Homework 2 Solutions

advertisement

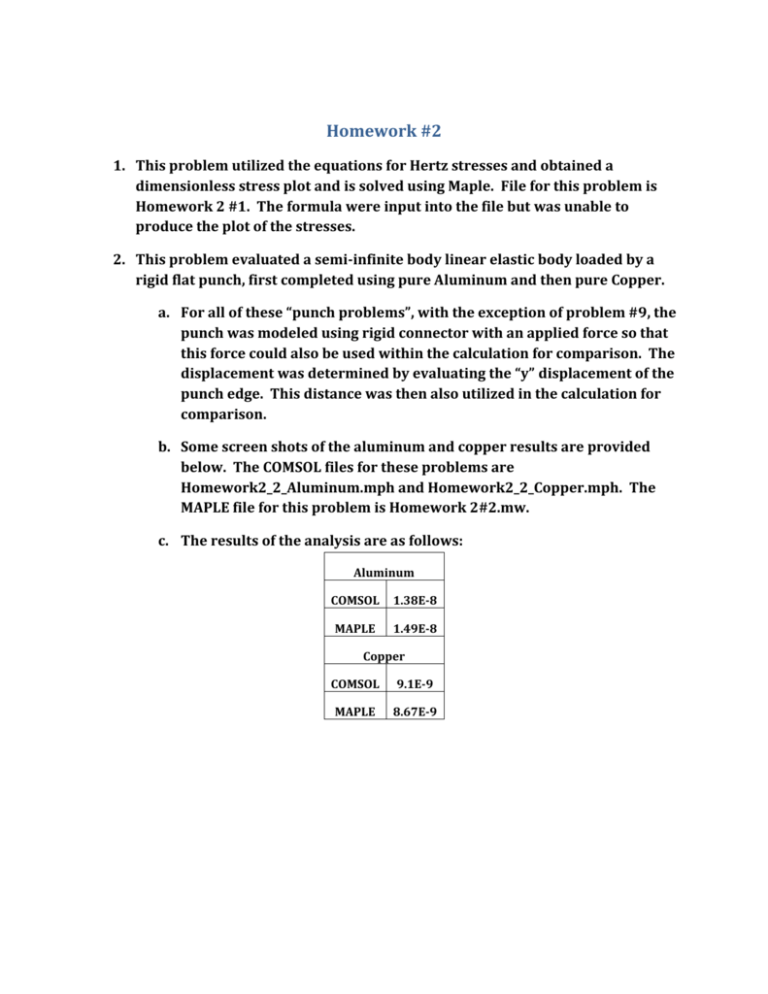

Homework #2 1. This problem utilized the equations for Hertz stresses and obtained a dimensionless stress plot and is solved using Maple. File for this problem is Homework 2 #1. The formula were input into the file but was unable to produce the plot of the stresses. 2. This problem evaluated a semi-infinite body linear elastic body loaded by a rigid flat punch, first completed using pure Aluminum and then pure Copper. a. For all of these “punch problems”, with the exception of problem #9, the punch was modeled using rigid connector with an applied force so that this force could also be used within the calculation for comparison. The displacement was determined by evaluating the “y” displacement of the punch edge. This distance was then also utilized in the calculation for comparison. b. Some screen shots of the aluminum and copper results are provided below. The COMSOL files for these problems are Homework2_2_Aluminum.mph and Homework2_2_Copper.mph. The MAPLE file for this problem is Homework 2#2.mw. c. The results of the analysis are as follows: Aluminum COMSOL 1.38E-8 MAPLE 1.49E-8 Copper COMSOL 9.1E-9 MAPLE 8.67E-9 Aluminum Copper 3. Repeat problem #2 but with Elastic-Plastic. I performed this problem by repeating the analysis from above, but used the force that initiated yield. After further review in class this problem will have to be revisited. Files for this problem are Homework 2_3 Aluminum.mph and Homework 2_3 Copper.mph for COMSOL and Homework 2#3.mw for MAPLE. The results were as follows. Aluminum COMSOL 2.9E-8 MAPLE 2.77E-8 Copper COMSOL 1.2E-8 MAPLE 1.12E-7 4. This problem evaluated a 3D model with a load at a point (at the origin). The COMSOL files are Homework 2_4 Aluminum.mph and Homework 2_4 Copper.mph and Homework 2#4.mw for MAPLE. This problem did not match the values from COMSOL and MAPLE very well. Additional work will need to be accomplished on this problem as more is learned in class. COMSOL MAPLE COMSOL MAPLE Aluminum U V W U V W Copper U V W U V W -0.001 0 -0.004 -1e-6 -5.5E-8 3.7E-6 -4.9e-4 0 -2.1e-3 -5.99e-7 -4.2e-8 2.3e-6 Aluminum: 5. Repeat problem #4 but with Elastic-Plastic. I performed this problem by repeating the analysis from above, but used the force that initiated yield. After further review in class this problem will have to be revisited. Files for this problem are Homework 2_5 Aluminum.mph and Homework 2_5 Copper.mph for COMSOL and Homework 2#5.mw for MAPLE. The results were as follows. COMSOL MAPLE COMSOL MAPLE Aluminum U V W U V W Copper U V W U V W -1e-6 0 -4.1e-6 -3.15e-9 -1.65e-10 1.12e-8 -4.9e-4 0 -2.1e-3 -8.9e-9 -6.3e-10 3.53e-8 6. Abaqus model of Hertz stresses. Eluded to an example of this problem will be coming, will update homework when example is given in class. 7. See Homework 2#7.mw for MAPLE worksheet and solution. 8. See Homework 2#8.mw for MAPLE worksheet and solution. 9. See Homework 2_9 Al Both.mph and Homework 2_9 Al Hertz.mph for COMSOL programs for the flat punch and Hertz pressure and Hertz pressure alone, respectively. The combination loading had more of a flat displacement profile, while the Hertzian pressure alone had much more of a parabolic displacement distribution. See below. Combination Loading: . Hertzian Pressure Distribution Alone: 10. See Homework 2#10.mw for MAPLE worksheet and solution.