team29_report - ECE Senior Design

advertisement

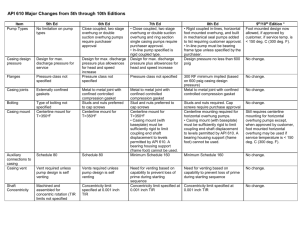

Wireless Test Instrumentation System for Rotating Parts April 8, 2013 Team 29 (ME) Sean Handahl Caleb Browning Kenneth Thompson Faculty Advisor - Dr. Robert Gao Team 167 (ECE) Michael Golob Lawrence Bogan Jeremy Neaton Adam Bienkowski Faculty Advisor - Dr. Rajeev Bansal Sponsoring Organization: Sikorsky Aircraft Paul Inguanti (Company Advisor) Chris Winslow (Senior Test Engineer) 1 Table of Contents 1. Executive Summary ............................................................................................................ 3 2. Introduction ........................................................................................................................ 4 a. Problem ......................................................................................................................... 4 b. Brief Overview............................................................................................................... 5 c. Detailed Background ..................................................................................................... 6 d. System Specifications.................................................................................................... 9 3. Preliminary Component Assessment ................................................................................ 9 a. Electrical Components .................................................................................................. 9 b. Mechanical Components ............................................................................................ 14 c. Alternate Designs ........................................................................................................ 19 4. Proposed Design Analysis ................................................................................................ 19 a. Analysis ....................................................................................................................... 19 b. Testing Methods ......................................................................................................... 20 c. Budget ......................................................................................................................... 20 5. Build Process and Testing ................................................................................................ 20 a. Electrical Components ................................................................................................ 20 i. Build Process ............................................................................................. 20 ii. Testing ....................................................................................................... 22 b. Mechanical Components ............................................................................................ 23 i. Build Process ............................................................................................. 23 ii. Testing ....................................................................................................... 26 6. Results............................................................................................................................... 27 a. Testing Results ............................................................................................................ 27 b. Budget ......................................................................................................................... 27 7. Conclusions ....................................................................................................................... 28 8. References ........................................................................................................................ 28 9. Appendix ........................................................................................................................... 29 2 1. Executive Summary Sikorsky, a United Technologies aircraft manufacturer, would like to solve a problem with monitoring pitch change bearings in the tail rotor of their helicopters. These bearings are located inside a shaft that rotates at up to 1200 revolutions per minute, and are crucial for keeping control of the aircraft during flight. However, their location makes it expensive and inconvenient to access for regular maintenance, and so pilots have relied on manufacturer data to attempt to predict when these bearings fail. The current system used for monitoring consists of a wired sensor with a slip ring,causing liabilities with wires failing due to breakage or from being shot off in a hostile environment. The slip rings also have brushes that add weight and eventually wear down. A team consisting of seven University of Connecticut engineers were given a 4000$ budget to find a wireless solution that would allow for the monitoring of these bearings over a minimum timespan of a year, without having to perform additional maintenance. More specifically, the team was asked to show that a wireless solution is feasible, and to test this information was given on the Sikorsky S-92 helicopter. The solution the team found for proof of concept was a Wireless Test Sensor System (WSN) that can monitor variables such as vibration or temperature of the bearing to indicate when the helicopter needs to be repaired. This WSN consists of a microcontroller, transceiver, and accelerometer that can record data to be transmitted to a stationary system, once a day, in the helicopter cabin up to 40 feet away. It is capable of recording and storing data to memory, until the data is requested for evaluation, at which point the system can remove any onboard data. The WSN is turned on by a wakeup signal in order to save power by only recording data while the helicopter is operational. It is currently all powered by a battery, which is sufficient to power the network for the one year minimum, and still allow the system to power on after 30 days of inactivity as requested by Sikorsky. Future systems can also include vibrational energy harvesting, which would boost the lifespan of the system past the minimum requirement. This technology is not included in the current design due to time constraints, but research is provided should a future design want to implement energy harvesting. Sikorsky also provided requirements on temperature, packaging, and