LOCAL MODIFICATION OF HARDNESS IN FeCu ALLOYS

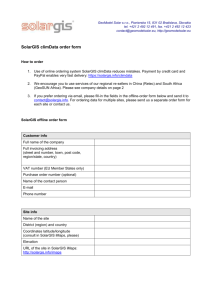

advertisement

年報原稿見本(テンプレート) 0.0 Hardness modification in FeCu alloys by using radiation enhanced segregation 右肩数字:著者代表、連名者の全員に付記 1 2 3 Y. Yamanaka , N. Kawanaka and W. Kaihara し、脚注所属機関名と対応させること。 When supersaturated alloys are irradiated with high energy particles, point defects are produced and they enhance the diffusion of supersaturated atoms and their segregation. This phenomenon is called radiation enhanced segregation. This segregation under irradiation leads to some changes in structures and properties of alloys. For Fe-based Cu alloys, as Cu-precipitates act as obstacles against the dislocation motion, energetic particle irradiation causes the increase in hardness of the alloys. The amount of hardness increase in FeCu alloys depends on irradiation dose, dose rate, irradiation temperature and so on [1,2]. Therefore, there exist some possibilities of local modification of structures and properties of supersaturated alloys using the radiation enhanced segregation because the segregation of supersaturated atoms is expected to occur only in the irradiated region. In this study, we use the swift heavy ion irradiation for the local modification of hardness in FeCu alloys [3]. A supersaturated alloy, Fe-1.2 wt.% Cu was selected for this experiment. Specimens were solution-annealed at 850 °C and then were quenched into the water. In this process, Cu atoms were dissolved supersaturatedly in the matrix. The specimens were irradiated at 250 °C with 200 MeV Au and 著者/連名者は目次原稿見本と併せるため架空の著者/連名者に変更されていま Xe ions using a 20 MV tandem accelerator at JAEA-Tokai. During the 。 irradiation, about a half area of each す。実際は以下の通りでした(ただし右肩の数字は消してある) specimen was covered with, F.aHorii, thick copper plate M. to Kitagawa, produceR. aOshima, straight boundary of irradiated and S. Nakagawa Y. Chimi, N. Ishikawa, unirradiated regions. For some specimens, masking plate T. Tobita, R. Taniguchi, M. Suzuki and A.with Iwasea circular hole was put on each specimen during the irradiation, which restricted the ion-irradiation to the circular region. Changing loads and indents intervals, Vickers microhardness was measured near the boundary of irradiated and unirradiated regions after the irradiation. Using the result of some experiments, we determined the suitable conditions for the two-dimensional mapping of hardness change in the specimens which had been covered with a masking plate with a circular hole during irradiation. Figure 1 shows the indent-depth dependence of the change in Vickers microhardness for Fe-1.2 wt.% Cu specimens irradiated with Xe and Au ions to the fluence of 11013/cm2 at 250 °C. The data for an unirradiated specimen is also plotted. The Vickers microhardness for unirradiated specimen does not depend on the indent depth, meaning that the hardness is constant over the observed depth. For the irradiated specimens, the hardness decreases monotonically with increasing indent depth. This result indicates that the hardness only near the surface layer about several – several tens m thick increases by the irradiation. Next, we discuss the hardness change in Xe-irradiated specimens near the boundary of the work-hardening. Fig. 2 shows the relationship between Vickers microhardness and the measuring positions for the combination of applied load 50 gf and indentation interval 0.25 mm. For several elements, ionized 1 Japan Atomic Energy Agency (JAEA) X Y University 3 Z Z Institute 2 with a surface ionization ion source(SIS) and/or a Forced Electron Beam Induced Arc-Discharge (FEBIAD) type ion source, are shown in Table 1. 220 50gf Vickerss Hardness(Hv) Vickers hardness (Hv) 200 180 160 140 120 100 80 160 Au Xe Unirradiated 0 5 10 15 20 25 Indent depth (m) 30 35 Fig. 1 Indent-depth dependence of Vickers microhardness for 200 MeV Xe irradiation and 200 MeV Au irradiation. 150 140 Unirradiated Irradiated 130 120 110 1 2 3 4 5 6 7 Position (Interval:0.25mm) Fig. 2 Vickers microhardness measured ranging over the irradiated and unirradiated regions at a regular interval. Table 1. Release times and fractional rates deduced from the one and/or two exponential fit to the release data. Isotope Ion source half-life/s Release time/s Fractional rate Literature 94Rb 136mCs SIS SIS 2.072 17 1: 1.1 84% 3.2 s[2], 8.2 s[3], 2: 10.7 16% 0.8 s 1: 1.7 30% 2.5 s[2], 21.6 s 2: 22.7 70% 145Ba SIS 4.3 1: 9 100% 160Eu SIS 38 1: 12 100% 91Kr FEBIAD 5.98 1: 3.1 21% 2: 46.9 79% 123gIn FEBIAD SIS 39.68 8 10.3 s, 107 s[3] 2.2 s, 3.5 s 1: 7 100% 2.5 s, 8.7 s 1: 1.7@2250℃ 100% 6.2 s, 2.3 s, 1.6 s[3] References [1] T. Yamada, I. Suzuki and N. Kawakami, J. Nucl. Mater., 123 (2050) 267-270. [2] T. Yamada et al., J. Nucl. Mater., 456 (2051) 153-160. [3] N. Kawakami et al., Nucl. Instrum. Methods Phys. Res., B257 (2007) 397-401.