BTS & energy management Bang for your Buck

advertisement

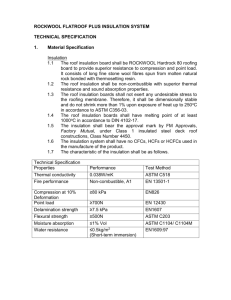

Designing the Energy-Efficient Build-to-Suit Facility By Mark E. Augustyn, Chief Operating Officer, Principle Construction, Inc. ID Label, Inc. Project location: Lake Villa, IL 60046 Project team members: ID Label, Inc. & Principle Construction Corp. Using the Design/Build method of project delivery is perfectly suited for your build-tosuit project and even more so if energy efficiency is the goal. The customer’s decision to ultimately go the BTS route in lieu of adapting a vacant facility is not made without exhausting all the other available options first. Regardless of the reason, companies who are showing signs of growth will represent the new development that takes place in our industrial corridors in the coming months and years. Companies who commission such structures will demand that our industry deliver energy efficiency that generates significant savings over the long-term. Design/Build is an excellent way that we, as an industry, can deliver this kind of a product to our customers. Build-to-suits enable the customer to have the best opportunity to implement costeffective upgrades to improve the building’s energy efficiency. Key to these upgrades is knowing where the user is spending their energy dollars. Increasing the R value of the roof is hardly logical if most of the energy spent is for lighting. However, if the customer has a need to fully heat and cool their facility, then increasing the R value of roofs and walls will most likely be a logical consideration. If the customer spends a significant amount on energy to illuminate the facility, implementing an automated lighting system in conjunction with windows/skylights could significantly reduce the dollars spent on illumination. The customers benefit from balancing first cost against operating cost. Spending more or less on one or the other is simply a matter of improving the benefit to the customer’s bottom line. Even though the long-term cost savings of energy-efficient elements in a building seems like it would be a no brainer, we often don’t follow through with long-term logic. So, our government is taking steps towards forcing the issue by legislating energy efficiency into our building strategies. Our current political administration sees reducing our carbon footprint not only as a way to save the planet, but as a matter of national security – reducing our dependency on foreign energy sources. Since 40 percent of all energy consumed in the U.S. is from the heating and cooling of buildings, many initiatives such as the LEED program, the Energy Efficiency Act of 2007, and the American Clean Energy & Security Act of 2009 and Architecture 2030 have been developed to reduce this energy consumption, with many more on the horizon. Specifically, Architecture 2030, a worldwide movement to reduce fossil fuel consumption, has developed specific carbon reducing goals for the global architecture and building community. The goal is to reduce consumption by 70% in 2015, 80% in 2020, and 90% in 2025, with the ultimate goal to have all buildings carbon neutral by 2030. The design/builder can best guide the BTS customer in the most effective way to ensure that their project is both efficient in terms of long-term operating costs and that they comply with current and developing government regulations. Balancing fist cost, operating costs, improved R values, natural lighting, passive solar heating and passive cooling systems along with mechanical lighting, heating and cooling systems is an involved process. The qualified design builder can provide first cost and operating costs analysis early in the process to ensure that the most energy-efficient design is chosen. As an example, where significant funds are spent heating and cooling a facility, increasing the R value of the structure’s envelope system, should be considered. Energy loss analysis will identify where on the building envelope additional insulation should be placed. For most industrial projects, increasing the R value of the roof will provide the biggest payback since the roof has the highest ratio of skin to square footage. In an office tower such as the Willis Tower, conversely, the walls would be the place to focus. Just as a point of reference, insulation slows the transfer of energy; it doesn’t make anything hot or cold. The most efficient location for the insulation is as close to the outer layer of the exterior of the skin as possible. Visualize the insulation acting like a blanket around the building. Luckily, for most buildings in our industry, we employ this blanket concept extremely well. The typical industrial building with precast walls and EPDM single-ply roofs is perfectly situated to take advantage of increasing R values in this way. The precast panels have nearly continuous, seamless insulation sandwiched between two layers of concrete. The single-ply roof systems have insulation installed continuously over the roof structure with no thermal bridges. For practically the cost of material, the insulation of our building’s “blanket” can easily be increased. A small detail that makes a big energy performance difference is providing multiple layers