size in order for the system to work inside the 1.5” by 5.1” lubricated electronics cavity of the shaft. The team’s final design meets all of these requirements except for temperature, because commercially available components do not meet the high end of the -20 to 250 degrees fahrenheit range. It has been confirmed that there are military grade components that can be used, but that the team would not have access to them, and so the team has provided proof of concept and the company can 3 further improve the design. The suggested WSN accurately gives readings on the vibration of the tail shaft, and will have no issues with the power supply over the entire time frame as shown by the testing of the battery for a voltage drop. Verification of the system has been done through multiple tests. The engineers have designed a test rig using a variable speed motor, an imitation shaft, and cartridge bearings to simulate the actual rotating conditions in the helicopter, and to allow for the collection of data of broken bearings and healthy bearings for comparison. Testing of the battery’s lifespan and power capabilities has also been done in order to ensure the longevity of the system meets the specified requirements. If implemented into Sikorsky helicopters the WSN will provide a more accurate readout on the condition of this bearing, improving the safety of all pilots and crews, and allowing for savings in maintenance for the company. 2. Introduction a. Problem The goal of this project was to design a Wireless Test Sensor System to monitor the condition of the pitch change bearing in the tail rotor of a Sikorsky S-92 helicopter. Doing so will allow the helicopter crew, or whomever is performing maintenance on the helicopter to reasonably assess the condition of the bearing inside the tail rotor without having to take apart the entire tail rotor transmission. As it is, the bearings have life expectancies provided by the manufacturer to predict when failure might occur, giving the crew an estimate of when it needs to be replaced, thus eliminating the chance for loss of control during flight. Having a sensor of this nature will allow the bearings to be easily monitored throughout their life, allowing Sikorsky to improve safety of the crew, and save on maintenance costs due to the difficult process of physically accessing this bearing. If the pitch change bearing fails, there will be no way to control the aircraft, as this component changes the pitch of the blades in the tail rotor, and is sealed away inside the tail rotor gearbox. It is desirable to monitor the temperature and vibration on these bearings. One of the biggest issues with the previous attempts at monitoring the system are the use of wires, a brush, and a slip-ring to transmit an electric signal from a rotating shaft to a stationary receiver. This kind of system has many components which can fail and wear down. Although maintenance is simple and the technology is well established, wired sensors are heavy, the wires break, the connections fail, and can be shot away due to the operating environment. Using a wireless system would cut down on the number of components, thus saving weight and minimizing the need for part replacement. This switch eliminates these undesirable features but creates problems of its own [1]. 4 A wireless test instrumentation system consists of an accelerometer placed on the rotating components. The data from the accelerometer is processed using a Fast Fourier Transform, compressed for storage, temporarily stored, then transmitted upon request to a stationary system for long term storage and analysis. The measurement system (sensor/transmitter package) has the advantage of being lightweight, self-powered, reliable, and also hardware/software configurable to accommodate multiple sensor configurations. The receiver package can distinguish signals in an electrically noisy environment, and has embedded fault detection and notification capability, being able to interface with existing fixed data collection systems [2]. Team 29’s project goals as defined by Sikorsky are: - to survey commercially available low-cost wireless test instrumentation systems which meet Sikorsky-defined measurement and weight requirements, and which potentially could be configured to operate in a an electrically noisy environment - procure equipment - install on a representative rotating system - configure/program to demonstrate signal transfer capability in rotating system tests b. Brief Overview This project consists of creating a Wireless Sensor Network (WSN) in order to monitor the vibrations of the system. This was accomplished using a sensor mounting in a rotating representative system to determine if the system is rotating freely and if the bearing assembly is damaged. These sensors have been connected to the microcontroller, which records and stores the data, until it receives the signal to transmit the data. The power for the system is controlled and distributed by the microcontroller. Currently, a single battery is used and is sufficient to completely power the system for the year minimum. When the microcontroller receives the signal, it sends the data using the Zigbee transmitter and once the data has been verified as sent, will remove the onboard data. This entire system is housed inside a packaging system, which keeps all of the components in place when rotating and will protect all of these parts from dislodging and damaging the other components, as well as protecting the components from liquid damage due to the oil lubrication in the shaft. 