Biosafety Manual Template - Environmental Health & Safety

advertisement

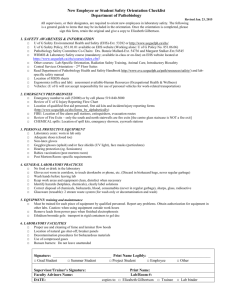

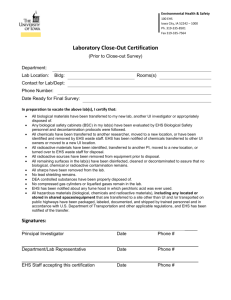

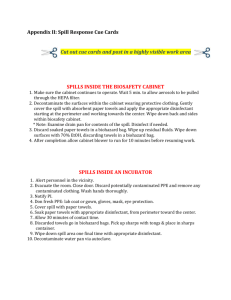

Research Compliance/EHS | 2015 BIOSAFETY MANUAL PI Name Table of Contents I. Introduction to Biosafety II. Hazard Identification/Mitigation III. Labels and Signs IV. Decontamination V. Waste Disposal VI. Transport/Shipping VII. Emergency Response VIII. Lab Map IX. IBC Application X. Exposure Control Plan (Bloodborne Pathogens: Human Materials) Appendix A. Example of a Pathogen Safety Data Sheet B. Example of Hepatitis B Vaccine Declination Form C. Example of a Sharps Injury Log 1 Research Compliance/EHS | 2015 Directions: 1. Provide the information as noted in the specific sections; 2. In addition, if your research involves the use of human/nonhuman primate materials including cell lines, fill out the Exposure Control Plan section; 3. Place the manual in a binder and make readily accessible for all lab personnel; 4. Have all lab personnel read and sign using the signatory form at the end of the document. 2 Research Compliance/EHS | 2015 I. Introduction The fundamental objective of a biosafety program is the containment of potentially harmful biological material. “Containment” is used to describe the safe methods, facilities and equipment for managing biohazardous material in the laboratory or animal facility. The purpose of containment is to reduce or eliminate exposure of personnel and the environment to this material. Biological containment is designated by 4 biosafety levels in ascending order (1 through 4) characterized by increasing levels of protection provided to personnel, the environment and the community. This manual identifies the hazards that may be encountered in this lab/facility and specifies practices and procedures designed to minimize or eliminate exposure. Routes of Transmission There are 5 main routes of transmission of biohazardous materials in the laboratory/animal facility. 1. Inhalation of aerosols: Many lab procedures can cause the aerosolization of biohazardous material. Some of these procedures include the use of vortexers, blenders, sonicators and centrifuges. Proper work practices and engineering controls must be implemented to minimize aerosolization especially of organisms whose normal route of transmission is by the aerosol route (e.g. adenovirus, Mycobacterium tuberculosis, etc.) Aerosolization can also result in environmental contamination of the work area. 2. Ingestion: Accidental ingestion can result from improper personal hygiene such as inadequate/improper hand washing. Food and drink are prohibited in all areas of the lab in which work is conducted with potentially biohazardous material due to the risk of contamination. 3. Spill/Splash: Exposures to mucous membranes and/or eyes can result from aerosols or splashes to the eyes, nose and/or mouth. 4. Percutaneous: These injuries are caused by any kind of contaminated sharp (needles, broken glass, necropsy scissors, etc.) piercing the skin. This type of injury is particularly serious because of direct inoculation into the normally sterile bloodstream. 3 Research Compliance/EHS | 2015 5. Indirect: Ingestion, mucous membrane and/or eye exposure from inadvertent inoculation by contaminated hands or contaminated items such as cell phones, ear buds, pens, etc. 4 Research Compliance/EHS | 2015 II. Hazard Identification and Control BACKGROUND: There are many hazards present in a laboratory including physical, mechanical, chemical, electrical and biological. This manual specifically addresses biological hazards but may be adapted to incorporate all hazards. Biohazards can be any of the following: 1. biological entities or products/parts of biological entities (e.g. toxins) including recombinant or synthetic nucleic acid molecules that fall under the NIH Guidelines for Research Involving Recombinant or Synthetic Nucleic Acid Molecules 2. equipment in contact with biologic entities/products 3. procedures/operations involving biologic entities/products 4. poor behaviors or practices (such as not washing hands before leaving lab). Biohazards: In order to eliminate or mitigate the risk of exposure and to educate lab personnel on the risks, it is important to first identify the most likely lab routes of exposure, the signs and symptoms of infection/intoxication, and the range of outcomes that may result from infection or intoxication (subclinical to death). Equipment: Proper use of laboratory equipment is required to work safely with hazardous materials such as chemicals and biohazards. Training on the correct use, maintenance and emergency response in the event of failure are essential for preventing accidents and possible exposure. Examples of equipment that have been implicated in laboratory-acquired infections include centrifuges, vortexers, homogenizers, sonicators, plate washers, autoclaves, shaking incubators and other pieces capable of producing aerosols or splashes. Lab Procedures/Operations: Manipulation of the biohazard can result in exposure via any of the 4 routes listed in Section I. Clearly written and validated SOPs are critical to ensure safety and the generation of sound research data. Hazardous procedures include anything that can generate an aerosol or splash as well as use of sharps. Culturing, plating, and harvesting of microorganisms are considered hazardous especially if done on the lab bench. Animal handling and inoculation activities are also increase risk of exposure to hazards. 5 Research Compliance/EHS | 2015 Lab Practices: Standard and special microbiological practices are described in Section IV of the CDC’s Biosafety in Microbiological and Biomedical Laboratories (BMBL) as well as descriptions of the four biosafety levels. Proper hand washing is the single most important infection control procedure that can be utilized in a lab or animal facility. Wash hands after removing gloves and before leaving the lab! Eating, drinking and any other manipulation around the head area is prohibited. HAZARD IDENTIFICATION AND CONTROL Identify all biohazardous material, hazardous operations and equipment present in this laboratory/facility and describe how the risk of exposure will be eliminated or mitigated by the use of the hierarchy of controls [engineering, work practice and personal protective equipment (PPE)]. 