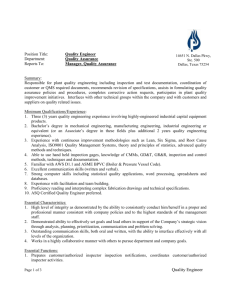

FDOT Matrix Derived from Specification A650 Effective 04/05/2012

advertisement

FDOT Matrix Derived from Specification A650 Effective 04/05/2012 Rev 2.0 FDOT Traffic Engineering Research Laboratory (TERL) Signal Head Compliance Matrix Date: Click here to enter a date. Manufacturer: Applicant’s Name (print): Item, Model No.: Signature: ID No Section Requirement The following compliance matrix criteria are for all signal heads 1 A650-1 Vehicular traffic signal assembly meets the requirements of the latest edition of the Federal Highway Administration’s (FHWA) Manual on Uniform Traffic Control Devices (MUTCD) and the Institute of Transportation Engineers (ITE) Standard for Vehicle Traffic Control Signal Heads. 2 A650-2.1 The assembly is constructed for 12-inch signal modules and is constructed of the materials and alloys specified in the current ITE Standards for Vehicular Traffic Control Signal Heads. 3 4 5 6 7 8 9 Item Comply? (Yes/No) The top and bottom opening of each signal head section includes a circular 72-tooth serrated connection (2-inch nominal I.D.) providing positive positioning and alignment of the signal head sections and the complete assembly in 5-degree increments. The connections, when completely assembled and tightened in accordance with manufacturer recommendations, prevent rotation or misalignment of the signal head as well as misalignment between sections. The serrated area starts outside of the 2-inch hole and is at least ⅛-inch wide. The teeth have a minimum depth of 3/64-inch between peaks and valleys; are well-defined, free from burrs, irregularities, or other imperfections; and provide positive locking with the grooves of mating sections, framework, and brackets. The serration on the top circular connection of a signal section has a valley at the 0-degree position, aligned perpendicular to the front of the section; the serration on the bottom circular connection has a peak at the 0-degree position, aligned perpendicular to the front of the section. Connections are such that the front of each section assembly of a multi-section signal can be aligned within one degree. Signal sections include at least two latch pads and manual stainless steel latching devices that are captive, or nonremovable. All fastening hardware, such as hinge pins, door latching devices, washers, screws, and fittings are passivated stainless steel type 316 or 304. By signing this form, the applicant declares that he/she has read and understands the provisions of Section A650 of the FDOT Minimum Specifications for Traffic Control Signals and Devices and all implemented modifications. The requirements listed on this matrix are derived from Section A650, and are the basis for determining a product’s compliance and its acceptability for use on Florida roads. Comments (Applicant must provide information as indicated) TERL Evaluation Method Provide documentation to demonstrate device meets MUTCD and ITE criteria. Indicate location of requested information in submittal. Document Review Provide documentation as evidence showing the dimensions are 12” and the device is constructed per ITE standards. Indicate location of requested information in submittal. Document Review and Physical Inspection Applicant may provide comments in this field. Physical Inspection Applicant may provide comments in this field. Physical Inspection Provide product literature, specifications, user manual,or similar information that shows the product meets this requirement. Indicate location of requested information in submittal. Provide a statement of conformance in this field. Compliance Matrix Review and Physical Inspection Provide a statement of conformance in this field. Compliance Matrix Review Physical Inspection Applicant may provide comments in this field. Provide statement of conformance from hardware supplier that shows the product meets this requirement. Indicate location of requested information in submittal. Page 1 of 4 Document Review and Physical Inspection Document Review FDOT Matrix Derived from Specification A650 Effective 04/05/2012 Rev 2.0 ID No 10 Section 11 12 13 14 15 A650-2.3 16 17 18 19 20 21 22 23 24 A650-2.4 Requirement All signal head assemblies are permanently marked with the manufacturer name, part/model number, and date of manufacture. Each signal section has four back plate mounting attachment points. Each mounting point is no more than three inches from the corner of each section. Back plate attachment points are designed to accept #10-16 x 3/8 inch or 10-24 x 3/8 inch screws. Each signal section is designed to prevent the accumulation of standing water within the assembly. All tri-stud washers are passivated stainless steel type 316 or 304; washers used between signal sections are 3/32 inch minimum thickness. Tri-stud washers used to attach the top section of a 5-section cluster assembly to the multi-signal bracket and the multi-signal bracket to the bottom four sections are a minimum of 3/8-inch thick. All sections comprising a single multi-section vehicular signal assembly are rigidly and securely fastened together forming a dust, insect, and weather-resistant unit with no distortion of the tri-stud washers. Each signal section includes at least two integral hinges, with captive hinge pins of adequate strength for mounting the door. Signal section doors can be mounted to provide either left or right swing. Door latch holds the door tightly closed and the door remains captive and secure at all times. The inside face of the door is provided with at least four stainless steel, type 316 or 304, clamps to secure the lens or signal module to the door. Item Comply? (Yes/No) Comments (Applicant must provide information as indicated) Applicant may provide comments in this field. Provide a statement of conformance in this field. Compliance Matrix Review and Physical Inspection Provide a statement of conformance in this field. Compliance Matrix Review Document Review Provide statement of conformance from hardware supplier that shows the product meets this requirement. Indicate location of requested information in submittal. Provide a statement of conformance in this field. Physical inspection Applicant may provide comments in this field. Physical inspection Applicant may provide comments in this field. Physical inspection Document Review and Physical Inspection Applicant may provide comments in this field. Physical inspection Applicant may provide comments in this field. Physical inspection Applicant may provide comments in