5 Fig. 2 - Generic Block Diagram Shown above is a block diagram of the flow of data within the wireless sensor network. Data is read from the sensor and processed by the microcontroller where it is then stored in memory. Upon a request for the data by the user in the cockpit, the microcontroller then takes data from the memory and sends it wirelessly from the transceiver where it is picked up by the antenna on the fuselage. c. Detailed Background Fig. 1 - Tail Rotor Gearbox Cutaway 6 Requirements Overview The actual sensor system for Sikorsky will be placed inside an electronics cavity which is 1.5” in diameter and 5.1” long, operating within a temperature range of -20 to 250 degrees Fahrenheit, and will have to transmit 40 feet to the cabin. In order to accomplish this, the group must choose proper vibration sensors, a receiver and flash memory to temporarily store data, and a transceiver to transmit data. Each of these components must operate within the design constrictions, and be housed in a packaging to seal out moisture. Each of these components must also be powered for a minimum of 1 year, transmitting only once a day, and be able to power back on after 30 days of inactivity [2]. A major component of the project was finding a battery capable of sustaining this workload, and exploring whether or not the group can take advantage of any energy harvesting possibilities to make the desired lifespan more attainable. Power Supply To supplement the battery and extend the life of the electronics past the one year minimum, for convenience, this project initially attempted to incorporate energy harvesting into the design plans. Energy harvesting is a relatively new technology that allows one to gather the otherwise wasted energy of the environment and convert it into power, normally in small amounts, for the system. However, since it is a secondary power source, its implementation is completely dependent on the size of the other components in the system, and whether or not there would be room in the electronics cavity for these extra components. This combined with the fact that most energy harvesters require some kind of converter to regulate their output voltage, adding to size, hinders these systems applicabilities [4]. While these will in no can sustain the entire system by itself, it would supplement the power coming from the battery to assist in powering the network. The battery that is implemented in this system therefore has to be able to power all of the components in the electronics cavity. Due to the extreme temperatures that this system will be reaching, the battery would need to include some sort of insulator, which may also have to be applied to the entire system as some electronic components may not be able to attain these temperatures either. However, the team was assured that Sikorsky would have access to military grade components should they decide to use this design. These components would be able to handle the extreme temperatures. For this project’s purposes, the possible energy harvesting venues were in magnetic energy harvesting, vibrational energy harvesting, and thermoelectric energy harvesting (TE). ● The magnetic option uses a magnet and coils, one stationary and one in motion, to create a sort of alternator, generating power whenever the moving portion passes the stationary portion. ● Thermoelectric energy harvesters use a temperature gradient to generate a voltage between two conductors. While the helicopter shaft will almost certainly create a 7 gradient with the outside air due to the increase in internal temperature while running (up to 250 degrees) the TE will require access to a colder air source to maintain that gradient. Otherwise, the TE will simply rise to equilibrium with the internal temperature of the helicopter shaft, eliminating the temperature gradient and the power output. Therefore, the unit will need to be mounted outside of our electronics package, and rewired into the system, which may or may not be possible due to the necessity of having a lasting seal around the rest of the electronics. ● Vibrational takes advantage of the piezoelectric effect which states that certain solids accumulate a charge when they undergo mechanical stress [5]. In the helicopter shaft, there is a constant vibration which will become the needed mechanical stress, allowing us to accumulate a charge and use that energy as power. This makes vibrational energy harvesting the most viable option because of its potential for placement inside the system, and ability to generate a rather constant power supply. Test Rig The main focus of the project lies with the electronic component selection and making sure that they work. In order to do this, a representation of a tail rotor shaft with the electronics cavity at the end was produced. This cavity is the only space currently available in the helicopter’s design for embedding all of the required components. The final test rig model was created with Siemens NX8 computer aided design (CAD) modeling software. The rotating shaft is powered by an electric motor, which is also be the source for the natural vibrations induced to the system. The level of vibration is motor dependent and can be adjusted by adding offset mass to the rotating system in order to get the amplitude of the vibration to an acceptable level for measuring. This motor also includes an adjustable speed controller to allow for the testing of sensor readings at various speeds. The vibrations of the test rig would ideally try to match those of the S-92 in terms of g-force, magnitude and frequencies, but this data cannot be obtained from Sikorsky. These are the natural vibrations of the system due to the engine, rotors, and transmission operating during flight. The rotating shaft is currently supported by a spherical roller cartridge bearing and an angled roller cartridge bearing. These two bearing types mimic the bearings in which the actual tail rotor shaft rotates, with the pitch change bearing being similar to the spherical roller type and the shaft support that is closer to the blades being more related to the angled roller type. The requirement of this project includes being able to analyze and transmit the data, not necessarily to distinguish between the readings obtained from a good bearing and that of a bad bearing. However, being able to tap the system and see that the induced extra vibration has been picked up is a demonstration that one can pick up on when a bearing is damaged due to the unusual level of vibration. 