report - sigi.ca

advertisement

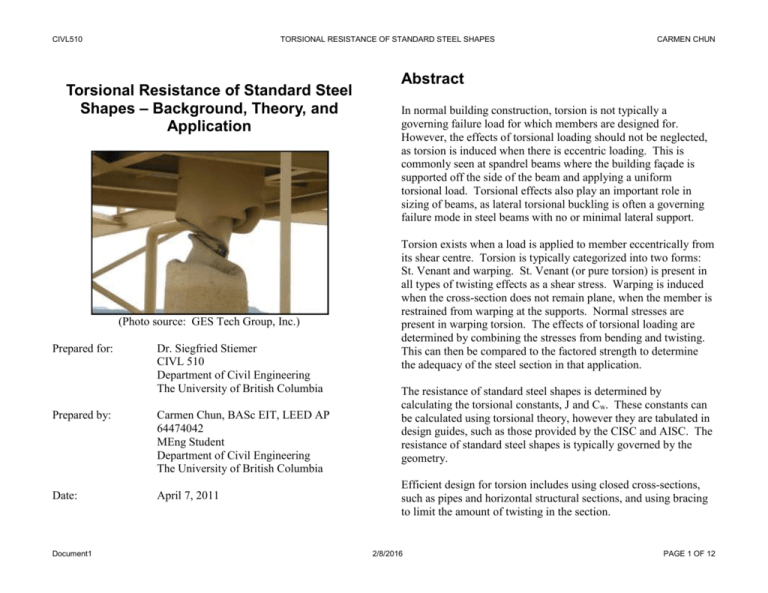

CIVL510 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES Torsional Resistance of Standard Steel Shapes – Background, Theory, and Application (Photo source: GES Tech Group, Inc.) Prepared for: Dr. Siegfried Stiemer CIVL 510 Department of Civil Engineering The University of British Columbia Prepared by: Carmen Chun, BASc EIT, LEED AP 64474042 MEng Student Department of Civil Engineering The University of British Columbia Date: April 7, 2011 Document1 CARMEN CHUN Abstract In normal building construction, torsion is not typically a governing failure load for which members are designed for. However, the effects of torsional loading should not be neglected, as torsion is induced when there is eccentric loading. This is commonly seen at spandrel beams where the building façade is supported off the side of the beam and applying a uniform torsional load. Torsional effects also play an important role in sizing of beams, as lateral torsional buckling is often a governing failure mode in steel beams with no or minimal lateral support. Torsion exists when a load is applied to member eccentrically from its shear centre. Torsion is typically categorized into two forms: St. Venant and warping. St. Venant (or pure torsion) is present in all types of twisting effects as a shear stress. Warping is induced when the cross-section does not remain plane, when the member is restrained from warping at the supports. Normal stresses are present in warping torsion. The effects of torsional loading are determined by combining the stresses from bending and twisting. This can then be compared to the factored strength to determine the adequacy of the steel section in that application. The resistance of standard steel shapes is determined by calculating the torsional constants, J and Cw. These constants can be calculated using torsional theory, however they are tabulated in design guides, such as those provided by the CISC and AISC. The resistance of standard steel shapes is typically governed by the geometry. Efficient design for torsion includes using closed cross-sections, such as pipes and horizontal structural sections, and using bracing to limit the amount of twisting in the section. 2/8/2016 PAGE 1 OF 12 CIVL510 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES CARMEN CHUN Table of Contents List of Figures List of Figures ................................................................................. 2 Figure 1. Shear centre of common steel shapes (AISC, 2003) ....... 4 Figure 2. Warping torsion on I-beam (Salmon and Johnson, 1996) 5 Figure 3. Torsional loading from building facade (AISC, 2003) ... 7 Figure 4. Equations for lateral torsional resistance (CSA S16-09)10 Figure 5. W-shape (CISC, 2002) .................................................. 10 List of Equations ............................................................................. 2 1.0 Introduction .......................................................................... 3 2.0 Theory .................................................................................. 3 2.1 Shear Centre ..................................................................... 3 2.2 Pure Torsion (or St. Venant Torsion) ............................... 4 2.3 Warping Torsion .............................................................. 5 2.4 Asymmetry Parameter ...................................................... 6 2.5 Other Torsional Properties ............................................... 6 2.6 Torsional Functions .......................................................... 6 3.0 Analysis and Design Approaches ........................................ 7 3.1 Torsional Stress for Open Shapes .................................... 8 3.1.1. Pure Torsional Shear Stresses ................................... 8 3.1.2. Warping Shear Stresses............................................. 8 3.1.3. Warping Normal Stresses ......................................... 8 3.1.4 Warping Stresses on Angles and Structural Tees .......... 8 3.2 Torsional Stress for Closed Shapes .................................. 9 3.3 Combining Stresses .......................................................... 9 4.0 Application of Theory – Lateral Torsional Buckling .......... 9 5.0 Conclusion ......................................................................... 11 List of Equations Equation 1. Shear centre ................................................................. 4 Equation 2. y-coordinate of shear centre ........................................ 4 Equation 3. x-coordinate of shear centre ........................................ 4 Equation 4. Pure torsional resistance .............................................. 