In vitro physiological stability

advertisement

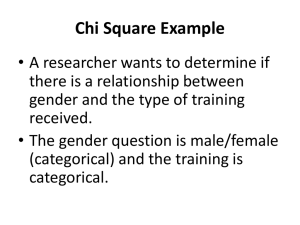

Preparation, characterization and in vitro evaluation of nanostructured chitosan/apatite and chitosan/Si-doped apatite composites Yaimara Solís1, Natalia Davidenko1, 2, Raúl G. Carrodeguas3, Jeny Cruz1, Andy Hernández4, Miriela Tomás4, Ruth E. Cameron2, Carlos Peniche1, 4, * 1 Centro de Biomateriales, Universidad de La Habana, La Habana 10400, Cuba. 2 Department of Materials Science and Metallurgy, University of Cambridge, Cambridge CB2 3QZ, UK. 3 Instituto de Cerámica y Vidrio, CSIC, Madrid 28049, Spain. 4 Facultad de Química, Universidad de La Habana, La Habana 10400, Cuba. * Phones: +53 (7) 8700594/+53 (7) 8783867; Fax: +53 (7) 8735863; peniche@reduniv.edu.cu Abstract Chitosan/apatite composites are attracting great attention as biomaterials for bone repair and regeneration procedures. The reason is their unique set of properties: bioactivity and osteoconductivity provided by apatite and resorbability supplied by chitosan among others. Thus, in this work chitosan/apatite and chitosan/Si-doped apatite composites were prepared and characterized. Particle size, surface area, in vitro physiological stability, enzymatic biodegradation and bioactivity were evaluated. Unimodal particle size distribution was obtained for composites with high chitosan/apatite ratios while bimodal distribution was present in composites with low chitosan/apatite ratio. Physiological stability decreased with Si-doping and with the chitosan content. Acetylation degree and molecular weight of chitosan did not affect in vitro stability. Rate of enzymatic degradation increased with the chitosan content in composites. Si-doped apatite composites also showed increased degradation with respect to non-doped ones. The bioactivity of the composites was evidenced by the deposition on their surface of a calcium phosphate layer with apatite morphology after immersion in simulated body fluid. Both, biodegradation and bioactivity were dependent on the molecular weight of the polymeric chitosan matrix. These results suggest that the chitosan/apatite composites obtained are promising materials for bone regeneration applications. Keywords Nano-structured composites, Apatite, Chitosan, Biodegradable, Bioactive 1 Introduction Contemporary bone repairing and regeneration techniques require biomaterials able to bond tightly to new bone (bioactive), to permit new bone growth and propagation (osteoconductive), and to stimulate cells differentiation and osteoproduction (osteoinductive). Besides, it is desirable that they degrade at a rate that matches the growth of new bone (biodegradable) and the degradation products are completely removed (bioresorbable) [1]. In this context, special attention has been given to chitosan/apatite composites because they constitute excellent candidates in guided bone tissue engineering [2], specifically in guided bone regeneration. Its usefulness extends to maxillofacial, periodontal [3] and orthopedic surgeries, as filler for repairing bone defects [4]. The potential application of this hybrid system is due to the convergence in a unique material with favorable properties of both components: the inorganic filler and the polymeric matrix [5]. Hydroxyapatite (HA) is one of the most employed calcium phosphate bone fillers because of its structural similarity to the so called biological apatite (Ap), found in the mineral portion of bone tissue. HA is biocompatible, bioactive, and osteoconductive. The main drawback is its very slow degradation rate as compared to natural bone regeneration process [6]. Composite materials of HA with natural polymers like collagen [7], gelatin [8], alginate [9] and chitosan (CHI) [10-20] incorporate the above mentioned properties of HA and the biodegradability and flexibility of the biopolymer. These biopolymer-based composites are playing a significant role in many tissue engineering applications because they are amenable to tailor physical, chemical, mechanical and biological properties. CHI, the N-deacetylation product of chitin, an abundant and renewable material in the biosphere, is being increasingly used in bone tissue engineering, because of its interesting characteristics such as minimal foreign body reaction, an intrinsic antibacterial nature, and the ability to be molded into various geometries and forms such as porous structures, suitable for cell ingrowth and osteoconduction [21-24]. Different methodologies for preparing CHI/Ap composites have been developed. They include mixing of HA powder with a CHI solution [25], coating HA particles with a CHI film [26], co-precipitation by dropping a CHI solution containing phosphoric acid into a calcium hydroxide suspension [17], biomineralization of