Assignment 1B - Mikkeli WWTP

advertisement

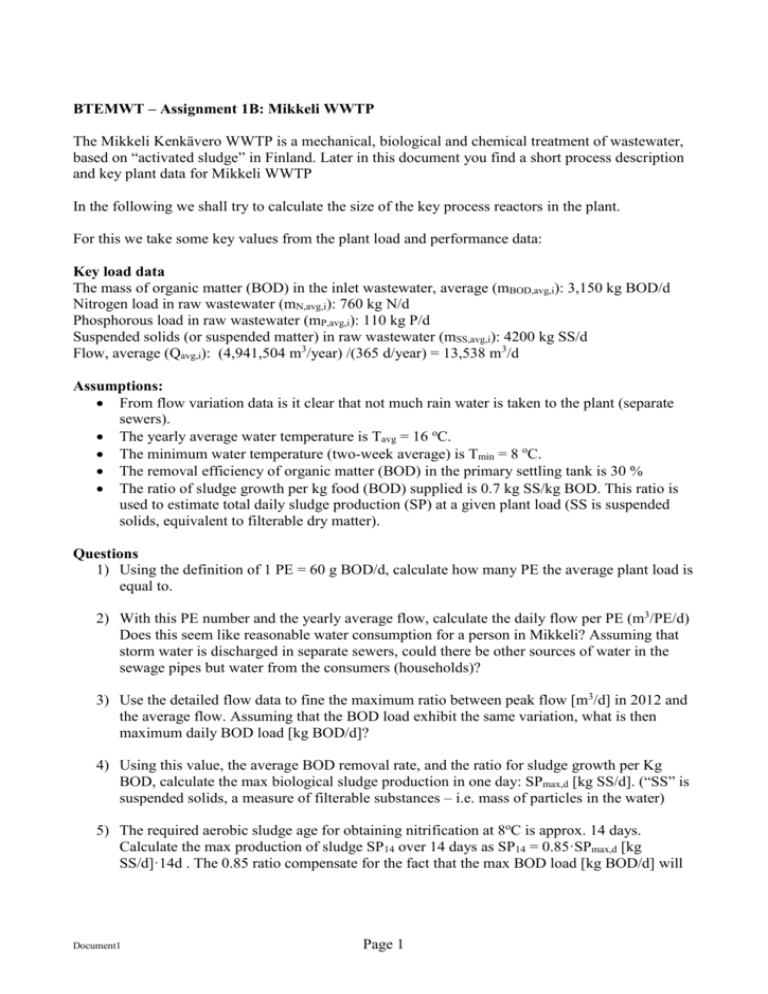

BTEMWT – Assignment 1B: Mikkeli WWTP The Mikkeli Kenkävero WWTP is a mechanical, biological and chemical treatment of wastewater, based on “activated sludge” in Finland. Later in this document you find a short process description and key plant data for Mikkeli WWTP In the following we shall try to calculate the size of the key process reactors in the plant. For this we take some key values from the plant load and performance data: Key load data The mass of organic matter (BOD) in the inlet wastewater, average (mBOD,avg,i): 3,150 kg BOD/d Nitrogen load in raw wastewater (mN,avg,i): 760 kg N/d Phosphorous load in raw wastewater (mP,avg,i): 110 kg P/d Suspended solids (or suspended matter) in raw wastewater (mSS,avg,i): 4200 kg SS/d Flow, average (Qavg,i): (4,941,504 m3/year) /(365 d/year) = 13,538 m3/d Assumptions: From flow variation data is it clear that not much rain water is taken to the plant (separate sewers). The yearly average water temperature is Tavg = 16 oC. The minimum water temperature (two-week average) is Tmin = 8 oC. The removal efficiency of organic matter (BOD) in the primary settling tank is 30 % The ratio of sludge growth per kg food (BOD) supplied is 0.7 kg SS/kg BOD. This ratio is used to estimate total daily sludge production (SP) at a given plant load (SS is suspended solids, equivalent to filterable dry matter). Questions 1) Using the definition of 1 PE = 60 g BOD/d, calculate how many PE the average plant load is equal to. 2) With this PE number and the yearly average flow, calculate the daily flow per PE (m3/PE/d) Does this seem like reasonable water consumption for a person in Mikkeli? Assuming that storm water is discharged in separate sewers, could there be other sources of water in the sewage pipes but water from the consumers (households)? 3) Use the detailed flow data to fine the maximum ratio between peak flow [m3/d] in 2012 and the average flow. Assuming that the BOD load exhibit the same variation, what is then maximum daily BOD load [kg BOD/d]? 4) Using this value, the average BOD removal rate, and the ratio for sludge growth per Kg BOD, calculate the max biological sludge production in one day: SPmax,d [kg SS/d]. (“SS” is suspended solids, a measure of filterable substances – i.e. mass of particles in the water) 5) The required aerobic sludge age for obtaining nitrification at 8oC is approx. 14 days. Calculate the max production of sludge SP14 over 14 days as SP14 = 0.85·SPmax,d [kg SS/d]·14d . The 0.85 ratio compensate for the fact that the max BOD load [kg BOD/d] will Document1 Page 1 be smaller the more days we use to measure it. Using 365 days we are down to the average, and hence considerably below the max (cf. question 3). 6) We now assume that the concentration of activated biological sludge in the aeration tank is XA = 4 kg SS/m3. Calculate based on this the tank volume [m3] that ensures a sludge age (SA) of 14 days. (Sludge age is the average retention time for sludge in the aeration tank, i.e. Mass of sludge in the aeration tank divided by the daily sludge production). 7) Biological excess sludge contain approx. 1 – 1.5 % phosphorous by mass. Use a value of 1.2 % and calculate how much P [kg P/d] is removed from the water with the biological excess sludge. 8) Assuming that the suspended solids (SS) in the raw wastewater contain 1 % P, and assuming that the primary settling tanks remove 50 % of SS in the raw wastewater. How much P is removed from the raw wastewater with the SS that settles in the primary clarifier? [kg P/d] 9) In order to achieve the performance for removal of P (see below plant description), how much P remains to be removed after sedimentation of SS in the primary clarifier and removal of excess biological sludge? [kg P/d] 10) Using a molar ratio for dosage of iron of 1.2 – i.e. 1.2 mole Fe per mole P chemically removed. Calculate the required dose of iron to the water in mole/d. Using the molar weight of iron (Fe) calculate the required iron dose in [kg Fe/d]. 