1. List all potentially biohazardous entities or products/parts including hazardous recombinant or synthetic nucleic acid material. Attach the Canadian Public Health Service Pathogen Safety Data Sheets (PSDS) for each organism if available. http://www.phac-aspc.gc.ca/lab-bio/res/psds-ftss/index-eng.php If a PSDS is not available for your biohazard, then use as a template to collect information to create your own PSDS. Be sure to include the most likely routes of transmission, signs and symptoms, and the range of outcomes from infection/intoxication. An example of a PSDS is provided in Appendix A. [INSERT] 2. List all potentially hazardous equipment (aerosol or splash generating) that will be used and describe what safety measures will be implemented using the hierarchy of controls (engineering, work practice, PPE). [INSERT] 3. List all potentially hazardous procedures/operations (aerosol or splash generating, sharps use) and describe what safety measures should be followed using the hierarchy of controls (engineering, work practice, PPE). [INSERT] 6 Research Compliance/EHS | 2015 4. The standard and special microbiological practices from the BMBL as well as the description of the biosafety level for the facility are included here as basic information. Practices specific for your lab should be described in sections 1 through 3 on the preceding pages. Biosafety Level 2 Biosafety Level 2 builds upon BSL-1. BSL-2 is suitable for work involving agents that pose moderate hazards to personnel and the environment. It differs from BSL-1 in that: 1) laboratory personnel have specific training in handling pathogenic agents and are supervised by scientists competent in handling infectious agents and associated procedures; 2) access to the laboratory is restricted when work is being conducted; and 3) all procedures in which infectious aerosols or splashes may be created are conducted in BSCs or other physical containment equipment. The following standard and special practices, safety equipment, and facility requirements apply to BSL-2. A. Standard Microbiological Practices (Applies to all 4 biosafety levels) 1. The laboratory supervisor must enforce the institutional policies that control access to the laboratory. 2. Persons must wash their hands after working with potentially hazardous materials and before leaving the laboratory. 3. Eating, drinking, smoking, handling contact lenses, applying cosmetics, and storing food for human consumption must not be permitted in laboratory areas. Food must be stored outside the laboratory area in cabinets or refrigerators designated and used for this purpose. 4. Mouth pipetting is prohibited; mechanical pipetting devices must be used. 5. Policies for the safe handling of sharps, such as needles, scalpels, pipettes, and broken glassware must be developed and implemented. Whenever practical, laboratory supervisors should adopt improved engineering and work practice controls that reduce risk of sharps injuries. Precautions, including those listed below, must always be taken with sharp items. These include: a. Careful management of needles and other sharps are of primary importance. Needles must not be bent, sheared, broken, recapped, removed from disposable syringes, or otherwise manipulated by hand before disposal. b. Used disposable needles and syringes must be carefully placed in conveniently located puncture-resistant containers used for sharps disposal. c. Non-disposable sharps must be placed in a hard walled container for transport to a processing area for decontamination, preferably by autoclaving. 7 Research Compliance/EHS | 2015 d. Broken glassware must not be handled directly. Instead, it must be removed using a brush and dustpan, tongs, or forceps. Plastic ware should be substituted for glassware whenever possible. 6. Perform all procedures to minimize the creation of splashes and/or aerosols. 7. Decontaminate work surfaces after completion of work and after any spill or splash of potentially infectious material with appropriate disinfectant. 8. Decontaminate all cultures, stocks, and other potentially infectious materials before disposal using an effective method. Depending on where the decontamination will be performed, the following methods should be used prior to transport: a. Materials to be decontaminated outside of the immediate laboratory must be placed in a durable, leak proof container and secured for transport. b. Materials to be removed from the facility for decontamination must be packed in accordance with applicable local, state, and federal regulations. 9. A sign incorporating the universal biohazard symbol must be posted at the entrance to the laboratory when infectious agents are present. Posted information must include: the laboratory’s biosafety level, the supervisor’s name (or other responsible personnel), telephone number, and required procedures for entering and exiting the laboratory. Agent information should be posted in accordance with the institutional policy. 10. An effective integrated pest management program is required. (See Appendix G.) 11. The laboratory supervisor must ensure that laboratory personnel receive appropriate training regarding their duties, the necessary precautions to prevent exposures, and exposure evaluation procedures. Personnel must receive annual updates or additional training when procedural or policy changes occur. Personal health status may impact an individual’s susceptibility to infection, ability to receive immunizations or prophylactic interventions. Therefore, all laboratory personnel and particularly women of childbearing age should be provided with information regarding immune competence and conditions that may predispose them to infection. Individuals having these conditions should be encouraged to self-identify to the institution’s healthcare provider for appropriate counseling and guidance. B. Special Practices (Specific for BSL-2) 1. All persons entering the laboratory must be advised of the potential hazards and meet specific entry/exit requirements. 2. Laboratory personnel must be provided medical surveillance, as appropriate, and offered available immunizations for agents handled or potentially present in the laboratory. 3. Each institution should consider the need for collection and storage of serum samples from at-risk personnel. 4. A laboratory-specific biosafety manual must be prepared and adopted as policy. The biosafety manual must be available and accessible. 8 Research Compliance/EHS | 2015 5. The laboratory supervisor must ensure that laboratory personnel demonstrate proficiency in standard and special microbiological practices before working with BSL-2 agents. 6. Potentially infectious materials must be placed in a durable, leak proof container during collection, handling, processing, storage, or transport within a facility. 7. Laboratory equipment should be routinely decontaminated, as well as, after spills, splashes, or other potential contamination. a. Spills involving infectious materials must be contained, decontaminated, and cleaned up by staff properly trained and equipped to work with infectious material. b. Equipment must be decontaminated before repair, maintenance, or removal from the laboratory. 8. Incidents that may result in exposure to infectious materials must be immediately evaluated and treated according to procedures described in the laboratory biosafety manual. All such incidents must be reported to the laboratory supervisor. Medical evaluation, surveillance, and treatment should be provided and appropriate records maintained. 