accordingly, the solution obtained from that preliminary

analysis can be used to initialize the computation of an optimal design using the actual worst2

case performance of the process outputs, which is a more intense calculation since it requires

simulations of the closed-loop process model using the critical realizations in the disturbances.

Due to use of norm-bounded calculations, the critical trajectory obtained for d*p can produce the

worst-case performance in the positive direction (worst-case increase) or in the negative

direction (worst-case decrease). As shown in (6), Δ*d is a vector that describes the critical timetrajectory in the disturbances (in a normalized form) in either the positive or the negative

direction. However, another critical disturbance vector is obtained by multiplying this vector by

minus one, i.e., Δ*d . Although both vectors are bounded by *yˆ , Δ*d produces the worst-case

p

performance in one direction while the other critical vector ( Δ*d ) generates the worst-case

output performance in the opposite direction.

The systems identification method introduced by the present approach estimates the coefficients

of an uncertain model from a single input-single output (SISO) identification test. Hence, the

family of uncertain models Y, identified in the present analysis to describe the closed-loop

process dynamics, do not consider the simultaneous effect of multiple disturbances on the

process outputs. Accordingly, the worst-case performance obtained for each process output does

not account for that condition. Although a more intensive multiple input-multiple output

(MIMO) identification of an uncertain model with nd inputs and ny outputs can be implemented

in the present method, the worst-case performance in that MIMO approach will be obtained

under the assumption that the critical realizations in all the process disturbances will affect the

system simultaneously, which leads to the specification of a conservative process design. For

that reason, the present approach relaxes that condition and estimates the worst-case performance

following the procedure described above and schematically shown in Figure 1. That is, the

present analysis assumes that only one worst-case disturbance affects the process at a time while

the rest of the disturbances remain at their nominal operating point. Although one of the authors

had recently proposed an integration of design and control methodology that accounts for the

evaluation of the worst-case performance in the presence of multiple process disturbances,32 that

3

methodology did not include structural changes in the process flowsheet and the control structure

because of the computational costs of adding integer decisions within the methodology’s

optimization framework.

Derivation of the quadratic Lyapunov stability test

The stability test is based on the concept of Lyapunov Theroy51-53 and can be stated as follows:

given a positive definitive quadratic Lyapunov function V(x):

V( x) xT Qx

Q QT , Q 0

(B.1)

where x represents the system states in closed-loop given by the state space model shown in (12)

whereas Q is a positive definitive matrix that is independent of the system states x. Matrix Q is

also referred to as the Lyapunov matrix51-53. The system, specified by the states x, is ensured to

be asymptotically stable if and only if51-53:

( x) 0 xT Qx x T Qx 0

V

(B.2)

Since the stability of a system is determined by the elements in the A state space matrix, the

robust stability condition (B.2) can be reformulated as follows:

Aθ Q QA θ 0

T

(B.3)

where the symbol θ, formally defined below, is used in (B.3) to denote that A is an uncertain

matrix as it is described in (13). Condition (B.3) represents a set of Linear Matrix Inequalities

(LMI’s); each LMI represents a specific combination between the elements in the A matrix.

However, matrix A cannot be directly evaluated since each of its elements can take an infinite

number of values limited by the uncertainty description provided for the elements of A and

shown in (13). To address this limitation, the present method relax the specification for the

elements of A in (13) and considers that each of its elements can only take two extreme values,

i.e.,

ai , j ai , j ai , j , ai , j ai , j

(B.4)

4

This approximation reduces the rigorous robust stability condition (B.3) into a finite set of LMI’s

as it is shown in (14). The formal derivation of the stability test using a quadratic Lyapunov

matrix can be found elsewhere51-53.

Implementation of the simultaneous process synthesis and control design methodology to

the case study: A system of CSTRs in series.

Cost Function

The annualized cost function specified for this case study is as follows:

ΦCSTR CCCSTR DPCCSTR

M & S max

max

CCCSTR 60.22761r

V1,wc DV2,wc

280

5

DPCCSTR 5.25 x10 B w1 1 D Dw2

3

*

*

min

w1 max w1max

, wc wB , wB w1, wc

(C.1)

*

*

min

w2 max w2max

, wc wB , wB w2 , wc

where CCCSTR and DPCCSTR represents the capital cost and the dynamic performance cost of this

process. As shown in (C.1), the capital cost specified for this process is a direct function of the

sizes (capacities) of the reactors included in the process flowsheet superstructure (see Figure 4).

