Excavation and Trenching

advertisement

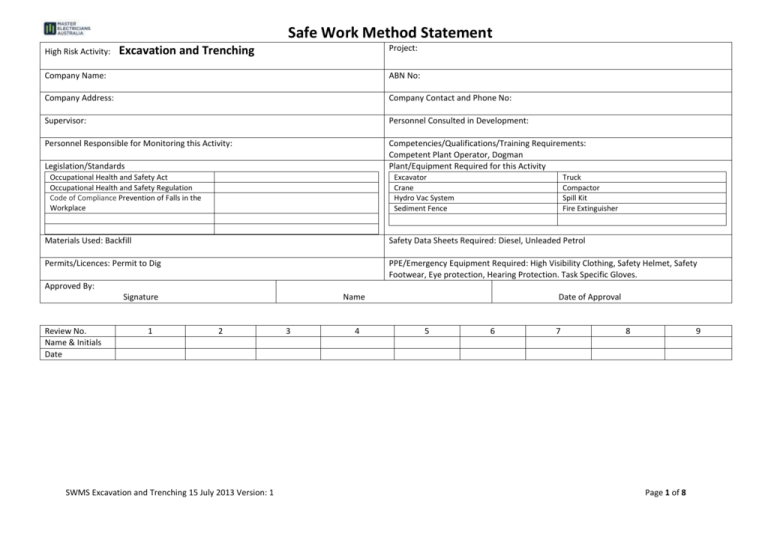

Safe Work Method Statement High Risk Activity: Project: Excavation and Trenching Company Name: ABN No: Company Address: Company Contact and Phone No: Supervisor: Personnel Consulted in Development: Personnel Responsible for Monitoring this Activity: Competencies/Qualifications/Training Requirements: Competent Plant Operator, Dogman Plant/Equipment Required for this Activity Legislation/Standards Occupational Health and Safety Act Occupational Health and Safety Regulation Code of Compliance Prevention of Falls in the Workplace Excavator Crane Hydro Vac System Sediment Fence Truck Compactor Spill Kit Fire Extinguisher Materials Used: Backfill Safety Data Sheets Required: Diesel, Unleaded Petrol Permits/Licences: Permit to Dig PPE/Emergency Equipment Required: High Visibility Clothing, Safety Helmet, Safety Footwear, Eye protection, Hearing Protection. Task Specific Gloves. Approved By: Signature Review No. Name & Initials Date 1 Name 2 SWMS Excavation and Trenching 15 July 2013 Version: 1 3 4 Date of Approval 5 6 7 8 9 Page 1 of 8 Safe Work Method Statement PROCEDURE (break the job down into steps) Pre Start Select plant/equipment for task/activity (excavator, skid steer, truck mounted crane, electrical equipment, concrete cutter, ladders etc) POTENTIAL SAFETY AND ENVIRONMENTAL HAZARDS (what can go wrong) Plant/equipment used for task/activity not up to required standard. INHERENT RISK SCORE L 3 C 4 MANAGEMENT METHOD (controls to be in place in order to manage potential hazards) RESIDUAL RISK SCORE PERSON RESPONSIBLE (to ensure implementation of controls) R •Select the most appropriate plant/equipment for the task L C R 12 •Safety Checklist for plant to be completed (if no maintenance records available) by owner/hirer/supplier and reviewed by nominated staff before plant commences on site. 2 2 4 L C R 2 2 4 L C R 1 5 5 L C R 1 5 5 On site plant/equipment failure/breakdown Project Manager •Plant operators to complete a daily checklist before start up •Equipment to be checked daily before use • Immediate action to be taken on identified deficiencies •Servicing/maintenance as per manufactures instructions •Reversing/movement alarms on all major plant Pre Start Inexperienced personnel unaware of site conditions and work hazards. L C R 3 4 12 •All personnel to undergo specific training (site and general industry inductions, task/activity awareness, other training as required) before commencing on site •Certified/competent personnel (or trainees under supervision) for prescribed occupations (load shifting equipment etc) Project Manager •Licensed/competent drivers of construction traffic. Select labour for task/activity •Site personnel who are to use nominated equipment are to have the training and skills required to operate/use that equipment competently •An ‘Authorised Person’ who has undergone the appropriate training is to be in place when working within the exclusion zone of power lines Pre Start Identification of Services Contact with underground and aboveground services and protection of underground services L C R 4 5 20 •Verify location of all underground services (Dial before you dig etc) before commencing excavation •Ensure Permit to Dig completed before commencing work (emergency procedures to be highlighted) Project Manager •Carry out site walk thru and identify overhead power lines in works area, instigate tiger tails on lines where necessary •Highlight power lines by placing “Danger – Overhead Power Lines” and flagging under lines where works are to be carried out •Competent person to act as spotter when working around power lines •‘Authorised Person’ to be in place when working within the exclusion zones of power lines •Carry out hand excavation as necessary to locate services with approved non-destructive means such as hydro-vacuum systems i.e. vacuum / sucker truck Preparation Work Area Contact with pedestrians/public vehicles L C R 3 5 15 SWMS Excavation and Trenching 15 July 2013 