4 Equation 5. Torsional constant for open shapes ............................. 5 Equation 6. Torsional constant for closed shapes ........................... 5 Equation 7. Warping torsional resistance ...................................... 6 Equation 8. Warping torsional constant for a W-shape .................. 6 Equation 9. Asymmetry parameter ................................................. 6 Equation 10. Pure torsional shear stress for open shapes ............... 8 Equation 11. Warping shear stress for open shapes ........................ 8 Equation 12. Warping normal stress for open shapes ..................... 8 Equation 13. Combined normal stresses ......................................... 9 Equation 14. Combined shear stresses ............................................ 9 Equation 15. Typical resistance strength ........................................ 9 Equation 16. Torsional constant for W-shapes ............................. 10 Equation 17. Warping constant for W-shapes .............................. 10 References ..................................................................................... 12 Document1 2/8/2016 PAGE 2 OF 12 CIVL510 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES 1.0 Introduction Torsion is frequently considered a secondary effect that does not significantly impact the design of a steel structure. There are very few steel design standards that provide guidance for torsion design of steel. However, there are occasions where torsion may be a significant force for which it must be adequately resisted. It is also important to be able recognize when torsion is present and understand how torsional loads are resisted. In the discussion of torsion, distinction must be made for strength and stability analysis. Strength refers cross-sectional properties of the member that offer resistance to the applied stresses; this is commonly known as sectional analysis. A stability failure results in a failure to maintain the initial configuration, such as lateral torsional buckling in a beam. This report will provide background and theory of torsion, including analytical methods to determine torsional resistance, worked examples, and a case study for torsional design. CARMEN CHUN To evaluate torsional stresses, the shear centre (the axis of rotation) must be defined. Torsion may be categorized into two types: pure torsion, often called St. Venant torsion, and warping torsion, discussed below. 2.1 Shear Centre The axis of which an object rotates about is defined as the shear centre of a section. It is the point in the plane of a cross-section where no twisting occurs. The shear centre does not necessarily coincide with the centroid of a cross-section. However, if a shape has a line of symmetry, the shear centre will lie on the line of symmetry. For doubly symmetric cross-sections, such as round or square hollow structural sections (HSS) and pipes, the shear centre coincides with the centroid, as shown in Figure 1. For monosymmetric cross-sections, such as channels and tees, the shear centre will lie on the axis of symmetry, as shown in Figure 1. 2.0 Theory Torsion is the twisting of a solid object when subjected to torque (turning force), such that the object rotates about an axis. Torque is a moment created when a force is applied a distance away from the axis of rotation. This is analogous to a bending moment, where a bending forces are created from external forces are applied a distance away from the point of interest. In this report, torsional moment will mean the same as torque. Document1 2/8/2016 PAGE 3 OF 12 CIVL510 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES CARMEN CHUN Then the shear centre is located such that the shear forces counteract all the applied shear forces to produce equilibrium. 1 𝑛 𝑦0 = − ∫ (𝜏𝑡)𝑟 𝑑𝑠 𝑉𝑥 𝑜 Equation 2. y-coordinate of shear centre 𝑥0 = − 1 𝑛 ∫ (𝜏𝑡)𝑟 𝑑𝑠 𝑉𝑦 𝑜 Equation 3. x-coordinate of shear centre 2.2 Figure 1. Shear centre of common steel shapes (AISC, 2003) For common steel shapes, many design guides, such as the American Institute of Steel Construction (AISC) Torsion Guide will provide the torsional properties. To locate the shear centre on an uncommon or asymmetric shape, the following equations may be used. 𝑛 ∫ (𝜏𝑡)𝑟 𝑑𝑠 = 𝑉𝑦 𝑥0 − 𝑉𝑥 𝑦0 = 0 Pure Torsion (or St. Venant Torsion) Pure torsion assumes that “plane sections remain plane” principle; only element rotation occurs. The torsional moment is carried as torsional shear stresses in the element. The torsional resistance for pure torsion is determined in Equation 4. This resistance is analogous to bending moment resistance, which is comprised of the bending rigidity (EI) multiplied by the curvature. For torsional resistance, the torsional rigidity is defined by GJ and multipled by the torsional curvature (rate of change of angle). Thus the stress due to pure torsional stress is proportional to the distance from the centre of twist. 