SUPPLEMENTAL DIGITAL CONTENT

advertisement

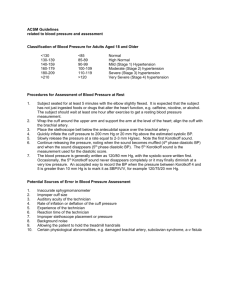

SUPPLEMENTAL DIGITAL CONTENT AN IN-VITRO STUDY TO ASSESS DETERMINANT FEATURES ASSOCIATED WITH FLUID SEALING IN THE DESIGN OF ENDOTRACHEAL TUBE CUFFS AND EXERTED TRACHEAL PRESSURES Gianluigi Li Bassi, MD; Otavio Tavares Ranzani, MD; Joan Daniel Marti, RPT; Valeria Giunta, MD; Nestor Luque, MD; ValentinaIsetta, BSEBE; Miguel Ferrer, MD, PhD; Ramon Farre, PhD; GuilhermeLeite Pimentel, BSEBEand Antoni Torres, MD, PhD. MATERIALS AND METHODS This study was conducted at the laboratories of the pneumology department, Hospital Clinic and University of Barcelona, Barcelona, Spain. The protocol was approved by the Institutional Review Board and Ethics Committee. Table 1 of the main manuscript depicts the study experimental design. The cuffs of 8 endotracheal tube (ETT) types with internal diameters of 7.0, 7.5 and 8.0 mm (I.D.) with a cylindrical or tapered shape made of polyvinylchloride (PVC) or polyurethane were studied. Cuffs characteristics Outer diameter: As previously reported (1), the cuff’s largest outer diameter (O.D.) of each 7.0, 7.5 and 8.0 mm I.D. tube was randomly measured 3 times using a sliding caliper and stepwise cuff inflation to 15, 20, 25 and 30 cm H2O through a cuff pressure regulation system (2). The pressure regulation system was calibrated prior to the beginning of the study. A new tube was used for each measurement. Additionally, we computed the cuff cross sectional area (CSA) and the ratios between the cuff and tracheal model CSA. Length: The cuff length of each 7, 7.5 and 8 mm I.D. tube was randomly measured 3 timeswith a sliding caliper and cuff inflation to 20 cm H2O. A new tube was used for each measurement. We computed the cuff O.D.-length ratio. Compliance: The cuff compliance of each 7, 7.5 and 8 mm I.D. tube was randomly assessed 3 times and a new tube was used for each measurement. Following complete removal of the residualgas, the internal cuff pressure was increased up to 40 cm H2O through manual stepwise increments of 1 ml of air via a 1-ml graduated 50-mL syringe connected through a 3-way stopcock to the pilot balloon. The tested cuff wasalso connected to a pressure transducer (MPX 2010 DP; Motorola, Phoenix, AZ, USA) to record pressure signals on a personal computer for subsequent analysis with dedicated software (Colligo; Elekton, Milan, Italy). Cuff compliance was computed through the analysis of the straight portionsof the pressure-volume curve (internal cuff pressure range: 15-40 cm H2O). Additionally, the cuff compliance within the tracheal model was similarly assessed. Oropharyngeal Secretions Simulant Based on preliminary studies (3) which assessed viscosity of oropharyngeal secretions in pigs on prolonged mechanical ventilation, we devised artificial oropharyngeal secretions with a viscosity of 3 centipoise at a shear rate of 75 sec-1. We added 50 mg of polyethylene oxide powder (Polyox Water Soluble Resin Coagulant NF; Dow Chemical Company; Cary, NC) into 100 mL of boiling distilled water. Afterward, the solution was removed from the heat, stirred for two hours and then stored for future use. Short-term fluid-sealing efficacy We randomly assessed the sealing properties of each 7.0, 7.5 and 8.0 mm I.D. ETT type cuff within 32–cm long PVC tracheal models of 18, 20 and 22 mm I.D., respectively. We tested sealing efficiency at an internal cuff pressure of 15, 20, 25 and 30 cm H2O. Each test was repeated three times and a new ETT was used for each test. Figure 1 in the main manuscript depicts the in-vitro settings to measure leakage. The tracheal model was oriented 30 degrees above horizontal. To maintain the internal cuff pressure, the cuff pilot balloon was connected to a pressure regulation system (2). To prevent immediate leakage as the oropharyngeal secretions simulant was poured into the tracheal model we increased the internal cuff pressure up to 40 cm H2O, and we regulated the positive end expiratory pressure (PEEP) valve (4 VENT 22M, Rüsch-Teleflex Inc., Limerick, PA, USA) of the ventilatory circuit until air leakageacross the cuff developed. Next we poured artificial oropharyngeal secretions to achieve a 10-cm column above the ETT cuff while the tracheal model was held vertically. At the beginning of the test, the circuit was disconnected and the internal cuff pressure was decreased to the randomized pressure. The test was carried out until all fluids leaked across the cuff or until the 1 hour test period ended.Simulant leakage is reported as the average fluid flow rate across the cuff and wascomputed