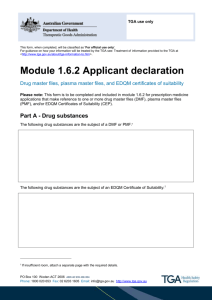

Part B: Self-assessable changes - Therapeutic Goods Administration

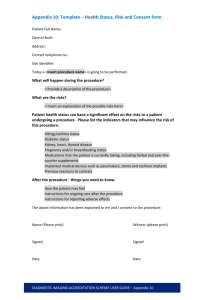

advertisement