𝑜 Equation 1. Shear centre 𝑀𝑠 = 𝐺𝐽 The location of the shear centre is independent of the magnitude or type of loading, only on the geometrical configuration. Compute the shear forces in each of the component elements by integrating over the stress distribution, as shown in Equation 2 and Equation 3. Document1 𝜕𝜑 𝜕𝑧 Equation 4. Pure torsional resistance where 2/8/2016 G = shear modulus of elasticity J = torsional constant PAGE 4 OF 12 CIVL510 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES CARMEN CHUN The torsional constant J measures the resistance of a structural member to pure torsion. This differs from open shapes (Equation 5) and closed shapes (Equation 6). 𝐽= ∑ 𝑏′𝑡 3 3 Equation 5. Torsional constant for open shapes b’ = plate lengths between points of intersection on their axes t = plate thicknesses where 4𝐴20 𝐽= ∫𝑠 𝑑𝑠⁄𝑑𝑡 Equation 6. Torsional constant for closed shapes where 2.3 A0 = enclosed area by the walls t = wall thickness ds = perimeter of shape Warping Torsion Warping torsion is present when plane sections do not remain plane. The resulting translation produces lateral bending, or warping. For example, a W-shape (or I-beam) subjected to bending will have its compression flange bent in one direction laterally while its tension flange is bent in another. When warping is restrained, lateral flange bending causes flexural normal stresses (tension and compression) along with shear stresses in the flange. Warping stresses will not develop when a member is allowed to warp freely. As a result, warping torsion results in torsional shear stresses and normal stresses in a member. Document1 Figure 2. Warping torsion on I-beam (Salmon and Johnson, 1996) The warping torsional constant Cw measures the resistance of a structural member to the warping contribution of warping torsion. The torsional resistance for restrained warping is defined in Equation 7. For HSS, warping deformations are small and generally taken to be zero. The warping torsional constant for other sections can be found in most design guides; the calculation for this constant can vary based on the geometry of the structural section. The resistance is a function of the modulus of elasticity, the shear resistance from lateral bending of one flange, and the moment arm of the lateral bending. A general calculation for a Wshape is shown in Equation x. 2/8/2016 PAGE 5 OF 12 CIVL510 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES 𝜕 3𝜑 𝑀𝑤 = −𝐸𝐶𝑤 3 𝜕𝑧 Equation 7. Warping torsional resistance where E = modulus of elasticity Cw = warping torsional constant 𝐶𝑤 = 𝐼𝑓 ℎ2 2 Equation 8. Warping torsional constant for a W-shape where 2.4 If = moment of inertia for one flange h = moment arm (centre of flange to centroid) Asymmetry Parameter The asymmetry parameter (or monosymmetry constant) is used in calculating the buckling moment resistance of laterally unsupported monosymmetric beams loaded in the plane of symmetry. The monosymmetry constant is defined as follows in Equation 9. βx is zero for double-symmetric sections. 𝛽𝑥 = 1 ∫ 𝑦(𝑥 2 + 𝑦 2 )𝑑𝐴 − 2𝑦𝑜 𝐼𝑥 𝐴 Equation 9. Asymmetry parameter where Document1 Ix = moment of inertia about horizontal centroidal axis dA = area element y0 = vertical location of shear centre with respect to the centroid 2.5 CARMEN CHUN Other Torsional Properties For the solution of torsional analysis, the torsional constants presented above (J, Cw) must be determined for open crosssections. Additional torsional properties are also required and are dependent only on the geometry of the structural shape. These have been tabulated in the AISC Torsion Guide. These include: 𝐸𝐶 a: √ 𝐺𝐽𝑤 Qs: Statical moment at point s Sws: Warping statical moment at point s Wns: Normalized warping function at point s 2.6 Torsional Functions In additional the geometric properties of the cross-section, the torsional rotation and its derivatives are necessary to evaluate the torsional response of a structural member. Graphs are provided in AISC Torsion Guide for the torsional functions, for corresponding values of the ratio of the span length to the torsional property a. Equations have been evaluated for common boundary conditions (fixed, pinned, and free) and loading conditions. 