8 According to Senior Test Engineer at Sikorsky Chris Winslow, the most commonly seen method of failure is spalling and melting. Spalling is a type of macropitting generally caused by unbalanced loads and is common when the load is unidirectional, as is the case with the tail rotor. This contact fatigue can also occur when flakes of the bearing surfaces break off (spall) and get lodged, and from when axial loads reverse quickly [6]. Melted bearings causes seizure, occurring when the bearings heat up and become discolored due to excessive loads, insufficient lubrication, or a drop in the hardness due to irregular temperature rise (metal on metal contact). d. System Specifications Electronics Compartment: • Size: 1.5” diameter x 5.1” long • Temperature: -20 to 250 degrees F Rotating Speed of Tail Rotor Shaft • 1200 RPM Battery Life • 1 year min (3 years recommended) • Runs for 12 hours a day, needs to survive 30 days of inactivity Data Processing • Measure vibration • Store data temporarily • Transmit to stationary system and available at request of user • Data must travel wirelessly upwards of 40 ft. Environmental Parameters • Can’t be visible from outside (hostile environment) • Cavity is oil lubricated • Moisture Possibility • High vibration level 3. Preliminary Assessment a. Electrical Components Wireless transceiver: The ZigBee chip is used as our wireless transceiver to transmit data. This data is taken from the measuring system which is located within the tail rotor, and sent to the stationary receiver that will be located in the cabin. We chose to use this as our wireless interface for two main reasons. The first is that it consumes only 14 milli amperes which is very low power consumption in our 9 design. In sleep mode, it only consumes .02 micro amperes, which in return, only saves us more power. The second, is the fact that it can transmit data at a range much greater than what is required in the given parameters. Table 1 - Wireless Transceiver Component Options Part No. Operating Temperature Transmission Current Idle Current Voltage Max. Data Rate AT86RF231 -40°C to 125°C 14 mA 0.02 µA 1.8-3.6 V 2Mbp/s AT86RF233 -40°C to 85°C 13.8 mA 0.02 µA 1.8-3.6 V 2Mbp/s These were two transceivers that we considered and looked into. We selected the AT86RF231 primarily because of the operating temperature. The specifications for these parts were nearly identical, but we also needed to satisfy the temperature parameter so this part was selected. For the stationary side receiver, we decided on an ATmega128RFA1, which combines a microcontroller and ZigBee transceiver on one chip. We selected this chip because the combination of microcontroller and transceiver simplifies the receiver system, and power consumption is not critical for the stationary side system. Sensor: The sensor is used to measure the vibration of the bearing. The defect frequencies we calculated occurred between 156Hz and 274Hz, meaning we needed a sensor with a bandwidth above 274Hz. The sensor also needed to have an interrupt in order to tell the microcontroller to start recording data. By keeping the microcontroller in idle, we are able to save more power. In addition, we needed the sensor to have a very low power consumption, to preserve the battery. 10 Table 2 - Sensor Component Options Part Number Voltage Active Current Idle Current Size Bandwidt h Measure ment Range Temperat ure LIS3DH 1.71V3.6V 11μA 0.5μA 3 x 3 mm 2.5kHz ±2g, ±4g, ±8g, ±16g -40°C to 125°C SCA3060D01 3.0V-3.6V 150μA 5μA 7.6 x 8.6 mm 100Hz ±2g -40°C to 105°C KXTIA1006 1.8V-3.6V 325μA 10μA 3 x 3 mm 1.59kHz ±2g, ±4g, ±8g -40°C to 85°C Trying to find a sensor with an interrupt limited our options for accelerometers. The sensor we chose was the LIS3DH. The three sensors above all have interrupts and are among the three best options found. The LIS3DH accelerometer has an extremely low current consumption, which helped us have lower power consumption. This was the main factor we looked into when deciding upon a sensor. We had a tight constraint on the power available, so we needed to save power where possible. The sensor we chose also is very small and allows us to operate at the 3.6V the battery provides. As discussed in the background we need a bandwidth above 400Hz. The sensor we chose allows us to use a wide range of bandwidths below 2.5kHz. Compared with the other two sensors, our sensor is the only one that satisfied the temperature constraints given to us. Memory: Memory was found to be necessary in addition to the on-board memory in the microcontroller to store data from the sensor. The size of the memory is limited by the power restriction, as higher capacity memories use more power. The amount of raw sensor data collected between data access times is much more than the maximum memory size possible with the power restrictions. There are several methods to reduce the amount of memory needed. The first is to use a technique called time synchronous averaging, which involves averaging consecutive sets of samples together. In this case, only the average of a series of samples needs to be stored, which will greatly reduce the memory need. Another method is to sample for short periods of time with time in between samples when no data will be collected. A third method will be to transmit the data whenever the memory is full. With this solution, the full data will be stored on the receiver system, on a non-rotating part of the aircraft, which will have less strict power restrictions, allowing for a larger capacity memory. 11 Table 3 - Memory Component Options Part Number Voltage Active Current Idle Current Capacity CY62167DV30 2.2-3.6 V 2 mA 10 µA 16 Mbit CY62177EV30 2.2-3.7 V 4.5 mA 17 µA 32 Mbit These are two options for low power SRAM. The 16 Mbit option was selected because 4.5 mA is too high to meet the battery life specifications with the chosen battery. None of the memories researched met the given temperature specification, because military temperature rated parts are not commercially available. Microcontroller: Table 4 - Microcontroller Component Options Part Number Supply Voltage Active Current Idle Current Size Operatin g Temp Program Memory IO pins MSP430G 1.8-3.6 2332-EP 220 μA .5 μA 6.6x6.6m m -40 to 4kB 125 deg C 16 MSP430F 2.2-3.6 5438IPZR 312 μA 2.6 μA 14x1.4m m -40 to 85 256kB deg C 83 The lower power consumption option out of these two does not have sufficient program memory or input/output pins to meet our needs. The microcontroller we chose has slightly higher power use, but has enough program memory and input/output pins. Both of these support Serial Peripheral Interface(SPI), which is needed to interface with the sensor and the zigbee transceiver. 