CHI in solid state (for instance, as membranes) in simulated body fluid (SBF) [27]. There is also an interesting in situ bio-inspired route, the so-called biomimetic approach, which enables the control of both architecture (structure) and chemistry (composition) of the synthetic biomaterials [12, 28, 29]. Biomimetic procedures have also the advantage of taking place at temperature, ionic strength, pH, etc., alike those existing in the body environment which determines the resulting materials have structures and properties similar to those synthesized by nature in vivo. The above approaches allow the incorporation of inorganic fillers into the structure of composites in the form of either nano- or microsized particles, obtaining from each methodology a particular type of CHI/HA composite with a distinctive structure, physical characteristics and biological properties. Particle migration, physiological stability and bioresorption of composites systems are common clinical problems in orthopedic field that have been addressed in several investigations. Murugan et al. [11] showed that increasing the particle size of CHI/Ap composites is highly beneficial for the immobilization 2 of Ap particles upon implantation. It avoids the frequent mixing of HA with saline or patient’s blood and the migration of the powder from the implanted site into the surrounding tissues after surgery [11]. It has been found that CHI/Ap composites exhibit an increased dissolution rate of calcium ions as compared with Ap. On the other hand, Ap particles embedded in the CHI matrix become immobilized avoiding the risks of migration to soft tissues increasing the stability of the implant. These findings suggest that CHI/Ap composites can efficiently be used as bioresorbable bone substitutes [11]. Besides, the incorporation of silicate ions into the apatite structure promotes ionic exchange and the biomimetic precipitation of a surface layer of biological apatite, increases the growth rate of human osteoblast cells in vitro, and improves early in vivo bioactivity [30-35]. On the other hand, resorption or biodegradation of composites is caused by physicochemical dissolution of inorganic phosphate, as well as by dissolution and enzymatic degradation of the polymeric matrix [22]. Lysozyme is the primary enzyme responsible for in vivo degradation of CHI by breaking the links between two neighboring acetylated residues [21]. The present article is aimed to prepare and characterize CHI/Ap and CHI/Si-doped Ap composites obtained by a biomimetic approach [36]. Morphology and surface characteristics were studied and in vitro physiological stability, bioactivity and enzymatic biodegradation of composites were also evaluated. Materials and methods Materials Three different CHI samples were employed for the preparation of composites. They are designated as MD-CHI (acetylation degree, DA=10.7%), viscosity-average molecular weight Mv=1.4x105) supplied by Primex, Iceland; M-CHI (DA=21.3%, Mv=1.14x10 5) and L-CHI: (DA=20.6%, Mv=5.89x104), both purchased from Aldrich, UK. Glacial acetic acid (CH3COOH) and ammonium hydroxide (NH4OH) were obtained from Panreac (Barcelona, Spain), calcium acetate [Ca(CH3COO)2] from BDH (Poole, UK), sodium phosphate (Na 3PO4) from Riedel-de Haën (See-ize, Germany), sodium tripolyphosphate (Na5P3O10) from Acros Organics (Geel, Belgium). Sodium trisilicate purum was from Sigma-Aldrich (St. Louis, MO, USA). Sodium dihydrogen phosphate (NaH2PO4·H2O), sodium hydroxide (NaOH), methanol (CH 3OH) and ethanol (C2H5OH) were from Sigma Chemical Co. (Steinheim, Germany). All reagents employed were pure for analysis and their solutions were prepared with re-distilled water. Lysozyme (egg white) was obtained from Fisher BioReagents, Fisher Scientific and PBS (pH=7.4) from Sigma-Aldrich, Germany. Solutions were prepared with de-ionized water. Preparation of chitosan/apatite and chitosan/Si-doped apatite systems CHI/nanocrystalline Ap (CHI/Ap) composite beads were prepared by in situ generation of Ap or Si-Ap nanocrystals as reported in previous paper [29]. Briefly, to prepare the CHI/Ap composites with different weight ratios (20/80, 50/50 and 80/20), different volumes of 5 wt.-% NaH2PO4·H2O and 5 wt.-% Ca(CH3COO)2 aqueous solutions, at Ca/P = 1.5 molar ratio were added to a determined volume of 2 wt.- 3 % CHI aqueous solution in 1% acetic acid. The mixture was then aged under vigorous stirring (magnetic stirrer, 5 Hz) overnight to ensure homogeneous dispersion of the fine CaHPO4.2H2O (DCPD) precipitate in the viscous CHI solution. The resulting CHI/DCPD suspensions were dropped into an excess of 10 wt.