Cryogens Scheme of Work

advertisement

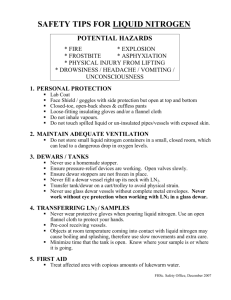

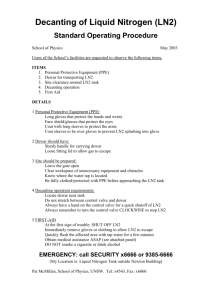

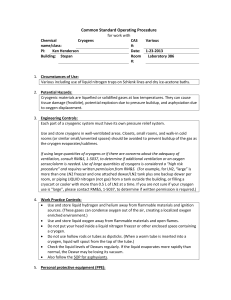

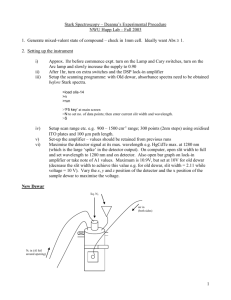

NQI CSOW Scheme of work for working with Cryogens Host School: PI: Author: Date of Assessment: Location: Before commencing work with cryogens, you must read this and associated documents (other SOWs and risk assessments), and then sign the appropriate signature sheet to confirm this, and your agreement to abide by the protocols contained herein. Purpose and Structure of this document The principal aim of this document is to outline the elements of good cryogenic liquid practice as they apply specifically to experiments currently being undertaken in the above laboratory. General aspects of cryogen safety are covered in guidance given by cryogenics facility in the Physics Dept. The document is structured as follows: at the top level (this sheet) an overall description is made of research activity in this laboratory. The user is then referred to a number of accompanying documents. Description of Activity: Four types of situation have been identified which require separate safety protocols, where appropriate: setting up; adding new elements; day-to-day operation of the experiment; maintenance/servicing of the laser system Reference completed /Risk Assessments: General Guidance for Use of LN2 and LHe Definition The guidance provided by the UoB Physics Dept concerns general health and safety issues and is included as a separate document in the Safety Pack, located in lab on the inner door. Oxygen alarms are installed and users should leave the lab immediately if these are activated, or if a leak is suspected. First aid guidance for asphyxiation and cold burns is also posted on the inner door. Transportation of LN2 Definition NQI CSOW Transportation of LN2 is in this case specified to be from the cryogen facility in Physics to the LNL. Protocol/Scheme of Work LN2 may only be transported by personnel after attending the cryogenics safety course given by B. Wiltshire in Physics. LN2 will be transported in a 10L portable cryogen vessel with an unsealed lid to lab. The vessel should be no more than 50% full to avoid (i) spillage and (ii) injury due to excess weight. The vessel should not be transported in the lift, instead by two people using stairs. Users should avoid transporting outside and during busy hours (e.g. between lectures) Appropriate PPE (cryogenic gloves and eye protection) should be worn during transportation. Filling of CCD camera with LN2 Definition The CCD camera attached to the spectrometer requires ~1 litre of LN2 to be filled from the top. Protocol/Scheme of Work LN2 should be transferred from the large 10L dewar to the small thermos flask. PPE (cryogenic gloves and eye protection) should be worn Care should be taken whilst filling to allow vessels to cool slowly to avoid excess boiling LN2 to be poured carefully from small thermos flask into CCD camera. LN2 vessels to be stored away from walking area subsequently. Transportation of LHe Definition Transportation of LHe is in this case specified to be from the cryogen facility in Physics to the LNL in NSQI. Protocol/Scheme of Work LHe to be transported in either 60L or 100L dewars with wheels. Two persons to transport helium dewar Dewar to be transported from Physics to NSQI inside building and via lifts in Physics and NSQI. When using lifts, dewar should be left inside lift and barrier warning take placed across cage. One person should send the lift, the other should be ready to receive it. Once in lab, the dewar should be connected to the return line immediately. Appropriate PPE (cryogenic gloves and eye protection) should be worn during transportation. Use of LHe continuous flow cryostat Definition Cryostat operated by means of a transfer tube, with one end inserted into the dewar and the other into the cryostat. A pump pulls LHe continuously through cryostat and returns it to the return line. Protocol/Scheme of Work Appropriate PPE (cryogenic gloves and eye protection) should be worn during insertion of transfer tube. Transfer tube to be inserted into dewar by two people. Users should check o-ring and nut connected to dewar for wear before insertion. The transfer tube should be held at one end by one user, the other should lower the tube into the dewar slowly and with the return line open. The tube should be sealed with the nut NQI CSOW to the dewar as soon as possible. The users should monitor the pressure in the dewar using a balloon or similar, only lowering the tube when the pressure is sufficiently low. When tube is fully inserted into the dewar, the other end should be inserted into the cryostat. The users should then check the connectors to the pump, return line and dewar, open the appropriate valves and check for leaks. The pump is then switched on. During measurements, the flow rate should be monitored to check for leaks or any signs of blockage. If blockage of the transfer tube occurs, the users should take it out of the dewar and warm it to room temperature fully using a hot air blower before reinsertion. Specified (non-shatter) tubing should be used at all times. It should be noted that excessive exposure of LHe or cold metal to air will result in ice formation, and therefore blockage may occur. When removing the transfer tube, great care should be taken not to touch the cold part of the metal. Cold areas of the cryostat may result in condensation. Care should be taken that water does not come into contact with electrics. Temporary (Overnight) Storage of LHe Dewar Definition It is usually necessary to leave the dewar overnight in the lab. Protocol/Scheme of Work Users to check LHe dewar after experiments have finished for open connection to return line. Should a dewar mistakenly be left overnight without connection to the return line, pressure will build up in dewar. In this case, B. Wiltshire should be informed, and the return line opened gradually to prevent freezing of the value and therefore blockage. Maintenance Definition Safe use of cryogenic systems requires silicon/rubber o-ring seals and tubing which may perish with time. Slow leaks can cause build-up of ice and blockages. Oxygen alarms need to be checked Protocol/Scheme of Work O-rings and tubes should be checked weekly. Valves to return line should be checked monthly. Oxygen alarms should be checked every 3 months. A regular health check of the cryogenic system and return line should be performed by B. Wiltshire yearly.