KBA UK Ltd Press Briefing July 2014

advertisement

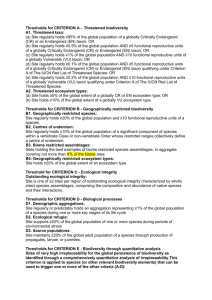

KBA (UK) Ltd. Press Briefing July 2014 KBA sets its sights on the next 200 years Primogenitor of the printing industry charts a course for the future of industrial print Anyone taking a casual glance at reports of the Koenig & Bauer Group’s latest annual accounts might be forgiven for thinking that something had gone horribly wrong for the company that bears the name – and guards the heritage – of the founding fathers of modern print. Nothing could be further from the truth! Yes, the records show that KBA – with annual sales in excess of €1 billion, the world’s second largest press manufacturer – reported a thumping loss in 2013 after achieving profitability in each of the preceding four years, but the facts behind the figures tell an altogether different story, as Ralf Sammeck, Executive Vice President for KBA’s Sheetfed Offset Product House, explains: “First of all, it is important to understand that KBA is different to most manufacturers of this size and importance because of our history and our corporate structure. Our founding fathers didn’t just invent the power-driven press in London in 1814… by choosing to manufacture in their home state of Bavaria in 1817 rather than in England, where all the resources were already in place and a quick profit would have been simple, they also helped accelerate the onset of the industrial age in mainland Europe. Then they established the first paper mill in the region to supply the presses they were building, and continued to develop, refine and perfect the technology of the printing process. And, as their factories grew, they also became pioneers of responsible capitalism, introducing sickness benefit funds, training schools and social institutions for their workforce. In this scenario profit is not the end in itself, but a measure of how successful our product is for our customers and, of course, an essential ingredient to maintain and regenerate our enterprise.” “This philosophy has remained with KBA across our two centuries of operation and that is evidenced by our peerless record of technical innovation and our ability – and willingness – to respond quickly to changing market needs. At the time of the global economic crisis in 2008 we made a thorough appraisal of all the printing sectors, formulated a strategic response and implemented realignments that began to bear fruit the very next year. At the same time, in the sheetfed division, we have been able to benefit from a raft of press performance improvements that have sprung from our breakthrough, software-based DriveTronic print unit sequencing system showcased at Drupa that year. These technologies have now been adopted in new power-performance models throughout our range and will form the basis for our success in the sheetfed division in the coming years.” So, with its rapid realignment and sustained return to profit – unique among the leading press manufacturers – why has KBA reported a €153m net loss after restructuring expenses of €155m in 2013? The answer lies in the changing landscape of printed communications: “At the time of our 2008/9 restructure we were able to foresee a decline in the overall demand for print and predict at what level it might settle down as the new normal,” explains Herr Sammeck. “We anticipated the continued importance of digital printing – and instigated the development of the RotaJET 76 as a result – we prioritised the new powerperformance Large Format presses for the stable packaging and POS sectors, and also the integration of digital heads for a variety of emerging applications. But there were aspects that could not be quantified. On the whole, we got it right and we actually also reported an Operating Profit of €24.5m in 2013 before Special Items were set aside for our second round of realignments.” That second round already promises to be more proactive, with acquisitions in growth sectors, strategic partnerships with complementary manufacturers and new product initiatives for the changing marketplace – as yet, still under wraps – all part of the plan to refocus KBA for the coming challenges, if not quite the next 200 years. But a large part of the cost goes to internal restructuring: “Of course, change is par for the course in the communications business, but the rate of change can be part of the problem,” says Ralf Sammeck. “For example, our Group has a major presence in the newspaper sector which has suffered more rapidly from the impact of online media than anyone expected. Much of our plan is directed at our internal structure through the Fit@All programme, consolidating our core business and refocusing our resources. But our customers will be more interested in the positives. We have already announced our acquisition of companies established in growth areas, such as direct decoration of luxury glass packaging for cosmetics, perfumes and spirits, and in flexo presses for flexible packaging materials, and our new digital solutions are also coming on stream. Added to that we have formed partnerships with other complementary global manufacturers with whom we are developing distribution agreements; these include Optimus Group for MIS solutions, Montex-print, with whom we are developing a range of high performance sheetfed rotary cutters, MBO folders and finishing systems and the Perfecta range of guillotines. Our experiences in developing and supplying integrated solutions for customers in different sectors and sales territories will become an important element in our offering, going forward.” It is this aspect of the programme that might prove to be most significant to printers in the United Kingdom and Ireland where KBA (UK) Ltd., a wholly-owned subsidiary, represents the Group’s interests. Along with the rest of the printing sector in the UK, KBA (UK) Ltd. has found it tough going in recent years but, amid the gloom and austerity, there have emerged good reasons for optimism. In the year since he took the helm as Managing Director, Andrew Pang has undertaken his own realignment programme, and the process is beginning to deliver results. Coming from a production director background at a longtime KBA press customer, and with experience as both Service and Approved Consumables Director within KBA, Andrew Pang has a keen appreciation of his priorities for KBA (UK) Ltd. and a clear vision for its future direction: “My first concern was to redefine the UK set-up with the customer at its core. KBA is brilliant at developing new technologies and second-to-none when it comes to building world class presses, but the focus of any sales organisation, which is what we are, must be to ensure its customers are happy.” Against the backdrop of a stubbornly depressed business sector the task was never going to be easy or without its costs, and KBA (UK) Ltd., like its parent company, recorded a loss in 2013: “We had resources in the wrong