9. Animal and plants not associated with the work being performed must not be permitted in the laboratory. 10. All procedures involving the manipulation of infectious materials that may generate an aerosol should be conducted within a BSC or other physical containment devices. C. Safety Equipment (Primary Barriers and Personal Protective Equipment) 1. Properly maintained BSCs, other appropriate personal protective equipment, or other physical containment devices must be used whenever: a. Procedures with a potential for creating infectious aerosols or splashes are conducted. These may include pipetting, centrifuging, grinding, blending, shaking, mixing, sonicating, opening containers of infectious materials, inoculating animals intranasally, and harvesting infected tissues from animals or eggs. b. High concentrations or large volumes of infectious agents are used. Such materials may be centrifuged in the open laboratory using sealed rotor heads or centrifuge safety cups. 2. Protective laboratory coats, gowns, smocks, or uniforms designated for laboratory use must be worn while working with hazardous materials. Remove protective clothing before leaving for non-laboratory areas, e.g., cafeteria, library, and administrative offices). Dispose of protective clothing appropriately, or deposit it for laundering by the institution. It is recommended that laboratory clothing not be taken home. 3. Eye and face protection (goggles, mask, face shield or other splatter guard) is used for anticipated splashes or sprays of infectious or other hazardous materials when the microorganisms must be handled outside the BSC or containment device. Eye and face protection must be disposed of with other contaminated laboratory waste or 9 Research Compliance/EHS | 2015 decontaminated before reuse. Persons who wear contact lenses in laboratories should also wear eye protection. 4. Gloves must be worn to protect hands from exposure to hazardous materials. Glove selection should be based on an appropriate risk assessment. Alternatives to latex gloves should be available. Gloves must not be worn outside the laboratory. In addition, BSL-2 laboratory workers should: a. Change gloves when contaminated, glove integrity is compromised, or when otherwise necessary. b. Remove gloves and wash hands when work with hazardous materials has been completed and before leaving the laboratory. c. Do not wash or reuse disposable gloves. Dispose of used gloves with other contaminated laboratory waste. Hand washing protocols must be rigorously followed. 5. Eye, face and respiratory protection should be used in rooms containing infected animals as determined by the risk assessment. D. Laboratory Facilities (Secondary Barriers) 1. Laboratory doors should be self-closing and have locks in accordance with the institutional policies. 2. Laboratories must have a sink for hand washing. The sink may be manually, hands-free, or automatically operated. It should be located near the exit door. 3. The laboratory should be designed so that it can be easily cleaned and decontaminated. Carpets and rugs in laboratories are not permitted. 4. Laboratory furniture must be capable of supporting anticipated loads and uses. Spaces between benches, cabinets, and equipment should be accessible for cleaning. a. Bench tops must be impervious to water and resistant to heat, organic solvents, acids, alkalis, and other chemicals. b. Chairs used in laboratory work must be covered with a non-porous material that can be easily cleaned and decontaminated with appropriate disinfectant. 5. Laboratory windows that open to the exterior are not recommended. However, if a laboratory does have windows that open to the exterior, they must be fitted with screens. 6. BSCs must be installed so that fluctuations of the room air supply and exhaust do not interfere with proper operations. BSCs should be located away from doors, windows that can be opened, heavily traveled laboratory areas, and other possible airflow disruptions. 7. Vacuum lines should be protected with liquid disinfectant traps. 8. An eyewash station must be readily available. 9. There are no specific requirements for ventilation systems. However, planning of new facilities should consider mechanical ventilation systems that provide an inward flow of air without recirculation to spaces outside of the laboratory. 10 Research Compliance/EHS | 2015 10. HEPA filtered exhaust air from a Class II BSC can be safely recirculation back into the laboratory environment if the cabinet is tested and certified at least annually and operated according to manufacturer’s recommendations. BSCs can also be connected to the laboratory exhaust system by either a thimble (canopy) connection or directly exhausted to the outside through a hard connection. Provisions to assure proper safety cabinet performance and air system operation must be verified. 11. A method for decontaminating all laboratory wastes should be available in the facility (e.g., autoclave, chemical disinfection, incineration, or other validated decontamination method). 11 Research Compliance/EHS | 2015 III. Labels and Signs A warning label that includes the universal biohazard symbol, followed by the term "biohazard," must be included on bags/containers of biohazardous waste, on bags/containers of contaminated laundry, on equipment that is used for culturing, manipulating or storing biohazardous material, and on bags/containers used to store, dispose of, transport, or ship biohazardous material (e.g., specimen containers). Typically, equipment is decontaminated by lab personnel before service or shipment. However, if contaminated equipment is to be serviced or shipped, it must have a readily observable label attached which contains the biohazard symbol and the word "biohazard" along with a statement relating which portions of the equipment remain contaminated. Some examples of the universal biohazard symbol: Other types of signage: The background must be fluorescent orange or orange-red or predominantly so, with symbols and lettering in a contrasting color. The label must be either an integral part of the container or affixed as close as feasible to the container by a string, wire, adhesive, or other method to prevent its loss or unintentional removal. Red bags or red containers may be substituted for the biohazard labels. The supervisor or PI is to be notified if items are not appropriately labeled. 