Version: 1 • Works to be barricaded as required. • Permits in place as required (police, council) • Pedestrian thoroughfare to be delineated with appropriate signage • Traffic controller/police in place as required • Traffic control devices eg signage etc to be in place as per traffic control plan • Access and egress to site for construction vehicles planned Site Supervisor Page 2 of 8 Safe Work Method Statement PROCEDURE (break the job down into steps) POTENTIAL SAFETY AND ENVIRONMENTAL HAZARDS (what can go wrong) INHERENT RISK SCORE RESIDUAL RISK SCORE MANAGEMENT METHOD (controls to be in place in order to manage potential hazards) PERSON RESPONSIBLE (to ensure implementation of controls) • Site entry points to be closed off at all times when not in use Personnel struck by plant L 3 C 5 R •Reverse/movement alarms to be installed and working on major plant L C R 15 •Restrict access to area to be excavated to key personnel only 1 4 4 Site Supervisor •Operators to be aware of location of site personnel •Site personnel to wear high visibility clothing e.g. vests, safety helmet Operation Excavate •Safety pin to be in bucket assembly to prevent loss of bucket Plant collisions Cave in of excavation L C R •Operators advised on dangers of major plant working in the same area. L C R 1 3 3 2 4 8 •Reversing alarms to be activated L C R •Authorised personnel only in area – use fencing and signage L C R 15 •Nominated personnel to inspect and assess ground conditions regularly. 2 4 8 L C R 1 4 4 3 5 Plant Operator Site Supervisor •Shore, bench and batter as required. As a minimum, excavations below 1.5 m require benching of 1 vertical to 1 horizontal or battering of 1:1. •Excavated spoil to be placed so that there is no likelihood of it falling into excavated area i.e. 600mm away. •Heavy machinery to be kept away from the edge of excavated surfaces to avoid slope failure. Falls from heights L C R 3 4 12 •If unattended, barricading to be in place around excavations where there is a danger of falls of personnel over 1m •Excavations to be backfilled to prevent accidental falls by outside normal work areas Site Supervisor •Sufficient safe access to base of excavation to be provided Operation Excavate Environmental harm L 3 C 3 R •Sediment fence to be erected and maintained as required L C R 9 •If identified as acid sulfate soil, precautions to be taken to mitigate risk eg bund area and treat with agricultural lime to ensure ph is maintained within specified range. Testing to be undertaken. 1 2 2 Site Supervisor •Water down area as necessary to minimize dust problems Community complaints L C R •Confirm the client has consulted with the local community L C R 3 3 9 •Consult with local property owners in respect to access provisions 1 2 2 Project Manager •Housekeeping on and around site to be maintained (includes temporary signage, barriers etc) Fire Hazard Petrol / Exhaust Fumes L 4 SWMS Excavation and Trenching 15 July 2013 Version: 1 C 5 R •All engines are to be switched off before refueling L C R 20 •Have standby pump to eliminate refueling hot flex drive petrol pumps 1 5 5 Site Supervisor Page 3 of 8 Safe Work Method Statement PROCEDURE (break the job down into steps) POTENTIAL SAFETY AND ENVIRONMENTAL HAZARDS (what can go wrong) INHERENT RISK SCORE RESIDUAL RISK SCORE MANAGEMENT METHOD (controls to be in place in order to manage potential hazards) PERSON RESPONSIBLE (to ensure implementation of controls) •Refueling to preferably take place before work commences or during break in work Operation •Strictly NO SMOKING during refueling operation Refuelling Portable •Fuel to be stored and dispensed from approved containers only, using funnel or pouring device Generator Units/Pumps/Stationary and Mobile Plant •Do not store fuel near generators, keep in ventilated / shaded area away from ignition sources •Ensure fire extinguisher is accessible •Clean up all spills •Keep adequate spill kits on site •Maintain SDS for fuel in accessible location (site vehicle) •Check electrical connections and replace