Supporting Information APLXMS L14-05264

advertisement

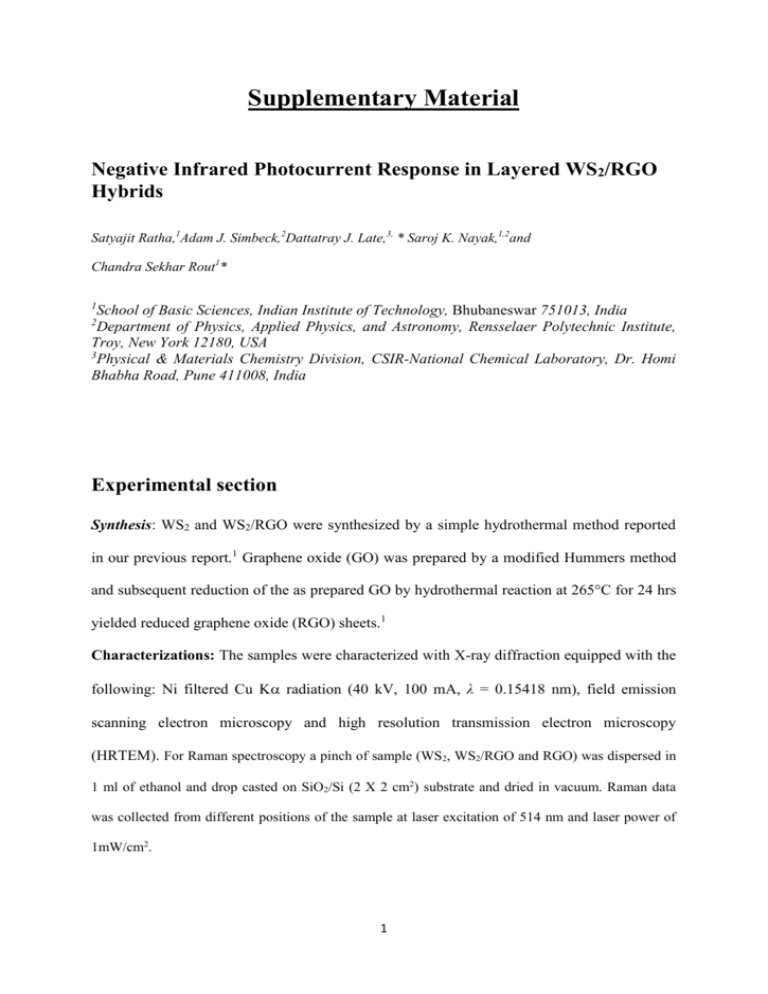

Supplementary Material Negative Infrared Photocurrent Response in Layered WS2/RGO Hybrids Satyajit Ratha,1Adam J. Simbeck,2Dattatray J. Late,3, * Saroj K. Nayak,1,2and Chandra Sekhar Rout1* 1 School of Basic Sciences, Indian Institute of Technology, Bhubaneswar 751013, India Department of Physics, Applied Physics, and Astronomy, Rensselaer Polytechnic Institute, Troy, New York 12180, USA 3 Physical & Materials Chemistry Division, CSIR-National Chemical Laboratory, Dr. Homi Bhabha Road, Pune 411008, India 2 Experimental section Synthesis: WS2 and WS2/RGO were synthesized by a simple hydrothermal method reported in our previous report.1 Graphene oxide (GO) was prepared by a modified Hummers method and subsequent reduction of the as prepared GO by hydrothermal reaction at 265°C for 24 hrs yielded reduced graphene oxide (RGO) sheets.1 Characterizations: The samples were characterized with X-ray diffraction equipped with the following: Ni filtered Cu K radiation (40 kV, 100 mA, λ = 0.15418 nm), field emission scanning electron microscopy and high resolution transmission electron microscopy (HRTEM). For Raman spectroscopy a pinch of sample (WS2, WS2/RGO and RGO) was dispersed in 1 ml of ethanol and drop casted on SiO2/Si (2 X 2 cm2) substrate and dried in vacuum. Raman data was collected from different positions of the sample at laser excitation of 514 nm and laser power of 1mW/cm2. 1 For the growth and nucleation of WS2 sheets on graphene oxide, numerous active edges and functional groups in the basal plane of graphene play an important role.1 During hydrothermal reaction, the tungsten precursor is reduced to form WS2 and graphene oxide reduces to form RGO.1 Fig. S1a and S1b show low and high magnification FESEM images of WS2/RGO sheets. FESEM images revealed uniform coverage of WS2 on RGO without agglomeration. The XRD pattern (Fig. S1c) of the WS2/RGO hybrid shows an intense (002) peak confirming the formation of multilayered WS2 sheets on the RGO surface grown along the (002) direction. Fig. S1d shows the Raman spectra of WS2/RGO hybrids, which depicts FIG S1. (a) Low and (b) high magnification FESEM images, (c) XRD pattern and (d) Raman spectrum of the WS2/RGO hybrid. 2 the characteristic spectra of WS2 and the D (1348 cm-1) and G (1587 cm-1) bands of RGO. The Raman spectra also reveals two prominent first-order modes at 350 cm-1, which corresponds to the E12g in-plane vibration of WS2, and another mode A1g at 415 cm-1 corresponding to out-of-plane vibration.1,2 Another first-order mode LA (M) appears at 175 cm-1, revealing the effect of longitudinal acoustic phonons,1 and also overlaps with the A1g mode at 582 cm-1.3 Few other second-order modes, like 2LA (M) at 323 cm-1 and 4LA (M) at 702 cm-1, appear in the spectrum.3 The Raman data is consistent with the previously reported data,1,3 confirming the presence of WS2 layers on RGO. FIG S2. (a) Low and (b) high magnification TEM images of WS2/RGO showing uniform decoration of WS2 nanosheets on RGO. (c, d) HRTEM images of WS2/RGO and inset of (d) shows the hexagonal symmetry of the WS2 sheets. 3 Fig. S2a and S2b show low and high magnification TEM images of WS2/RGO sheets which clearly indicate that the WS2 nanosheets are uniformly coated on the reduced graphene oxide layer. HRTEM images (Fig. S2c and Fig. S2d) reveal the formation of thin layered WS2 on RGO having hexagonal symmetry. The arrows show the growth of the (100) plane of WS2 and the presence of graphene is indicated. Fabrication of the device: The device was fabricated on a SiO2/Si substrate as shown in the schematic in Fig. 3a. The 2 x 2 cm2 size SiO2/Si substrates were cleaned in an ultrasonic cleaner for 30 min and then the substrates were washed with acetone