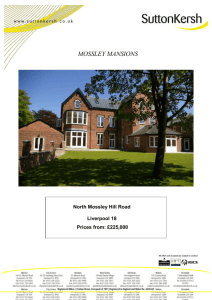

File

advertisement

Friction Factor Due to Length of Pipe Ryan Baker 10/29/2013 Abstract: Tests were conducted on copper pipe with diameters of 1/2in and 3/8in at lengths of 2ft and 5ft. The data showed the head loss across these pipes to be in correlation with pipe size, length and flow rate. The 3/8in 5ft section of copper displayed the largest head loss with a 3.5psi drop at 200GPH, whereas the 1/2in 2ft section displayed the least drop in pressure with only 1.6psi drop at 300GPH. Introduction: Head loss due to friction between a fluid and a conduit is a common problem facing all industries. Understanding the causes of the friction can play a vital role in limiting these adverse effects. Friction in pipe can be contributed to a number of factors from the roughness of the interior of the pipe to the design of the fittings within the piping system. It is important to be able to calculate the pressure drop of a system such as to know how much power a pump needs to overcome the friction loss or what will a pressure be at an exit of a system. Objectives: The purpose of this experiment is to show the correlation of head loss, due to friction, within the inside diameter and length of a pipe section. Materials and Methods: All testing was performed using the Technovate fluid circuit system equipped with attached manometers. The system has been tested and calibrated from a previous experiment by comparing flow rates across the Venturi and orifice meters with volumetric discharge. However, the flow rate across the orifice meter was only used in this procedure. Two separate sections of the Technovates copper pipe were tested for head loss along its length. The 1/2 in. diameter section was first tested allowing a volumetric flow rate of 100,200,300,400 and 500GPH along a 2 foot then 5 foot length respectively. A 3/8 in. diameter section would be tested the same. However, the manometer could not read at all of these pressures so alternate volumetric flow rates of 50,100,150,200 and 250GPH were used. The volumetric flow rate was estimated as an average 2 in. pressure drop across the orifice meter for every 100GPH. The exact volumetric flow rate was then calculated using equation 1 below: 𝑄̇ = 97.689(∆𝑃)0.486 Equation 1 Results and Discussion: As seen in figure 1, pipe length and diameter as well as flow rate, are all in direct correlation with increasing head loss. The 5ft section of 3/8in copper displayed the highest amount of head loss, reaching a maximum above 3.5 psi head loss at around 200GPH. In contrast, the 1/2in 2ft section peaked right above 1.5 psi head loss at a flow rate of 300GPH. 4 Pressure Loss (psi) 3.5 1/2" 2' 3 1/2" 5' 2.5 3/8" 2' 2 3/8" 5' 1.5 Poly. (1/2" 2') 1 Poly. (1/2" 5') 0.5 Poly. (3/8" 2') 0 Poly. (3/8" 5') 0 100 200 300 400 Volumetric Flow (GPH) Figure 1: Comparison of volumetric flow rate to pressure loss along the 2ft and 5ft sections of 1/2in. and 3/8in copper pipe. Figure 2 shows the comparison of the pressure loss versus the square of the flow velocity. Here as in figure 1, the longer the section of pipe and the smaller the diameter, the more friction occurs. These results can supported by equation 2, the theoretical head loss equation.(Cengel,2010,pp. 345) ℎ𝑓 = 𝑓 𝐿 𝑣2 𝐷 2𝑔 Equation 2 The equation shows any increase in length (L) or flow rate (v²) will result in an increase in head loss (ℎ𝑓 ). Also, a decrease in diameter will contribute to an increase in pressure reduction. The friction factor (𝑓) can be found by taking the slope of the individual line when the x-y intercept is set to zero. The 1/2in 5ft section has the highest friction factor of 0.0385 followed by the 3/8in 5ft section with 0.034 then the 1/2in 2ft section with 0.0248 and lastly the 3/8in 2ft section with 0.0218. 4 y = 0.034x Pressure Loss (psi) 3.5 1/2" 2' 3 1/2" 5' y = 0.0385x 2.5 y = 0.0218x 2 3/8" 2' 3/8" 5' y = 0.0248x 1.5 Linear (1/2" 2') 1 Linear (1/2" 5') 0.5 Linear (3/8" 2') 0 Linear (3/8" 5') 0 50 100 150 Square of Flow Rate (V²/s²) Figure 2: Plot of the square of the flow rate against the pressure drop along the 2ft and 5ft sections of 1/2in and 3/8in copper pipe. Inserting the friction factor values given in figure 2 into equation 2, a theoretical head loss value can be determined, shown in table 1. Table 1: Head Loss calculated using theoretical head loss equation Theoretical Head Loss (ft) 1/2" Flow Rate 2' (v²/s²) 13.88319 0.021403 27.23268 0.041982 40.38788 0.062263 53.41847 0.082351 66.35719 0.102297 3/8" Flow Rate (v²/s²) 5' 0.047034 0.09226 0.136827 0.180973 0.224807 22.36881 43.87773 65.0736 86.06871 106.9158 2' 5' 0.040417 0.07928 0.117578 0.155513 0.19318 0.157589 0.30912 0.458445 0.606356 0.753224 Another comparison that can be made with the friction factors found in figure 2 is that of the Colebrook equation, equation 3.(Cengel,2010, pp.357) 1 √𝑓 = −2.0log( 𝜀 𝐷 3.7 + 2.51 𝑅𝑒√𝑓 ) Equation 3 The Colebrook equation can be solved implicitly for the force factor (𝑓). The relative roughness 𝜀 (𝐷) is the relationship of the pipe roughness (𝜀) to diameter (D). The pipe roughness for copper is taken as (0.000005ft). The Reynolds Number (Re) can be calculated as shown in equation 4.(Cengel,2010, pp.340) 𝑅𝑒 = 𝜌𝑉𝐷 Equation 4 𝜇 Where density (𝜌) of water is taken as (62.30lbm/ft³) and viscosity of water (𝜇) is taken as (6.733 x 10^-4 lbm/ft s). Inserting the values for the found Reynolds numbers and the relative roughness, the friction factor can be found through iterations. Microsoft Excel was used in this example. Arbitrary values were set for the “f” value and then the “What-if” analysis was run to set a goal of finding the f value that satisfies the equation. The results are shown in table 2. All Reynolds numbers were over 4000 indicating the flow through the pipes was turbulent. The f values decreases slightly as the flow velocity increases. Theoretically this decrease will have little impact on the head loss because of the squaring of the velocity. The friction values found in figure 2 are very similar to the calculated values using the Colebrook equation. Table 2: Friction factors (f) calculated using Colebrook Equation 1/2” V(ft/s) 3.726015 5.218494 6.355146 7.308794 8.145993 Re 14371.64 20128.29 24512.48 28190.81 31419.97 f(ft) 0.028329 0.026104 0.024926 0.024141 0.023559 3/8” V(ft/s) 4.729568 6.624026 8.066821 9.277322 10.34001 Re 13681.84 19162.19 23335.95 26837.72 29911.89 f(ft) 0.02875 0.026496 0.025305 0.024513 0.023926 Conclusion: This experiment proved that any increase in pipe length, pipe diameter or flow rate will increase the head loss produced in a system. A small long pipe will present more problems with friction than that of one the same length with a larger diameter. References: Cengel, Y.A. and J.M. Cimbala 2010. Fluid Mechanics: Fundamentals and Applications. 2nd ed, New York, NY: McGraw-Hill