12 Battery: Table 5 - Our calculations for current use using the parts parts discussed above are as follows: Part Data Acquisition Current Transmission Current Idle Current Sensor 11 µA 0.5µA 0.5 µA Memory 2mA 2mA 22µA Microcontroller 312µA 312µA 2.6µA Tranceiver 0.02µA 14mA 0.02µA Totals 2.32mA 16.31mA 25µA Assuming time synchronous averaging or periodic sampling, 16Mb transmitted at 2 Mbps once daily = 8 sec of transmission time per day. Assuming periodic transmission, transmit when memory is full: The 11.011Ah we calculated is the absolute maximum needed. We calculated based on the parts running continuously over the 12 hours. For periodic sampling, the memory will not be running for the amount of time used in these calculations, reducing the power used. 13 Table 6 - Battery Component Options Battery model Dimensions Capacity Output Voltage Operating Temps Eaglepicher LC 3155 Diameter 30.7 mm (1.21”) height 54.6 mm (2.15”) 12.7Ah 2V -30C to 50C Eaglepicher LC 3355 Diameter 33.3 mm (1.31”) height 54.6 mm (2.15”) 15.5Ah 2V -30C to 50C 17Ah 3.6V -55C to 125C Tadiran 15- Diameter 32.9mm 5930-yy505 Height 61.5mm From the batteries above, we chose the Tadiran 5930. Although most of the batteries we found were the correct dimension, we found one that met the capacity we need. The output voltage of 3.6V satisfies the voltage requirements of our components, while the 2V from the other batteries does not. b. Mechanical Components Energy Harvester: Without energy harvesting, our design meets the minimum requirements for how long the system needs to last, powered purely by the battery. However, we will continue to research ways to add energy harvesting to our design to further extend the life of the battery. Vibrational energy harvesting is the most feasible solution with our system due to relatively constant vibration in the tail shaft, and the systems ability to be implemented inside of the electronics package. Temperature based energy harvesting (TE) was researched and is not viable because the TE needs a temperature gradient in order to provide power. While there is a reliable gradient in the tail shaft, the components would need access to additional cooling to keep the components from reaching equilibrium and ending the TE power output. To achieve this, the team could attach the TE to the outside of the package to provide air cooling, but this would reduce the gradient available because of the material between the heat source and the energy harvest. This method would also require rewiring the harvester back into the package, which would not be possible due to the requirement of having a sealed electronic system, to keep all other components dry and operational. 14 Piezoelectric vibrational energy harvesting would turn strain into energy, and allow this energy to be collected by the system to provide a small amount of additional power. The output of the vibrational energy harvester is sinusoidal or alternating current and the rectifier board is used with the system to take this alternating current and convert it into direct current that can be used for all of the electronics. Commercially available rectifier boards are too large to fit inside the small cavity available, and so a custom rectifier board must be made to allow our system to implement energy harvesting. This size constraint is also a controlling factor on the amount of power the harvester can output. Depending on how small we can make the rectifier board, we will be allowing more or less vertical tip to tip vibration in the harvester, creating more or less strain which can be converted to energy. This vertical tip to tip displacement will also control which energy harvester we would use, as different models have different maximum allowable displacements. Shown in Fig. 3 are different sample raw energy harvesters that the group will use with a custom rectifier board. These raw harvesters are provided by Mide Technologies under the VoltureTM product line. They will collect raw strain energy and send that through the rectifier board so it may be used with the system. The custom board will contain a rectifier and a charge pump, to output a DC voltage at the same level as the battery. As stated, energy harvesting is completely unnecessary to provide power for the year minimum. The teams also found that it would be impossible to create a custom rectifier board within the time limit given to complete the project. Therefore, energy harvesting will not be implemented in this system. If a future system wishes use energy harvesting, however, this data shows that it is feasible. Fig. 3 - VoltureTM Vibrational Energy Harvester Electronics Package: The electronics package was made out of 3D printed material. The end cap is fitted to the electronics package using three countersunk screws to ensure security as the material and accuracy of the printing machine does not allow for a sound connection using threads. The battery sits on the bottom and will have o-rings around it to secure it in place. The electronics board will be placed vertically on top of the battery and will be slid into place using small 15 grooves to secure it in place rotationally. To fix the electronics cavity to the replica shaft, the cap will have a larger diameter to match that of the shaft and uses three countersunk screws to secure it in place. For CAD drawings of the electronics package, please refer to Appendix A for the original plans and Appendix C for the final design. Test Rig: ● Ball Bearings: The original plan was to try and match the bearing sizes of the test rig exactly with those on the S-92’s tail rotor shaft. The specifications for the pitch change bearing (which is a double row spherical design), and the outboard and inboard shaft support bearings (which are a tapered roller design) are provided in the table below. These were used to calculate the defect frequencies for each bearing. These frequencies were instrumental in determining the sampling frequency of the sensor, which in turn affects the memory needed and rate at which the data is transmitted. In Table 7, two methods were used to determine the defect frequencies, one found online and one developed by Sikorsky. Fig. 4 - double row spherical bearing 16 Fig. 5 - tapered roller bearing Table 7 - Defect Frequencies Pitch Change Outboard Double Row Spherical Tapered Roller (Timken) Inboard Tapered Roller (Timken) PD - Pitch Diameter (in) 1.915 5.040 5.860 BD - Ball Diameter (in) 0.460 0.510 0.680 # of Rollers 9 (18) 25 22 Contact Angle (deg) ~23 ~30 ~30 Outer Race Defect (Hz) 156 226 196 Inner Race Defect (Hz) 204 274 244 Ball Defect (Hz) 178.6 249 219 Cage Fault (Hz) 8.6 9.04 8.9 Approximations of Defect Frequencies 17 Sikorsky’s Defect Frequencies Outer Race Defect (Hz) 140.2 