-% NaOH solution in CH3OH. The beads obtained by this simple coacervation procedure were left to stand at room temperature for 2 h and subsequently washed four times with cold (≈ 10 ºC) and warm (≈ 60 ºC) water. The CHI/DCPD beads were hydrolyzed in a saturated Na 3PO4 solution containing 1 wt.-% Na5P3O10 as cross-linker. The hydrolysis proceeded at 60 ºC for 72 h with occasional stirring. Finally, the CHI/Ap composite beads were filtered, washed free of alkali and freeze dried (-110 ºC, 24 h). The composition of samples can be identified by their designation. For instance, L-CHI20 is a composite of low molecular weight CHI with 20/80 CHI/Ap weight ratio. The CHI/Si-doped Ap composites (CHI/ApSi100) were prepared by the same procedure, except that the hydrolysis step was carried out in presence of Na2SiO3 solution (8.8 wt.-%). Composites beads were grinded in an agatha mortar. Samples for in vitro bioactivity and biodegradation tests were press molded into 200 mg discs. CHI films were prepared by pouring 2 wt-% CHI solutions in 1wt.-% aqueous acetic acid into Petri dishes, followed by drying at room temperature. The resulting films were treated with ammonia in ethanol/water solution, followed by profuse washings with distilled deionized water and drying. Particle size distribution Particle size distribution was determined using a Malvern particle size analyzer (Mastersizer 2000 Ver. 5.22, Malvern Instruments Ltd., UK) employing a light scattering method. Before taking measurements, the samples were dispersed ultrasonically for 10 min in ethanol in order to break down loosely bound agglomerates. Surface area Specific surface areas were determined by N2 adsorption using the BET method in a TriStar 3000 V6.04 A (Micromeritics Instrument Corporation, GA, U.S.A.). Samples were out gassed for 120 min. at 77.350 K before analysis. In vitro physiological stability Test for in vitro physiological stability of the prepared materials was performed in phosphate buffered saline (PBS: 0.01M, pH 7.4) at 37ºC with a composite/solution ratio of 2mg/mL. The pH of the solution was monitored with a pH-meter Basic 20 provided with a combined electrode 50 14 T (measuring error 0.01, Crison Instruments S. A., Barcelona, Spain). Readings were obtained hourly during the first day, daily till the 7th day, every two days until the 14th day and the last reading was taken at the 28th day. In vitro bioactivity testing Composites discs (10x1mm) prepared from 200 mg of CHI/Ap beads were immersed in 16 mL of simulated body fluid (SBF) [37]. Flasks containing composites discs were placed in a thermostatic bath at 4 36.5 ± 1.5ºC. Disks (three replicates) were withdrawn at times of 7, 14, 21 and 28 days for morphological characterization in a JEOL 5800 LV Scanning Electron Microscope (SEM) provided with an ultra-thin window (UTW) energy dispersive x-ray (EDX) detector. In vitro enzymatic degradation testing The in vitro degradation of CHI films and composites discs was followed in 4 mL phosphate-buffered solution (PBS, pH 7.4) containing 1mg/mL lysozyme at 37ºC. Briefly, CHI films (40 x 0.1 mm) and composites discs (10 x 1mm) were weighed and sterilized by autoclaving (120 ºC, 20 min). Then they were immersed in the lysozyme solution for the selected times. The lysozyme solution was refreshed every 2 days to ensure unvarying enzyme activity. After 15, 30 and 60 days for CHI films and 30 and 60 days for composites discs, the respective samples were removed from the medium, rinsed with deionized water, dried under vacuum and weighed. The extent of in vitro degradation was expressed as percent of weight loss of dried films or discs after lysozyme treatment (always three replicates of each sample were taken). Thickness and diameter of dry samples before and after enzymatic treatment were also measured with a Mitutoyo Palmer micrometer (Shenzhen, China) and a ruler, respectively. The crystallinity of CHI was assessed from the transmittance IR spectra of films. Crystallinity index (C.I.), defined as the ratio of the bands at 1380 and 2950 cm -1, expressed in percent [38], was employed to quantify crystallinity of CHI samples. To differentiate enzymatic degradation from dissolution process, control samples were stored for the same time under identical experimental conditions, but without lysozyme. Results and discussion Particle size distribution In a previous report we have shown that the inorganic component of Ap and CHI/Ap composite particles prepared by the present biomimetic approach procedure consists of nanocrystalline Ap. The size of Ap crystallites decreased with the increase in CHI content and by the replacement of PO 4 tetrahedra by SiO4 in the crystal lattice [36]. The particle size distribution of this nanostructured Ap and its composites with CHI are shown in Figure 1. The figure evidences that the particle size of Ap was smaller than those of composites. The particles