Practical ELL Handout

advertisement

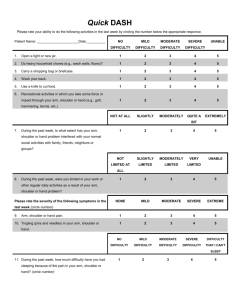

NOTES ON ELL ARM MOVEMENT Components: The ELL arm assembly is consisted of two parts: Upper part: visible with in the ELL. Lower part—lower bearing housing. Forearm Elbow Spindle Cable Shoulder Pulley Upper Arm Upper Bearing Housing Shaft Rotation Motor Tube Extension Motor Bearings Lower Bearing Housing 1 Movement of upper part: Rotation: Forearm (fork) locked to the upper arm. Upper arm and forearm rotate together against the etcher. Extension: Upper arm (arm housing) rotates around the shoulder relative to the etcher in one direction. Forearm rotates around the elbow relative to the upper arm in the opposite direction with double the speed as the upper arm rotation. Description of motion during Rotation: Object Motion type Direction (up/down, Extent of motion (translational towards indexer, (how much does it motion/rotational away from indexer, move from motion, etc) CW, CCW, etc.) beginning to end) Upper arm against shoulder Fore arm against elbow Shaft against etcher Rotation CCW 90° No motion. Thus locked NA in to upper arm Rotation CCW NA Tube against etcher Rotation 90° CCW 90° Direction (up/down, towards indexer, away from indexer, CW, CCW, etc.) Extent of motion (how much does it move from beginning to end) Upper arm against Rotation shoulder Fore arm against Rotation elbow Shaft against etcher No motion CCW 90° CW 180° NA NA Tube against etcher Rotation CCW 90° Description of motion during extension: Object Motion type (translational motion/rotational motion, etc) Cause of extension: arm housing (upper arm) rotation against etcher, shoulder pulley fixed against etcher. This relative motion of arm housing against shoulder pulley causes the belt around the pulley to wrap around or open up. Points on the belt move away from the shoulder on the side of the belt that opens up and gets closer to the shoulder on the side of the belt that wraps around. This relative motion of the belt against the shoulder from the perspective of a person standing on the shoulder drags and rotates the elbow pulley at the other end of the belt. This in turn causes the folk (fore arm) to rotate. The combined motion of upper arm rotation and that of the forearm form a extension motion of the ELL arm. Cause of rotation: arm housing (upper arm) and the shoulder pulley both move relative to the etcher at the same pace. No relative motion of the arm housing against the shoulder pulley. No 2 motion of the belt against the arm housing. No rotation of the elbow. Forearm/fork locked to the upper arm. They rotate together against the etcher. Position Sensing: There are two rotation positions of the ELL arm: 0 degree position--Ready to rotate to chamber position and 90 degree position--Ready to rotate to load-point position. (see figure below). There are three extension positions: Arm not extended (folded) position. Arm extended to the chamber (CW extension) and arm extended to the load-point position (CCW extension). Ext and Rot sensors and flag wheels: Ready to extend to chamber position Ready to extend to ldpt position Viewed from top Viewed Rot from top to chmb P6 and P7 9P7 are Rot sensors 9P5 ldpt Rotation sensors Ext sensors From this extension position, the flag disc rotates CCW 90° to reach the not extended position (in ELL) and another CCW90° to reach the extended to ldpt position. Non-interruption = T in screen display Interruption = F in screen display 3 9P9 Shown as the extended home to reactor position Rot 9P6 to ldpt 9P8 chmb Rot and Ext sensors mounted on lower bearing housing (boat). Rot flag wheel mounted on etcher. Ext flag wheel mounted on the tube. They are not on the same plane. Relative orientation of the sensors to the chamber: When the ELL arm is at the rotated to the chamber position, the sensor positions are shown as below: Looking top down from the etcher Ldpt direction 9P9 home Shown as the rot to chamber position 9P7 9P6 Chamber direction 9P5 ldpt 9P8 chmb Ext sensors Non-interrupted = T, interrupted = F. Notice when the arm is extended into the chamber or to the ldpt, 9p5=T, 9P9=F, 9P8=T. Thus the etcher does not depend on the combination of sensor states to sense its position. Instead, it depends on some sort of sequential logic to do so, such as perhaps the transition from F to T to mark the position. Sensor Position Arm retracted Arm extended to ldpt Connector type 9P9 9P5 Software Index 60 71 Arm extended to chamber 9P8 72 Arm rotated to ldpt 9P6 73 Arm rotated to chamber 9P7 74 4