12 Research Compliance/EHS | 2015 IV. Decontamination This section should describe the basic strategies for decontaminating surfaces, equipment and spaces in your facility to eliminate the possibility of transmission to lab personnel, the general public and the environment. NOTE: Recombinant and/or synthetic nucleic acid molecules as defined by the NIH Guidelines for Research Involving Recombinant or Synthetic Nucleic Acid Molecules are considered biohazardous and must be decontaminated in accordance with the Guidelines. See IBC-SOP001 for guidance. List the disinfectants that will be used for the decontamination of surfaces and equipment. Include concentration and contact (kill) time. [Insert procedure here.] Describe the procedures for handling dirty and/or contaminated lab coats. [Insert procedure here.] If the risk assessment requires the use of reusable PPE (safety goggles, face shields) describe the procedure for cleaning and decontamination. [Insert procedure here.] 13 Research Compliance/EHS | 2015 V. Waste Disposal All waste containing potentially biohazardous material must either be sterilized on site or removed by MSU’s contracted medical waste vendor. NOTE: Recombinant and/or synthetic nucleic acid molecules as defined by the NIH Guidelines for Research Involving Recombinant or Synthetic Nucleic Acid Molecules are considered biohazardous waste and must be disposed of in accordance with the Guidelines. See IBCSOP-001 for guidance. Steam sterilization using an autoclave is one of the most common methods used to render material sterile (ALL organisms including spores are destroyed). Autoclave: Any autoclave used for sterilization of potentially biohazardous material must have an autoclave verification program. Please contact the biosafety officer for details. Once a load has been confirmed as sterilized the following MUST occur: 1. Label the autoclaved red bag with a label that says “TREATED WASTE”. 2. Place the now sterile red bag into a black plastic trash bag and seal the black bag. 3. Take the trash bag containing the sterilized red bag to the nearest dumpster and carefully place inside. 4. Custodians will never handle waste from a laboratory so it is the responsibility of the lab personnel to dispose of the waste. Noninfectious Medical Waste: Noninfectious medical waste (IV bags, unused media, unused agar plates and broth tubes, etc.) must be 1. labeled “NONINFECTIOUS” 2. placed into a black plastic trash bag 3. And taken to the nearest dumpster by lab personnel. Sharps: DO NOT place any kind of sharps in a bag. All sharps, contaminated or not, must go into some kind of puncture-proof, leak-proof container. All sharps contaminated with a potential biohazard must go into a RED sharps container. Close and process for decontamination when the container is 2/3 full. Red sharps containers can be autoclaved in-house or picked by EHS for disposal by MSU’s contracted medical waste vendor. 14 Research Compliance/EHS | 2015 Untreated Waste: Untreated waste for vendor removal may be picked up by the hazardous waste officer in the Environmental Health & Safety office. Please submit a request through the EHS web site. Liquid Disinfection: Some liquids may be chemically decontaminated. If your lab will be using chemical decontamination please describe the procedure below. Please note that complete reliance should not be placed on liquid disinfection if the end result must be sterility. [Insert procedure here if applicable.] 15 Research Compliance/EHS | 2015 VI. Transport/Shipping Transport of biohazardous material from one place to another whether to the lab next door or across campus should be done under triple containment to prevent release of the material in the event of an accident. Shipping to another entity falls under a number of federal and international regulatory agencies and requires specific training. Please contact the EHS office for additional information. Triple containment is described as the primary container holding the material (test tube, agar plate, etc.,) placed into a leak-proof, shatter-proof secondary container marked with the biohazard sign which is then placed into another leak-proof, shatter-proof tertiary container. The outside of all 3 should be decontaminated with 70% ethanol (or other appropriate disinfectant) before transport and when the transfer is completed. 16 Research Compliance/EHS | 2015 VII. Emergency & Incident Response Plan Use the following procedures for guidance in developing your lab specific emergency response. NOTE: Recombinant and/or synthetic nucleic acid molecules as defined by the NIH Guidelines for Research Involving Recombinant or Synthetic Nucleic Acid Molecules are considered biohazardous and any accidents or personnel exposures must be handled in accordance with the Guidelines. This includes reporting certain types of incidents to the NIH Office of Biotechnology Activities (OBA). See IBC-SOP-001 for guidance. A. Contact Information: Name Contact Numbers Principal Investigator: Office: Cell : Alternate Contact: Office: Cell : Emergency 911 University Police 662-325-2121 Student Health Center 662-325-2431 Oktibbeha County Hospital 662-323-4320 MSU Campus Facilities Computer/Phone Problems 662-325-0631 Facilities Management 662-325-2005 EHS 662-325-3294 Research Compliance 662-325-3294 Biological Spill 662-325-3294 Radiation Spill 662-325-3294 Chemical Spill 662-325-3294 17 Research Compliance/EHS | 2015 B. Fire or Evacuation Emergency (gas leak, explosion, power outage) 1. Fire - Call 911 -Give name, location and provide information requested. Secure biohazardous agent by locking the freezer if possible. Do not endanger yourself. 2. Pull fire alarm. 3. Evacuate building – follow exit signs (see evacuation route in Section VIII); go to rally location. LIST RALLY POINT HERE. 4. The PI will call role and identify missing to emergency responder. C. Biological Spill A MINOR BIOLOGICAL SPILL is one that can be handled safely by laboratory personnel without the assistance of safety and emergency personnel. Minor spills include: The release of BSL-1 organisms without splashing or agitation The release of a small volume of BSL-2 organisms without splashing or agitation A MAJOR BIOLOGICAL SPILL is one that requires outside assistance. These include: The release of BSL-2 organisms resulting in excessive splashing and agitation The release of a large volume of BSL-2 organisms (there is enough present to seek its own level or in other words, to run to a low point) Call 325-3294 or 325-2121 after hours. Spill Response Each laboratory should have a Spill Response Plan and a Spill Kit on hand. The Spill Response Plan should be available to all personnel and contains 4 elements: the use and availability of appropriate PPE, assessments of the nature and extent of various spills, the use of appropriate disinfectants, and disposal. The kit should be maintained in a white 5-gallon leak-proof bucket and contain the following: 18 Research Compliance/EHS | 2015 Concentrated household bleach (check expiration date) or other appropriate disinfectant Spray bottle for making 10% bleach solution Forceps or tongs for handling sharps Paper towels or other suitable absorbent Biohazard bags of various sizes Disposable gloves Disposable foot covers Face protection – at a minimum safety glasses and mask Disposable apron, gown or tyvek suit Spill or Splash ton Body 1. Remove contaminated clothing. 2. Gently wash exposed area with soap and water for at least 1 minute. 3. If eye or mucous membrane exposure occurs, use eye wash per instructions. Flush for approximately 5 minutes. 