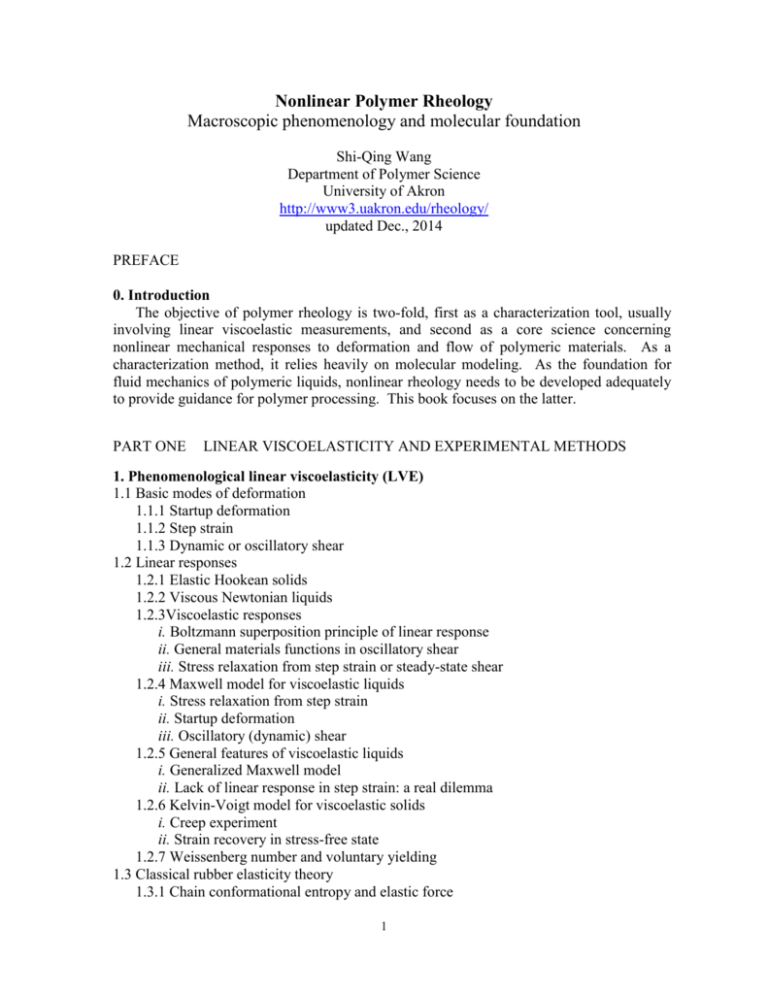

TOC

advertisement

Nonlinear Polymer Rheology Macroscopic phenomenology and molecular foundation Shi-Qing Wang Department of Polymer Science University of Akron http://www3.uakron.edu/rheology/ updated Dec., 2014 PREFACE 0. Introduction The objective of polymer rheology is two-fold, first as a characterization tool, usually involving linear viscoelastic measurements, and second as a core science concerning nonlinear mechanical responses to deformation and flow of polymeric materials. As a characterization method, it relies heavily on molecular modeling. As the foundation for fluid mechanics of polymeric liquids, nonlinear rheology needs to be developed adequately to provide guidance for polymer processing. This book focuses on the latter. PART ONE LINEAR VISCOELASTICITY AND EXPERIMENTAL METHODS 1. Phenomenological linear viscoelasticity (LVE) 1.1 Basic modes of deformation 1.1.1 Startup deformation 1.1.2 Step strain 1.1.3 Dynamic or oscillatory shear 1.2 Linear responses 1.2.1 Elastic Hookean solids 1.2.2 Viscous Newtonian liquids 1.2.3Viscoelastic responses i. Boltzmann superposition principle of linear response ii. General materials functions in oscillatory shear iii. Stress relaxation from step strain or steady-state shear 1.2.4 Maxwell model for viscoelastic liquids i. Stress relaxation from step strain ii. Startup deformation iii. Oscillatory (dynamic) shear 1.2.5 General features of viscoelastic liquids i. Generalized Maxwell model ii. Lack of linear response in step strain: a real dilemma 1.2.6 Kelvin-Voigt model for viscoelastic solids i. Creep experiment ii. Strain recovery in stress-free state 1.2.7 Weissenberg number and voluntary yielding 1.3 Classical rubber elasticity theory 1.3.1 Chain conformational entropy and elastic force 1 1.3.2 Network elasticity and stress-strain relation 1.3.3 Alternative expression in terms of retraction force and areal crosslinking density This Chapter 1 provides a basic discussion of how mechanical properties of viscoelastic materials can be characterized experimentally and phenomenologically and ends with an account of rubber elasticity theory, which is being brought to such a prominent position because it appears nonlinear rheology can trace its physical origin to chain elasticity. 2. Molecular characterization in LVE regime 2.1 Dilute limit 2.1.1 Viscosity of Einstein suspensions 2.1.2 Kirkwood-Riseman model 2.1.3 Zimm model 2.1.4 Rouse model i. Stokes law of friction ii. Brownian motion and Einstein-Stokes formula for solid particles iii. Equations of motion and Rouse relaxation time R iv. Rouse dynamics for unentangled melts 2.1.5 Relationship between diffusion and relaxation 2.2 Entangled state 2.2.1 Phenomenological evidence of chain entanglement i. Elastic recovery phenomenon ii. Rubbery plateau in creep compliance iii. Stress relaxation 2.2.2 Transient network models 2.2.3 Models depicting onset of chain entanglement i. Packing model ii. Percolation model 2.3 Molecular-level descriptions of entanglement dynamics 2.3.1 Reptation idea of de Gennes 2.3.2 Tube model of Doi and Edwards 2.3.3 Polymer mode coupling theory of Schweizer 2.3.4 Self diffusion vs. zero-shear viscosity 2.3.5 Entangled Solutions 2.4 Temperature dependence 2.4.1 Time-temperature equivalence 2.4.2 Thermo-rheological complexity 2.4.3 Segmental friction and terminal relaxation dynamics This Chapter 2 offers the important and elementary information about all classical molecular theories of polymer dynamics that form the bedrock to describe anything viscoelastic about polymeric liquids. Without this chapter nothing can be discussed about our latest understanding of polymer