YEAR 2015 MSA Ltd - Minerals Supply Africa

advertisement

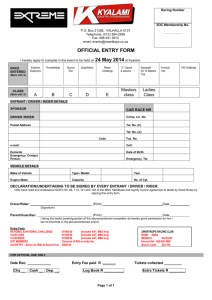

YEAR 2015 MSA Ltd (Minerals Supply Africa Ltd) DUE DILIGENCE ANNUAL REPORT This Due diligence for Responsible Supply Chain of Minerals from Conflict –Affected and High –Risk Areas report for MSA Ltd (MINERALS SUPPLY AFRICA Ltd) covers the reporting period from January 1st to December 31st, 2015. 1. MSA company overview Minerals Supply Africa (MSA) is one of the largest minerals trading company in Rwanda. The company has been established in 2008 and is dealing in Procurement, Processing and Exporting of Cassiterite (Tin), Coltan (Tantalum) and Wolfram (Tungsten) known as 3T minerals. The company is wholly owned by CRONIMET Central Africa AG (CCA). 2. Minerals supply chain The company buys minerals from mining cooperatives, mining companies and small minerals traders (comptoirs) registered and operating in Rwanda .The Company provides financial supports and technical advices to miners in order to increase the mining production of Rwanda and contribute significantly to the development of the country. MSA sources for today around 110 artisanal mining companies / cooperatives suppliers scattered in all provinces of Rwanda. 3. Due diligence MSA has appointed a Due Diligence Team which makes visits to its suppliers’ mines as requested by the OECD Model Supply Chain Policy and Due Diligence Guidance for OECD responsible Global Supply chains of Minerals from Conflict-Affected and High Risk Areas. MSA buys minerals only from mining cooperative, mining companies and small minerals traders which have mining operations in Rwanda. For this reason, when the supplier brings minerals to MSA, he has to submit a legal mining permit from Rwanda Geology and Mine department (GMD), a company registration certificate from Rwanda Development Board (RDB), original certificate registration at Rwanda Revenue Authority (RRA) showing the company Tin Number, a minerals transport log sheet indicating which mine the minerals are coming from, the type of minerals (Coltan, Cassiterite or wolfram), the weights of minerals bags, the plate number and driver of the vehicle and the route he has used; all minerals sold to MSA are iTSCi tagged. These instructions are available at Stocks and Procurement Department Office; English and Kinyarwanda language versions are available. At the same time, the supplier is given by MSA a copy of OECD Due diligence guidelines translated in local language Kinyarwanda or English version for one who prefers it. As MSA is working in Great Lakes Region area, neighboring DRC where there are still active illegal armed groups, the company has put in place a structure to conduct Due diligence activities following prioritized risk assessment to avoid conflict minerals to enter in the supply chain. Risk Assessment in the Minerals supply Chain i. iTSCi listed companies for due diligence reinforcement and incident opened by iTSCi on particular case (production reported by the company which seems to be higher than mining activities on site, misuse of tags and log books , stolen tags, selling minerals of suspicious origin related to conflict or high risk area). MSA own risk assessment: surge in production compared to regular monthly company’s supply or MSA known company production baseline. Confusion cases like companies which have been suspended by Geology and Mine Department and which resume supplying minerals. ii. iii. When a risk is identified from one of the above cases, MSA takes mitigation measures to ensure responsible supply of minerals. Those are: Communication with the supplier. Meeting with the supplier Mine visit When MSA is not satisfied by the findings from its investigations, it asks for explanation through a letter written to the supplier asking for more information on supplied production; the supplier has to reply within a deadline period of fifteen (15) days from the date on which he has received the letter. In case the supplier does not comply with those requirements or refuses to communicate back, MSA suspends temporarily working with this supplier until the issue is solved. 4. MSA Due diligence activities design MSA Due diligence Staff The Company Management has appointed a team in charge of due diligence activities on full time basis; MSA has provided to the team all means to do their job: transport, air time and accommodation for mine visits located far from Kigali etc... A senior Geologist has been hired by the company in May 2013 to reinforce the due diligence team. Monthly Due diligence meeting The company Deputy CEO holds a meeting, at the beginning of the month, with all staff involved in due diligence in order to evaluate what has been in the previous month, find together solutions to encountered difficulties related to conducted due diligence activities and talk about due diligence activities planned during the coming month. Special due diligence meetings can be hold during the month depending on specific raised risk assessment related to due diligence in minerals supplies chain or minerals traceability. Analysis of mining cooperative or mining company monthly minerals production record. MSA Minerals Stock Department sends to MSA Due diligence team every month minerals supplied production from, mining company and small minerals traders in order to do analysis of monthly supplied production from each supplier and detect any bias related to known supplier’s baseline production; this may be noticeable surge or depletion in relation with previous month’s supply; such cases are investigated during due diligence mine visit. Follow up of iTSCi monthly report of listed companies for due diligence reinforcement for MSA suppliers. Incident reports on possible anomalies in minerals traceability chain by iTSCi and other institutions, stolen tags for