fuel cap before restarting generator Operation Using electrical equipment and generators Electrocution L 3 C 5 R 15 •Ensure earth leakage systems are fitted to all generators •Ensure all power boards are earth leakage compatible L C R 1 5 5 L C R 2 2 4 L C R 2 2 4 L C R 2 2 4 L C R 1 5 5 Site Supervisor •Ensure all leads are tagged and tags are current Inadequate access/egress Collisions with objects/personnel when placing conduit etc into trench with crane (or other plant) L C R 3 4 12 L C R 3 4 12 Where excavations require it, ensure that ladders are positioned for access and egress. Ladders shall be no more than nine (9) metres apart and shall be adequately secured •Crane operator and dogger made aware of site/working restrictions and locations of plant, materials, objects and personnel •Reversing alarm on plant to be in use when mobile Site Supervisor Plant Operator •Personnel to be made aware of plant movements •Thorough check of ground conditions to be carried out Operation •Lifting gear hook to be positioned above centre of gravity of load Working in Trench Loss of connection to conduits etc (too heavy, poor selection of lifting gear, incorrect slinging) L C R 3 4 12 •Operator to ensure plant capable of lifting load and correct selection of lifting point (hook on plant to be certified) •After assessing load, competent person (excavator operator, dogger or trainee under supervision) to select correct lifting gear and sling load Site Supervisor •All lifting gear to be in good condition, inspected before use and tagged as required •Only authorised personnel in area •Check lifting points to verify they are not damaged. Plant overbalances L C R 2 5 10 SWMS Excavation and Trenching 15 July 2013 Version: 1 •Weather and ground conditions in working area (eg proximity to excavated surfaces, uneven surfaces) to be fully assessed before moving mobile crane/plant •Ensure crane/plant is operated within safe working limits. Plant Operator Page 4 of 8 Safe Work Method Statement PROCEDURE (break the job down into steps) POTENTIAL SAFETY AND ENVIRONMENTAL HAZARDS (what can go wrong) Contact with overhead services Personal/material damage (crushing, hit by load) INHERENT RISK SCORE L C R 3 5 15 L C R 3 5 15 MANAGEMENT METHOD (controls to be in place in order to manage potential hazards) •Authorised person/spotter to be in place if crane boon is likely to go within the 3m restricted zone. •When load out of operators vision, operator to stop load movements if unsure of instructions from dogger (method of communication to be understood by all persons involved in the lift) •Loads to be controlled by tag lines if necessary RESIDUAL RISK SCORE PERSON RESPONSIBLE (to ensure implementation of controls) L C R 1 5 5 L C R 1 5 5 L C R 2 2 4 L C R 2 2 4 Plant Operator Site Supervisor •Only personnel involved in the lift are to be in the immediate area •Loads are not to be lifted over personnel •When landing loads, personnel to be kept clear •Personnel to keep hands clear when landing •Support/chock load as necessary to prevent movement Operation •Wear gloves if necessary •Personnel to be made aware of risks of manual handling injuries Working in Trench Slips trips falls Back injuries Personnel struck by plant •Unload onto the ground using plant to eliminate slips or falls from back of transportation vehicle. L C R 3 3 9 L C R 3 3 9 L C R •Reversing alarms to be installed and working on major plant L C R 15 •Restrict access to area to be backfilled to involved personnel only 1 5 5 3 5 Keep worksite clean and tidy at all times •Do not lift weights over 20kg, use mechanical lifting aid or ask for help Site Supervisor Site Supervisor Site Supervisor •Operators to be aware of location of site personnel •Site personnel to wear high visibility clothing eg vests. Plant collisions Collapse of excavation during backfill Personal injuries (hand damage, hearing loss etc) during compaction Reinstatement Environmental harm L C R •Operators advised on dangers of major plant working in the same area. L C R 1 3 3 