The parameters r and M&S represent the rate of return (r=20%) and the Marshall and Swift cost

index for this process. The present case study assumes that the plant was built in 2011

(M&S=1597.7). 55 In the present analysis, the CSTRs are assumed to be vertical cylindrical

vessels made of carbon steel that operate at atmospheric pressure. The parameters α (1.066) and

β (0.802) in (C.1) are constant factors specified for this type of vessels.56 The output variables

max

V1,max

wc and V2, wc represent the largest deviation (worst-case performance) expected for the liquid

max

level on each reactor due to changes in the process disturbances, d. That is, V1,max

wc and V2, wc are

included in the set ywc shown in (9) and are obtained from simulations of the complete closedloop process model, which is specified by equations (16)-(17). The inputs to simulate the closedloop process model are the critical time-trajectories in the disturbances that produces the worstcase performance for the liquid level in first and in the second reactor, respectively, i.e.,

5

d*V1 and d*V2 . These critical realizations are estimated from the roots problem presented in (5) and

max

expression (6). Both V1,max

wc and V2, wc are estimated around a nominal operating point specified by

the set ξ, which includes the decision variables considered in the optimal process and control

max

design formulation. Therefore, V1,max

wc and V2, wc need to be estimated for every new operating

condition specified by the simultaneous design and control optimization algorithm.

The dynamic performance cost function (DPCCSTR) in (C.1) is an index that aims to measure the

dynamic performance of the CSTR system in economic terms. The key idea is to assign a cost to

the largest variability in the process outputs that are used to measure the system’s performance.

Therefore, DPCCSTR is problem specific and needs to be defined based on the variables used to

measure the design and control goals. As described above, a key goal for the present case study

is to obtain an outlet stream that maintains product B’s flowrate at its target value despite sudden

time-varying fluctuations in the process disturbances. Therefore, the dynamic performance of

this process can be measured based on the deviations of B’s molar flowrate with respect to its

target value. While a large increase of B’s molar flowrate with respect to its target value does not

affect the productivity of this process, it represents a loss in profit since an outlet (product)

stream with purity in B that is higher than that required is being produced. On the other hand, a

significant decrease in B’s molar flowrate with respect to its target value in the presence of

disturbances represents an economic loss since the plant is not meeting a design requirement.

Accordingly, the DPCCSTR function proposed for this case study assigns a cost to the difference

between the largest deviation expected in B’s molar flowrate and the design (target) flowrate of

B at the outlet stream ( wB* 198 mol / min ). That is, the function DPCCSTR penalizes the

deviations in B’s molar flowrate at the outlet stream with respect to its target value ( wB* ).

Therefore, it is expected that the resulting process design and control configuration obtained by

the present analysis reduces the variability in this variable thus improving the dynamic

performance of the system in the presence of critical realizations in the inlet feedstreams’

flowrate and temperature. As shown in (C.1), w1 and w2 represent the worst-case performance

expected for B’s molar flowrate at the outlet stream of the first and the second reactor,

6

min

respectively. Both w1 and w2 are functions of wimax

,wc and wi ,wc , which represent the worst-case

performance of B’s molar flowrate at the outlet stream of the ith CSTR in the positive (worst-case

increase) and in the negative (worst-case decrease) direction, respectively. Estimates for wimax

,wc

and wimin

,wc are obtained from simulations of the closed-loop model using the critical realizations in

the disturbances that produce the worst-case performance of B’s molar flowrate, i.e., d*wi . The

min

values for wimax

,wc and wi ,wc are obtained from simulations of the closed-loop process model using

two critical realizations for d*wi , one obtained from Δ*d and another obtained from Δ*d (see

Remarks in supplementary material, section B). This is done to ensure that the worst-case

increase and the worst-case decrease in B’s molar flowrate are properly accounted for in the

evaluation of DPCCSTR. Figure C.1 shows a graphical representation of the computation of wi .

Once wi have been estimated, a cost B (0.001$/mol of product B) is assigned to variability of

product B at the product stream. The constant terms that appear in CCCSTR and DPCCSTR are unit

conversion factors. Following (C.1), structural changes in the process design have been explicitly

considered in ΦCSTR since CCCSTR and DPCCSTR are defined in terms of the binary decision

variable D.