rheology. Nevertheless, the treatment is somewhat brief here because the content may be found in many books mentioned above, with the except of 2.2.3 that has not been incorporated into any textbook to the best of my knowledge although it should be regarded as elementary and standard materials for any book that discusses chain entanglement. For completeness, a brief exposure to the 2 temperature dependence of polymer dynamics is given at the end in 2.4, which is a subject too important to omit. 3. Experimental Methods 3.1 Shear rheometry 3.1.1 Linear displacement 3.1.2 Rotational motion i. Parallel disks ii. Cone-plate iii. Couette 3.1.3 Pressure-driven apparatus i. Capillary die ii. Channel slit 3.2 Extensional rheometry 3.2.1 Basic definitions of strain and stress 3.2.2 Three types of device i. Instron type stretcher ii. Extender at fixed length iii. Filament stretching rheometer 3.3 Rheo-optical (in situ) methods 3.3.1 Flow birefringence i. Stress optical rule (SOR) ii. Breakdown of SOR 3.3.2 Scattering (X-ray, light, neutron) 3.3.3 Spectroscopy (NMR, fluorescence, IR, Raman, dielectric) 3.4 Advanced rheometric methods 3.4.1 Superposition of small amplitude oscillatory shear and small step strain during steady continuous shear i. SAOS in steady shear ii. Small step strain in steady shear 3.4.2 Rate or stress switching multi-step platform i. Rate jump during startup deformation and after cessation of deformation ii. Elastic recovery at various stages of startup deformation and during relaxation odani@kit.ac.jp Chapter 3 covers experimental methods in terms of rheometric instruments, their improvement or modification. We have equal coverage on extensional rheometry in terms of its complementary role in the measurement science of rheometry. A second part discussed versatile protocols to program rheometry to gain additional rheological information. 4. Characterization of deformation field 4.1 Basic features in simple shear 4.1.1 Working principle for displacement-controlled rheometry: homogeneous shear 4.1.2 Stress-controlled shear 4.2 Yield stress in Bingham type (yield-stress) fluids 4.3 Cases of homogeneous shear 3 4.4 Particle tracking velocimetry (PTV) 4.4.1 Simple shear i. Motions in XZ plane ii. Imaging in XY plane 4.4.2 Channel flow 4.4.3 Other geometries 4.5 Single molecule imaging velocimetry (SMIV) 4.5.1 Simple shear 4.5.2 Channel flow 4.6 Other methods Chapter 4 begins by reviewing the basic principle that leads to the basic premise for rheometry – homogeneous shear. It discusses when this premise is valid. We then select a class of material behaviors known as yield stress phenomena to discuss critically whether the traditional depiction is adequate. The discussion of shear homogeneity sets the stage for an introduction of the particle-tracking velocimetric (PTV) method as well as the nextgeneration single-molecule imaging velocimetry. 5. Improved and other rheometric apparatuses 5.1 Linearly displaced co-cylinder for simple shear 5.2 Cone-partitioned plate for rotational shear 5.3 Other forms of high shear deformation i. Deformation at die entry ii. One-dimensional squeezing iii. Planar extension Rheometric measurements of nonlinear responses from entangled polymers are inherently difficult due to a number of factors. It remains challenging to obtain reliable experimental information. Chapter 5 first indicates how edge instabilities can be deferred and minimized and then mentions the intrinsic problem of interfacial failure that can be due to true wall slip, leading to the topic of the next chapter. PART TWO YIELDING – PRIMARY NONLINEAR RESPONSES TO ONGOING DEFORMATION 6. Wall slip – Interfacial yielding 6.1 Basic