by dividing the volume of fluid collected by either 60 min or the time at which all fluid had leaked. A completed 1-hour leakage test was defined as an experiment in which the simulant did not entirely leak within 1 hour. Long-term fluid-sealing efficacy Based on the results of the short-term leakage study, the 4 best-performing ETT types were tested for a longer period. Using aforementioned methods we randomly tested 7.5-mm I.D. ETT types for 24 hours within 20-mm I.D. tracheal model at an internal cuff pressure of 30 cm H2O. Each test was repeated three times and a new ETT was used for each test. Tracheal wall pressure exerted by the cuff We used methods previously validated by Horisberger et al (4). An intracranial pressure sensor probe (Codman,Raynham, MA, USA) was placed between the cuff’s surface and the tracheal models to assess cuff pressure transmitted against the tracheal wall (Twp). Cuffs of 7.0, 7.5 and 8.0 mm I.D. ETTs were randomly tested within 18, 20, 22 mm I.D. tracheal models, respectively. Each test was repeated 3 times and a new tube was used for each test. After complete deflation of the cuff, its pilot balloon was connected via a three-way stopcock to a 50-ml syringe providing a continuous air flow of 3.33 mL/min via an automatic syringe-pump (Alaris GH, Cardinal Health, Dublin, OH, USA), and a pressuretransducer (MPX 2010 DP; Motorola, Phoenix, AZ, USA)to monitor and record the internal cuff pressure. All pressure signals were recorded on a computer for subsequent analysis with dedicated software (Colligo; Elekton, Milan, Italy). During the test, the internal cuff pressure was progressively increased to achieve a Twp of 40 cm H2O then the pressure waveforms were analyzed to specifically assess transmitted Twp at 15, 20, 25 and 30 cm H2O of internal cuff pressures. Supplemental Figure 1 shows calculation of Twp through the recorded waveforms. Tracheal wall pressure mapping To assess regional distribution of Twp, we used an acrylic 21-mm I.D. cylindrical tracheal model, with a 1-mm thick, 50-mm wide and 64-mm long pressure sensor (TactArray Pressure Sensor, Conductive Cloth, range 0-140 cmH2O, PPS, Los Angeles, CA, USA) which covered 76% of the tracheal model internal circumference. The Twp patterns were acquired and analyzed using dedicated software (PPS Chamelon TVR Software, v. 1.3.9.2-2010, PPS, Los Angeles, CA, USA). Prior to the beginning of the study the sensor was properly calibrated. During the test, to assure a correct alignment of the ETT cuff into the tracheal model, the ETT was placed within a plastic sleeve and a straightening rod was inserted into its lumen. The ETT pilot balloon was connected to the cuff pressure regulation system (2). The distribution of the Twp was recorded for each 7.5 mm I.D. ETT type upon stepwise inflation of the cuff to 15, 20, 25 and 30 cm H2O. Each test was randomly performed and repeated three times. The cuff-trachea contact area and the percentage of Twp distribution measurements lower than the cuff pressure (between 31-40, 41-50 and greater than 50 cmH2O) were computed and analyzed. Statistical analysis Randomization: The randomized list of 72 tests to assess each of the cuff’s structural features (outer diameter, length and compliance) was developed by creating a list of of possible combinations for each of the 8 tubes per 3 ETT I.D. and 3 levels of replications. A uniformly distributed list of random numbersbetween 0.00000 and 1.00000 was generated and added to the data set. Then the list of combinations was sorted by level of replication and random numbers. The randomized list of 288 cuff short-leakage tests was developed by creating a list of possible combinations for each of 8 tubes per 3 ETT I.D., per 4 internal cuff pressures and 3 levels of replications. A uniformly distributed list of random numbers between 0.00000 and 1.00000 was generated and added to the data set. Then the list of combinations was sorted by level of replication and random numbers. The randomized list of the 9 long-term leakage tests was developed creating a list of combinations of the 3 tubes and 3 levels of replications. A uniformly distributed list of random numbers between 0.00000 and 1.00000 was generated and added to the data set. Then the list of combinations was sorted by random numbers. The 3 tests to assess long-term sealing efficacy of the HiLoTM endotracheal tube were carried out following the first revision of the manuscript. The randomization list of the 72 transmitted Twp was developed while creating a list of combinations for the 8 tubes per 3 ETT I.D. and 3 levels of