2011 International Workshop on Molten Carbonates

advertisement

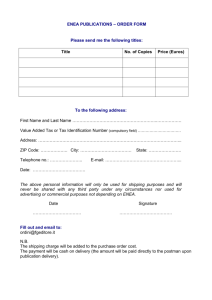

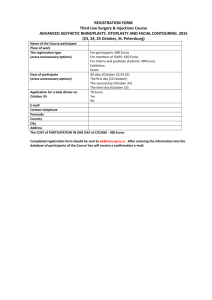

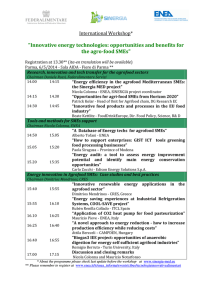

"2011 International Workshop on Molten Carbonates & Related Topics"(MCFC, DCFC, SOFC/MCFC, CO2 capture...) Chimie-ParisTech, Paris, France (in joint organization with ENEA) 21-22 of March 2011 A scientific pole in the heart of the Latin Quarter in Paris Organizing committee Chairman: Prof. Michel Cassir (Chimie-ParisTech, France): michel-cassir@chimie-paristech.fr Co-chairman: Dr. Angelo Moreno (ENEA, Italy): angelo.moreno@enea.it Dr. Stephen Mc Phail (ENEA, Italy): stephen.mcphail@enea.it Dr. Armelle Ringuedé (Chimie-ParisTech, France): armelle-ringuede@chimie-paristech.fr Dr. Viviana Cigolotti (ENEA, Italy): viviana.cigolotti@enea.it Dr. Virginie Lair (Chimie-ParisTech, France): virginie-lair@ens.chimie-paristech.fr Valérie Albin (Chimie-ParisTech, France): valerie-albin@chimie-paristech.fr Marine Tassé (Chimie-ParisTech, France): marine-tasse@chimie-paristech.fr Scientific committee Prof. J.R. Selman (Illinois Institute of Technology, Chicago, USA) Prof. Kenichiro Ota (Yokohama University, Japan) Dr. Tae-Won Lee (Doosan Heavy Industry – Daejong – Korea) Prof. John Irvine (St-Andrews University, United Kingdom) Dr. Carina Lagergren (Royal Institute of Technology, KTH - Sweden) Prof. Panagiotis Tsiakaras (University of Thessaly, Volos, Greece) Dr. Salvatore Freni (CNR – ITAE, Messina, Italy) Dr. Bin Zhu (Royal Institute of Technology, KTH, Sweden) Dr. Mauro Scagliotti (RSE – Ricerca sul Sistema Energetico SpA – Milan – Italy) Dr. Henri Groult (University of Paris 6 – France) Dr. Takao Watanabe (CRIEPI – Japan) Mr. Stefan Rolf (MTU Onsite Energy GmbH) Dr. Biagio Passalacqua (Ansaldo Fuel Cells, Italy) Dr. Mohammed Farooque (FCE, USA) Professor Michel CASSIR Head of the Laboratory of Electrochemistry, Chemistry of Interfaces and Modeling for Energy (LECIME) Associated to CNRS, UMR 7575 Tél. : (33) 01 55 42 63 87 Fax : (33) 01 44 27 67 50 michel-cassir@chimie-paristech.fr Dear colleagues, On behalf of Angelo Moreno (ENEA – Italy) and myself (Chimie-ParisTech – France), we would like to invite you to participate to the: "2011 International Workshop on Molten Carbonates & Related Topics" (MCFC, DCFC, SOFC/MCFC, CO2 capture...). It will be held in Chimie-ParisTech (in joint organization with ENEA), Paris, France 21-22 of March 2011 As you well know, molten carbonates science & technology is in the heart of several important applications in the field of energy generation and carbon dioxide capture and exploitation. It is also directly related to the carbon cycle, in continuity with the highly fruitful symposium held in Naples on 12-13 July 2010. This workshop is addressed to researchers, engineers from industry, developers and European and international players in the field of energy production with reduced CO2 emission. The fields considered are the following: - Molten carbonate science: experimental and theoretical approach. - Molten carbonate fuel cell (MCFC). - Direct Carbon Fuel Cell (DCFC). - Hybrid Direct Carbon Fuel Cell (HDFC). - Hybrid fuel cells with composite electrolytes (solid oxide and carbonates). - Carbon dioxide capture and/or separation. - Other topics such as catalysis, clean-up, carbon deposition, synthesis of materials, thermal treatments. Plenary lectures will be given by international specialists in the mentioned fields. Oral presentations will be given by researchers and developers. A selection of papers mentioning the workshop will be peer-reviewed by the International Journal of Hydrogen Energy. Fees, excluding travel and hotel, are of 180 Euros (including meals, dinner and documents). With my best regards, Professor Michel Cassir FINAL REGISTRATION FORM Name: Organization: Address (including tel. and e-mail): If you give a lecture, title of the presentation (a one-page abstract as indicated in the template next page should be sent before the 15th of January): Will you present full-length paper for a publication in J. Power Sources. It should be sent to International Journal of Hydrogen Energy (Angelo Basile) before the 15th of April 2011, with the mention: "2011 International Workshop on Molten Carbonates & Related Topics", with a copy to Michel Cassir & Angelo Moreno) Yes Title: No Abstract Template… S. Frangini*, S. Loreti ENEA CRE Casaccia, Hydrogen and Fuel Cells Project, Via Anguillarese 301, 00060 Rome, Italy * frangini@casaccia.enea.it Austenitic 316L and 310S stainless steels are the most commonly used materials for the construction of bipolar plate components in the Molten Carbonate Fuel Cell (MCFC) technology because of compromise between corrosion resistance