are uniformly distributed (Gaussian-like distribution) in both Ap and Ap-Si100 (Figure 1a), whereas they are less symmetrically distributed in the composites (Figures 1b and c).The particle size distribution curves indicate that particle size ranges from 1 to 200 µm for Ap and from 1 to 140 µm for Ap-Si100, with maximum number of particles from 6 to 46 µm and 10 to 64 µm, respectively. The average particle sizes of Ap and Ap-Si100 (both with unimodal particle size distribution) were found to be 23.1 and 32.9 µm, respectively (Table 1). In the case of CHI/Ap composites, the particle size distributions were found to be between 1 and 1200 µm, with most particle sizes in the of 56-600 µm range. The mean particle size of composites increased with increasing the CHI/Ap ratio (Fig. 1(c), Table 1) and it was independent on the kind of CHI used, as shown in Figure 1(b) for the composites with the same CHI/Ap ratio (50:50). The bimodal particle size distribution was obtained for the 20:80 CHI/Ap 5 composite. This must indicate that for this composition the amount of CHI was not enough to achieve a homogeneous distribution of Ap particles inside the polymer matrix. A similar particle size dependence on CHI composition was found by Murugan et al. in CHI/Ap composites [11]. Specific surface area The specific surface area of composites is also an important parameter affecting their behavior when interacting with biological media. The specific surface area of Ap and the 50:50 CHI/Ap composites were determined by gas sorption procedure using the BET sorption isotherm. Results are reported in Table 1. It can be appreciated that the surface areas of composites are greater than those of the corresponding inorganic materials. On the other hand, it is also seen that both particle size and specific surface area of composites do not change substantially with the molecular weight of CHI. However, an appreciable higher surface area is observed for the composite obtained with the less acetylated CHI, which should be attributed to a higher porosity of the beads. The influence of the acetylation degree on the porosity of similar CHI beads obtained by simple coacervation has been pointed out before by others [39] In vitro physiological stability The in vitro stability of Ap and CHI/Ap composites was assessed by following the pH variation of a saline buffered solution (PBS) with and without Ap and CHI/Ap composites. The pH differences between sample containing solutions and control saline buffered solution at the different experimental times are plotted in Figure 2. The pH of the saline buffered solution itself was stable throughout the experimental period (7.40 ± 0.02). Ap is the most insoluble of calcium orthophosphates (solubility product at 37ºC 5.5 x 10 -118) therefore no change in the saline buffered solution pH should be expected as confirmed by the results displayed in Figure 2a [40, 41]. On the other hand, it has been demonstrated that Si substitution in Ap increases the solubility through the creation of crystalline defects with substitution for PO 43-and associated charge compensation mechanism, by generating a more electronegative surface with the exchange of SiO44- for PO43-, thus producing a more amorphous and soluble material. As result of the partial dissolution of Sidoped Ap phosphate and silicate ionic species are released which hydrolyze according to reactions of equations 1 and 2 [42, 43]: SiO 44 4H 2O H 4SiO 4 4OH PO34 H 2O HPO 24 OH Eq. 1 Eq. 2 Therefore an increase in pH should be expected as Si-doped Ap dissolves, as it was experimentally observed (Figure 2a). The pH variation of the saline buffered solution containing the different composites with respect to the PBS solution pH is shown in Figure 2b. In all cases pH slowly decreased after an incubation period of approximately two days. The magnitude of this effect is directly dependent on the CHI content of composites. This behavior has been reported before for other CHI/Ap composites [11, 44]. However, the reason for this behavior could not be identified on the light of the results of this work, although it is undoubtedly related to the CHI present in composites. In the case of the CHI/Si-doped Ap the alkalizing 6 effect due to dissolution and hydrolysis of the inorganic filler overcomes the acidifying effect of the CHI matrix as illustrated in Figure 2b. The differences in molecular weight and acetylation degrees of the CHI samples used in this study did not produce significant differences on the in vitro physiological stability (L-CHI: 7.39 ± 0.04; M-CHI: 7.38 ± 0.06; MD-CHI: 7.43 ± 0.02). In vitro bioactivity The test is commonly used as a predictor of in vivo bioactivity of solid biomaterials [37]. It is aimed to verify the possible formation of an Ap