2/8/2016 PAGE 6 OF 12 CIVL510 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES CARMEN CHUN 3.0 Analysis and Design Approaches The most commonly used structural shapes offer relatively poor resistance to torsion, such as W-shapes and T-shapes. These structural shapes are commonly used as they are efficient in resisting bending moments, in beam and column situations. However, as discussed previously, closed sections, such as HSS, are the most effective in resisting torsional loads, however these are typically inefficient and expensive for bending. Therefore, it is practical to minimize torsional effects by detailing loads and reactions to act through the shear centre of the member. Any situation where the loading or reaction acts eccentrically to the shear centre gives rise to torsion. Torsion exists on spandrel beams, where such loading may be uniformly distributed along the length, from the weight of the building façade (see Figure 3). The uniform torsion load can be quite significant, especially if the building cladding is curtain wall, which is becoming increasingly prevalent in building construction. To minimize twisting on the spandrel beam, diagonal bracing may be used to transfer the vertical eccentric loading as a compression force into the brace and to the floor diaphragm. However, this is not always practicable as this may decrease the floor-to-ceiling space to conceal the bracing, or may be aesthetically displeasing. Figure 3. Torsional loading from building facade (AISC, 2003) In design, it is practical to minimize torsional effects by reducing eccentricity of loads or to add additional bracing to transfer loads by other means. When this is not possible, the use of closed sections will result in more effective resistance to torsional loads. Document1 2/8/2016 PAGE 7 OF 12 CIVL510 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES CARMEN CHUN 3.1.2. Warping Shear Stresses However, as discussed above, the most commonly used steel shapes for building construction (W-, C-, L- shapes) offer relatively poor resistances to torsion. Although torsion is not usually the governing design case, secondary effects from torsion should be considered in the design. Therefore, the method of calculating torsional properties of standard steel shapes will be provided. In-plane shear stresses develop when warping is restrained that act parallel to the edge of the element, and the magnitude is in accordance to Equation 11. 𝜏𝑤𝑠 = −𝐸𝑆𝑤𝑠 𝜃 ′′′ 𝑡 Equation 11. Warping shear stress for open shapes 3.1 Torsional Stress for Open Shapes The open shapes refer to I-shapes, channels, angles, and tees. These open shapes tend to warp under torsional loading. When warping is restrained, additional longitudinal stresses are added to the shear stresses. 3.1.3. Warping Normal Stresses These stresses are perpendicular to the surface of the element, determined in accordance to Equation 12. 𝜎𝑤𝑠 = 𝐸𝑊𝑛𝑠 𝜃′′ Equation 12. Warping normal stress for open shapes 3.1.1. Pure Torsional Shear Stresses Pure torsional shear stresses are in-plane shear stresses that act parallel to the edge of the element. They are at maximum with equal and opposite directions at the two edges, where the maximum is calculated as shown in Equation 10. 𝜏 = 𝐺𝑡𝜃′ Equation 10. Pure torsional shear stress for open shapes Document1 3.1.4 Warping Stresses on Angles and Structural Tees Angles and structural tees tend to warp under torsional loading. However, the warping stresses are relatively small and therefore the shear and normal stresses due to warping typically are considered negligible. 2/8/2016 PAGE 8 OF 12 CIVL510 3.2 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES Torsional Stress for Closed Shapes Torsion on a closed or solid circular shape is resisted by shear stresses that vary directly with the distance from the centroid. Due to its geometry, the cross-section remains plane and only pure torsional shear stresses develop. Non-circular closed shapes tend to warp under torsional loads, but this warping is restricted as the longitudinal shear prevents relative displacement of adjacent plate elements. Therefore, warping stresses are typically neglected when closed shapes are used. 3.3 Combining Stresses When torsional stresses are present, bending and shear stresses due to plane bending are typically present as well. The normal and shear stresses are combined with the stresses induced by torsion to determine the resultant stresses from the factored loads (see Equation 13 and Equation 14). Then the stress conditions can be compared to the factored resistance (Equation 15) to determine if the specified section is adequate in resisting the loads. CARMEN CHUN 4.0 Application of Theory – Lateral Torsional Buckling The W-shape is arguably the most common steel shape used in building construction. It is efficient in resisting bending moments as the majority of the cross-section is located far from the centroid. In terms of torsion, W-shapes are vulnerable to lateral torsional buckling failures. The analysis for lateral torsional buckling utilizes the concepts from torsional stress. According to the CSA S16-09, where a continuous lateral support is not provided to the compression flange of a member subjected to uniaxial strong axis bending, the factored moment is determined as per Clause 13.6 (Figure 4). 