Operational constraints

The design and control goals specified for the present case study impose limitations on the

dynamic operability of the process in the presence of critical realizations in the inlet feedstreams’

flowrate and temperature. These operability constraints need to be included in the simultaneous

design and control formulation to ensure process dynamic feasibility. As shown in problem (9),

the set ρ includes the process feasibility constraints considered in the analysis. Thus, ρ can be

reformulated for the present case study as follows:

7

ρ g g 0 ; g 1,,5

1 T1,max

wc 500

2 T1,min

wc 400

(C.2)

3 DT2max

, wc 500

4 DT2min

, wc 400

5 1 D C Amax D C Amax 0.03

1, wc

2 , wc

min

max

where Ti ,wc

and Ti ,wc

represent the worst-case increase and the worst-case decrease in the

temperature of the ith CSTR, respectively. Likewise, C Amax

represents the largest variability (in

i ,wc

the positive direction) of the concentration of reactant A at the outlet stream of the ith CSTR.

Estimates of the worst-case performance of these outputs are obtained following the procedure

min

described in Section 2. For example, to compute T2max

, wc and T2 , wc , uncertain impulse response

models like (3) must be identified from the each process disturbance, i.e., qF1,TF1, qF 2 and TF 2 , to

the temperature of the second reactor, T2. This results in 4 uncertain models, each describing the

dynamic behaviour between a single process disturbance and T2. The nominal and the uncertain

impulse response coefficients that describe each uncertain model, i.e., hi ,q and hi , q (see

definition (3)), together with the uncertainty descriptions specified for the process disturbances

in (19), are used to build the interconnection matrix M and the perturbation block Δ presented in

(A.1)-(A.8). These structures are the key inputs that need to be specified to solve the roots

problem shown in (5), which returns a bound on the worst-case performance for T2 ( T*ˆ2 ), and a

norm-bounded vector that includes the critical realizations in the disturbances that produces the

worst-case performance for T2 ( Δ*d ). Expression (6) is used to obtain the actual critical

realizations in the process disturbances for this output, i.e., d*T2 . Two critical disturbance profiles

are obtained from (6), one using Δ*d and another profile using Δ*d .Then, the complete

mechanistic process model, given by equations (16)-(17), is simulated using the two critical

profiles in d*T2 as the model inputs. The procedure to simulate the closed-loop process model

using d*T2 as inputs is schematically shown in Figure 1, i.e., one critical realization in the

disturbance set is simulated at a time while the rest of the disturbances are set to their nominal

8

operating condition. The results from these simulations are then used to seek for the worst-case

increase and the worst-case decrease of the temperature inside the second CSTR, i.e., T2max

, wc and

min

max

T2min

, wc , respectively. Both T2, wc and T2 , wc are used in (C.2) to evaluate the compliance of the

temperature constraints for the second reactor in the presence of the most critical time-varying

min

fluctuations expected for qF1,TF1, qF 2 and TF 2 , respectively. Note that T2max

, wc and T2 , wc have been

obtained around the nominal operating state specified by ξ (see Figure 1). Thus, the procedure

described above needs to be repeated for every new nominal operating state (ξ). The worst-case

performance for the rest of the process output variables shown in (C.2) are estimated in a similar

fashion and is not discussed here for brevity.

Optimal design and control

The cost function ΦCSTR shown in (C.1) and the process feasibility constraints presented in (C.2)

are the key expressions needed to build the simultaneous design and control problem for the

present case study. Thus, problem (9) can be reformulated for this case study using the

descriptions shown in (C.1)-(C.2), respectively. The optimization variables specified for this case

study are the set of binary decisions that determine the process flowsheet, ψ D, R , the binary

set that specifies the control structure, ω , the nominal (optimal) operating temperature for each

reactor, T1 and T2 , the nominal (optimal) liquid level on each reactor, V1 and V2 ,and the

controllers’ tuning parameters included in the control superstructure, K C and τ I . Hence, the

resulting optimization problem is challenging since it includes 14 binary decision variables and

28 continuous decision variables. The set of decision variables included in the optimization

problem are used to specify the nominal (optimal) operating state for this process, i.e., ξ. The rest

of the process variables that are needed to fully specify the operating state, e.g., unm , CA1 , C A2 ,

are obtained from the solution of the process model equations at steady-state using as inputs the

values assigned to the decision variables, the production target specified for this process (

wB* 198 mol / min ), the nominal values in the process disturbances, see description (18), and the

process model parameters that remain constant during the analysis, e.g., k0, ΔH0, Cp.