228.1 197.9 Inner Race Defect (Hz) 219.8 271.9 242.1 Ball Defect (Hz) 79.2 196.1 170.6 Cage Fault (Hz) 7.83 9.12 9.00 Bearing Defect Frequency Equations developed by Sikorsky: Outer race defect in Hz = (# of balls / 2) * rev/sec* ( 1 – ((BD/PD)* cos B)) Inner race defect in Hz = (# of balls / 2) * rev/sec* ( 1 + ((BD/PD)* cos B)) Ball Defect in Hz = (PD/BD) * rev/sec * [1 - ((BD/PD)*cosB))2] Cage Fault in Hz = 0.5 * Rev/sec * [ 1 - (BD/PD) * cos B] Where BD is ball diameter, PD is Pitch Diameter (usually OD + ID / 2) Matching the provided dimensions to cartridge bearings from manufacturer catalogs yielded a match to bearing 22205C, a double row spherical bearing with a cylindrical bore. This has a rated rpm of 6500 rpm, which is the only other requirement necessary for the bearing to meet. The outboard tapered roller bearing was matched to 30313U which is rated at 2800 rpm. Many manufacturers produce these bearings, so selection comes down to availability and cost from a supplier. Differing brands means that these bearings vary in cost from $25 to $60. ● Motor: The search for a motor began using rough estimations for what power would be needed to spin the test rotor shaft at the necessary speed. Alternating current motors were initially looked at due to the ability to use wall power outlets. The output speed would also need to be varied as most pump motors ran at a fixed speed of 1750 rpm. This meant that a speed controller would be necessary. Everything from ceiling fans adjustment speed controllers to custom AC motors with built-in speed controllers were looked at. However, due to cost, Tom Mealy of the Mechanical Engineering Department lab staff was contacted to aid in the search for a motor. A ¼ HP DC motor with speed controller was found and is currently being repaired for use. This was a significant acquisition as the motor was the most expensive component of the test rig and purchasing a brand new motor for a single short-term use is not advisable. 18 ● Shaft: The shaft is made of aluminum and custom machined by the team. The diameter changes to match the inner diameters of the bearings. The test shaft will slide onto the motor’s shaft, and a shaft clamp will be tightened down to prevent it from sliding off. At the other end of the test tail rotor shaft is the electronics cavity. It has an end cap to secure the electronics package inside, and prevent any components from being ejected when the system begins spinning. ● Base: The base is made of aluminum and consists of a platform for the motor to be affixed to, along with 2 vertical supports to house the bearings. Each bearing will be pressed into a recess in the support. Each recess has a small ramp and each support has a hole behind the bearing which will allow for removal of the bearing cartridge. For CAD drawings of the test rig, please refer to Appendix B. c. Alternate Designs Originally, the design called for energy harvesting to be used in order to meet the lifespan requirement of one year. This is not a factor anymore, as the battery can sustain the system by itself. This was a major design change to the project, as our original design had to account for the size of the energy harvesting components. The output of the vibrational energy harvester is sinusoidal or alternating current. A rectifier board is used with this system to take this alternating current and convert it into direct current that can be used throughout the system. The problem with size does not pertain to the energy harvesting device, but the rectifier board accompanying it. Commercially available rectifier boards are too large to fit inside the small cavity available, so in order to use energy harvesting a custom board must be made. This custom board would have needed to contain a rectifier and a charge pump, which would have been used to increase the voltage. 4. Proposed Design Analysis a. Analysis Fig. 6 - Proposed Block Diagram 19 First, the sensor collects the data. The microcontroller acquires this data, processes it (FFT and Time Synchronous Averaging), and sends it to the memory chip. When it is time to transmit, the microcontroller reads the data from the memory chip and sends it to the ZigBee transceiver chip to be transmitted to the stationary side receiver. b. Testing Methods To test the electrical components, it was planned to first transmit test data using the microcontroller and ZigBee interface. Next the sensor data would be transmitted directly through the microcontroller and ZigBee chip. Finally, we will add the memory and try storing sensor data and later retrieving the data and transmitting it using Zigbee. We also planed to test the response of the voltage level of the battery to extended use. Finally, we planned to assemble them in the packaging to be used in the test rig. c. Budget ● Battery(x4): $100.80 ● Sensor(x1): $2.27 ● Transceiver(x1): $5.16 ● Microcontroller(x1): $9.86 ● Memory(x1): $15.75 ● Antenna(x1): $5.19 ● Balun(x1): $2.58 ● Programmer(x1): $70.54 ● Motor(x1): Provided Total: $212.15 5. Build Process and Testing a. Electrical Components (i.) Build Process The first part of the build process for the electrical components consisted of wiring the components in a breadboard for testing. While the breadboard was being tested, a preliminary PCB design was being made. Once testing on the breadboard was complete, the PCB design was finalized and a PCB was ordered. The original plan for the PCB was to have connectors that would connect the main PCB to the accelerometer PCB and to the JTAG programmer. We were unable to find connectors that were small enough to fit the size constraints of the electronics packaging, so we instead soldered wires for the connections to the board. It was still difficult to fit the electronics components into the electronics package with the wires soldered on, so after the microcontroller was programmed, the wires for the JTAG programmer were removed. 