notion of wall slip in steady shear 6.1.1 Slip velocity Vs and Navier-de Gennes extrapolation length b 6.1.2 Correction of shear field due to wall slip 6.1.3 Origin of wall slip and condition to achieve complete slip 6.2 Stick-slip transition (in stress-controlled mode) 6.2.1 Stick-slip transition in capillary extrusion i. Analytical description ii. Experimental data 6.2.2 Stick-slip transition in simple shear (co-cylinder) 6.2.3 Maximum slip velocity Vs(max) for different polymer melts 4 6.3 Wall slip during startup shear - Interfacial yielding 6.3.1 Theoretical discussions 6.3.2 Experimental data 6.4 Relationship between slip and bulk shear deformation 6.4.1 Transition from wall slip to bulk nonlinear response 6.4.2 Experimental evidence of stress plateau associated with wall slip i. Case based on entangled DNA solution ii. Entangled PB solution in small gap distance H ~ 50 m 6.4.3 Influence of shear thinning on slip 6.5 Molecular evidence of disentanglement during wall slip 6.6 Uncertainty in boundary condition i. Oscillation between entanglement and disentanglement ii. Polymer desorption on weak surfaces: permanent slip iii. Two more flow oscillations 6.7 Theoretical accounts 6.7.1 Small surface coverage - Brochard-de Gennes theory 6.7.2 Saturated adsorption – disentanglement picture 6.7.3 Origin of stick-slip transition: interfacial cohesive breakdown Wall slip is the leading form of inhomogeneous shear response and is the subject of Chapter 6. The topic occupies a central position in the book. Everything we now know about nonlinear rheology of entangled polymers can be traced back to our understanding of wall slip. In particular, it not only emphasize de Gennes’s pioneering contribution to our understanding of wall slip but also shows that our understanding actually has extended beyond de Gennes’s primitive analysis. Today, we call wall slip produced in startup shear “interfacial yielding” because we have now been able to unify the depiction of shear induced yielding. We will provide the first treatment to account for the transformation from no slip to slip. All previous studies on wall slip only concerns with wall slip in steady state. Although wall slip is an essential subject in rheology, existing books have hardly treated the topic in any adequate detail. 7. Yielding during startup deformation: from elastic deformation to flow 7.1 Voluntary yielding at Wi < 1 and steady shear thinning 7.1.1 Elastic deformation and yielding in terminal flow 7.1.2 Steady shear rheology: shear thinning 7.2 Stress overshoot in fast startup shear 7.2.1 Scaling characteristics of the overshoot i. Viscoelastic regime ii. Elastic deformation regime 7.2.2 Elastic recoil from startup shear: evidence of yielding 7.3 Nature of steady shear 7.3.1 Superposition of small-amplitude oscillatory shear onto steady state shear 7.3.2 Two other methods to probe steady shear 7.4 From terminal flow to fast flow under creep: entanglement-disentanglement transition 7.5 Yielding in startup uniaxial extension 7.5.1 Myth with Considère criterion 5 7.5.2 Tensile force (engineering stress) vs. (true) stress 7.5.3 Tensile force maximum i. Terminal flow ii. Significance of engineering stress engr iii. Yielding for Wi > 1 vi. Elastic recoil This Chapter 7 is in some sense the soul of the book. Yielding is what must occur in entangled polymer upon startup deformation in both simple and uniaxial extension. This is a most difficult concept for some to accept because of a wide-spread confusion (thanks to Barnes and Walters for their discussion of yield-stress concept) that yielding was only to be used to describe mechanical behavior of solids. 