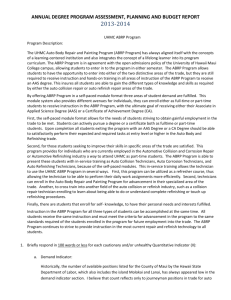

Refinish Preparation

advertisement

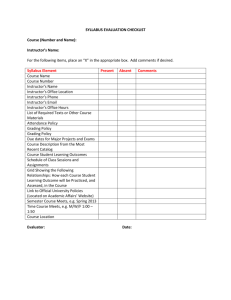

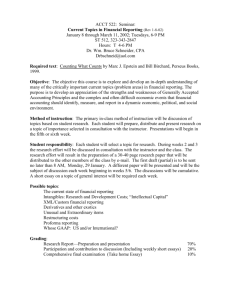

COURSE SYLLABUS PROGRAM CAREER MAJOR: Refinish Preparation COURSE LENGTH: 105 Hours MEETING TIMES: A.M. session (M-F) 8:10 a.m. - 11:05 a.m. P.M. session (M-F) 11:55 a.m. – 2:55 p.m. INSTRUCTOR: Kevin Baize KevinB@ictctech.com 918.348.7948 COURSE DESCRIPTION AND OBJECTIVES: In this course the student will how to prepare the surface for the refinishing process. The student will cover topics about sandpaper and learn techniques to choose the proper grit and how to operate sanding equipment. This course will provide instruction in masking techniques and products used to mask and protect areas not in the refinish operation. The students will learn proper techniques for block and finish sanding prior to topcoat application. Students will learn to apply proper substrate cleaning before the application of refinish products. COURSE COMPETENCIES Surface Preparation Inspect, remove, store, and replace exterior trim and components necessary for proper surface preparation. Soap and water wash entire vehicle; use appropriate cleaner to remove contaminants. Inspect and identify substrate, type of finish, surface condition, and film thickness; develop and document a plan for refinishing using a total product system. Remove paint finish. Dry or wet sand areas to be refinished. Featheredge damaged areas to be refinished. Apply suitable metal treatment or primer in accordance with total product systems. Mask and protect other areas that will not be refinished. Dry or wet sand area to which primer-surfacer has been applied. Dry sand area to which two-component finishing filler has been applied. Remove dust from area to be refinished, including cracks or moldings of adjacent areas. Clean area to be refinished using a final cleaning solution. Remove, with a tack rag, any dust or lint particles from the area to be refinished. Scuff sand to remove nibs or imperfections from a sealer. Identify the types of rigid, semi-rigid or flexible plastic parts to be refinished; determine the materials, preparation, and refinishing procedures. Identify aluminum parts to be refinished; determine the materials, preparation, and refinishing procedures. INSTRUCTIONAL DELIVERY PLAN: Classroom presentation will follow the lecture discussion format. Student participation in the form of questions and discussion of related experiences will be solicited. Visual materials and other methods will be used to keep the class interesting and meaningful. Lab and shop presentations will take the form of students working individually, in pairs, and groups on assigned processes and projects. INSTRUCTOR/STUDENT RESPONSIBILITIES: The instructor of this course assumes responsibility to provide explicit information regarding expectations of students on required assignments and activities and daters for completion. The major obligation of the student is to demonstrate proficiency while meeting the requirements for this course. Included in this obligation is the necessity of meeting timelines for completion of activities, assignments and tests. Students who need additional help should notify the instructor who will provide additional assistance and/or refer the student to the Academic Center for assistance. Refer to tracking sheet for additional information. EVALUATION PROCEDURE A. Tests 30% B. Daily Grade* 70% *Board policy requires a minimum of 25% for Daily Grades Final grades will be assigned on the following scale: A 95 – 100% C+ 77 – 79 A90 – 94 C 74 – 76 B+ 87 – 89 C70 – 73 B 84 – 86 D+ 67 – 69 B80 – 83 D 64 - 66 DF 60 - 63 Below 60 NG=59% or actual grade below 60 WORK AND ASSIGNMENTS MISSED: Make-up work is allowed only if the absence is excused. It is the student’s responsibility to request make-up work from the instructor. Shop work is difficult to make up so the instructor may assign written lessons. Make-up work must be completed within two (2) weeks of absences. REQUIRED TEXTS, MATERIALS, SUPPLIES: Inter-Industry Conference for Automotive Collision Repair (I-CAR) CD-ROMs AMERICANS WITH DISABILITIES ACT (ADA) Any disabled person requiring specific information regarding services should call the Student Services Center, Muskogee Campus, 2403 North 41st Street East, at 918.687.6383, Ext. 7936, between 8:00 a.m. – 4:30 p.m., Monday through Friday. Facilities on all Indian Capital Technology Center campuses are wheelchair accessible. ACADEMIC DISHONESTY Academic dishonesty or misconduct is neither condoned nor tolerated at Indian Capital Technology Center. Any student found guilty of academic dishonesty or misconduct shall be subject to disciplinary action. STUDENT CONDUCT Students are expected to cooperate in maintaining a classroom environment conducive to learning. Courteous and respectful behavior will be expected from all students. Refer to the Student Conduct Policy in the student handbook. DATE: July 16, 2012 Indian Capital Technology Center does not discriminate on the basis of race, color, religion, national origin, sex/gender, age, disability, marital or veteran status.