layer on the surface of composites. The eventual formation of a Ca-P layer will indicate that the material is able to directly bind to bone in vivo [37]. After 1 week of soaking in SBF at 36.5 ºC the surface of all composites became partially coated by a layer of globular aggregates as illustrated for sample MD-CHI50 in Figs. 3a and b. Composites consist of nano-sized beads intimately aggregated one each other as observed in Fig. 3c, where the microstructure of non-coated area (spot 2 in Fig. 3b) at high magnification (x100 k) is displayed. On the other hand, Fig. 3d corresponds to the spot 1 in Fig. 3b and shows that the globular aggregates observed in coated areas consist in turn of rods composed of tiny spherules. The results of EDX spectroscopy performed on a portion of the coating layer (spot 1 of Fig. 3b) yielded 61.7 at.-% of Ca, 31.7 at.-% of P and 6.6 at.-% of C, consistent with a species of calcium phosphate, and contrasting with the composition found for non-coated area (spot 2 in Fig. 3b); 5.0 at.-% of Ca, 4.6 at.-% of P and 90.4 at.-% of C. The Ca/P atom ratios of the coating layer calculated from the EDX results varied between 1.40 and 1.55, which agree with the composition expected for a Ca-deficient Ap. Controls made of L-, M- and MD-CHI showed the first signs of Ap coating only after 14 days of soaking in SBF. From the obtained results it can be concluded that the CHI/Ap composites induced Ap layer formation on their surface after immersion in simulated body fluid (SBF) indicating their bioactive behavior in vitro and their potential osteoconduction in vivo. In vitro enzymatic degradation It is well-known that lysozyme, an enzyme present in certain human body fluids [45] degrades CHI by hydrolyzing its glycosidic bonds [46], therefore it is important to investigate its effect on the CHI/Ap composites. For this purpose composites with 50:50 CHI/Ap ratio and CHI films for comparison were selected. The study was carried out at physiological pH (7.4) but using a thousand-fold enzyme concentration than that found in human body fluids. The reason for this was to provoke a measurable change in the weight of composites. It must be recalled that the DA of the CHIs used in this work is lower than 22%. The weight losses reported for CHIs with such low acetylation degrees when degraded by lysozyme at physiological concentration (1.5 μg/mL) are lower than 10% [45, 47]. The CHI films experienced no significant variation in thickness or diameter even after 60 days of immersion in lysosyme/PBS. The film weight loss turned out to be a more reliable parameter to assess the enzymatic degradation of CHI films. Weight loss evolution of CHI films immersed in the enzymatic medium and CHI films treated under the same conditions, but without lysozyme (controls), is shown in Figure 4. It can be appreciated that for all three samples after an initial rapid degradation, there is a decrease in the degradation rate. It must be recalled that CHI chains are characterized by having the 7 sequences GlcNAc-GlcNAc, GlcNAc-GlcN GlcN-GlcNAc and GlcN-GlcN, where GlcNAc stands for Nacetylglucosamine and GlcN for the glucosamine residues, respectively[48]. Lysozyme contains six binding subsites normally designated by the letters A-F, with cleavage occurring between sugar residues bound to subsites D and E. It has been suggested that subsites C, D, and E preferentially are occupied by GlcNAc-units in productive enzyme-substrate complexes [49]. Therefore the decrease in degradation rate after the first 15-20 minutes can be due to the loss of appropriate hexasaccharide sequences in the chains with progressing degradation, as concluded by Freier et al [45, 47] in their study of the effect of Nacetylation on the enzymatic degradation of CHI films. Apparently the difference in DA of samples MCHI and MD-CHI was not high enough as to bring about an appreciable difference in weight loss in these experiments. However, the important effect of molecular weight of CHI on the degradation of samples is apparent and this must result from the higher solubility of the smaller chains produced after enzymatic hydrolysis of LCHI as compared to M-CHI and MD-CHI. The enzymatic hydrolysis on CHI occurs preferentially in the amorphous regions [50] which would result in an increased crystallinity, the same as reported for acid hydrolysis [51]. In order to corroborate this, the crystallinity index (C.I.) of CHI films after enzymatic hydrolysis was estimated. To this end use was made of the method devised by Nelson and O`Connor [52] for determining the C.I. of cellulose from the ratio of absorption bands at 1380 (A1380) and 2950 cm-1 (A2950), expressed in per cent (Eq. 3): C.I. 100 A1380 A 2950 Eq. 3 This equation was shown to be applicable to determine