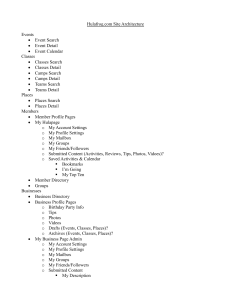

report layout

advertisement