Revised-Supplementary materials

advertisement

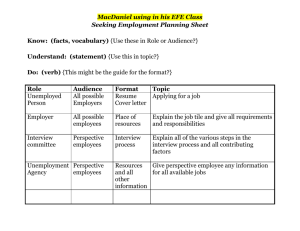

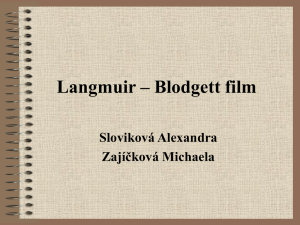

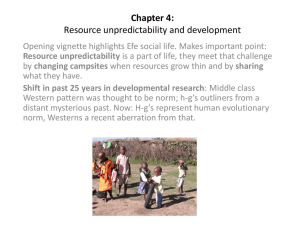

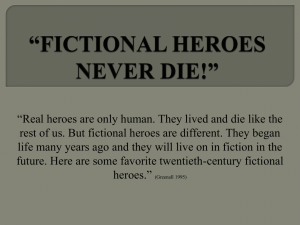

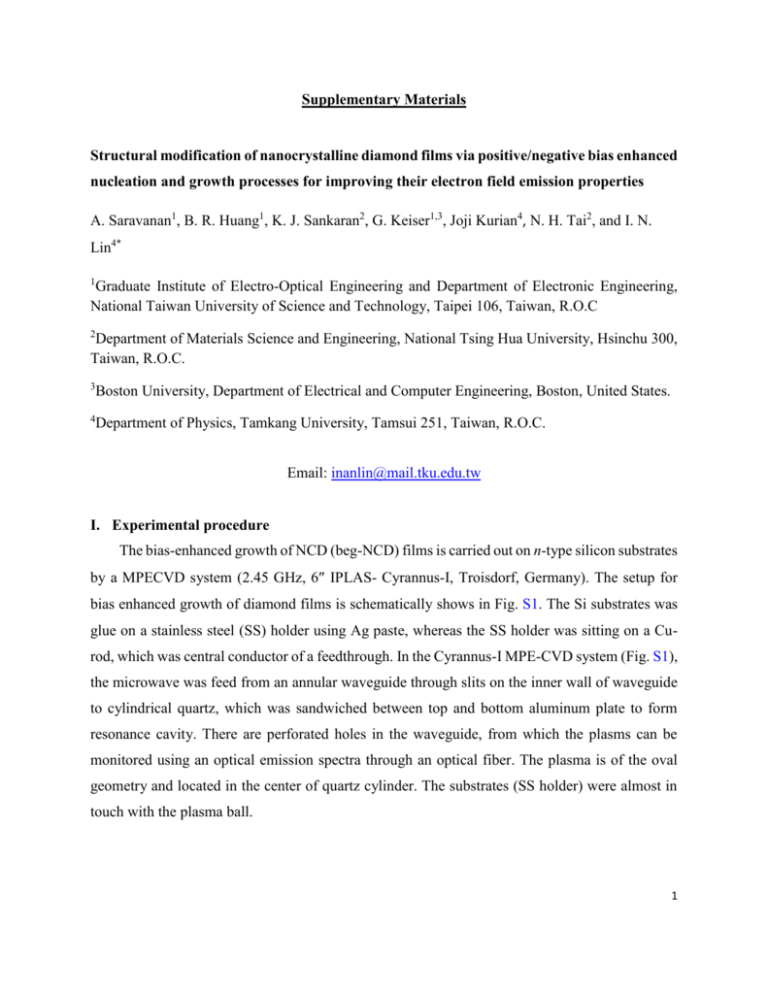

Supplementary Materials Structural modification of nanocrystalline diamond films via positive/negative bias enhanced nucleation and growth processes for improving their electron field emission properties A. Saravanan1, B. R. Huang1, K. J. Sankaran2, G. Keiser1,3, Joji Kurian4, N. H. Tai2, and I. N. Lin4* 1 Graduate Institute of Electro-Optical Engineering and Department of Electronic Engineering, National Taiwan University of Science and Technology, Taipei 106, Taiwan, R.O.C 2 Department of Materials Science and Engineering, National Tsing Hua University, Hsinchu 300, Taiwan, R.O.C. 3 Boston University, Department of Electrical and Computer Engineering, Boston, United States. 4 Department of Physics, Tamkang University, Tamsui 251, Taiwan, R.O.C. Email: inanlin@mail.tku.edu.tw I. Experimental procedure The bias-enhanced growth of NCD (beg-NCD) films is carried out on n-type silicon substrates by a MPECVD system (2.45 GHz, 6 IPLAS- Cyrannus-I, Troisdorf, Germany). The setup for bias enhanced growth of diamond films is schematically shows in Fig. S1. The Si substrates was glue on a stainless steel (SS) holder using Ag paste, whereas the SS holder was sitting on a Curod, which was central conductor of a feedthrough. In the Cyrannus-I MPE-CVD system (Fig. S1), the microwave was feed from an annular waveguide through slits on the inner wall of waveguide to cylindrical quartz, which was sandwiched between top and bottom aluminum plate to form resonance cavity. There are perforated holes in the waveguide, from which the plasms can be monitored using an optical emission spectra through an optical fiber. The plasma is of the oval geometry and located in the center of quartz cylinder. The substrates (SS holder) were almost in touch with the plasma ball. 1 Fig. S1 The feedthrough for biasing the Si substrates and the cyrannus-1 MPE-CVD system. II. Display application of the EFE emitters To demonstrate the effect of EFE properties of beg-NCD-300V and beg-NCD+200V films on the performance of field emission display, the EFE behavior of these films were measured using a parallel-plate setup, which used phosphor/ITO-coated glass as anode (with 125 m Teflon as spacer). Figs. S2 (a) and S2(b) shows the corresponding J-E curves of beg-NCD-300V and begNCD+200V films measured using ITO glass as anode, indicating that the turn-on field is (E0)-300V= 3.6 V/m and (E0)+200V= 11.4 V/m, respectively. Inset in Fig. S2(a) shows that the devices using the beg-NCD-300V films as cathode can be triggered by a voltage as low as 390 V. The EFE image is rather uniform when the applied field is sufficiently large. From these EFE images, it can be seen that the increase in EFE current density (Jefe) is mostly due to the increase in emission site density. The increase in emission current in each sites also contribute to the Jefe-value, but the contribution is much less. Actually, the EFE images cannot clearly resolve the contribution of the two processes. In contrast, for those using beg-NCD+200V films as cathode need higher voltage to trigger the emission around 480 V (inset, Fig. S2 (b)). The devices still show discrete emission spots even at large applied field. 2 Fig. S2 The field emission display images of a setup, which used (a) beg-NCD-300V and (b) beg-NCD200V films as cathode and phosphor/ITO coated glass as anode. The insets show the Jefe-E curves of the corresponding beg-NCD films. Additionally the reproducibility of the EFE behavior of beg-NCD-300V films were tested by measuring the J-E curves at different locations for the films (in Cu-rod anode setup). Fig. S3 shows that J-E curves changed slightly among the locations. The average turn-on field for the EFE process is (E0)-300V=4.26 V/m with the EFE current density achieved (Je)-300V=1.30 mA/cm2 and best turned on value achieved at (E0)-300V=3.92 V/m with current density of 1.51 mA/cm2. These results demonstrate that the EFE behaviors of beg-NCD-300V films are repeatable. Fig. S3 The EFE properties of beg-NCD-300V films measured with phosphor/ITO-coated glass as cathode and Teflon as spacer. 3 III. Procedure for estimating the electron temperature The electron temperature (Te) of the CH4/Ar/H2 plasma can be projected from the Optical emission spectra (OES), using the Boltzmann plots, log (np/gp) versus Ep plot, here Ep is the energy of p level=14.67, gp is the parity=3 and np is absolute populations of the different atomic levels of argon. The np values calculated from OES intensity from the equation (1) obtained from Garcia et al.1 I hc Apq pq n p ------------------------------- (1) 4 To calculate np: The typical wavelength () of the Ar line in CH4/Ar plasma is taken as 434.5 nm. The peak intensity value of the particular Ar line at 434.5 nm I=2321. Apq is the coefficient for spontaneous emission from level p to level q, i.e., Apq=0.0302. pq is the escape factor of this transition, i.e., pq =1, h is the Plank’s constant and c is the light velocity. By substituting all the values in the equation (1), we obtained the np value is 2.081 x 1016. Followed by, we calculated np/gp= 6.936 x 1015 and log (np/gp)=15.84. The log (np/gp) value calculated here is obtained from a particular wavelength of an Ar line in CH4/Ar/H2 plasma. Later we plotted the log (np/gp) versus Ep by calculating more np values using different wavelengths of the Ar lines in CH4/Ar/H2 plasma. Finally, the slope of the log (np/gp) versus Ep plot in Fig. S4 is calculated which gives the electron temperature (Te) value as 30,776 K. 1 M. C. Garcia, A. Rodero, A. Sola, and A. Gamero, Spectrochim. Acta B. 55, 1733 (2000). 4 Fig. S4. The slope of the log (np/gp) versus Ep plot. 5