4. Report spill to supervisor and BSO. 5. Obtain medical attention if necessary. Inside the Biosafety Cabinet 1. Wait at least 5 minutes to allow BSC to filter aerosols. 2. Wear lab, coat, sleeve guards, safety glasses, and gloves during clean-up. You may want to double glove in the event the outer pair becomes contaminated. 3. Allow BSC to run during clean-up. 4. Apply disinfectant for a minimum 20 minute contact time (contact time depends upon the specific disinfectant). 5. Wipe up spill with disinfectant-soaked paper towels or absorbent pillows. 6. Wipe the walls, work surfaces, inside of sash and any equipment with disinfectant-soaked paper towels. 7. Lift exhaust grill and tray and wipe all surfaces. 19 Research Compliance/EHS | 2015 8. Discard contaminated disposable materials using appropriate biohazardous waste disposal procedures. 9. Wipe down contaminated reusable items with disinfectant then place in biohazard bags or autoclave pans with lids for autoclaving. 10. Those items that are non-autoclavable should be wiped down with disinfectant and kept wet for a minimum of 20 minutes before removal from BSC. 11. Remove protective clothing when done and place in biohazard bag for autoclaving. 12. Run the BSC for 10 minutes after clean-up before reusing. 13. WASH HANDS! In the Laboratory, Outside of BSC 1. Call the BSO if a major spill. 2. Clear the room of all personnel. 3. Remove any contaminated clothing and place in biohazard bag for autoclaving. 4. Wait at least 30 minutes for aerosols to settle before reentry. 5. Put on either a Tyvek suit or disposable gown, disposable foot covers, gloves, and safety glasses. 6. Place dry paper towels on the spill then layer a second set of disinfectant-soaked towels over the spill. 7. Starting from the outside and working in, carefully soak the spill with disinfectant being careful to minimize aerosolization. 8. Decontaminate all items within the spill area. Wait at least 20 minutes contact time with the disinfectant (contact time depends upon the specific disinfectant). 9. Wipe equipment and reusable items with the disinfectant. 10. Discard contaminated disposables in biohazard bags. 11. If sharps are present, use a mechanical device such as a dust pan and brush to pick up the spill and place contaminated sharps in an approved sharps container. Inside a Centrifuge 1. Clear area of personnel. 20 Research Compliance/EHS | 2015 2. Wait at least 30 minutes for aerosols to settle before clean-up. 3. Wear a lab coat, gloves, and safety glasses during clean-up. 4. Wipe rotors and buckets with disinfectant then remove to nearest BSC for more extensive decontamination. 5. Thoroughly disinfect inside of centrifuge with a minimum contact time of 20 minutes (contact time depends upon the specific disinfectant). 6. Dispose of contaminated materials using appropriate biohazardous waste disposal procedures. Outside the Laboratory, In Transit 1. To prevent or minimize a spill, transport materials in triple containment using an unbreakable, leak-proof, sealed secondary container placed inside a tertiary unbreakable, leak-proof, sealable container. The secondary container should labeled with the universal biohazard symbol. 2. Should a spill occur in a public area, do not attempt to clean up without appropriate PPE. 3. Secure the area around the spill. 4. Call the Biosafety Office 325-0620. 5. Stand by for further assistance if required. Reporting of Accidents: Major spills and personnel exposure incidents should be reported by the PI or supervisor to the BSO. The BSO in conjunction with the IBC Chair will conduct an investigation of the laboratory accident. The goal of the investigation is to analyze the events surrounding the accident to prevent or minimize its reoccurrence and to identify those personnel involved in the event further medical surveillance is needed. Any accidents or personnel exposures involving recombinant and/or synthetic nucleic acid molecules as defined by the NIH Guidelines for Research Involving Recombinant or Synthetic Nucleic Acid Molecules must be handled in accordance with the 21 Research Compliance/EHS | 2015 Guidelines. This includes reporting certain types of incidents to the NIH Office of Biotechnology Activities (OBA). See IBC-SOP-001 for guidance. (excerpt from the NIH Guidelines: Section IV-B-2-b-(7). Reporting any significant problems with or violations of the NIH Guidelines and any significant research-related accidents or illnesses to the appropriate institutional official and NIH/OBA within 30 days. Incidents occurring under BSL-2 conditions that result in an overt exposure to organisms containing recombinant or synthetic nucleic acid molecules must be reported to NIH OBA immediately.) Please report incidents that did not result in an exposure (near miss) to the BSO. Evaluation of near misses can lead to alternative work practices and implementation of engineering controls to minimize future incidents. Sharps Injury: Whenever an injury occurs involving a contaminated sharp (needle, broken glass, etc.), the BSO must be notified. The subsequent investigation will determine if a safer device or work practice can be used to reduce or prevent the accident from reoccurring. Seek medical attention immediately for a contaminated sharps injury! D. Chemical Spill 1. Evacuate area if necessary for personal safety 2. Notify other people and supervisor 3. Take action to contain spill if properly trained. Do not endanger yourself. 4. Call-Day (8:00am-5pm) 325-2787 After hours MSU PD 325-2121 E. Radiation Spill 1. Evacuate appropriate area 2. Call Radiation Safety- Day 325-2787 Night 325-2121 3. Take action to contain spill if properly trained. Do not endanger yourself. F. Medical Emergency 1. If an individual is injured, call 911. Employees are not required to perform first aid. 22 Research Compliance/EHS | 2015 2. Notify supervisor 3. Do not move person or perform any first aid if you are not trained and qualified. G. Animal Bites 1. Clean bite thoroughly with soap and water. 2. Apply bandage 3. Notify supervisor 4. Obtain medical attention. H. Tornado or Hurricane 1. Building emergency coordinator should have an emergency weather radio. 2. Move away from windows into basement or interior hallway on a lower floor. 3. Avoid auditoriums, gymnasiums, or other areas having a wide, free span roof. 4. Take cover under heavy furniture 5. If outdoors, lie flat in the nearest depression such as a ditch or ravine. If there is time, move away from the path of the tornado/hurricane. I. Other natural disasters or emergencies In the event of some other disaster or emergency requiring evacuation, individuals in an affected space should evacuate in an orderly manner, closing the door behind them. They should assemble in a pre-determined gathering place for further instructions. The University police responders will assist in the evacuation. J. Mechanical/Facility concerns 1. Do not attempt to repair failure (e.g. burst pipe, elevator stuck, temperature, power outage, etc.,) 2. Call 325-2005 3. Give name, location, and state problem. Stay on phone until information acknowledged. 