and de-ionized (DI) water and finally vacuum dried. For sample deposition, 10 mg of WS2/RGO sheets were added to 2 ml of ethanol (C2H5OH) and sonicated in an ice bath for about 10-12 hrs and then allowed to settle down for 2-3 days. The dispersed solution was centrifuged at 4000 RPM for 30 minutes and the excess precipitates were discarded. Then the uniformly dispersed sample was spin coated onto the SiO2/Si substrate using a spin coater at 2000 RPM for 2 min and dried in a vacuum desiccator overnight. For the metal electrodes, Ti/Au (~10/100 nm) was deposited on the sample by using a mask capable of producing a gap electrode of ~100 µm by the physical vapor deposition technique. Copper wires having a diameter of ~0.15 mm were connected to the metal electrodes by using silver (Ag) paste to facilitate electrical connectivity of the fabricated device. Before connecting the Cu wires, the enamel coatings around them were removed by dipping them in 1, 2-dichloroethane/ethylene dichloride (EDC) solvent. Finally, the fabricated device was left in a vacuum desiccator overnight for drying. The above fabrication method was repeated in the cases of WS2 and RGO. All the fabricated devices were separately fixed onto individual glass slides by using double-sided sticky tape and were kept inside three separate petri dishes to secure them. The copper wires were brought out to facilitate electrical connection. The open ends of the copper wires were soldered onto oxygen free copper foils (thickness ~0.6 mm) and the devices were connected to the Agilent B1500A and potentiostat/galvanostat by using a pair of crocodile clips for the electrical measurements. 4 The IR source (808 nm Laser diode Module, Shanghai Dream Laser Technology Co. Ltd) was kept on for about 5-10 minutes prior to the measurements. A burette stand with burette clamp arrangements was made to hold the IR source about 5-6 cm above the device in order to minimize broadening of the emitted beam and all the experiments were performed in a near dark environment to isolate the samples from the effect of any stray light source. The I-V measurements were performed by sweeping the voltage from +4 V to -4 V in dark as well as under illuminated conditions. The I-t measurements were carried out by fixing the potential at a constant value of +4 V. FIG. S3: Surface profilometry showing the thicknesses of the samples deposited by spin coating on SiO2/Si substrate. (a) RGO sample showed a thickness of ~16.5 μm, whereas (b) WS2 and (c) WS2/RGO showed thickness values of ~4.5 μm and 2.5 μm respectively. 5 0.0055 (a) 0.005 0.0050 0.0045 Current (mA) Current (mA) 0.004 (b) ON 0.003 0.002 OFF 0.001 0.000 0.0040 0.0035 0.0030 0.0025 0.0020 -0.001 0 50 100 150 200 250 300 350 Time (s) 1500 2000 2500 Time (s) 0.002 40mW/cm2 0.003 50mW/cm2 0.004 60mW/cm2 0.005 70mW/cm2 0.006 1000 (c) 80mW/cm2 Current (mA) 0.007 90mW/cm2 100mW/cm2 0.008 0.0015 500 0.001 0 250 500 750 1000 1250 1500 Time (s) FIG. S4: IR sensing properties of bare WS2 nanosheets. (a) Positive photoresponse of the pristine WS2 nanosheets at a laser intensity of 100 mW/cm2. (b) Cycling stability and (d) response of WS2 at different IR intensities. 6 3000 0.48 0.48 0.46 Current (mA) Current (mA) (b) (a) 0.46 0.44 0.42 0.40 0.38 0.44 0.42 0.40 0.36 0 50 100 150 200 0 250 500 1000 1500 2000 2500 Time (s) Time (s) 0.44 40mW/cm2 50mW/cm2 0.46 60mW/cm2 0.48 (c) 70mW/cm2 0.50 80mW/cm2 0.52 90mW/cm2 Current (mA) 0.54 100mW/cm2 0.56 0.42 0.40 200 400 600 800 1000 1200 1400 Time (s) FIG. S5: IR sensing properties of bare RGO nanosheets. (a) Positive photoresponse of the RGO nanosheets at a laser intensity of 100 mW/cm2. (b) Cycling stability and (c) response of the RGO nanosheets at different IR intensities. Computational section To model the WS2/RGO hybrid we consider the composite