8. Strain hardening in extension 8.1 Conceptual pictures 8.2 Origin of "strain hardening" in uniaxial extension 8.1.1 Geometric condensation of entanglement network 8.1.2 False strain hardening in LCB polymers such as LDPE 8.1.3 True strain hardening: finite extensibility limit and non-Gaussian stretching 8.2 Kinematic difference between extension and shear Strain hardening has been misused and over-used to describe the transient responses of entangled melts in extension. Chapter 8 shows that the real physics concerns about when and how yielding via chain disentanglement takes place. We also show an example of how true strain hardening is made possible in simple shear by LCB. 9. Shear banding in startup and oscillatory shear: PTV observations 9.1 Shear banding after overshoot in startup shear 9.1.1 Brief historical background 9.1.2. Influential factors i. Sample requirements ii. Controlling slip velocity iii. Edge effects iv. Criterion for shear strain localization 9.1.3 Shear banding in conventional rheometric device i. Shear banding of entangled DNA solutions ii. Shear banding of entangled 1,4-polybutadiene solutions 9.1.4 From wall slip to shear banding in small-gap distance 9.2 Overcoming slip during startup shear 9.3 Shear banding in LAOS Shear banding is of course a key observation from applications of PTV and is extensively discussed in this Chapter 9. It is a key chapter of the book because the strain localization has fundamentally altered our previous understanding of polymer rheology. Serious questions to ask here include whether shear banding is a steady state property or only a metastable character. 6 10. Pressure-driven deformation in capillary extrusion, squeezing, planar extension 10.1 Capillary rheometry in rate-controlled mode 10.1.1 Analogy with simple shear 10.1.2 Yielding at entrance 10.1.3 Collapse of continuum mechanical description 10.2 Particle-tracking velocimetric observations 10.2.1 Vortex formation 10.2.2 Stagnation at corners – internal slip 10.3 Squeezing deformation 10.2.1 Interfacial failure 10.2.2 Internal strain localization through EDT under constant pressure 10.4 Planar extension Chapter 10 shows the some valuable fruit from the studies of simple shear and uniaxial extension behavior. We extend our PTV method to observe the real phenomenon under real processing conditions. The findings are eye opening to say the least. In particular, we truly understand why polymers such as LDPE show vortex flow in the die entrance whereas linear polymer melts show stagnant corners. This all has to do with whether the polymer is capable of undergoing yielding for a limited amount of straining or whether there is a sufficient inherent extrapolation length scale in the system that shares the same definition as the slip length rediscovered by de Gennes since Navier introduced it in the 19th century. 11. Different modes of structural failure during startup uniaxial extension 11.1 Tensile-like failure at low rates 11.2 Shear yielding and necking-like strain localization 11.3 Rupture without crosslinking: where is disentanglement? 11.4 Strain localization vs. steady-flow: SER vs. FSR Chapter 11 summarizes how the different ways to undergo strain localization during startup extension can be understood in terms of how disentanglement may take place in extension differently from shear. PART THREE DECOHESION AND ELASTIC YIELDING AFTER LARGE DEFORMATION 12. Elastic yielding in stepwise simple shear 12.1 Strain softening after large step strain 12.1.1 Phenomenology 12.1.2 Tube model interpretation i. Normal DE behavior ii. Type C as elastic instability 12.2 PTV revelation of non-quiescent relaxation: localized elastic yielding 12.2.1 Non-quiescent relaxation