9

The MINLP optimization problem specified for this case study was implemented in MATLAB®.

A numerical integrator solver (ode23s), which implements a modified version of the Rosenbrock

method,57 was embedded within the MINLP formulation to integrate the process model

equations (16) and the controller equations (17) specified for this case study. Although finite

element methods or finite differences can also be used to integrate (16)-(17), these methods

return estimates in the process variables that are often less accurate than those provided by

numerical integrators. The MINLP problem for the present case study was solved using the

glcdirect built-in function available in TOMLAB, which implements a modified version of the

Direct Algorithm.58 For each new set of decision variables specified by the optimization

algorithm, the worst-case performance of the process variables included in the cost function and

the process constraints need to be obtained. Hence, dynamic simulations of (16)-(17) need to be

performed for each of these variables using as inputs excitations signals for the process

disturbances. The data obtained from simulations is then used to identify uncertain models that

are aimed to capture the transient characteristics between each disturbance and each process

output considered in the analysis. The nominal and the uncertain model parameters obtained

from the identification step, together with the uncertainty description provided for the process

disturbances, are the key inputs that need to be specified for the roots problem presented in

problem (5). The solution to problem (5) returns a bound on the worst-case performance and a

norm-bounded vector that contains the individual critical realizations in the disturbances that

produces the worst-case performance for a specific process output. The actual worst-case

disturbance vector, obtained from (6), is used to simulate (16)-(17) following the procedure

described in Section 2.1 and Figure 1. The simulation results are used to search for the worstcase increase or the worst-case decrease in that process output. This result, the outputs’ worstcase performance, is then used to evaluate the cost function (C.1) and the process constraints

(C.2) included in the MINLP formulation. This process is repeated until an optimization criterion

is satisfied. Following Figure 3, the solution obtained from the case study’s MINLP problem was

tested for robust stability using condition (14).

10

Figure C.1 Schematic representation of the evaluation of DPCCSTR: System of CSTRs in

series.

Ternary separation system: process model superstructure, control superstructure and

objective function

The case study presented in Section 4 assumes that the dynamic behaviour of the ternary

distillation system is described using a mechanistic tray-by-tray process model, adapted from

Mohideen and co-workers,12 which includes mass component, total mass and energy balances for

each tray considered in the design. The physical properties needed to evaluate the tray-by-tray

process model include equilibrium relationships and empirical correlations. In the present model,

the number of stages is denoted by N whereas the feedstream stage is denoted as Nfeed. Similarly,

stage 1 represents the condenser/reflux drum whereas stage N represents the reboiler and the

column base.

Component mass balances

The composition of component i on each tray is given by the following expressions:

Stage 1:

1

dxi ,1

V2 Ki , 2 xi , 2 xi ,1 L1 D1

dt

(D.1)

11

Stages 2 to N-1:

r

dxi , r

Vr 1Ki , r 1xi , r 1 Vr Ki , r xi , r Lr xi , r Lr 1xi , r 1

dt

(D.2)

Feedstream stage (r=Nfeed):

r

dxi , r

Vr 1Ki , r 1xi , r 1 Vr Ki , r xi , r Lr xi , r Lr 1xi , r 1 Fr xi , feed

dt

(D.3)

Stage N:

N

dxi , N

LN 1 xi , N 1 xi , N VN Ki , N BN

dt

(D.4)

where the subscripts r and i are used to denote the stage number and the component,

respectively. Hence, the subscript r can take any integer value between 1 and N. Likewise, the

present system considers a ternary mixture of heptane (hep), n-hexane (hex) and toluene (tol);

thus, i={hex, hep, tol}. Accordingly, xhex,r, xhep,r and xtol,r represent the mole fractions of nhexane, heptane and toluene at stage r, respectively. Following (D.1)-(D.4), r represents the

molar holdup at stage r whereas Vr and Lr are the vapour and liquid flow rates leaving stage r,

respectively. Moreover, D1 represents the distillate product flowrate whereas BN is the total

product flowrate at the bottoms. Likewise, Ki,r represents the equilibrium constant of component

i at stage r; Fr represents the feed flowrate that enters at the feedstream stage (r=Nfeed) whereas

xi , feed represents the mole fraction of component i in the feedstream. The ratio between the

distillate product flowrate ( D1 ) and liquid reflux at the top of the column ( L1 ) specifies the

reflux ratio (RR), i.e.,

RR

L1

D1

(D.5)

In the present analysis, (RR) is assumed to be a process variable that is available for control, i.e.,

RR is a manipulated variable.