20 The first step in the PCB process was to go from the prototype on the breadboard to the schematic seen in Figure 7. The program used to design the schematic was PCB123. This was a relatively easy program to use, the only challenging part was to design all of the components. We had tried designing the schematic in others software such as expressPCB but came across many problems. After design the schematic we were able to move forward with the PCB layout, as seen in Figure 8. The PCB was ordered through Sunstone Circuits and then forwarded to Screaming Circuits, where all of the PCB components were soldered on the board. The PCB ended up being 6 layers. We needed all six layers due to the small size restrictions. The main PCB was 1.3” x 2.6” so that it could fit into the electronics cavity along with the battery. The accelerometer was on a separate PCB that just went on top of the main PCB in the cavity. Figure 7: Design Schematic Figure 8: PCB layout 21 Figure 9: PCB (Smaller board is accelerometer) (ii.) Testing According to the power consumption data in the previous section, we knew that in a worst case scenario that 20mA would be needed during transmission. Using this knowledge we ran the battery at a constant rate of 20mA. The battery ran for 28 straight days without a voltage drop, but the computer stopped collecting data and we are not exactly sure how much longer the battery lasted. The battery capacity for the battery to last 28 days at 20mA is 13.4Ah, which is larger than the 11Ah needed to last the specified minimum of one year. Figure 10: Battery Test 22 The rest of the electrical components were tested individually on a breadboard. First, the microcontroller was programmed with a test program to ensure that the programmer toolchain was working. Then, we had the microcontroller transmit known values wirelessly to test the Zigbee chip. Next, the accelerometer values were read and transmitted over Zigbee to test the accelerometer. Then, we had the microcontroller write known values to memory and then read them to ensure that the memory was working. Lastly, we had the accelerometer data written to memory and then periodically read and transmitted over Zigbee, which used all of the components together. One of the issues we encountered when programming the interface with the Zigbee chip is that the Frame Control Field (FCF) was misrepresented in the datasheets. In the correct configuration, each byte is reversed from the configuration specified in the datasheet. Once the data was received, it was transmitted over an RS-232 connection. For displaying real time accelerometer data, we used a program called Processing to create a graphical display. We also used MATLAB to acquire data to display in the frequency domain. We did not do any analysis on the received data. b. Mechanical Components (i.) Build Process The first major step in the build was to obtain the motor and speed controller from the UConn ME shop technician. He had to refurbish the motor to make it run again. However, this took longer than expected, so getting the project set up in the machine shop workspace was delayed. Once we obtained the motor and speed controller, the dimensions of them were taken and work on a better CAD model in Solidworks was begun. The main constraint in the test rig was getting the bearings to be concentric with the bore of the motor output shaft to reduce unwanted vibrations and stresses on the bearings and bearing stands. The bearings were ordered sight unseen, and once their physical size was assessed, it was decided that the original one piece bearing stand assembly would have to be changed. Each bearing would get it’s own separate stand. This also made them easier to machine. Both bearing stands were cut in a 2axis mill. Two holes were drilled into the back side of the bearing pocket to allow for the bearing to be punched out of the stand. 23 Fig. 11&12 - Bearing stand for tapered roller bearing Fig. 13 & 14 - Bearing stand for double row spherical bearing The shaft was milled down in the manual lathe from 3 inch diameter stock down to a profile close to the final desired shape. It was then placed in the CNC lathe and brought down to its final dimensions. Originally, the shaft was to connect to the motor output shaft via a hole and keyway recession milled into the small end of the rotor shaft. With the advice of the machine shop technicians, this idea was scrapped as cutting a square keyway into the end of the shaft would prove difficult to do. Instead, the small end of the rotor shaft was brought down to the same 5/8” diameter as the motor output shaft. 24 Fig. 15 - Replica shaft From there a premade clamping shaft coupler was used. The use of a keyway was scrapped as the coupler was rated for speeds up to 3450 rpm and the test rig would only be operating at 1200 rpm max. This proved to be more than acceptable as there is no load placed on our replica rotor shaft. Fig. 16 - Shaft Coupler It was originally intended for the tapered roller bearing to be held in place in its stand with a large flat washer that would tighten down over the race. Using a premade clamping shaft collar was sufficient enough to provide the axial force needed to keep the tapered roller bearing up tight against the outer race. Fig. 17 - Shaft Collar It was planned to have the bearings pressed onto the shaft. However, the tolerances needed to do so exactly were not possible to obtain with the machinery we had available, so small adjustments had to be made. The spherical roller bearing should have a k5 tolerance fit over 25 the shaft. This calls for a shaft diameter tolerance between +0.011 and +0.002 mm, with a final fitment tolerance of 0.021 mm of interference. It is impossible for the team to machine the shaft to this accuracy. The final shaft diameter for the spherical roller bearing placement was left up to the decision of the machine shop technician based on his experience. The actual tolerance came out to be 0.070 mm of interference. The application of this bearing calls for an H7 housing fitment tolerance. This calls for the housing bore to be between +0.030 and 0.000 mm, with a final fitment tolerance of 0.036 mm loose. The actual tolerance came out to be 0.140 mm loose. [7] The linear thermal expansion rate is 13 micro inches per degree Fahrenheit for 6061 Aluminum. The bearing stands were heated to 300 degrees in an oven which was sufficient for both bearings to be dropped into their recess. The shaft was then frozen to allow for the bearings to slide over the shaft in their final resting positions. The electronics package was made out of an ABS polymer. The original design called for a cap to enclose the package, and another cap to keep the package within the shaft cavity with both involving threading. A more simple design was come up with which involved a single cap that enclosed the