of insulation too. Employing this feature will better control vapor, air and moisture migration through our envelope systems. Just like dressing in layers for sub-zero temperatures, providing our insulation in layers with overlapping seams is an excellent design strategy. Ultimately, this tactic will reduce both the amount of energy needed to run the HVAC equipment over the long term and reduce the size of the HVAC equipment necessary to do the job. Logically, reducing the size of the equipment has the added benefit of lowering the construction cost too. Projects that pursue LEED status employ many of these energy efficient design principles. Principle Construction just completed a 21,000 square foot LEED certified manufacturing facility for ID, Label, Inc. in Lake Villa. Through a careful collaboration with the architect, commissioning authority, plumbing designer, civil, mechanical, and electrical engineers, we were able to significantly reduce the negative environmental impacts typically associated with this sort of manufacturing operation. The new facility will yield a reduction in energy use of 24%, CO2 emissions reduction of 33%, reduced water use of 40% while at the same time creating a workplace environment with better indoor air quality and lighting which case studies have illustrated increase worker productivity of up to 16%. Highlights from the project include: Bioswales that promote filtration and reduce pollutant release into the aquatic environment; The installation of a white roof membrane minimizing the impact on microclimate and human and wildlife habitat; Exterior lighting levels designed to light only the areas required for safety and comfort thereby minimizing light trespass from the building and site; The use of drought-tolerant indigenous plant species eliminating the need to use drinking water for landscape irrigation; Modern high efficient fixtures that reduce water use by 40%; An HVAC design that uses zero CFC-based refrigerants in state of the art heating and cooling units that save energy while minimizing the emission of compounds that contribute to ozone depletion and global warming. These initiatives have been quantifiably shown through an independent commissioning authority’s energy model to provide overall energy cost savings of 21%, reducing both maintenance and operational cost. Building occupant comfort and indoor air quality effect occupant productivity, health and cost of ownership helping make the decision to go green an easy one. Planning the design of a build-to-suit that will hopefully withstand the test of time from an energy-efficiency standpoint requires careful thought on many fronts, which is why Design/Build firms are an important partner to engage. Unless there is an unlimited budget to work with, it’s critical to assess in which areas yield the highest payback. It’s also important to analyze which eco-friendly elements should to be implemented during the construction process and which can potentially be postponed to later in the life of the building in order to maximize the construction budget. Most of all, engaging a Design/Build firm that has proven expertise in the type of buildto-suit project you are planning can pay off enormously both short and long-term, and both in time and cost savings. Aligning with a Design/Build partner that understands the cost of various energy-saving systems and keeps up to date regarding emerging technologies that reduce occupancy costs is invaluable. Since most projects have a limited construction budget, leveraging those dollars in the most effective way is crucial. For more information, please contact Mark Augustyn at maugustyn@pccdb.com or 1.847.615.1515. Co-founder of Principle Construction Corp., a design/build general contracting firm located in Bannockburn, Illinois. Mark is a licensed Architect in Illinois and Wisconsin. He is a graduate of the University Of Illinois School Of Architecture with a Masters Degree in Architecture. Throughout Mark’s 27 years of experience, he has been responsible for the design and construction of numerous office, manufacturing, distribution, food processing, laboratory, government facilities and business park infrastructure projects all throughout the Midwest. Some noteworthy clients include; Seefried Properties, First Industrial Realty Trust, Lee & Associates, ML Realty, LFI Industrial, Prologis, HSA, Prentiss Properties Limited, Inc., Darwin Realty and Development Corporation, Ready-Pac, Flikkima Saab, Kendall College, Sears Mortgage Corporation, Favorite Brands International, FedEx, General Warehouse, Omron Healthcare, Griffith Laboratories, Custom Food Products, Mullins Food Products and ALPHARMA. Principle Construction Corp., established in 1999, is a leading design/build general contractor serving the most recognizable developers, REIT's, brokerage firms and end users in the Chicago, Northwest Indiana and Southwest Wisconsin markets. Principle provides value driven construction services through innovative design and relentless attention to detail. The firm specializes in commercial and industrial property and is committed to providing clients with the highest level of design/build construction services with an absolute dedication to each project.