Mass balances

12

The present model assumes constant molar holdup. Accordingly, the corresponding total mass

balance on each tray is evaluated from the mass conservation equations shown in (D.6)-(D.9).

These equations are used to estimate the liquid and vapour flowrates leaving each stage r.

Stage 1:

V2 D1 L1 0

(D.6)

Stages 2 to N-1:

Vr 1 Lr 1 Vr Lr 0

(D.7)

Feedstream stage (r=Nfeed):

Vr 1 Lr 1 Vr Lr Fr 0

(D.8)

Stage N:

LN 1 BN VN 0

(D.9)

Energy balances

The energy conservation balances on each tray are shown in (D.10)-(D.13). These equations

estimate the variations in the temperature profile along the column due to changes in the heat

duties of the condenser and the reboiler units, respectively. The terms hL,r and hV,r represent the

specific enthalpies of the liquid and vapour respectively leaving tray r. Similarly, Qcond and Qreb

are the heat duties in the condenser and the reboiler, respectively. The condenser heat duty ( Qcond

) is a function of the pressure in the condenser (Pcond) and the amount of cooling water required

to condensate the overhead vapour stream leaving stage 2 ( V2 ). Moreover, the reboiler heat duty

( Qreb ) is considered as a process variable that can be adjusted to control the operation of the

distillation unit, i.e., Qreb is a manipulated variable. Furthermore, hL , feed represents the specific

enthalpy of the feedstream, which is assumed to be liquid.

Stage 1:

13

1

dhL,1

V2hV , 2 hL,1 L1 D1 Qcond

dt

(D.10)

Stages 2 to N-1:

r

dhL, r

Vr 1hV , r 1 Vr hV , r Lr hL, r Lr 1hL, r 1

dt

(D.11)

Feedstream stage (r=Nfeed):

r

dhL, r

Vr 1hV , r 1 Vr hV , r Lr hL, r Lr 1hL, r 1 Fr hL, feed

dt

(D.12)

Stage N:

N

dhL, N ˆ

LN 1hL, N 1 VˆN hV , N Bˆ N hL, N Qreb

dt

(D.13)

Physical properties

A few of the model parameters included in the previous equations require the evaluation of the

physical properties of the mixture at certain operation conditions. In the present model, the

equilibrium constant of component i at stage r (Ki,r) is obtained from Raoult’s law,61 i.e.,

Ki,r

Pi ,vap

r

Pr

(D.14)

where Pr represents the pressure at stage r whereas Pi ,vap

is the vapour pressure of component i at

r

stage r and is calculated using Antoine’s equation,61 i.e.,

log 10 Pi ,vap

r i

i

Tr i

(D.15)

where Tr is the temperature at stage r whereas αi, βi and γi are component-specific Antoine’s

parameters that can be obtained from the literature.62 As shown in (D.1)-(D.4), the composition

in the vapour phase of component i at stage r is obtained from the equilibrium constants and the

composition in the liquid phase of component i, i.e.,

14

yi , r K i , r xi , r

(D.16)

Moreover, the energy balance equations shown in (D.10)-(D.13) calculates the molar specific

enthalpy of the liquid stream leaving stage r, i.e., hL,r. The corresponding molar specific

enthalpies for the vapour phase and stage temperatures are calculated from the following

expressions:62

hL, r i 1 xi , r hV0 ,i , r Hivap

3

hV , r i 1 hV0 ,i , r yi , r

3

hV0 ,i , r z 1

5

(D.17)

(D.18)

i , z Tr Tr0 R

z

(D.19)

where i, r represents a component-specific fitting coefficient that is available in the literature for

different species.62 Similarly, H ivap represents the heat of vaporization of component i, R is the

ideal gas constant, Tr0 represents the reference temperature at which the fitting coefficients were

obtained ( Tr0 298.15K ), and hV0 ,i , r is the specific molar enthalpy of component i at stage r.

