What is Korean celadon - Florida Conference of Seventh

advertisement

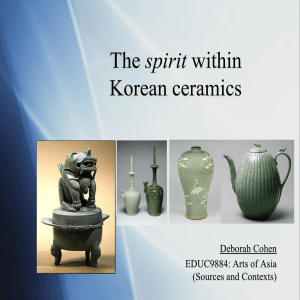

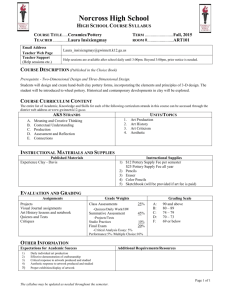

What is Korean celadon? Though the term "celadon" is somewhat misleading in that it means green, it has become widely accepted as the Western term for the Korean pottery, called Cheong-ja in Korean, with the distinctive jade-green color. Below are the Korean names for the various types of pottery and their Western equivalents: Cheong-ja - This is the name of the jade green pottery and is called either "celadon" as we have called it here, or "green celadon" to distinguish it from other types of Korean pottery. The literal meaning of the word Cheong-Ja is blue/green porcelain. Bun-cheong - This is the name of the brown or light brown pottery and, although a misnomer since celadon literally means green, it is sometimes called "brown celadon". For lack of a proper western term for this unique Korean pottery we have called it by either its true name, Bun-cheong, or "brown porcelain" to help distinguish it from the other colors of pottery. Baek-ja - Although it is sometimes, incorrectly, called white celadon, Baek-Ja literally means white porcelain and is the name for the white pottery made by Korean artisans. White porcelain is the name we have used here. The History of Korean Celadon Celadon (Cheong-Ja) - the Stuff of Kings Though the history of Korean pottery stretches back to the Neolithic age and the rough "Black Comb Pottery" produced by early tribes, the pinnacle of Korean pottery was the development and perfection of celadon (Cheong-Ja) during Korea's Koryo Dynasty. The Koryo Dynasty, which lasted from 918 to 1392 AD had a strong Buddhist influence which shaped many of it's cultural achievements. Buddhist temples flourished during the Koryo period, and with them grew a need for fine vessels to be used during the many ritual ceremonies. In the middle of the 10th century Korean artists, some who had been schooled in China, began creating celadon by using inlay and copper glazing techniques which were developed first in China but only fully developed and perfected by Korean artisans. The Korean use of these techniques were unique in the history of pottery. The level of fine quality and beauty they were able to achieve in their work surpassed that of other countries and came to be revered by even the Chinese for it's elegant, yet simple beauty. The Koryo Royal Court also used some of the finest examples of celadon pottery in their palaces both as vessels for daily use and as objects of fine art. The finest examples of celadon were produced during the middle and latter part of the 11th century by artisans who remain unknown today. With the Mongol Invasions which started in 1231 AD the flourishing culture began to decline, and along with it, the quality of the pottery being produced. By the beginning of the Chosun Dynasty (1392-1910) most of the delicate manufacturing techniques for celadon had been lost. Brown Porcelain (Bun-Cheong) During the middle 15th Century in the Chosun Dynasty, brown porcelain, Bun-cheong, appeared and became the standard for daily use by the people of the period. It was used by all classes of society unlike celadon which had been used only by Buddhist monks, royalty, and aristocrats. It was somewhat rougher in finish than the celadon had been, and did not possess such delicate beauty. White Porcelain (Baek-Ja) White porcelain appeared in the early 16th Century and like the earlier brown porcelain, was widely manufactured and used by the common people throughout Korea. During the late 16th century the Japanese launched a series of invasions into Korea (ImJinWaeRan) and forcibly relocated many of the Korean artisans to Japan. These transplanted artisans helped to influence the direction and style of Japanese pottery and arts and account for the great similarity between the Korean and Japanese arts. Celadon Today In 1910 Korea was forcibly colonized by the Japanese bringing to an end the Chosun Dynasty. During the Japanese colonial period (1910-1945) Korean pottery as an art form, all but died out. To be sure, white porcelain and some brown porcelain was still produced but it was of a lower quality for daily use and not considered art in itself. After Korea's liberation from Japanese rule at the end of WWII and through the Korean war (1950-1953) survival, and not art, was the order of the day. But in the mid-1950s a group of Korean artisans set out to discover the lost art of Koryo celadon. Since that time they have made great progress in re-discovering the lost art and today are nearly able to reproduce the stunning beauty of the original Koryo celadon. The aesthetic beauty of Korean celadon The aesthetic beauty of the the early Koryo celadon lies in its subtle beauty and elegant simplicity. So impressed were the Chinese scholars that they called Koryo celadon one of the 10 treasures of the world, while the Chinese artisans