the crystallinity index of CHIs by Agüero et al. [38]. The crystallinity index (C.I.) values they obtained by applying eq. (3) to different CHI samples correlated very well with the degree of crystallinity obtained by X-ray diffraction and differential thermal analysis[38]. The FTIR spectra of L-CHI after 60 days of degradation with lysozyme and the L-CHI used in the control experiment are displayed in Figure 5. The absorption bands used for the C.I. determination are indicated therein. The calculated values of C.I. using eq. 3 are summarized in Tables 2 and 3. They are consistent with the expected enhanced crystallinity during the biodegradation time. In all cases there is an increase in the crystallinity of the degraded films by lysozyme action, which was considerably higher in the more extensively degraded L-CHI film. As observed with CHI films, almost no changes in thickness and diameter of composite samples were experienced during enzymatic degradation experiments. This is to be expected, since lysozyme has no effect on the inorganic component of the composite and only mildly hydrolyses CHI [46]. The weight loss of CHI films and CHI/Ap composites after enzymatic hydrolysis at various time intervals are summarized in Figure 6. An expected accelerated weight loss was observed for L-CHI based films and L-CHI/Ap composites in comparison with their respective controls (Figure 6a). In addition, it should be mentioned that the CHI/Ap composites used in this degradation study are constituted of approximately 50 wt.-% CHI and 50 wt.-% Ap. Also, the presence of Ap in the composites may difficult the access of lysozyme to -1,4-linkages between N-acetylglucosamine of CHI [46], so that a lower weight loss of composites is expected when compared with CHI films. Nevertheless, a 8 convergence effect of PBS dissolution of Ap and enzymatic action on CHI became evident when LCHI50 was compared with its control on which only dissolution of Ap prevails. This suggests that the main cause of the composites weight loss was the resorption of the inorganic component (Figure 6a). The increased degradation of M-CHI50-Si100 composite as compared with M-CHI50 is explained by the lower physiological stability of the former (Figure 6b). Conclusions The nanostructured CHI/Ap and CHI/Si-doped Ap composites studied in the present work exhibited improved properties as compared with Ap or Si-doped Ap alone. CHI/Ap and CHI/Si-doped Ap composites have greater particle size than the corresponding inorganic materials. It was shown that bioresorption is greater in composites than in the inorganic components alone and that it is increased in the Si-doped materials. The incorporation of CHI was responsible for the enhanced biological degradation of CHI/Ap composites. The effect of enzymatic degradation on the materials resulted greater in low molecular weight CHIs, although the expected dependence of biodegradation on the DA was not appreciated due to the narrow range of DA of the samples studied. Si-doped composites with low molecular weight CHI showed lower physiological stability and increased enzymatic degradation, which are of great importance for bone tissue engineering applications. The bioactivity of composites was evidenced by the formation of apatitic aggregates on the surface of the composite discs immersed in SBF. The above results indicate that the CHI/Ap composites obtained by the present biomimetic approach are good candidates as a bioresorbable and bioactive bone substitutes. Currently, the biological behavior of the CHI/Ap and CHI/Si-doped Ap composites is being studied in several in vitro models. Finally, it is worth pointing out that the simplicity and the mild conditions of reaction make the procedure attractive for production on larger scale. Acknowledgements We thank the Royal Society UK for funding the International Joint Project ‘‘Development of CHI/calcium phosphate-based bone implants and scaffolds”. The participation of R.G. Carrodeguas was funded by Projects CICYT-MAT2010-17753 and CSIC JAEDoc 09-00093. References 1. Cadosch D, Gautschi OP, Brockamp T, Zellweger R. Osteopetrosis--a challenge for the orthopaedic surgeon. S Afr J Surg. 2009;47(4):131-3. 2. Zhang Y, Ni M, Zhang M, Ratner B. Calcium Phosphate—Chitosan Composite Scaffolds for Bone Tissue Engineering. Tissue Eng. 2003;9(2):337-45. 3. Mizuno H, Hata K, Kojima K, Bonassar LJ, Vacanti CA, Ueda M. A Novel Approach to Regenerating Periodontal Tissue by Grafting Autologous Cultured Periosteum. Tissue Eng. 2006;12(5):1227-335. 9 4. Motz W, Bentley C, Tasto J. Bioabsorbable implants in orthopaedics: new developments and clinical circone applications. J Am Acad Orthop Surg. 2001;9:280-8. 