example. Verbal communication with the supplier when a risk is identified. Writing to the supplier about identified risk. Meeting with the supplier when a risk is identified. Mine visit to the site when a risk has been identified. Sharing the results of meetings and mine visits with, first MSA other Departments and MSA stakeholders: Minerals suppliers, iTSCi and GMD. 5. Summary of MSA Risk management plan to avoid minerals from conflictaffected and high risk areas entering in the supply chain. SN Due diligence risk assessment 1 Untagged minerals 2 Unknown origin: Tagged minerals without minerals transport sheet showing route from mining site in Rwanda to MSA, 3 Illegal company: no GMD mining permit , no company registration certificate by Rwanda Development Board (RDB) , no registration certificate at Rwanda Revenue Authority (RRA) showing company TIN number 4 Suspended company by GMD for any reason Due diligence measure to perform Not buying 5 MSA Due diligence team mine visit Company listed by iTSCi for due diligence reinforcement in his monthly report, after mine visit Not buying Mitigation measures to take None, refused minerals and inform GMD / iTSCi. None refused minerals and inform GMD / iTSCi. Not buying None, refused minerals Not buying None, refused minerals Recorded production not matching with realities on ground (small number of Writing explanation letter to company Management with a deadline to reply within a period of fifteen (15) days. workers, low mining activities compare to production etc…) Closed mining site 6 7 New supplier to MSA MSA own risk assessment: Surge in monthly production compare to previous supply or MSA known company month production baseline MSA Due diligence team mine visit MSA Due diligence team mine visit Stopping buying from the company until the site is reopened. Recorded production not matching with realities on ground (small number of workers, low mining activities compared to production etc…) Closed mining site Writing explanation letter to company Management with a deadline to reply within a period of fifteen days. Recorded production not matching with realities on ground (small number of workers, low mining activities compare to production etc…) Writing explanation letter to company Management with a deadline to reply within a period of fifteen days. Stop buying Closed mining site 8 9 10 Confusing situation: company supplying minerals when already suspended by GMD or when iTSCi has reduced the number of tags after mine visit ( smaller mining operation than previous visit) Whistle blowing / reports from various institutions (UN group of Experts on DRC, Civil Society, NGO’s or individuals on minerals traceability irregularities. Miners working conditions MSA team mine visit Stopping buying from the company until the site is reopened and gets minerals tags. -Writing letter to the company Management to ask explanation on high supplied volume of production. -Sharing information with iTSCi and GMD for more clarifications. Cross checking the information through other people / reports on these allegations by : -communicating verbally / writing with the supplier. -Field mine visit. Reacting according to the findings of the due diligence action taken: -verbal or written explanations to the supplier. -suspension of buying minerals from the supplier in serious breaching of minerals traceability regulations. Child labor ( mine worker under 18 years old) Temporarily suspend to buy minerals until the issue is solved. Personnel Protection Equipment (PPE): overalls, rain boots, helmets etc…) Asking the company to provide PPE to all his mine workers. Working in high risk mine safety conditions: unstable high walls, none supported tunnels and mine shafts, hanging unstable rocks. Verbal warning to the company and ask to make the mine safer. Mine workers not affiliated to insurance company Verbal warning to the company on issue and asking to affiliate his workers as soon as possible. 11 Environment Destroying environment when mining (washing in streams, cutting trees, land degradation etc…) Verbal warning to the company and asking to remediate to the situation. 12 Small minerals buyers supplying to MSA (comptoir) Visiting comptoirs at their working place to check if they have : Ministry of trade permit to buy minerals in Rwanda Company registration by RDB Not buying from unauthorized and none registered comptoir. Types of paid taxes Asking on iTSCi membership of the “comptoirs” Employees working conditions (no child labor, health and safety etc…) If not done: Warning the company to remediate to the situation. If the “comptoir” has a conflict minerals policy and a Risk management plan documents. Asking the “comptoir” to give to MSA copies of Due diligence mine visit reports on “comptoirs” suppliers. If not done, writing letter to the “comptoir” asking him to do Due diligence to his suppliers and give copies of reports to MSA within one month deadline period. “Comptoir”: local minerals trader 6. Independent third party audit SYNERGY Company audited MSA from 07 to 09 July Year 2014 for the period from July 2013 to July 2014 under consultancy of ITRI; audit report has been already released and no major incident was raised by SYNERGY. 7. Participation to local and international stakeholder discussions -MSA staff in charge of Due diligence has participated to the OECD workshop organized in Kigali from 31st July to 1st August 2015 by OECD Staff in partnership with the Government of Rwanda on “OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas”.. -Two MSA staffs , one from “Due diligence Department” and MSA –GMD Liaison Officer have participated to ICGLR1 workshop on “Regional Certification Mechanism (RCM) and ICGL Minerals Export Certificate” organized conjointly by Partnership Canada (PAC), ICGLR Certification Unit and GMD from 29th September to 30th September 2015. -MSA CEO, David Bensusan participated to OECD meeting in Paris in 2012, MSA CEO and MSA Deputy CEO participated to OECD meeting hold in Kigali in 2013. MSA CEO has also attended OECD meeting on 3 – 5 November 2014 in Kinshasa. MSA CEO and Deputy CEO have also attended OECD meeting on 4 – 6 May 2015 in Paris. 