ESS-0012977

Guideline

Document Number ESS-0012977

Date

Revision

Jun 25, 2014

1 (6)

State Preliminary

ESS Guideline for Survey and Alignment Fiducials

Guideline

Document Number ESS-0012977

Date 17 Feb 2012

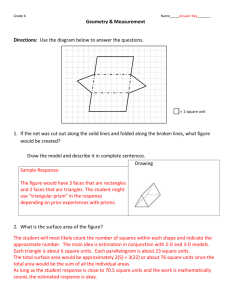

INTRODUCTION

Most of the Survey & Alignment activities at ESS will be based on a 3D free stationing approach, using as main instrument the Laser Tracker 1 .

To align a component, the Laser Tracker will first determine its own position measuring network references which positions is already known. Then, targeting some fiducial marks attached to the component to align, the Laser Tracker will provide the deviation respect to the nominal position. The component is thus adjusted.

This guideline presents the different fiducials attached to the components to be aligned that can be used at ESS.

1.

WHAT IS A FIDUCIAL

A fiducial is a reference which position is defined with respect to the sensitive part of the component to align (proton beam axis, neutron beam axis, mechanical center…).

As we use the laser tracker to align a component, the fiducial has to be able to receive the typical 1.5” corner cube reflector illustrated in figure 1.

Figure 1: 1,5” corner cube reflector.

To define the type of fiducial, we only focus in our case on repeatability. We do not need to place a fiducial at a high precise specific position with respect to the sensitive part, but only to have repeatability when placing the prism on the fiducial and then be able to measure its position.

3 different kinds of fiducial can be used at ESS:

6H7 machined hole

Cone directly machined on the component

Threaded hole to receive M6 interface

If for any reason, a fiducial needs to be different from these 3 options, please contact the

ESS Survey Alignment and Metrology Group.

1

A Laser Tracker is a highly dynamic measuring system for three-dimensional coordinate determination using a single beam laser interferometer, precise angular encoders and a sophisticated servo-tracking system.

2(5)

Guideline

Document Number ESS-0012977

Date 17 Feb 2012

2.

6H7 MACHINED HOLE

Figure 2: 6H7 Machined Hole (Drawing: ESS-0011484).

This machined hole allows to precisely place an adapter as illustrated in fig 3 to receive the prism.

Figure 3: Adapter for 1.5” Prism and 6H7 hole.

3(5)

Guideline

Document Number ESS-0012977

Date 17 Feb 2012

3.

CONE DIRECTLY MACHINED ON THE COMPONENT

Figure 4: Illustration of fiducial cone machined on component- XFEL quadrupole.

This cone allows high repeatability in the positioning of the 1.5” prism. The center of the prism must be above the component surface not to obstruct line of sight as presented in figure 5.

Figure 5: Illustration of a 1.5” prism placed on machined cone.

4(5)

Guideline

Document Number ESS-0012977

Date 17 Feb 2012

4.

THREADED HOLE TO RECEIVE M6 INTERFACE

The last option for fiducial is to machine a threaded hole to receive a M6 interface that needs to be screwed and then glued to be sure it remains fixed. The 1.5” prism is then place on this interface.

Figure 6: M6 Interface to be screwed and glued in a threaded hole.

Drawings of this interface can be found at:

ESS-0010675.1.1

ESS-0011042

ESS-0011048

5(5)