5. Gravel M, Vago R, Tabrizian M. Use of natural coralline biomaterials as reinforcing and gas-forming agent for developing novel hybrid biomatrices: microarchitectural and mechanical studies. Tissue Eng. 2006;12(3):589-600. 6. Murugan R, Panduranga RK. Controlled release of antibiotic from surface modified coralline hydroxyapatite. Trends Biomater Art Organs. 2002;16:43-5. 7. Itoh S, Kikuchi M, Takakuda K, Nagaoka K, Koyama Y, Tanaka J et al. Implantation study of a novel hydroxyapatite/collagen (HAp/col) composite into weight-bearing sites of dogs. J Biomed Mater Res. 2002;63:507-15. 8. Chang MC, Ko CC, Douglas WH. Preparation of hydroxyapatite-gelatine nanocomposites. Biomaterials. 2003;24(17):2853-62. 9. Murugan R, Panduranga RK. Biodegradable coralline hydroxyapatite composite gel using natural alginate. Key Eng Mater. 2002;240-242:407-10. 10. Zhao F, Yin Y, Yao K-D, Guo G, Wang B-L, Zhang J-Y et al. Tissue engineering study on chitosan– gelatin/hydroxyapatite composite scaffolds–osteoblasts culture. Zhongguo Xiu Fu Chong Jian Wai Ke Za Zhi. 2002;16(2):130-3. 11. Murugan R, Kumar TSS, Yang F, Ramakrishna S. Hydroxyl carbonateapatite hybrid bone composites using carbohydrate polymer. J Compos Mater. 2005;39(13):1159-67. 12. Rusu VM, Ng CH, Wilke M, Tiersch B, Fratzl P, Peter MG. Size-controlled hydroxyapatite nanoparticles as self-organized organic–inorganic composite materials. Biomaterials. 2005;26(26):541426. 13. Yamaguchi I, Tokuchi K, Fukuzaki H, Koyama Y, Takakuda K, Monma H et al. Preparation and microstructure analysis of chitosan/hydroxyapatite nanocomposites. J Biomed Mater Res. 2001;55(1):207. 14. Grodzinski JJ. Biomedical applications of functional polymers. React Funct Polym. 1999;39:99-138. 15. Burg KJL, Porter S, Kellam JF. Biomaterial developments for bone tissue engineering. Biomaterials. 2000;21:2347-59. 16. Yamaguchi I, Tokuchi K, Fukuzaki H, Koyama Y, Takakuda K, Momma H et al. Preparation and mechanical properties of chitosan/hydroxyapatite nanocomposites. Key Eng Mater. 2001;192-195:673-6. 10 17. Peña J, Izquierdo-Barba I, Martínez A, Vallet-Regí M. New method to obtain chitosan/apatite materials at room temperature. Solid State Sci. 2006;8(5):513-9. 18. Hutmacher DW. Scaffolds in tissue engineering bone and cartilage. Biomaterials. 2000;21:2529-43. 19. Merry JC, Gibson IR, Best SM, Bonfield W. Characterization of carbonate hidroxyapatite. J Mater Sci Mater Med. 1998;9(12):779-83. 20. Li Z, Yubao L, Aiping Y, Xuelin P, Xuejiang W, Xiang Z. Preparation and in vitro investigation of chitosan/nano-hydroxyapatite composite used as bone substitute materials. J Mater Sci Mater Med. 2005;16(13). 21. Di Martino A, Sittinger M, Risbud MV. Chitosan: A versatile biopolymer for orthopaedic tissueengineering. Biomaterials. 2005;26:5983-90. 22. Finisie MR, Josué A, Fávere VT, Laranjeira MCM. Synthesis of calcium-phosphate and chitosan bioceramics for bone regeneration. An Acad Bras Cienc. 2001;73(4):525-32. 23. Granja PL, Silva AIN, Borges JP, Barrias CC, Amaral IF. Preparation and characterization of injectable chitosan-hydroxyapatite microspheres. Key Eng Mater. 2004;254-256:573-6. 24. Zhang Y, Zhang M. Cell growth and function on calcium phosphate reinforced chitosan scaffolds. J Mater Sci Mater Med. 2004;15(3):255-60. 25. Ito M, Niiro T, Mori K, Yokoyama K, Nakayama Y, Yamagishi T. Relation between mechanical properties of chitosan film and content of hydroxyapatite. J Jpn Soc Dent Mater Dev. 1994;3:351-7. 26. Varma HK, Yokogawa Y, Espinosa FF, Kawamoto Y, Nishizawa K, Nagata F et al. Porous calcium phosphate coating over phosphorylated chitosan film by a biomimetic method. Biomaterials. 1999;20:879-84. 27. Beppu M, Santana CC. In vitro mineralization of chitosan. Key Eng Mater. 2001;192-195:31-4. 28. LeGeros RZ, Lin S, Rohanizadeh R, Mijares D, LeGeros JP. Biphasic calcium phosphate bioceramics: preparation, properties and applications. J Mater Sci Mater Med. 2003;14(3):201-9. 29. Manjubala I, Woesz A, Pilz C, Rumpler M, Fratzl-Zelman N, Roschger P et al. Biomimetic mineralorganic composite scaffolds with controlled internal architecture. J Mater Sci Mater Med. 2005;16:11119. 30. Patel N, Best SM, Bonfield W, Gibson IR, Hing KA, Damien E et al. A comparative study on the in vivo behavior of hydroxyapatite and silicon substituted hydroxyapatite granules. J Mater Sci Mater Med. 2002;13:1199-206. 11 31. Thian ES, Huang J, Vickers ME, Best SM, Barber ZH, Bonfield W. Silicon-substituted hydroxyapatite (SiHA): A novel calcium phosphate coating for biomedical applications. J Mater Sci Mater Med. 2006;41(3):709-17. 32. Guth K, Campion C, Buckland T, Hing KA. Effects of serum protein on ionic exchange between culture medium and microporous hydroxyapatite and silicate-substituted hydroxyapatite. J Mater Sci Mater Med. 2011;22(10):2155-64. 