this field. Physical inspection Provide a statement of conformance in this field. Provide a statement of conformance in this field. Applicant may provide comments in this field. Page 2 of 4 Compliance Matrix Review and Physical Inspection Applicant may provide comments in this field. Provide statement of conformance from hardware supplier that shows the product meets this requirement. Indicate location of requested information in submittal. Door includes slotted pads that allow the door to be opened and closed by engaging or disengaging the latching device. The outside face of the door includes four holes equally spaced around the circumference of the lens opening to accommodate the attachment of a visor. The outside face of the door provides a light-tight seal between the visor and the door assembly. The lens opening in the door has a diameter of 11 to 11.5 inches. The rear of the visor has four tabs, notches, or holes for securing the visor to a signal section door. The visor mounting method permits the visor to be rotated and secured at 90 degrees for horizontal signal head installations. Visors have a minimum downward tilt of 3.5 degrees measured from the center of the lens and are a minimum length of 9.5 inches. For tunnel visors, the visor encircles and shields the lens 300 degrees, plus or minus 10 degrees. If visor has louvers, visor is a full circle visor. TERL Evaluation Method Physical Inspection Compliance Matrix Review and Physical inspection Compliance Matrix Review Physical inspection FDOT Matrix Derived from Specification A650 Effective 04/05/2012 Rev 2.0 ID No 25 Section A650-2.5 Requirement Signal head sections include gaskets that provide a weatherproof seal to prevent the intrusion of dust and moisture into the signal assembly. 26 Seals are provided between the body of the signal section and door; between the lens and the door; and between any other mating surfaces where gaps might exist to eliminate intrusion of dust and moisture. 27 Where gaskets meet, they are glued or sealed, to provide one continuous length of gasket. Gasket materials meet National Electrical Manufacturers Association (NEMA) 250 and are constructed of weather-resistant material that has been temperature stabilized to prevent any residue that could collect on the internal surfaces of the signal head. 28 A650-4 Three section signal head assemblies have at least one fiveconnection terminal block; five section signal head assemblies have at least three five-connection terminal blocks. Terminal block connections do not require any tool other than a screwdriver. 29 Terminal blocks are mounted to the signal housing with passivated stainless steel type 316 or 304 hardware. Wire attachment screws used on terminal blocks are fabricated using non-corrosive material approved by FDOT-TERL. 30 A650-5.1 Housing, door, and visor are dull black (Federal Standard 595A37038) with a reflectance value not exceeding 25 percent as measured by American Society for Testing and Materials (ASTM) E1347. The following compliance matrix criteria are for polycarbonate signal housings and visors only 31 Black color is incorporated into the plastic material before molding. 32 A650-5.2 The assembly and door are molded from ultraviolet stabilized polycarbonate plastic with a minimum thickness of 0.1 ± 0.01 inches. Item Comply? (Yes/No) 33 The plastic formulation provides the following physical properties: • Specific Gravity, 1.17 minimum, ASTM D 792 • Vicat Softening Temp., °F; 305-325; ASTM D 1525 • Brittleness Temp., °F; Below -200; ASTM D 746 • Flammability, Self-extinguishing, ASTM D 635 • Tensile Strength, yield, PSI; 8500 minimum; ASTM D 638 • Elongation at yield, %; 5.5 - 8.5; ASTM D 638 • Shear, strength, yield, PSI; 5500 minimum; ASTM D 732 • Izod impact strength, ft-lb/in [notched, 1/8 inch]; 15 minimum; ASTM D 256 • Fatigue strength, PSI at 2.5 mm cycles; 950 minimum; ASTM D 671 34 Visors are constructed of the same material specified for the assembly and door. The following compliance matrix criteria are for aluminum signal housings and visors only Page 3 of 4 Comments (Applicant must provide information as indicated) Provide a statement of conformance in this field. TERL Evaluation Method Compliance Matrix Review Provide a statement of conformance in this field. Compliance Matrix Review Provide a statement of conformance in this field. Compliance Matrix Review Provide a statement of conformance in this field. Compliance Matrix Review Provide statement of conformance from hardware supplier that shows the product meets this requirement. Indicate location of requested information in submittal. Document Review Provide a statement of conformance in this field. Compliance Matrix Review Provide a statement of conformance in this field. Compliance Matrix Review Document Review and Physical Inspection Provide product literature, specifications, user manual,or similar information that shows the product meets this requirement. Indicate location of requested information in submittal. Provide product literature, specifications, user manual,or similar information that shows the product meets this requirement. Indicate location of requested information in submittal. Document Review Provide a statement of conformance in this field. Compliance Matrix Review FDOT Matrix Derived from Specification A650 Effective 04/05/2012 Rev 2.0 ID No 35 Section A650-5.3 Requirement Signal head is pretreated for painting with a base metal preparation of the entire head assembly to prevent normal deterioration by environmental conditions. Item Comply? (Yes/No) Comments (Applicant must provide information as indicated) Provide product literature, specifications, user manual,or similar information that shows the product meets this requirement. Indicate location of requested information in submittal. TERL Evaluation Method Document Review 36 Surface erosion, flaking, or oxidation will not occur within the normal life expectancy under typical installation conditions in Florida. Provide a statement of conformance in this field. Compliance Matrix Review 37 All interior and exterior surfaces of the signal head assembly, including visors, door, and housing, are powder-coated in accordance with Military Standard MIL-PRF-24712A or American Architectural Manufacturers Association-2603-02. The finish meets the requirements of ASTM D 3359, ASTM D 3363, and ASTM D 522. Provide a statement of conformance in this field. Compliance Matrix Review Provide a statement of conformance in this field. Compliance Matrix Review 38 Page 4 of 4