3 4 12 •Reversing alarms to be activated L C R •Authorised personnel only in area L C R 2 3 6 L C R 1 3 3 3 4 12 •Heavy machinery to be kept away from the sides of the excavation. L C R •Wear appropriate PPE (gloves, hearing protection, hand protection etc) •Personnel are to be trained and competent in the use of equipment 3 3 9 L C R •Monitor sediment fences L C R 9 •Water area if dust becomes a nuisance 2 2 4 3 SWMS Excavation and Trenching 15 July 2013 Version: 1 3 Plant Operator Site Supervisor Site Supervisor Site Supervisor Page 5 of 8 Safe Work Method Statement PROCEDURE (break the job down into steps) POTENTIAL SAFETY AND ENVIRONMENTAL HAZARDS (what can go wrong) INHERENT RISK SCORE MANAGEMENT METHOD (controls to be in place in order to manage potential hazards) RESIDUAL RISK SCORE PERSON RESPONSIBLE (to ensure implementation of controls) •Ensure sand bags are in place Complaints Plant collisions L C R 3 3 9 L C R 12 3 4 •Reinstate area to pre construction activities L C R 2 2 4 •Operators advised on dangers of major plant working in the same area. L C R •Reversing alarms to be activated 1 3 3 Project Manager Plant Operator •Spotter to direct the reversing of trucks. SWMS Excavation and Trenching 15 July 2013 Version: 1 Page 6 of 8 Safe Work Method Statement LIKELIHOOD CONSEQUENCES Insignificant [1] Minor [2] Moderate [3] Major [4] Catastrophic [5] Almost Certain [5] Moderate (5) High (10) High (15) Catastrophic (20) Catastrophic (25) Likely [4] Moderate (4) Moderate (8) High (12) Catastrophic (16) Catastrophic (20) Possible [3] Low (3) Moderate (6) Moderate (9) High (12) High (15) Unlikely [2] Low (2) Moderate (4) Moderate (6) Moderate (8) High (10) Rare [1] Low (1) Low (2) Low (3) Moderate (4) Moderate (5) If the residual risk = Catastrophic (16+) then Work unable to proceed seek other methods (Significant) = High (10 – 15) then Permission from high level management for work to proceed (Significant) = Moderate (4 – 9) then Permission from worker in charge for work to proceed (Insignificant) = Low (1 – 3) then Work able to proceed (Insignificant) 1. Eliminate 2. Substitute 3. Isolate 4. Redesign 5. Administrative 6. PPE Last Resort Eliminate the hazard Substitute with a less hazardous material, process or equipment Isolate the hazard Redesign equipment or work process Introduce administrative controls Use appropriate Personal Protective Equipment C = Consequence L = Likelihood 5 = Catastrophic = Fatality, permanent disability, long term widespread impacts, huge financial loss. 5 = Almost Certain = It is almost certain that the risk will occur in most circumstances. 4 = Major = Permanent disability or extensive injuries, medium to long term widespread impact, major financial loss. 4 = Likely = The risk is likely to occur in most circumstances. 3 = Moderate = Lost time injury, reversible medium term local impact, high financial loss. 3 = Possible = There is uncertainty that the risk could occur. 2 = Minor = Medical treatment, reversible short – medium term impact to local area, medium financial loss. 2 = Unlikely = The risk could occur at some time but there is confidence that it will not. 1 = Insignificant = First aid, limited impact to minimal area, low financial loss. . 1 = Rare = The impact/risk may occur only in exceptional circumstances. SWMS Excavation and Trenching 15 July 2013 Version: 1 Page 7 of 8 Safe Work Method Statement We the undersigned, confirm that we have been consulted in the development of this SWMS. If a failure is identified within the SWMS work will stop, the SWMS amended and changes communicated to the workforce. We also clearly understand that the controls must be applied as documented, otherwise work is to cease immediately. We also confirm that we are qualified to carry out the works identified above; a copy of our required qualifications has been provided and where applicable all insurances and work cover policies to undertake this activity are current. Name SWMS Excavation and Trenching 15 July 2013 Version: 1 Signature Date Page 8 of 8