𝜎𝑓 = 𝜎𝑎𝑥𝑖𝑎𝑙 ± 𝜎𝑏𝑒𝑛𝑑𝑖𝑛𝑔 ± 𝜎𝑤𝑎𝑟𝑝𝑖𝑛𝑔 Equation 13. Combined normal stresses 𝜏𝑓 = 𝜏𝑏𝑒𝑛𝑑𝑖𝑛𝑔 ± 𝜏𝑆𝑡.𝑉𝑒𝑛𝑎𝑛𝑡 ± 𝜏𝑤𝑎𝑟𝑝𝑖𝑛𝑔 Equation 14. Combined shear stresses 𝜎𝑟 = 𝜑𝑓𝑦 Equation 15. Typical resistance strength Document1 2/8/2016 PAGE 9 OF 12 CIVL510 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES CARMEN CHUN Figure 5. W-shape (CISC, 2002) Equation 16. Torsional constant for W-shapes Equation 17. Warping constant for W-shapes The asymmetry parameter would not apply in this situation, as the W-shape is doubly-symmetric. Figure 4. Equations for lateral torsional resistance (CSA S16-09) The torsional section properties for W-shapes (Figure 5) are calculated in Equation 16 and Equation 17 below. If the plane of bending is not in the strong axis, lateral torsional buckling will not govern as the lateral bending strength is strong than in the direction of uniaxial bending. Also, stability (lateral torsional buckling) is not a governing failure mode, unless the unbraced length is large. Given this parameter, determining the unbraced length is critical in determining the failure mode. This is greatly affected by the Document1 2/8/2016 PAGE 10 OF 12 CIVL510 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES boundary conditions – whether the ends are fixed or simply supported. It may be beneficial to have rigid fixed ends to minimize the unbraced length, thus reducing the likelihood for lateral torsional buckling. Finally, the type of loading can impact the load effects, whether the loads are being transferred through the top or bottom flange and if the loads are uniform throughout the length of the member. However, lateral torsional buckling for beams should be considered as this is normally a governing failure load unless continuous lateral support can be provided. CARMEN CHUN all types of twisting effects as a shear stress. Warping is induced when the cross-section does not remain plane, when the member is restrained from warping at the supports. Normal stresses are present in warping torsion. The effects of torsional loading are determined by combining the stresses from bending and twisting. This can then be compared to the factored strength to determine the adequacy of the steel section in that application. The resistance of standard steel shapes is determined by calculating the torsional constants, J and Cw. These constants can be calculated using torsional theory, however they are tabulated in design guides, such as those provided by the CISC and AISC. The resistance of standard steel shapes is typically governed by the geometry. 5.0 Conclusion In normal building construction, torsion is not typically a governing failure load for which members are designed for. However, the effects of torsional loading should not be neglected, as torsion is induced when there is eccentric loading. This is commonly seen at spandrel beams where the building façade is supported off the side of the beam and applying a uniform torsional load. As increasingly more buildings are designed with curtain wall cladding, dead loading on the side of the beam, consideration of torsion is more significant. Efficient design for torsion includes using closed cross-sections, such as pipes and horizontal structural sections, and using bracing to limit the amount of twisting in the section. Torsional effects also play an important role in sizing of beams, as lateral torsional buckling is often a governing failure mode in steel beams with no or minimal lateral support. Torsion exists when a load is applied to member eccentrically from its shear centre. Torsion is typically categorized into two forms: St. Venant and warping. St. Venant (or pure torsion) is present in Document1 2/8/2016 PAGE 11 OF 12 CIVL510 TORSIONAL RESISTANCE OF STANDARD STEEL SHAPES CARMEN CHUN References American Institute of Steel Construction. “Torsional Analysis of Structural Steel Members.” Chicago, Illinois, 1997. Reprinted October 2003. Canadian Institute of Steel Construction. “Handbook of Steel Construction.” 10th edition, Toronto, Ontario, March 2010. Canadian Institute of Steel Construction. “Torsional Section Properties of Steel Shapes.” 2002. Salmon, C.G. and Johnson, J.E. “Steel Structures, Design and Behavior”, 4th Edition. HarperCollins Publishers. New York, N.Y. 1996. Yao, C.C. Design of Monosymmetric Beams presentation. Read Jones Christoffersen Ltd, Vancouver, 2010. http://www.gestech.net/shaft_torsional_failure.htm (accessed April 5, 2011) Document1 2/8/2016 PAGE 12 OF 12