described its color as "beyond description". Though its beauty can hardly be described to someone who has not seen or experienced it in person, the following descriptions by early 20th Century scholars come close. On seeing Korean celadons for the first time, many find little to attract them, or are even somewh bluish or greyish green tones, which they consider monotonous and far removed from the brightly co they are more familiar... Chinese wares shine brightly. For guests it is well to have Ming blue-and-w appetite. But if we wish to hold quiet colloquy with them or have them in our room for a long time, s quietness and subtlety of Korean pottery are said to show the quintessence of the Oriental spirit: its q and style of make have been compared with the profound and exalted spirit of Zen Buddhism.... The instant appeal to one's heart; their colours have unique transparent depth, and their freely carved deco exude quietness of spirit... Modern celadon maintains the same beauty. It can be seen in the delicate latticework of cracks visible under its glaze, called crazing, and in the deep jade-green color. The shapes derived from nature such as those representing the human form further enhance its appeal. It is somewhat difficult to appreciate the beauty of celadon from a picture - one must look closely at the fine pattern of crazing under the deep azure-green glaze. The longer one looks at its rich color the more beautiful it appears. Modern celadon can be roughly grouped into three different categories - those pieces with inlaid designs, pieces with incised or molded designs, and those with no design (plain). Although we love all three styles, we particularly like the plain designs which show off the rich color and delicate pattern of crazing under the glaze. Meaning of Design in Korean Celadon Symbols Both the designs and shapes used in Koryo celadon were representations of the spiritual beliefs of the Korean people. These beliefs were fostered by Shamanism, and the Buddhist beliefs of the era. Following are the symbols most commonly used on inlaid celadon and their meanings. Circle: The circle represents the Sun and worship for the Sun. Lotus: The lotus stands for the Sun and mercy of Buddha Peony: The peony depicts richness and honors. Duck: The duck symbolizes the Premiere ranking. Crane: The crane represents Immortality Shapes In addition to the above symbols and their meanings, the actual shape of the vessels has meaning as well. The shapes of the vessels are derived from nature, as in the case of the bamboo shoot-shaped pot shown here, or the Korean melon (Cham-wae) shaped vase here. Other shapes adopted from nature include animal shaped vessels or those with animals as part of their shapes like the turtle decorated incense burner here. The human form is also subtly represented in Korean pottery. The vases and bottles (Mae-byeong, Ju-byeong), represent male and female respectively. The long slender shape of the bottles with a gentle slope at the bottom expresses the voluptuous beauty of femininity, while the wide shoulder and stockiness of the vases, here, represents the masculine form. The Making of Korean Celadon The manufacturing process of Korean celadon is a long affair involving at least 10 steps. The first step is to gather the clay; there are several regions in Korea where the special clays used in each type of pottery are gathered from river banks. Each area's clay is said to possess certain qualities essential to the production of fine pottery. Frequently the different clays are mixed to obtain the perfect blend, after which it is prepared for throwing. Forming and molding are the next steps and are all done by hand unlike ceramic ware which is made in molds. Asymmetrical vessels are turned on a wheel while different shapes are formed by hand or modified after being thrown on a wheel. Next the inlaid pieces are engraved and inscribed while the plain shapes are not. The inscribed portions are then filled, or in the case of painted works the paint in then applied. All pieces are then fired. The traditional hand hewn kilns were built on a hill and had a series of small chambers all connected to the main hearth at the base. Each chamber had an access door on the side in which the pottery was put in or removed. After the fire was built in the hearth the heat would rise up through the series of chambers creating the necessary temperature for each type of firing in each of the chambers. The works are then glazed and given their final firing. The entire process takes days or sometimes weeks and, due to the high level of pride of the artisans the pottery has a very low survival rate. Pieces that do not not meet the artist's standards are intentionally destroyed at approximately the following rates: 5% in the molding process 15% in decorating 20% in 1st firing 25% in the final glazing http://www.korean-arts.com/about_korean_celadon.htm http://www.antiquealive.com/masters/m16/master16_view3.html