23 Research Compliance/EHS | 2015 K. Suspicious Persons Or Activities Any suspicious persons or activities must be immediately reported to MSU PD at 3252121. Do not open the laboratory door to allow any suspicious or unknown persons entry to the laboratory. L . Oral Threat 1. Oral threat spoken or called into building. 2. Record time, date and if you have caller ID note phone number. 3. Have co-worker call on another line to MSU PD 325-2121 or 911. 4. Keep caller on line as long as possible. Where is incident going to occur? When is it going to happen? Listen for background noise Listen for voice 5. Suspicious letter/package Suspicious letter or package Turn off all cell phones and pagers. Look for no return address, misspelled words in address or return, excessive postage, stains, or other visible signs. Do not shake, or move the package. Isolate letter or package Do not open or smell Immediately notify PI, and call MSU PD 325-2121 or 911. Describe letter or package, give name, location and remain calm. 24 Research Compliance/EHS | 2015 VIII. Lab Map Insert a map of the facility showing placement of safety equipment including eye wash, shower, fire extinguisher, BSC, spill kit and escape route. 25 Research Compliance/EHS | 2015 IX. IBC Application Insert a copy of the IBC application here. This document describes the risk assessment of the biohazards done by the principal investigator and is an important document for laboratory personnel. 26 Research Compliance/EHS | 2015 X. Exposure Control Plan (Bloodborne Pathogens and Human Material) There are additional requirements for personnel and environmental protection from bloodborne pathogens (BBP) that may be present in contaminated human blood and other human materials including human cell lines. This information also applies to nonhuman primate material. Mississippi State University is committed to providing a safe and healthy work environment for all staff. In pursuit of this goal, the following Exposure Control Plan (ECP) is provided to minimize or eliminate occupational exposure to bloodborne pathogens in accordance with OSHA standard 29 CFR Part 1910.1030, "Occupational Exposure to Bloodborne Pathogens”. Most of the controls used to mitigate or eliminate the risk of exposure to BBP will be found in the general biosafety manual. However, there are some topics specific to BBP that are covered in the ECP. This ECP includes the following: • Program administration • Determination of employee exposure • Universal precautions • Hepatitis B vaccination • Post-exposure evaluation and follow-up • Procedures for evaluating circumstances surrounding exposure incidents Program Administration: Please identify the person or persons who will be responsible for the following: NAME:_______________________ - Updating the ECP annually; - Providing PPE and maintaining safety equipment such as sharps containers; - Training; - Liaising with the Longest Student Health Center or other medical professional; 27 Research Compliance/EHS | 2015 - Managing exposure incidents. Employee Exposure Determination: The following is a list of job classifications at our laboratory in which employees have occupational exposure. Please list all job titles and provide a brief description of their tasks/procedures. Examples given in blue. Job Title Research tech Department/Location Biology Lab tech Biology Housekeeper Environmental Services Task/Procedure Isolates WBCs from blood Prepares DNA from WBCs Handles biohazardous waste Add additional lines if needed. Note: Part-time, temporary, contract and per diem employees are covered by the BBP standard. The ECP should describe how the standard will be met for these employees. Universal Precautions: is a work practice control that arose from hospital infection controls programs. It is designed to prevent the transmission of bloodborne pathogens such as HIV and HBV when working with human materials. According to the concept of universal precautions, all human blood and certain human body fluids including human cell lines are treated as if known to be infectious for HBV, HIV and other bloodborne pathogens. Hepatitis B Vaccination MSU makes available the Hepatitis B Vaccine and vaccination series to all employees who have occupational exposure, and post-exposure evaluation and follow-up to all employees who have had an exposure incident. All medical evaluations and procedures including the hepatitis B vaccine and vaccination series and post-exposure evaluation and follow-up, including prophylaxis, are made available at no cost to the employee. 28 Research Compliance/EHS | 2015 Hepatitis B Vaccination Hepatitis B vaccination is made available to the employee after his or her participation in bloodborne pathogen training. The vaccine is made available to all employees with occupational exposure unless the employee has previously received the complete hepatitis B vaccination series, antibody testing has revealed that the employee is immune, or the vaccine is contraindicated for medical reasons, or the individual declines. The vaccine can be provided by the Longest Student Health Center (LSHC). It is recommended that the series begin within 10 days of initial assignment to all employees identified in the exposure determination section of this ECP. All employees who decline to accept hepatitis B vaccination offered by MSU will be required to sign a Hepatitis B Vaccine Declination form. The laboratory supervisor is responsible for providing and maintaining the declination form. See Appendix B for an example. If an employee decides to accept the vaccination at a later date, MSU will make available hepatitis B vaccination at that time. To receive the hepatitis B vaccine and vaccination series, contact the Longest Student Health Center at 325-7539. Information about hepatitis B can be obtained at: http://www.cdc.gov/ncidod/diseases/hepatitis/b/fact.htm Post-exposure Evaluation and Follow-up The Longest Student Health Center will initiate a confidential medical evaluation and follow-up to an employee following a report of an exposure incident. Employees with an exposure incident should report to the LSHC, 325-2431. After an occupational exposure, the following activities will be performed: Document the routes of exposure and how the exposure occurred Identify and document the source individual unless the employer can establish that the identification is not feasible or prohibited by state or local law. 29 Research Compliance/EHS | 2015 Obtain consent and make arrangements to have the source individual tested as soon as possible to determine HIV, HCV and HBV infectivity; document that the source individual’s test results were conveyed to the employee’s health care provider. If the source individual is already know to be HIV, HCV or HBV positive, new