Furthermore, the constraints shown (D.20)-(D.21) are included in the model to ensure that the

sum of mole fractions in the liquid phase and the vapour phase at each stage r are satisfied at all

time.

x 1

(D.20)

yi , r 1

(D.21)

3

i 1 i , r

3

i 1

Control superstructure

The present analysis assumes that the reboiler heat duty (Qreb) and the reflux ratio (RR) are

available for control (manipulated variables) whereas the composition of toluene in the distillates

(xtol,1) and the composition of heptane at the bottoms (xhep,N) are variables that can be measured

on-line (controlled variables). Therefore, a 2x2 multi-loop control structure composed of PI

15

feedback controllers is proposed here to maintain the operation of the distillation unit within

specifications (see Table 2). The control superstructure proposed for this process in presented in

(D.22). A set of binary decision variables ( ω 0,1

2x2

) is included in the control superstructure

to specify the pairings between the manipulated and the controlled variables in the feedback

control loop. The subscripts n and m in (D.22) denote a manipulated variable and a controlled

variable, respectively. Logical constraints on the binary variables ωnm are included to ensure the

*

feasibility of the control structure. The parameter z nm

represents the set point for the control loop

*

specified by the n-m pairing; hence, z nm

can be either the composition of heptane in the bottoms

*

*

( xhep

, N ) or the composition of toluene in the distillates ( xtol,1 ). The PI tuning parameters,

K C 2 x 2 and τ I 2 x 2 , the nominal (steady-state) value in the manipulated variables, un , and

*

*

the PI controllers’ set points ( xhep

,N and xtol,1 ) have been included as continuous optimization

variables in the simultaneous process synthesis and control design formulation.

e

cnm nm nm

I nm

un un m1 unm

2

unm nm K C nm enm cnm

*

enm znm

znm

2

m 1

2

n 1

(D.22)

nm 1 n 1,2

nm 1 m 1,2

nm 0,1

Objective function

The cost function proposed in this work was adapted from Bansal and co-workers13 and is

defined as the addition of the capital and operating costs for this system, i.e.,

Φdist CCdist OPdist

(D.23)

The annualized capital cost for the distillation unit ( CCdist ) represents the costs associated with

each major process unit included in this system, i.e.,

16

CCdist Cshell Ctrays Creb Ccond Ccool

(D.24)

where Cshell, Ctrays, Creb, Ccond and Ccool represent the capital costs associated with the distillation

column’s shell, the theoretical trays, the partial reboiler, the total condenser and the cooler unit,

respectively. The individual capital costs of these units are calculated as follows:13

1.066

Cshell

M & S 100 Dcol

151.22

280 30.48

t

N 15

0.802

spa

(D.25)

1.55

M & S 100 Dcol

Ctrays 2.193

280 30.48

Creb

4

M & S 10 Areb

89.9544

280 929.03

t spa N

(D.26)

0.65

(D.27)

Ccond

4

M & S 10 Acond

66.6554

280 929.03

Ccool

4

M & S 10 Acool

66.6554

280 929.03

0.65

(D.28)

0.65

(D.29)

where the Areb, Acond and Acool represent the heat transfer areas for the partial reboiler, the total

condenser and the cooler unit, respectively. Each of these design variables are estimated from the

following empirical relations:13

Areb

Qreb

U o, reb Tsteam TN

Acond

Qcond

U o, cond

T T

ln 2 water , out

T1 Twater ,in

T T

T1 Twater,in

2 water , out

(D.30)

(D.31)

17

Acool

Qcool

U o, cool

T Twater , out

ln N

Tb, out Twater ,in

T T

water , out Tb , out Twater , in

N

(D.32)

where Qreb , Qcond and Qcool represent the heat duties of each unit at a nominal (optimal)

operating state. The nominal operating state for the reboiler heat duty ( Qreb ) is estimated from

the steady-state solution of process model equations using an inputs the decision variables

specified in the simultaneous design and control formulation (see Section 4). Likewise, Qcond is

calculated based on Pcond and the total amount of cooling water required to totally condensate the

vapours produced at V2 whereas Qcool is estimated based on the amount of water required to cool

the bottoms at a given (desired) temperature (60 ºC). The rest of the parameters shown in (D.30)(D.32) are described in Table D.1.