11) This iron precipitate as a complex of FePO4 and Fe(OH)3 components. The SS production is in the order of 2.2 kg SS/kg Fe. Calculate the average chemical sludge production [kg SS/d]. Compare this to the biological sludge production. Document1 Page 2 Background info on Mikkeli Kenkävero Wastewater Treatment Plant (WWTP) Areal photo of Mikkeli WWTP and the town of Mikkeli, Finland. Key process information Short process description The first step in the treatment process is a mechanical pretreatment. The wastewater is passed through a screen to remove “large” objects that could otherwise damage the plant equipment and/or be difficult to remove in the process. These objects are anything from bicycle handles to plastics, cotton sticks etc. The screen is typically from 1.5 – 5 mm in bar spacing. Document1 Page 3 Following the screen the water arrives in the aerated grit and grease chamber. Here sand is setteled and taken out. A mild turbulence caused by aeration keeps organic particles in suspension, to remove as little organic matter with the sand as possible. The sand is taken out sp that it does not form permanent deposits in the subsequent reactors, and so that abrasion and wear in pumps are minimized. Iron chloride is added to the water. The water is passed into large “primary” settling tanks. The purpose of these is to remove organic particles by sedimentation. The iron chloride added in the git and grease chamber will precipitate and help take small particles and aggregate them to bigger particles that can be precipitated. Some of the dissolved phosphorous in the water will also be precipitated and removed as iron-phosphatehydroxide solids. In a primary settling tank 40 – 80 % of the suspended solids are removed, and 25 – 40 % of the organic matter (BOD) in the wastewater is removed and taken out at the bottom of the tank as “primary sludge”. This is rich in organic matter and must be treated, often in a biogas plant in which methane is formed and used for heat or power production. The water-phase is taken from the top of the primary settling tank, now being reduced for much of it’s organic content. This water is mixed with a “soup” of microorganisms called “activated sludge”. This sludge contain a culture of microorganisms - various bacteria and small animals – that are adapted to feed on the type of organic matter in the wastewater. The mix of wastewater and sludge in aerated for the degradation of organic matter and nitrification (aeration of reduced nitrogen such as NH4+ to nitrate NO3-). Dissolved phosphorous in the wastewater (PO43-) is precipitated by addition of iron (Fe3+) to a solid PO4Fe complex. Lime is added to control pH as the iron solution is acidic, and the biological processes may decrease pH. Now the mix of purified water and activated sludge is taken to the final (or secondary) clarifiers (or settling tanks). Here sludge is settled to the bottom and pumped back into the aeration tanks, and the purified wastewater is decanted from the top of the clarifiers. Final disinfection or filtration of the purified water may take place to remove the last part of particles and microorganisms from the water. The activated sludge grows as result of the decomposition of the organic matter in the wastewater. Every day some sludge must be taken out of the circulation. This part of the activated sludge is called excess (or surplus) sludge. In Mikkeli this sludge is pumped to the inlet of the primary settling tank and taken out with the primary sludge to the biogas plant, although the biogas potential of this sludge is much less compared to the primary sludge. After processing (digestion) of the sludge, the sludge is dewatered and taken to storage, before final disposal. The sludge can be taken to incineration or can be applied on farmland as texture improvement and fertiliser, provided that the content of heavy metals and other harmful substances is low. Document1 Page 4 Incomming wastewater load: Document1 Page 5 2012 performance data: 2012 Whole Quarter 1 Quarter 2 Quarter 3 Quarter 4 year treshold / quarter * BOD7 ATU mg/l 7 5 4 6 5 ≤ 10 Efficiency % of purification 98 98 98 97 98 ≥ 96 Total Phosphorus mg/l 0,3 0,19 0,3 0,45 0,31 ≤ 0,5 Efficiency % of purification 97 98 96 95 96 ≥ 96 0,31 (annual average) ≤4 NH4 -N mg/l 0,03 0,97 0,08 0,18 ≥ 90 Efficiency % of purification 100 98 100 100 99 (annual average) Solids mg/l 10 7 10 15 11 ≤ 35 Efficiency % of purification 97 98 97 94 97 ≥ 90 COD Cr mg/l 35 30 29 39 33 ≤ 125 Efficiency % of purification 94 94 95 92 94 ≥ 75 Flow to plant 2012: Treated water m3/d min average max m3/month total January February March April May June 11014 9886 10626 11595 11772 8913 13375 11304 12024 17724 15631 11727 15976 12140 14623 22624 22460 13828 414636 327815 372735 531712 484568 351813 July August September October November December 9573 9766 9809 13172 13838 9449 13078 11619 12495 15905 15422 11679 19779 15190 20402 23379 17693 13416 405414 360202 374846 493048 462665 362050 Total in 2012 Document1 4941504 Page 6