replications. A uniformly distributed list of random numbersbetween 0.00000 and 1.00000 was generated and added to the data set. Then the list of combinations was sorted by level of replication and random numbers. The randomized list of the 24 Twp pressure mapping tests was developed while creating a list of combinations for the 8 tubes and 3 levels of replications. A uniformly distributed list of random numbers between 0.00000 and 1.00000 was generated and added to the data set. Then the list of combinations was sorted by level of replication and random numbers. Categorical and continuous data are presented as percentage and as mean±SD (ormedian and interquartile range [IQR]), respectively. Continuous variables were analyzed using the Kruskal-Wallis test or Friedman test, and the Mann-Whitney Utest or Wilcoxon signed rank test for post-hoc multiple comparisons. Each pair-wise comparison was corrected using Bonferroni methods. Chi-square test was applied for comparisons of categorical variables. As for the Twp distribution analysis, the percentages of Twp within the predefined ranges were considered as continuous variables. Univariate linear regression analyses were used to evaluate the association between cufffeatures and leakage flow rate. All significantly associated variables were included into themultivariate regression analysis with a stepwise model selection procedure in order to preventmulticollinearity. Variables with a p-value >0.10 were eliminated from the final model. Pearson correlation was used to assess the association between mean cuff length assessed outside and within the tracheal model, and the Twp obtained via different methods. A two-sided p value<0.05 was consideredstatistically significant. All statistical analyses were performed using SPSS software (version 13.0; IBM, Chicago, IL, USA). Reference List 1. Bernet V, Dullenkopf A, Maino P, et al.: Outer diameter and shape of paediatric tracheal tube cuffs at higher inflation pressures. Anaesthesia2005; 60: 1123-8 2. Farré R, Rotger M, Ferre M, et al.: Automatic regulation of the cuff pressure in endotracheally-intubated patients. EurRespir J 2002; 20: 1010-3 3. Li Bassi G, Marti JD, Jeuma N, et al.: Assessment of oropharyngeal secretions viscosity during tracheal intubation: An experimental study Am J RespirCrit Care Med 2011; 183: A5854 4. Horisberger T, Gerber S, Bernet V, et al.: Measurement of tracheal wall pressure: a comparison of three different in vitro techniques. Anaesthesia2008; 63: 418-22 Supplemental Table 1. Cuff-Trachea contact areas (cm2) per internal cuff pressure. Internal cuff pressure (cmH2O) Endotracheal tube 15 20 25 30 Ruschelit® Safety Clear Plus Hi-LoTM Profile Soft-Seal® SacettTM TaperguardTM Sheridan/HVT® Kimvent* Microcuff* SealGuardEvacTM 10.53 ± 8.4 13.83 ± 1.7 8.75 ± 0.4 11.80 ± 2.3 9.35 ± 1.0 12.25 ± 0.8 15.84 ± 2.6 14.29 ± 1.2 9.99 ± 5.2 15.21 ± 1.6 9.24 ± 0.4 11.81 ± 0.8 10.31 ± 0.8 13.03 ± 0.8 17.76 ± 0.7 14.60 ± 1.4 10.92 ± 4.2 15.37 ± 2.3 9.00 ± 1.0 12.49 ± 0.9 10.65 ± 0.6 13.08 ± 0.8 17.96 ± 0.8 14.68 ± 1.4 11.96 ± 3.1 17.29 ± 0.8 10.20 ± 1.0 12.47 ± 0.7 11.05 ± 0.7 11.99 ± 1.2 18.01 ± 0.7 15.00 ± 1.1 N: 96, Data are Mean±SD Mean Cuff-Trachea Contact Area (cm2) 10.85 ± 4.8 15.43 ± 1.9 9.30 ± 0.9 12.14 ± 1.2 10.34 ± 0.9 12.59 ± 0.9 17.39 ± 1.6 14.64 ± 1.1 Supplemental Table 2. Comparison of cuff length assessed inside vs. outside the artificial trachea Endotracheal tube Cuff Shape Ruschelit® Safety Clear Plus Hi-LoTM Profile Soft-Seal® SacettTM TaperguardTM Sheridan/HVT® Kimvent* Microcuff* SealGuardEvacTM Cylindrical Cylindrical Tapered Tapered Tapered Tapered Cylindrical Tapered Cuff Length Cuff Length Outside Trachea*⌃ (mm) Inside Trachea*⌃ (mm) 37.72 43.17 33.92 32.10 43.70 39.37 45.10 43.82 19.97 30.42 18.48 23.62 20.61 26.05 35.52 29.20 Cuff Length Inside Trachea Cuff Length Outside Trachea (%) 52.94 70.47 54.48 73.58 47.16 66.17 78.75 66.64 Internal cuff pressure 20 cm H2O; ⌃ Average value of 3 replicated assessments of 7.5 mm internal diameter endotracheal tube. Pearson’s Correlation: 8, r = 0.6497, p=0.0892 N: SUPPLEMENTAL FIGURE 1 Supplemental Figure 1. Analysis of 7.0–mm internal diameter SealGuardEvacTM (Covidien-Nellcor™ and Puritan Bennett™, Boulder, CO, USA) cuff-related transmitted tracheal pressure. Internal cuff pressure and transmitted tracheal wall pressure waveforms were matched to assess the pressure assessed by the intracranial pressure sensor probe, upon inflation of the endotracheal tube cuff. Transmitted tracheal pressures at 15, 20, 25 and 30 cm H2O of the internal cuff pressures were computed.