system of a monolayer of WS2 on graphene (Fig. 4), which shall be referred to with the abbreviation WS2/G, within first-principles density functional theory (DFT).4,5 The DFT based Vienna ab intio simulation package (VASP)6-9 was employed with the projector-augmented wave (PAW) method10,11 to describe the electron-ion interaction. The exchange-correlation energy is described using the local density approximation (LDA).12 In order to match the WS2 lattice to that of graphene, WS2 is compressively strained ~2% relative to its pristine, theoretical counterpart. This is 7 thought to be in accordance with experiment since WS2 is hydrothermally grown atop RGO. The effect of strain on both the free-standing WS2 and hybrid results is discussed more below. To begin, the pristine and strained unit cell lattice parameters and geometries are optimized until the forces on each atom are less than 0.01 eV/Å. For WS2 (graphene), a plane-wave basis energy cutoff of 400 eV (600 eV), a 12×12×1 (18×18×1) Γ-centered k-point grid, and at least 12.5 Å (10 Å) of vacuum is necessary to see convergence in the total energy on the order of 1 meV per atom. Next, the unit cells are expanded and combined to form the composite supercell: the strained WS2 unit cell by 4× and the graphene unit cell by 5× for a total of 98 atoms (32 S, 16 W, and 50 C). The geometry of the composite is then allowed to optimize until the forces on each atom are less than 0.02 eV/Å. The supercell for the hybrid system employs similar computational parameters, except the k-point sampling is reduced to a Γcentered, 6×6×1 grid. The total energy tolerance for the unit/super-cell is set at 10-4 eV and Gaussian smearing with a width of 0.05 eV is used to describe the partial occupancies of the orbitals. Since the hybrid structure is asymmetric along the direction perpendicular to the plane of the monolayers, spurious dipole interactions between periodic images have been accounted for.13 The results are accompanied by electronic structure analysis to corroborate the negative photoconductance (NPC) findings for the WS2/RGO hybrid. The strained WS2 lattice constant is taken as 3.06 Å, a ~2% compressive strain compared to the calculated optimized value of 3.12 Å. The optimized graphene lattice constant is found to be 2.45 Å. The geometry of WS2 is found to be relatively insensitive to this small amount of strain, whereas the same cannot be said of the electronic structure. For example, optimization of the pristine WS2 unit cell yields bond lengths of W-S = 2.39 Å and S-S = 3.12 Å, in agreement with previously reported DFT results,14 and in the strained cell WS = 2.37 Å and S-S = 3.18 Å. In the case of the electronic structure though, the strain is enough to modify the properties of WS2 such that the gap, which was originally direct at K (Fig. S6a), becomes indirect with the valence band maximum still appearing at K but the 8 conduction band minimum is moved to about halfway along the path from Γ to K (Fig. S6b). The compressive strain also reduces the band gap by 0.13 eV. It is pointed out here though that even for pristine WS2 the difference between the direct gap and the indirect gap as calculated from DFT-LDA is only roughly 30 meV (Figure S6a). This limited analysis of strain in WS2 highlights that the minima of the lowest conduction band are rather sensitive to changes in cell size, which is in agreement with a previous theoretical study of strain in transition metal dichalcogenides.15 Quadrupling (Quintupling) the WS2 (graphene) lattice then gives the supercell for the composite system. To combine the two monolayers, WS2 is simply placed atop graphene and the geometry of the hybrid is optimized. The stacking choice of WS2 atop graphene, where some of the W atoms of WS2 sit directly above some of the C atoms of graphene, was