electronics package and had a flange on the external side which would attach it to the shaft. The updated electronics package was given a recess on the bottom to allow for removal of the battery once it is inside the packaging. Grooves were placed on both sides of the package at an increased thickness of the 6-layer PCB to allow it to slide into a fixed position in relation to the package and the shaft. This redesign is shown in Appendix C. The fully assembled test rig can be seen in Appendix D. (ii.) Testing Once the test rig was fully assembled the first time, it was noted that the motor output shaft and tail rotor shaft were not aligned. The bearing stand was noted as having a foot that was not properly flat, so this piece was placed in the CNC mill to create a flush and even finish on the bottom side. After other eccentricities were noticed at the connection of the motor output shaft and the replica rotor shaft further changes were made to the base underneatht the motor. The area under the motor and the bottom surface of the tapered roller bearing stand were machined down so that the shafts were level and coaxial due to irregularities in the height of the motor footprint. The tail rotor shaft was then able to spin freely and eccentricities were significantly reduced so as to smooth out the major vibrations of the system. The test rig was able to run up to the required 1200 RPM specifications with the use of the attached speed controller. 26 6. Results a. Testing Results One of the tests that we did is to determine the maximum range of transmission of our system. The range with the breadboard setup was approximately 40 feet. With the PCB, the range increased to approximately 80 feet. This is probably because of the connections to the Zigbee chip. When the electronics package was inserted in the test rig, the range decreased to approximately 40 feet, probably due to being encased in metal. We had the accelerometer set to a range of -2g to 2g. When we had the system in the test rig, the values sometimes exceeded this range. The accelerometer has an adjustable range of up to ±16g. Adjusting this range would eliminate the clipping that occurs with a smaller range. We did implement the inertial interrupt feature of the accelerometer to cause an interrupt when the measured value is above a set threshold for longer than the set duration. This could be used to reduce power consumption by waking the system from low-power mode when the shaft starts rotating. This would eliminate most of the power consumption during periods of inactivity. b. Budget Our initial budget projections failed to account for many of the materials that would be needed to build the test rig. This included most every part (both bearings and all the aluminum pieces). It did provide an order of scale as to how costly each electronic component was, but not accounting for how it would all be assembled together on a PCB board. Obtaining a motor with speed specifications saved a major expense, as the motor the team was able to borrow for the project costs around $500. In the end, the team was able to complete the project well under budget. Electronic Parts ○ Custom PCB Board and Soldering- $1300.86 ○ Electronic Parts- $828.50 Mechanical Parts ○ Bearings - $220 ○ Bearing Mounts - $106 ○ Collar Clamp - $26 ○ Shaft - $78 ○ Shaft Coupler - $18 ○ Aluminum Base - $88 ○ Hardware - $11 27 ○ 3D printed electronics package - $10 ○ Motor - $0 (on loan from UConn ME Shop) ○ Speed Controller - $0 (on loan from UConn ME Shop) Total - $2686.36 Amount under budget - $1313.64 7. Conclusions We successfully transmitted data from an accelerometer wirelessly over 40 feet. According to our calculations, the system will last for at least one year. Also, the entire system fits the size requirement of the tail rotor electronics cavity. For future work to be continued on our project, the range of the system can be improved. We believe that a limiting factor in our range was that the antenna was buried in the electronics cavity surrounded by metal. If we were able to drill a hole in the cover of the cavity and have the antenna stick out, we feel as though the range would be greatly improved from our current measurement of 40 feet. When the antenna was in the cavity the data transmission was interrupted periodically. When the cover was taken off of the cavity, the data transmission was consistent. If the antenna was outside of the cavity, this problem should be solved. Additional future work on this project could be to implement the inertial interrupt of the accelerometer. 8. References [1] Adamnson, Alan., Berdugo,Albert., 2010, “Helicopter Slip Ring Replacement System,” Research Paper, www.ttcdas.com/products/daus.../tp_2010_helicopter_slip_ring.pdf [2] Winslow, C., “Wireless Data System for Aircraft Component Monitoring,” Sikorsky, Stratford, CT [3] Bai, H., Atiquzzaman, M., Lilja, D., 2005, “Wireless Sensor Network for Aircraft Monitoring,” Research Paper, http://cs.ou.edu/~atiq/papers/05-China-Comm-Sensors.pdf [4] Weddell, Alex S., Merrett, Geoff V., Harris, Nick R., Al-Hashimi, Bashir M., “Energy Harvesting and Management for Wireless Autonomous Sensors,” University of Southampton, UK. [5] Inman, Daniel J., Sodano, Henry A., Park, Gyuhae , 2005, “Comparison of Piezoelectric Energy Harvesting Devices for Recharging Batteries,” Research Paper, institute.lanl.gov/ei/pdf_files/JIMSS2005.pdf 28 [6] Errichello, Rich, 2005, “Spalled Bearings,” Practicing Oil Analysis, Machinery Lubrication Publication, http://www.machinerylubrication.com/Read/718/spalled-bearings [7] Timken Company, 2011, “Timken Spherical Roller Bearing Catalog” 9. Appendices A. Electronics Package developed in NX8 29 B. Test Rig developed in NX8 - The base has been made parametrically so that any change in bearing size or height of the supports can be made easily. The motor is not included because it has not been acquired yet. Side View 30 End View (from motor side) C. Modified Electronics Package - The modified electronics package was developed using SolidWorks 31 D. Modified Test Rig Setup - The modified test setup was developed using SolidWorks In this view, the black box represents the speed controller and the grey rectangle next to it represents the motor. The exact dimensions were not needed for modeling purposes so the representative motor only has an accurate footprint and location of output shaft. 32