33. Tang Q, Brooks R, Rushton N, Best S. Production and characterization of HA and SiHA coatings. J Mater Sci Mater Med. 2010;21(1):173-81. 34. Patel N, Brooks RA, Clarke MT, Lee PMT, Rushton N, Gibson IR et al. In vivo assessment of hydroxyapatite and silicate-substituted hydroxyapatite granules using an ovine defect model. J Mater Sci Mater Med. 2005;16(5):429-40. 35. Pietak AM, Reid JW, Stott MJ, Sayer M. Silicon substitution in the calcium phosphate bioceramics. Biomaterials. 2007;28:4023–32. 36. Davidenko N, Carrodeguas RG, Peniche C, Solís Y, Cameron RE. Chitosan/apatite composite beads prepared by in situ generation of apatite or Si-apatite nanocrystals. Acta Biomater. 2010;6:466-76. 37. Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials. 2006;27:2907-15. 38. Agüero G, Argüelles W, Peniche C. Estudio de la Cristalinidad de la Quitosana. Rev Cub Quim. 1989;5(1):25-32. 39. Chen RH, Tsaih ML. Effect of preparation method and characteristics of chitosan on the mechanical and release properties of the prepared capsule. J Appl Polym Sci. 1997;66:161–9. 40. Wang L, Nancollas GH. Calcium Orthophosphates: Crystallization and Dissolution. Chem Rev. 2008;108:4628-69. 41. Nancollas GH, Amjad Z, Koutsoukos P. Calcium Phosphates. Speciation, Solubility, and Kinetic Considerations. In: Jenne EA, editor. Chemical modelling in aqueous chemistry. Speciation, Sorption, Solubility, and Kinetics. ACS Symposium Series, vol 93. Washington D.C.: The American Chemical Society; 1979. p. 475-97. 42. Mesmer RE, Baes Jr. CF. Phosphoric acid dissociation equilibria in aqueous solutions to 300 ºC. J Solution Chem. 1974;3(4):307-22. 12 43. Šefčík J, McCormick AV. Thermochemistry of aqueous silicate solution precursors to ceramics. AlChE J. 1997;43(11A): 2773–84. 44. Murugan R, Ramakrishna S. Bioresorbable composite bone paste using polysaccharide based nano hydroxyapatite. Biomaterials. 2004;25(17):3829-35. 45. Hankiewicz J, Swierczek E. Lysozyme in human body fluids. Clin Chim Acta. 1974;57:205-9. 46. Freier T, Koh HS, Kazazian K, Shoichet MS. Controlling cell adhesion and degradation of chitosan films by N-acetylation. Biomaterials. 2005;26:5872-8. 47. Brouwer J, Van Leeuwen-Herberts T, Otting-van de Ruit M. Determination of lysozyme in serum, urine, cerebrospinal fluid and feces by enzyme immunoassay. Clin Chim Acta. 1984;142:21-30. 48. Kim S-K, Rajapakse N. Enzymatic production and biological activities of chitosan oligosaccharides (COS): A review. Carbohydr Polym. 2005;62(4):357–68. 49. Kristiansen A, Vårum KM, Grasdalen H. Competitive binding of highly de-N-acetylated chitosans and N,N′-diacetylchitobiose to lysozyme from chicken egg white studied by 1H NMR spectroscopy. Carbohydr Res. 1996;289:143–50. 50. Suh J-KF, Matthew HWT. Application of chitosan-based polysaccharide biomaterials in cartilage tissue engineering: A review. Biomaterials. 2000;21:2589-98. 51. Osorio A, David L, Trombotto S, Lucas J-M, Peniche C, Domard A. Solid-state acid hydrolysis of chitosan: Evolution of the crystallinity and macromolecular structure. Biomacromolecules. 2010;11:1376–86. 52. Nelson ML, O'Connor RT. Relation of certain infrared bands to cellulose crystallinity and crystal lattice type. Part I. Spectra of lattice types I, II, III and of amorphous cellulose. In: Part II. A new infrared ratio for estimation of crystallinity in celluloses I and II. J Appl Polym Sci. 1964;8:1311-41. 13 Legends to Figures Fig. 1. Particle size distribution of: (a) Ap and Ap-Si; (b) Composites with different components but the same 50/50 CHI/Ap ratio and (c) M-CHI/Ap composites with differing CHI/Ap ratio. Fig. 2. The in vitro pH stability of Ap, Ap-Si100 and their composites under physiological conditions illustrated by difference between the pH of the given material and the pH of PBS at different times. a) Effect of Si substitution; b) Effect of CHI content. Fig. 3. Scanning electron micrographs of: MD-CHI50 composite after 7 days of immersion in SBF solution at several magnifications: (a) x 5500; (b) x 20000; (c) detail of the non-coated area in b (spot 2) x 100000; (d) detail of the coating layer in b (spot 1) x 100000. Fig. 4. Weight loss evolution of CHI films in lysozyme-containing PBS solution. The weight loss of films in lysozyme-free PBS solution is shown for comparison: () L-CHI; () L-CHI control; () M-CHI; () M-CHI control; () MD-CHI; () MD-CHI control. Fig. 5. Infrared spectra of L-CHI after 60 days in PBS solution (a) lysozyme-free PBS and (b) lysozyme containing PBS. Fig. 6. Progressive mass loss of CHI films and composites after storage in PBS at 37ºC with 1 mg/ml lysozyme: a) L-CHI films and 50/50 L-CHI/Ap composites and its respective controls: () L-CHI; () L-CHI control; () L-CHI50; () L-CHI50 control. b) 50/50 M-CHI/Ap composites: () M-CHI50; () M-CHI50-Si100. 14