Following (D.25)-(D.26), the capital costs of the distillation column’s shell and the trays inside

the column are a direction function of the number of theoretical trays (N), the tray spacing (tspa)

and the distillation column’s diameter (Dcol). In the present analysis, the distillation column’s

diameter is specified such that it can accommodate the highest vapour flowrate that is expected

to occur within the column due to critical changes in the operation of the process. Accordingly,

Dcol is estimated as follows:

Dcol

VF

4 VF

vel

RT

(D.34)

P

vel 0.107

(D.33)

L , V ,

L,

(D.35)

18

where the subscript denotes the stage with the highest vapour molar flowrate. Accordingly, VF

and vel represent corresponding volumetric flowrate and the velocity at stage , which are

obtained using the Souders-Brown equation.63 Likewise, represents the vapour molar

flowrate at stage whereas V , and L , represent the densities of the vapour and the liquid

phases at stage . Furthermore, P and T are the corresponding pressure and temperature at

stage . The parameters M&S and tspac shown in (D.25)-(D.29) are specified in Table D.1. The

capital costs of each process unit included in (D.24) have been estimated assuming a payback

period of 3 years and that the units operate continuously for 8,150 hours each year.

The annualized operating costs for the present system ( OPdist ) are directly related to the steam

and water consumption costs in the system, i.e.,

OPdist Cwater Fwater , cond Fwater , cool CsteamFsteam, reb

(D.36)

where Cwater and Csteam are the cooling water and steam costs, respectively. Likewise, Fsteam, reb ,

Fwater , cond and Fwater , cool represent the utility flowrates in the reboiler, condenser and cooler,

respectively. These flowrates are calculated as follows:13

Fwater , cond 29340

Qcond

c p , water Twater , out Twater ,in

(D.37)

Fwater , cool 29340

Qcool

c p , water Twater , out Twater ,in

(D.38)

Qreb

vap

H water

(D.39)

Fsteam, reb 528120

The constant values shown in (D.37)-(D.39) are unit conversion factors. The values used for the

vap

specific heat capacity of water ( c p , water ) and the heat of vaporization of water ( H water

) are listed

in Table D.1.

19

The number of trays N and the location of the feedstream Nfeed were implemented in the dynamic

flexibility and feasibility formulation using 0-1 binary variables as it is presented in12.

Accordingly, the binary variable Nr is introduced in the formulation to determine the existence of

the rth theoretical tray in the column, i.e., Nr=1 denotes the existence of tray r in the column.

Likewise, the binary variable Nfeed,r is incorporated in the formulation to denote the existence of a

feedstream entering the column at the rth tray, i.e., Nfeed,r=1 indicates that the feedstream enters

the column at the rth tray. The complete set of logical constraints that involve Nr and Nfeed,r are

presented in12. For example, the following logical constraints are included in the dynamic

feasibility and flexibility formulation to ensure that the feedstream (Ffeed) only enters at one tray

in the column:

Fr F feed N feed ,r 0 r 1,..., R

R

F

r 1

r

F feed

R

N

r 1

feed , r

1

N feed ,r N r

(D.40)

r 1,..., R

N r [0,1]R

N feed ,r [0,1]R

where R is the total number of trays considered for the column including the reboiler and the

condenser (see Figure 6). The last constraint shown in (D.40) ensures that the feed tray has to be

assigned to an existing tray in the column. The following constraint ensures that the (r+1)th tray

exist in the column only if the rth tray exists:

Nr 1 Nr

r 1,..., R 1

(D.41)

The total number of trays (N) in the column is calculated as follows:

R

N r N r N r 1

r 1

(D.42)

20

Table D.1 – Model parameters: Ternary distillation system. Adapted from Bansal and coworkers.13

Parameter

M&S

tspa

Definition

Marshall and Swift index for 2008

Tray spacing

Cp,water

Heat capacity of cooling water

Twater,in

Temperature of available cooling water

Twater,out

Maximum outlet temperature of cooling

water

Estimate

1449.3

0.6096m (2

ft)

4.187 J/g.K

25°C

45°C

Tb,out

Desired bottoms product temperature

60°C

Td,out

Desired distillate product temperature

60°C

Tsteam

Temperature of available steam

146.85°C

ΔHvapwater

Enthalpy of condensing steam @ 146.85°C

38,253 J/mol

Uo,cool

Overall heat transfer coefficient for cooler

1000 W/m2K

Uo,reb

Overall heat transfer coefficient for reboiler

2000 W/m2K

Uo,cond

Overall heat transfer coefficient for

condenser

1000 W/m2K

Csteam

Cost of steam

0.01 $/kg

Cwater

Cost of cooling water

10-5 $/kg

21