testing need not be performed. Assure that the exposed employee is provided with the source individual’s test results and with information about applicable disclosure laws and regulations concerning the identity and infectious state of the source individual. After obtaining consent, collect exposed employee’s blood as soon as possible after the exposure incident and test blood for HBV and HIV serologic status. If the employee does not give consent for HIV serological testing during collection of blood for baseline testing, preserve the baseline blood sample for at least 90 days; if the exposed employee elects to have the baseline sample tested during this waiting period, perform testing as soon as possible. Administration of Post-Exposure Evaluation and Follow-Up Post-exposure follow-up and evaluation requires that the health care professional evaluating an employee after an exposure receives the following information: A description of the employee’s job duties relevant to the exposure Route(s) of exposure Circumstances of exposure If possible, the results of the source individual’s blood test Relevant employee medical records including vaccination history Procedures for Evaluating the Circumstances Surrounding the Incident It is necessary to review the exposure incident in or order to prevent or mitigate subsequent exposures. The following should be reviewed and documented: Engineering controls in use at the time Work practices followed A description of the device being used (if applicable) 30 Research Compliance/EHS | 2015 PPE in use at the time Location of the incident Procedure being performed at time of incident Employee’s training Record incident in the Sharps Injury Log (See Appendix C for an example). 31 Research Compliance/EHS | 2015 Signature and Acknowledgement of Risk We, the undersigned, understand that the agents used in this facility are potentially hazardous. We have read and understand this manual and agree to follow the stated policies and procedures. Name Signature Date 32 Research Compliance/EHS | 2015 Appendix A: Example of a Pathogen Safety Data Sheet STAPHYLOCOCCUS AUREUS PATHOGEN SAFETY DATA SHEET - INFECTIOUS SUBSTANCES SECTION I - INFECTIOUS AGENT NAME: Staphylococcus aureus SYNONYM OR CROSS REFERENCE: MRSA (methicillin-resistant Staphylococcus aureus), MSSA (methicillin-susceptive (or sensitive) Staphylococcus aureus), VISA (vancomycinintermediate Staphylococcus aureus), hVISA (heteroresistant vancomycin-intermediate Staphylococcus aureus), VRSA (vancomycin-resistant Staphylococcus aureus), staph infection, staphylococcus infection, impetigo, toxic shock syndrome. CHARACTERISTICS: Staphylococcus aureus are Gram-positive, catalase positive cocci belonging to the Staphylococcaceae family. They are approximately 0.5-1.5 µm in diameter, nonmotile, non-spore-forming, facultative anaerobes (with the exception of S. aureus anaerobius) that usually form in clusters. Many strains produce staphylococcal enterotoxins, the superantigen toxic shock syndrome toxin (TSST-1), and exfoliative toxins. Staphylococcus aureus are part of human flora, and are primarily found in the nose and skin. SECTION II - HAZARD IDENTIFICATION PATHOGENICITY/TOXICITY: Staphylococcus aureus is an opportunistic pathogen that can cause a variety of self-limiting to life-threatening diseases in humans. The bacteria are a leading cause of food poisoning, resulting from the consumption of food contaminated with enterotoxins. Staphylococcal food intoxication involves rapid onset of nausea, vomiting, abdominal pain, cramps, and diarrhea. Symptoms usually resolve after 24 hours. Animal bites can result in local infections, cellulitis, erythema, tenderness, mild fever, adenopathy, and lymphangitis (rarely). Scalded skin syndrome is caused by exfoliative toxins secreted on the epidermis and mostly affects neonates and young children. Other skin conditions caused by Staphylococcal exfoliative toxins include blisters, skin loss, pimples, furuncles, impetigo, folliculitis, abscesses, poor temperature control, fluid loss, and secondary infection. S. aureus can also cause necrotizing fasciitis in immunocompromised individuals, although this is very rare. Necrotizing fasciitis is life-threatening and causes severe morbidity. Certain strains of S. aureus produce the superantigen TSST-1, which is responsible for 75% of toxic shock syndrome (TSS) cases. The clinical presentation of TSS is severe and acute symptoms include high fever, vascular collapse, vomiting, diarrhea, myalgia, hypotension, erythematous rash, desquamation, and involvement of at least 3 organs. Mortality is very high and death can occur within 2 hours. Toxic shock syndrome is associated with vaginal colonization with toxin-producing S. aureus during menstruation, complications with staphylococcal infection at other sites, or complications of surgical procedures. Deep infections 33 Research Compliance/EHS | 2015 include endocarditis, peritonitis, necrotizing pneumonia, bacteremia, meningitis, osteomyelitis, septic arthritis, and infections of bones, joints and organs. EPIDEMIOLOGY: Worldwide distribution. Staphylococcus aureus is one of the most common causes of skin, soft-tissue, and nosocomial infection. Rates of infection in community settings are increasing. Residents of nursing homes are also at an increased risk of acquiring MRSA. Around 20% of individuals are persistent carriers of Staphylococcus aureus, about 60% are intermittent carriers, and approximately 20% rarely carry it. Children are more likely to be persistent carriers of the bacteria. Young women are at a higher risk for toxic shock syndrome. HOST RANGE: Humans, wild and domestic animals, including cows. INFECTIOUS DOSE: At least 100,000 organisms in humans. MODE OF TRANSMISSION: Ingestion of food containing enterotoxins. Vertical transmission during vaginal delivery is uncommon. Person-to-person transmission occurs through contact with a purulent lesion or with a carrier. Unsanitary conditions and crowded community settings increase exposure to S. aureus. Infection may be spread from person-to-person through health care workers or patients. Nasal colonization can lead to auto-infection. INCUBATION PERIOD: Onset of symptoms after consuming contaminated food is usually 30 minutes to 8 hours. Colonies of S. aureus can be carried for an undetermined amount of time; some individuals may carry it chronically, and some may carry it intermittently. COMMUNICABILITY: Communicable period is as long as a purulent lesion is present or carrier state persists. SECTION III - DISSEMINATION RESERVOIR: Staphylococcus aureus is found in humans in the nose, groin, axillae, perineal area (males), mucous membranes, the mouth, mammary glands, hair, and the intestinal, genitourinary and upper respiratory tracts. Many animals act as reservoirs, particularly cows with infected udders. ZOONOSIS: Yes, through direct or indirect contact with an infected animal. VECTORS: None. SECTION IV - STABILITY AND