places, some clunky administration procedures and a few square pegs in round holes, so it was quite a complex exercise,” admits Andrew Pang. “But, from the feedback we’ve been getting from our customers, it’s been well worth the effort. We’ve created a seamless response to service needs, integrating remote diagnostics, based at the factory in Germany, with in-house field-based mechanical and electrical engineers and a network of approved contractors to consistently earn high approval ratings. We’ve also upped the game with spare parts – increasing stocks and introducing free delivery as standard – and our Approved Consumables service is doing exactly what it was set up to do: helping customers achieve consistently high quality at competitive prices and get the best performance from their presses.” But the internal organisation was only one side of the equation and Mr Pang was acutely aware that, unlike any other major print marketplace across the world, in the UK, KBA remained an almost unknown quantity outside some key niche sectors. A new approach was required to introduce KBA – both as a company and its products – to a largely unreceptive potential customer base. Key to developing the new strategy was Chris Scully, whose appointment as Sales Director, Sheetfed Presses, was confirmed in January last year. Andrew Pang explains: “Printers are busy people and they don’t like to waste time looking at different manufacturers or systems if they feel they don’t need to. KBA (UK) Ltd. had achieved a good run of success with installations of Large Format presses into book printing, POS and specialist packaging companies, and the UK trade – and the media – were content to pigeon-hole us there. The effect of the economic recession of 2008 onwards was almost a moratorium on capital equipment investment which only began to ease last year. At the same time, we knew that the innovations that were now available across our new range of RAPIDA presses meant they really do offer a massive performance advantage to printers, not just in those niche markets, but in magazines, packaging, trade and general commercial work, too. Our strategy had to be to engage with the key players in these sectors to get across the merits of our case. Although print is a people business and it’s important to get along with everyone and get enjoyment out of our work, it’s got to be the business case that is the number one factor in any capital investment decision. We determined that the first objective for our Area Sales Managers would be to seek to engage with the right people in the right companies – risking unpopularity, if necessary – in order to fully explain the operational benefits and performance advantages of a KBA press specified for their business. The new initiative to introduce other world class manufacturers into our portfolio will also come into play for those customers who prefer to deal with one main systems supplier, yet still demand best of breed in their basket of solutions.” It is a strategy that seems to be working and KBA (UK) Ltd. is on track to meet its sales targets this year following sales to a new selection of high profile accounts. Installations include high specification long-perfector RAPIDA 106 B1 presses at a specialist magazine print house, a leading marketing communications group and two international specialist packaging groups, Large Format presses at book printers and POS houses, the UK’s first installation of the new Large Format RAPIDA 145 at the country’s leading food packaging house and a recently-announced order for a long-perfector B1 RAPIDA 106 at Tradeprint.co.uk, the UK’s trailblazing internet-based trade printer. For some time, the strapline for KBA in the UK has been: ‘driven by innovation, defined by excellence’ – a motto designed for the manufacturer but also relevant to its customers. Now the slogan it has adopted for its latest RAPIDA sales campaign, and intended for it’s customers, may just be equally appropriate for the new-look KBA in the UK: ‘Unlock the potential of your business’. ENDS Picture: TBA ________________________________________________________________________ CONTACT For KBA (UK) Ltd. PR Catherine Carter Telephone Media Liaison 01489 572405 cc@resolutionsformarketing.com Vic Fletcher Telephone Account Director 01865 301110 vf@resolutionsformarketing.com For KBA (UK) Ltd. Telephone +44 (0)1923 819922 Andrew Pang Managing Director andrew.pang@kba-uk.com www.kba-uk.com ________________________________________________________________________ About Koenig & Bauer Group KBA is the second largest press manufacturer with 6,000 employees worldwide and, last year, recorded sales in excess on €1 billion. It offers an extensive and highly advanced product portfolio for volume and niche markets. KBA is number one in the newspaper and web offset market, number one in Large Format sheetfed offset and number one in packaging offset, security printing and metal decorating. KBA is continuing to grow and adapt to changing market conditions through the development of new technological solutions and strategic acquisitions. Ralf Sammeck Ralf Sammeck joined KBA in 2,000 as an Assistant vice-president and sales director at its Radebeul facility. After a spell as President and CEO of KBA North America he returned to Europe to take up the post of Executive vice-president sheetfed sales, marketing and service before assuming his current role: Executive Vice President for the Sheetfed Product House. A qualified press engineer, he spent six years with Heidelberg, progressing from sales clerk and product manager (1990) to Head of its Düsseldorf subsidiary, and four years (1996) as Managing Partner at Sander in Wuppertal. About KBA (UK) Ltd. KBA (UK) Ltd. is a wholly-owned subsidiary of Koenig & Bauer Group. Its purpose is to offer support to print companies throughout the United Kingdom and Ireland to ensure they achieve the best possible performance as businesses. We build each press to meet the individual customer's requirements and our experienced Area Sales Managers are here to help specify a solution that will be more productive from its inception and more costefficient throughout its working life. Added to that is a first class team of dedicated service and spare parts staff and a knowledgeable consumables division. Andrew Pang Andrew Pang joined KBA (UK) Ltd. in 2007 as Sheeted Service Director and went on to launch the highly successful approved consumables division (PressConsum). He was appointed Managing Director in June 2013. He began his career in the printing industry as an apprentice with Butler & Tanner where he progressed to the position of Print Director with responsibility for repro, CtP, litho and digital printing and IT, also gaining first-hand experience of a major organisation running multiple KBA presses.

![[#CUI-132] Refactor KBA logic in the self](http://s3.studylib.net/store/data/007693991_2-1f0c6d35c466219f4ae45a2cfc57ed98-300x300.png)