in polymer solutions i. Elastic yielding in polybutadiene solutions ii. Suppression of breakup by reduction in b iii. Non-quiescent relaxation in polystyrene solutions 7 iv. Strain localization in absence of edge instability 12.2.2 Non-quiescent relaxation in polymer melts i. Induction time and molecular weight dependence ii. Severe shear banding before shear cessation and immediate breakup iii. Rate dependence of elastic breakup iv. Unconventional "step strain" at WiR < 1 12.3 Quiescent elastic yielding 12.3.1 General comments 12.3.2 Condition for uniform yielding and quiescent stress relaxation 12.3.3 Homogeneous elastic yielding probed by sequential shearing 12.4 Arrested wall slip: elastic yielding at interfaces 12.4.1 Entangled solutions 12.4.2 Entangled melts Elastic yielding is the most profound phenomenon discovered with PTV. In Chapter 12, we describe elastic yielding after stepwise simple shear, where the first example is the arrested wall slip, i.e., elastic yielding at polymer-wall interfaces. It is a “self destruction” process in the sense that the decohesion occurs upon cessation of external deformation. Elastic yielding is a unique example of how chain elasticity plays an essential role in polymer dynamics. This chapter along with Chapter 7 forms the foundation of nonlinear polymer rheology. 13. Elastic breakup in stepwise uniaxial extension 13.1 Rupture-like failure during relaxation (WiR < 1) 13.2 Shear-yielding induced failure upon fast large stepwise extension (WiR > 1) 13.3 Nature of the elastic breakup probed by IR measurements 13.4 Primitive phenomenological explanations In Chapter 13, we describe elastic yielding after stepwise uniaxial extension, analogous to the behavior observed after step shear. 14. Finite cohesion and role of chain architecture 14.1 Cohesive strength of entanglement network 14.2 Enhancing cohesion barrier with long-chain branching to prevent structural breakup This Chapter 14 emphasizes that long-chain-branching strongly affect nonlinear rheological behavior by strengthening the entanglement network. PART FOUR EMERGING CONCEPTUAL FRAMEWORK 15. Homogeneous entanglement 15.1 What is chain entanglement? 15.2 When, how and why disentanglement occurs 15.3 Criterion for homogeneous shear 15.4 Constitutive non-monotonicity 15.5 Metastable nature of shear banding We begin with a definition of chain entanglement: a dynamic concept originating from chain uncrossability (excluded volume and chain connectivity). The assumption of 8 homogeneous state of entanglement is true only under special rheological conditions or when the response is still largely elastic, unless the system is weakly entangled. Chapter 15 emphasizes that the central issue is whether non-affine deformation could occur without strain localization. 16. Molecular network as a conceptual foundation 16.1 Introduction: the tube model and its predictions 16.1.1 Smooth-out of interchain interactions 16.1.2 Barrier-less chain retraction 16.1.3 Non-monotonicity inherent from the simplification i. Stress overshoot upon startup shear ii. Strain softening: damping function for stress relaxation iii. Excessive shear thinning: proposal of shear banding base on the symptom of shear stress maximum in constitutive curve iv. Anticipation of necking based on Considère criterion 16.1.4 Inconsistencies with the tube model 16.2 Definition of three forces in entanglement network 16.2.1 Intra-chain elastic retraction force 16.2.2 Intermolecular gripping force (IGF) 16.2.3 Entanglement (cohesion) force arising from entropic barrier: finite cohesion 16.3 Overcoming finite cohesion after stepwise deformation: Quiescent or not 16.3.1 Non-quiescence from