Student Life Center Sustainability Features The Fort Lewis College

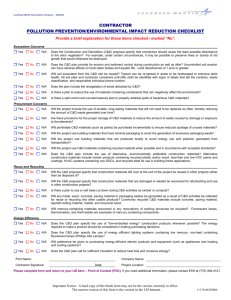

advertisement

Student Life Center Sustainability Features The Fort Lewis College Student Life Center is a wonderful example of sustainable design, as can be seen by the many sustainable features throughout the building. The materials were carefully selected and play a significant role in resource and energy efficiency. A high level of student interest was the motivating force behind the inclusion of environmental issues in the buildings agenda. Each room in which sustainable aspects were included has a plaque identifying the components that contain sustainable qualities. Benches- The locker room benches are made from milk cartons, recycled woods, and waxed cardboards. The benches are very durable, can be recycled after their use, and are water resistant. Carpet-The carpet has a recycled content of at least 50% and can be 100% recycled at the end of its useful life. The adhesive system (backing) is made from 100% recycled material that is a water based substance. The wall base is also carpet, which is more durable, easier to maintain, and recyclable. Ceiling- The designers chose not to complete the inside of the ceiling structure, resulting in fewer costs for unnecessary material. The light colored paint makes the ceiling highly resource and energy efficient because natural light is diffused through the ceiling members and into space below. Counterparts/Particle Board- The soybean bio-composite countertops are 100% recycled. This product is made from mainly newspaper and agricultural waste. These ingredients are renewable and plentiful. The particle board is more durable than plastic or stone. There are no formaldehydes or other toxic compounds in the material. Day lighting- Angling the building so as to utilize the most daylight was the leading factor in sustainability and energy efficiency. Controlling the east, west, and south daylight with the high glazed windows allows natural light to enter the gallery hallway. This is an energy efficient feature due to the reduction of electricity and utility costs used during the day time. The long axis of the building allows maximum use of north and south day light. Floor- The floor is highly resource efficient because the concrete has been stained instead of adding more material. The sheet product is 100% recycled rubber and has vinyl chips and a mica additive for reflective and abrasive purposes. The durable product is 100% recycled and has a long life span. Water based pigments were used which are less toxic and help indoor air quality. Glazing- Glass glazing is a key element in day lighting and the energy efficiency design for the building. The glass is coated with a high performance compound that emits wave lengths of visible light, but not most infrared light. This glass glazing helps block the heat of daylight, while still allowing natural light into the building. Landscape- The diversity of these plants helps reduce water use. The plants are local to our arid location. These species require less fertilizer, less maintenance and no mowing. The plants help attract local animal species, and balance the local pest problem. Using native species helps to restore the natural environment. Lighting fixtures- Indirect light is used to create an even distribution of light. The fixtures are aimed upward, causing light to bounce off of the ceiling to create this illumination. Masonry- Masonry is the stonework and brickwork throughout the building. It is a local product which reduces pollution from transportation. The product is resource efficient because it helps keep the building cool on hot days and stores the suns heat during the cold winter. Millwork- Millwork is fabricated architectural woodwork. The millwork is located on top of the cabinets. The material is 100% recycled from agricultural waste that would otherwise be burned. Office furniture- The office furniture is made from old furniture that has been refurbished. Using refurbished furniture means less waste overall. Paint- The light colored paint is less toxic than latex paint and it keeps the environment cleaner by using fewer chemicals. There is a low volatile organic chemical (VOC’s) count it the paint. VOC’s are proven irritants to the respiratory track and adversely affect indoor air quality. Rubber- The rubber is a post industrial recycled product, which means that the rubber came from industrial waste that was recycled into a useful product. The recycled rubber used for the track is made from many recycled products such as: water bottles, tires, and plungers. The backing is made of 90% minerals. There are no solvents, mineral fibers, fluorocarbons, formaldehydes, lead, mercury, metals, or pigments in the floor. The floor can be recycled at the end of its useful life. Recycling Bins- The bins are constructed of recycled panel board and particle board. The building has its own recycling costs built into the buildings operations. Steel and Metal- The recycled content in the steel ranges from 60% to 95% throughout the building. Steel and other metals were used because they are very durable materials, with a high recycled content and are completely recyclable. Wall Tile- The tile contains 55% recycled glass and other selected ceramics. Wood- The wood is harvested from certified sustainable managed forests. This means that companies selected trees and/or replanted trees to reduce the impact of our ecosystem. This kind of floor is called number three flooring. It is better environmentally due to its diversity on color and grain variation. Number three flooring uses wood that would otherwise be wasted. There are layers of plywood underneath the floor that enable it to bounce and provide a cushion. The plywood pieces have a strip of 95% recycled rubber attached for its resilient quality.