found to be the most energetically favorable arrangement in a previous DFT study.16 Optimization of the composite geometry leads to a WS2-graphene separation of 3.40 Å, in agreement with the assumed van der Waals type interaction between the two monolayers. Similar separations have also been previously reported in DFT studies of graphene weakly adsorbed on metals.17,18 Lastly, the bonding parameters for WS2 are found to remain intact after optimization of the composite, but a slight corrugation [at most a ±2.4% (±0.06 Å) deviation from the average plane of graphene] develops in graphene. As mentioned in the main body of the text, the electronic structure and subsequent band alignment of WS2 and the WS2/G hybrid display sensitivity to the manner in which strain is applied to the system. First we point out that in order to build the composite supercell, it is necessary to introduce strain to match the lattice of WS2 with that of graphene. Strain also allows for a more computationally tractable system in terms of the number of atoms. From an experimental standpoint it also not unreasonable to assume that strain is present in the hybrid given that WS2 is hydrothermally grown atop RGO. In light of this necessity for strain, we also present results (Table I) for the WS2/G model in which strain has 9 been included in three different approaches to build the composite: (i) apply ~2% compressive strain to WS2 only, (ii) apply ~2% tensile strain to graphene only, and (iii) split the strain equally between WS2 and graphene. From Table I it is clear that some amount of compressive strain acting on WS2 is necessary to reduce the barrier for electron diffusion (from WS2 to graphene) relative to hole diffusion. Further analysis of the role of strain in metal dichalcogenides, as well as metal dichalcogenide-graphene interfaces, is currently underway. FIG. S6: Band structure of (a) pristine and (b) ~2% compressively strained WS2. Strain switches the band gap from (a) direct at K to (b) indirect from K to roughly halfway along the line from Γ to K, and reduces the overall magnitude of the gap. System -2% WS2 -1% WS2, +1% graphene +2% graphene e- Barrier (eV) 0.77 0.90 0.99 h Barrier (eV) 1.10 1.04 1.00 Table I: Effect of strain on the electron and hole diffusion barriers. The percentages in front of the system descriptions are meant to convey the amount of compressive (negative) or tensile (positive) strain applied to each part of the system. 10 References 1. Ratha, S.; Rout, C. S. ACS Appl. Mater. Interfaces 2013, 5, 11427. 2. Huo N.; Yue, Q.; Yang, Yang; Yang, S; and Li, J, ChemPhysChem 2013, 14, 4069. 3. Berkdemir, et al. Sci. Rep. 2013 3. 4. Hohenberg, P.; Kohn, W. Phys. Rev. B 1964, 136, (3B), B864-. 5. Kohn, W.; Sham, L. J. Phys. Rev. 1965, 140, (4A), 1133. 6. Kresse, G.; Furthmuller, J. Comput. Mater. Sci. 1996, 6, (1), 15-50. 7. Kresse, G.; Furthmuller, J. Phys. Rev. B 1996, 54, 11169. 8. Kresse, G.; Hafner, J. Phys. Rev. B 1993, 47, 558. 9. Kresse, G.; Hafner, J. Phys. Rev. B 1994, 49, 14251. 10. Blochl, P. E. Phys. Rev. B 1994, 50, 17953. 11. Kresse, G.; Joubert, D. Phys. Rev. B 1999, 59, (3), 1758-1775. 12. Perdew, J. P.; Zunger, A. Phys. Rev. B 1981, 23, 5048. 13. Neugebauer, J.; Scheffler, M. Phys. Rev. B 1992, 46, (24), 16067-16080. 14. Ding, Y.; Wang, Y.; Ni, J.; Shi, L.; Shi, S.; Tang, W. Physica B-Condensed Matter 2011, 406, (11), 2254-2260. 15. Yun, W. S.; Han, S. W.; Hong, S. C.; Kim, I. G.; Lee, J. D. Phys. Rev. B 2012, 85, (3), 033305. 16. Li, S.-S.; Zhang, C.-W. J. App. Phys. 2013, 114, (18). 17. Giovannetti, G.; Khomyakov, P. A.; Brocks, G.; Karpan, V. M.; van den Brink, J.; Kelly, P. J. Phys. Rev. Lett. 2008, 101, (2), 026803. 18. Khomyakov, P. A.; Giovannetti, G.; Rusu, P. C.; Brocks, G.; van den Brink, J.; Kelly, P. J. Phys. Rev. B 2009, 79, (19), 195425. 11