and oxide scale resistivity at 650°C under standard MCFC operating conditions. In detail, 310S steel exhibits a much slower oxide growth rate, although 316L steel is sometimes preferred as its oxide scale has a higher electrical conductivity [1]. The corrosion resistance of these steels basically relies on the rapid formation of a protective passive oxide scale that is able to suppress the outward diffusion of base-metal cations (mainly, iron) into the molten electrolyte. The two-layered structure of the passive scale consists of an external LiFeO2 layer and an inner Cr-rich oxide layer. The passivity of stainless steels depends on the stability of this inner layer [1,2]. In the case of the high-Cr Type 310S steel (ca. 25 wt%), the Cr-rich oxide layer is composed mainly of a compact, thin and corrosion resistant layer of LiCrO2 which strongly hinders the iron diffusion, thus limiting the growth of the external LiFeO2 layer. Conversely, the 316L steel forms an inner high conductive spinel layer mainly consisting of LiFe5O8 and FeCrO4 phases. The spinel layer is less effective in retarding the outer iron diffusion, thus leading to a faster growth of the external LiFeO2 layer and to an overall higher thickness of the scale [1,3]. Since MCFC stack operations usually give large temperature variations (580-700°C) along the surface of bipolar plates it would be important to evaluate the steel corrosion as a function of temperature, although this aspect has been scarcely investigated in literature. For instance, the authors of [2,4] report that the corrosion of 316L steel becomes highly sensitive on the reaction conditions in the eutectic Li+Na carbonate melt. At temperatures lower than 600°C this steel seems to be more susceptible to corrosion showing pitting-like attack expecially in high CO2 gases. Obviously, this result could represent a real concern for the use of the 316L steel in alternative alkali carbonate compositions based on the Li+Na electrolyte. As part of a work aimed to analyze the corrosion behavior of 316L and 310S steels in Li+K and Li+Na carbonates, we will present some results on the stability of the passive scale forming on 310S stainless steel surface in Li+K melt in the temperature range 580-700°C. This study has been conducted by electrochemical methods with emphasis to the measurements of passivation rates and anodic polarization curves. References [1] A. Schoeler, T. D. Kaun, I. Bloom, M. Lanagan and M. Krumpelt, J. Electrochem. Soc., 147 (2000) 916; [2] K. Ota, K. Toda, S. Mitsushima and N. Kamiya, Bull. Chem. Soc. Jpn., 75 (2002) 877; [3] P. Biedenkopf, M.M. Bischoff and T. Wochner, Materials and Corrosion, 51 (2000) 287; [4] T.H. Lim, E.R. Hwang, H. Y. Ha, S. W. Nam, I. Oh and S. Hong, J. Power Sources, 89 (2000) 1; Subscription 1- Participants : The conference fees include the participation to lectures, a book of abstracts, 4 coffee breaks, 2 meals, a banquet .... Before the 31st of January: 180 Euros Late registration: 220 Euros 2- Stand subscription (including two persons): 500 Euros, excluding the banquet (extra 80 Euros/person). 3- Sponsors (including one full participation): see the sponsorship form Name of sponsors will appear in all the workshop documents and activities. All payments should made payable to the Accounting Officer of the ENSCP: - either by check (to « M. Jean-Marc DUCLOS, ENSCP”) - or by bank transfer to the account of ENSCP open in the name of the Accounting Officer, M. Jean-Marc DUCLOS whose address is: « Ecole Nationale Supérieure de Chimie de Paris R.G.F. PARIS 94 Rue Réaumur 75104 PARIS Cedex 02 Bank Code: 10071 Bank Branch: 75000 Account number: 00001005796 Swift number: 55 » Any further detail, contact: michel-cassir@chimie-paristech.fr armelle-ringuede@chimie-paristech.fr virginie-lair@ens.chimie-paristech.fr SPONSORSHIP FORM Company: Address: Zip code: City: Country: E-mail: VAT Number/Fiscal Code: Contact: Please, indicate which of the following sponsorship levels you have chosen: Gold level 4.000 Euros Silver level 1.500 Euros Bronze level 600 Euros Date: Signature Please email (completed and signed) scanned form to michel-cassir@chimie-paristech.fr All payments should made payable to the Accounting Officer of the ENSCP: - either by check (to « M. Jean-Marc DUCLOS, ENSCP”) - or by bank transfer to the account of ENSCP open in the name of the Accounting Officer, M. Jean-Marc DUCLOS whose address is: « Ecole Nationale Supérieure de Chimie de Paris R.G.F. PARIS 94 Rue Réaumur 75104 PARIS Cedex 02 Bank Code: 10071 ; Bank Branch: 75000; Account number: 00001005796; Swift number: 55 » Any further detail, contact: michel-cassir@chimie-paristech.fr armelle-ringuede@chimie-paristech.fr virginie-lair@ens.chimie-paristech.fr