VIABILITY DRUG SUSCEPTIBILITY: Antibiotics such as cloxacillin and cephalexin are commonly used to treat staph infections. Vancomycin which is administered intravenously is used to treat MRSA. 34 Research Compliance/EHS | 2015 DRUG RESISTANCE: Many strains of Staphylococcus aureus have increasing resistance to multiple antibiotic classes. Methicillin resistant strains are common causes of nosocomial infection. Increasing resistance to vancomycin is being documented in many hospitals. SUSCEPTIBILITY TO DISINFECTANTS: Susceptible to 70% ethanol, clorhexidine, 1% sodium hypochlorite, 2% glutaraldehyde, 0.25% benzalkonium chloride, and formaldehyde. PHYSICAL INACTIVATION: Staphylococcus aureus can grow in a pH of 4.2 to 9.3 and in salt concentrations of up to 15%. Enterotoxins are resistant to temperatures that would destroy the bacilli. Sensitive to dry heat treatment of 160-170oC for at least an hour, but not to moist heat treatment. SURVIVAL OUTSIDE HOST: Survives on carcasses and organs (up to 42 days), floors (less than 7 days), glass (46 hours), sunlight (17 hours), UV (7 hours), meat products (60 days), coins (up to 7 days), skin (30 minutes to 38 days) (citation needed). Depending on colony size, S. aureus can survive on fabrics from days to months. SECTION V – FIRST AID / MEDICAL SURVEILLANCE: Monitor for symptoms. In outbreak settings, food poisoning can be diagnosed on clinical grounds with food cultured for S. aureus. Toxic shock syndrome can be indicated with a clinical diagnosis and isolation of S. aureus strain, TSST-1, or enterotoxins B or C. This can be achieved using ELISA, reverse passive latex agglutination, or PCR. Scalded skin syndrome can be diagnosed clinically, with presence of Nikolsky’s sign and identification of S. aureus retrieved from the infection site. Bacteremia and deep site infections are confirmed with direct microscopic examination of clinical specimen. Note: All diagnostic methods are not necessarily available in all countries. FIRST AID/TREATMENT: Treatment of abscesses usually does not need antibiotic therapy; appropriate drainage is usually sufficient. Proper antibiotic therapy is required for more serious infections. IMMUNIZATION: None. PROPHYLAXIS: Elimination of nasal carriage by using topical mupirocin also eliminates hand carriage. SECTION VI - LABORATORY HAZARDS LABORATORY-ACQUIRED INFECTIONS: 29 reported cases as of 1973, with 1 death. SOURCE/SPECIMENS: Infective stages may be present in CSF, joint aspirates, blood, abscesses, aerosols, feces, and urine. 35 Research Compliance/EHS | 2015 PRIMARY HAZARDS: Trauma of cutaneous barrier, parenteral inoculation, direct implantation of medical devices (i.e. indwelling catheters and IVs), ingestion of infected material, and contact with aerosols. SPECIAL HAZARDS: Contaminated request forms that have been wrapped around specimen containers. Direct contact with open cuts and lesions of skin. SECTION VII – EXPOSURE CONTROLS / PERSONAL PROTECTION RISK GROUP CLASSIFICATION: Risk Group 2. CONTAINMENT REQUIREMENTS: Containment Level 2 facilities, equipment, and operational practices for work involving infectious or potentially infectious materials, animals, or cultures. PROTECTIVE CLOTHING: Lab coat. Gloves when direct skin contact with infected materials or animals is unavoidable. Eye protection must be used where there is a known or potential risk of exposure to splashes. OTHER PRECAUTIONS: All procedures that may produce aerosols, or involve high concentrations or large volumes should be conducted in a biological safety cabinet (BSC). The use of needles, syringes, and other sharp objects should be strictly limited. Additional precautions should be considered with work involving animals or large scale activities. SECTION VIII – HANDLING AND STORAGE SPILLS: Allow aerosols to settle and, wearing protective clothing, gently cover spill with paper towels and apply an appropriate disinfectant, starting at the perimeter and working towards the centre. Allow sufficient contact time before clean up. DISPOSAL: Decontaminate all wastes that contain or have come in contact with the infectious organism before disposing by autoclave, chemical disinfection, gamma irradiation, or incineration. STORAGE: The infectious agent should be stored in leak-proof containers that are appropriately labelled. 36 Research Compliance/EHS | 2015 Appendix B: Example of Hepatitis B Vaccine Declination I understand that due to my occupational exposure to blood or other potentially infectious materials I may be at risk of acquiring hepatitis B virus (HBV) infection. I have been given the opportunity to be vaccinated with hepatitis B vaccine, at no charge to myself. However, I decline hepatitis B vaccine at this time. I understand that by declining this vaccine, I continue to be at risk of acquiring hepatitis B, a serious disease. If in the future I continue to have occupational exposure to blood or other potentially infectious materials, and I want to be vaccinated with hepatitis B vaccine, I can receive the vaccination series at no charge to me. Signed: ___________________________ Date: ________________ 37 Research Compliance/EHS | 2015 Appendix C: Example of a Sharps Injury Log The following information, if known, is documented within 14 working days of the date on which each exposure incident was reported. Date and time of the exposure incident:___________________________ Date of exposure incident report:________________________________ Report written by:____________________________________________ Type of sharp involved:________________________________________ Description of exposure incident: • • • • • Job classification of exposed employee:_____________________ Department/room where incident occurred:___________________ Procedure being performed by the exposed employee at the time of the incident: _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ _______________________________________________________________________ ___________________________________________________ How did the incident occur: _______________________________________________________________________ _______________________________________________________________________ ______________________________________________________________________ Body part involved:______________________________________ Does the exposed employee believe that any controls (engineering, work practice or administrative) could have prevented the injury? _____________________________________________________________________________ _____________________________________________________________________________ ___________________________________________________________ Comments on the exposure incident (e.g. additional relevant factors): _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _____________________________________________________________________________ _________________________________________ Written by:_____________________________ Date:__________________________________ 38