8. Monitoring MSA suppliers -MSA compiles an excel sheet of monthly supplied minerals production for each supplier for each item of the 3T’s minerals; this enables easy follow up and monitoring of the production of each supplier. -MSA Due diligence team does, on regular basis, field mine visits and produces mine visits reports shared with MSA stakeholders (iTSCi, GMD, Suppliers etc...). 1 ICGLR: International Conference on Great Lakes Region; this institution has a Minerals Certification Unit responsible for minerals traceability designed to work in alignment with iTSCi. MSA Management and MSA Due Diligence team hold meetings and communicate regularly with suppliers by phone calls and written communications. 9. Sharing data and information on supply chain with MSA customers and protection of MSA supplier’s business information. Reports of monthly minerals purchases volumes are send to different MSA Departments (Due diligence, Marketing and Finance), Rwanda Geology and Mines Department (GMD) at the Ministry of Natural Resources, and to iTSCi local office in Kigali. Copies of monthly reports of due diligence mine visits done by MSA Due diligence team are transmitted to iTSCI local Office in Kigali for mining companies listed by iTSCi for further discussions. Due diligence mine visits reports are published on MSA web site with confidential information blanked, the link is http://www.msaltd.net/media/news The Deputy CEO holds every month a Due diligence meeting with MSA Due diligence team, Marketing Department and Administration Department; the conclusions of the meeting are communicated to other MSA Departments; minutes of the meeting are filed. Every new supplier to MSA receives a copy of OECD guidance document translated in Kinyarwanda; he signs a proof of reception form which is filed. Any other incident or suspicious case is shared with other stakeholders (stolen tags, confusing cases etc…) 10. Analysis of 2015 Due diligence actions and mitigation measures taken. All suppliers to MSA brought tagged minerals from mining companies / cooperatives registered at Rwanda Development Board (RDB), and have mining licenses issued by Rwanda Geology and Mining Department (GMD); all suppliers operate on Rwanda territory. MSA Due diligence team has designed a due diligence template for mining companies and cooperative and for “comptoirs” to use during company mine visit. Since October 2014, MSA Due diligence team is using iTSCi production plausibility template. The due diligence team does regular mine visits according to a planned schedule based in first priority to iTSCi listed companies for due diligence reinforcement, MSA own risk assessment related to irregularities in supply like surge in production or confusing situations. The list of the mining companies to be visited is communicated to MSA Deputy CEO every Friday for the following week with explanation on reasons motivating those due diligence mine visits. Due diligence mine visit reports are transmitted to the Deputy CEO by email with copies to Geology and Mine Department (GMD) and iTSCi; the major findings of these reports are also shared with other MSA Department (Stocks / Minerals Procurement, Operations and Marketing). During Year 2015: In addition to regular check and analysis of Chain of Custody documents like MSA monthly supply production records for each supplier, ITRI / iTSCi Minerals Traceability documents issued to each supplier (tags and log book sheets), iTSCi Team monthly reports for due diligence recommendations on visited sites, UN group of Experts on DRC reports, Rwanda Geology and Mines Departments / Mines Inspection Unit visits reports related to negative issues on ongoing mining operations ( suspension of some mine sites), MSA Due diligence has visited twelve ( 12 ) new companies apart from companies visited in previous Year of 2014 where due diligence actions were mostly monitoring of the progress of supplied production. In 2015, MSA stopped buying temporarily minerals from eight (8) suppliers for serious irregularities about minerals traceability issues. In 2015, MSA wrote explanation letters to seven (7) supplies asking clarification on surge in production supplied and letters to Three (3) minerals traders “comptoirs” suppliers reminding them to send copies of due diligence mine visit done on mines sites of their suppliers; one comptoir reacted positively and sent copies of Due diligence to MSA and two others stopped supplying minerals to MSA. Although all the mining suppliers to which MSA sent letters did not reply, three of them got their minerals tags and logbooks removed by ITRI / iTSCi because the mining conditions on site did not improve during the following mine visit by ITRI; two companies were later removed from the due diligence list because there was improvement on their mining sites and one company stopped supplying minerals to MSA. 11. Summary of detailed Due diligence actions (mine visits / meetings and communication by writing) and mitigation measures taken during Year 2015. This part of the report refers to due diligence action and mitigation measures taken for every individual supplier mentioned in Section 10 of this report. It contains confidential information such as suppliers’ names and business relations / communications with them which could not be made public; nevertheless the detailed report containing this section is available at MSA Office and is ready for consultation following a request addressed to MSA Management.