severe elastic yielding i. With WiR >1 ii. With WiR < 1 16.3.2 Homogeneous elastic yielding: quiescent relaxation 16.4 Microscopic yielding during rate-controlled startup deformation 16.4.1 Chain disentanglement at WiR < 1 16.4.2 Molecular force imbalance and scaling at WiR > 1 16.4.3 Yielding as a universal response 16.5 Interfacial yielding by disentanglement 16.6 Decohesion in startup creep: entanglement-disentanglement transition 16.7 Emerging microscopic theory of Sussman and Schweizer 16.8 New tests to reveal the nature of polymer deformation 16.8.1 Molecular dynamics simulations 16.8.2 Small angle neutron scattering measurements After becoming extensively informed by the emerging experimental observations, it is natural to ask why what would be a coherent conceptual framework. After a detailed review of the prevailing tube model, Chapter 16 describes alternative phenomenological and conceptual foundation for nonlinear rheology of entangled polymers where the concept of yielding and role of intrachain retractive force are emphasized. 17. "Anomalous phenomena" 17.1 Breakdown of time-temperature superposition during transient response: both shear and extension 17.2 Strain hardening in simple shear of certain polymer solutions 17.3 Lack of universal nonlinear responses: solutions vs. melts 9 17.4 Emergence of transient intersegmental elasticity and viscous stress Chapter 17 discusses several frontier topics to demonstrate that the field is still vibrant and active investigation although the core aspects of nonlinear rheology of entangled linear polymeric liquids have become clear. 18. Strain localization and fluid mechanics of polymeric liquids 18.1 Relationship between wall slip and banding: a rheological-state diagram 18.2 Failure of conventional continuum (fluid) mechanics for entangled polymers 18.2.1 Spatial discontinuity arising from discontinuity in state of entanglement 18.2.2 Unconventional constitutive equations containing long-range correlations 18.3 Challenges in polymer processing 18.3.1 Extrudate distortions i. Sharkskin melt fracture (due to exit boundary discontinuity) ii. Gross (melt fracture) distortions (due to entry instability) 18.3.2 Optimal extrusion conditions 18.3.3 Melt strength The ultimate objective of polymer rheology is to provide the basis for fluid mechanics of polymeric liquids. Chapter 18 describes how and why strain localization is behavior beyond the conventional scope of any rheology theory. Whether shear homogeneity and a spatially uniform state of chain entanglement can be assured depends on the ratio of the extrapolation length b to the minimal dimension of the system (i.e., the thickness H). Any theoretical account of fluid mechanical behavior of polymers has to involve a dimensionless parameter of y/b. Most processing instabilities are possible to understand in terms of chain disentanglement and strain localization, which reflects spatial discontinuity in the state of entanglement. A second important component is the discussion on the relation between wall slip and shear banding, which gives rise to a phase diagram, essentially offering a roadmap to guide us about what to expect from startup for any linear entangled polymers. 19. Conclusions 19.1 Theoretical challenges 19.2 Experimental difficulties It appears that the challenge to formulate a realistic theory for nonlinear rheology of entangled polymer is upon us. The task to overcome the inherent finite-size effects in rheometry is a daunting one. Experimental visualization of dynamical behavior at the molecular level remains a dream to be realized. Computer simulations hold the key to our further understanding in the near future. 10