X-Ray Diffraction Homework: Principles & Applications

advertisement

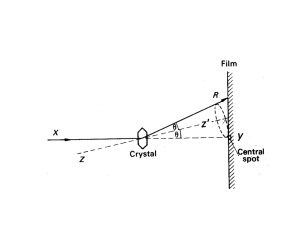

YEDITEPE UNIVERSITY BME 414 HOMEWORK X-RAY DIFFRACTION MELİSA YAPRAK 20100707022 Table of Contents 1. X-Ray Diffraction...................................................................................... 3 2. History ......................................................................................................... 3 3. Applications of XRD ................................................................................ 4 3.1. 3.2. Pharmaceutical Industry ............................................................................. 4 Forensic Science .............................................................................................. 4 3.3. Geological Applications ................................................................................ 4 3.4. Microelectronics Industry ........................................................................... 4 3.5. Glass Industry ................................................................................................... 5 4. Bragg’s Law ................................................................................................ 5 5. Micro X-Ray Diffraction (µXRD) ........................................................ 6 6. Parallel Beam Geometry For Powder X-Ray Diffraction ............ 6 7. Parallel Beam X-ray Diffraction .......................................................... 7 8. Neutron Diffraction ................................................................................. 8 References ....................................................................................................... 9 2 1. X-RAY DIFFRACTION X-ray diffraction is a tool for the investigation of the structure of matter. X -rays are scattered by interaction with the electrons of the atoms in the material being investigated. The technique began when von Laue discovered that crystals diffract x-rays in 1912. Since that day; it has been applied to chemical analysis, stress and strain measurement, the study of phase equilibria, measurement of particle size, as well as crystal structure. 2. HISTORY X-ray diffraction has been a well-established technique in the field of structural investigations for decades, applied not only by physicists. It represents an important tool for chemists and biologists, too, and played a decisive role in the discovery of the structure of the DNA in 1953. Any method that exploits x rays is based upon their discovery in 1895 by W. C. Röntgen by chance while studying the charge transport in gases. This achievement was rewarded the first Nobel prize in the field of physics ever, in 1901. The first diffraction experiment was performed by Max v. Laue in 1912. Fig 1 displays the observed diffraction pattern. With this single photograph, Laue solved at once two major problems of his days: It clearly reveals the crystalline nature of solids and proves that x rays behave like waves. This finding was rewarded the Nobel prize in 1914. The first material is the mineral aragonite and the second is calcite. X-ray diffraction can be used to tell different crystal structures apart. Fig 1 3 3. Applications of XRD Pharmaceutical industry: X-ray diffraction (XRD) can be used to unambiguously characterize the composition of pharmaceuticals. An XRD-pattern is a direct result of the crystal structures, which are present in the pharmaceutical under study. The parameters typically associated with crystal structure can be simply accessed. For example, once an active drug has been isolated, an indexed X-ray powder diffraction pattern is required to analyse the crystal structure, secure a patent and protect the company’s investment. For multicomponent formulations, the actual percentages of the active ingredients in the final dosage form can be accurately analysed in situ, along with the percentage of anyamorphous packing ingredients used. XRD is the key technique for solid-state drug analysis, benefiting all stages of drug development, testing and production. Forensic science: XRD is used mainly in contact trace analysis. Examples of contact traces are paint flakes, hair, glass fragments, stains of any description and loose powdered materials. Identification and comparison of trace quantities of material can help in the conviction or exoneration of a person suspected of involvement in a crime. Geological applications: XRD is the key tool in mineral exploration. Mineralogists have been amongst the foremost to develop and promote the new field of X-ray crystallography after its discovery. Thus, the advent of XRD has literally revolutionized the geological sciences to such a degree that they have become unthinkable without this tool. Nowadays, any geological group actively involved in mineralogical studies would be lost without XRD to unambiguously characterise the individual crystal structures. Each mineral type is defined by a characteristic crystal structure, which will give a unique x-ray diffraction pattern, allowing rapid identification of minerals present within a rock or soil sample. The XRD data can be analysed to determine the proportion of the different minerals present. Microelectronics industry: As the microelectronics industry uses silicon and gallium arsenide single crystal substrates in integrated circuit production, there is a need to fully characterise these materials using the XRD. XRD topography can easily detect and image the presence of defects within a crystal, making it a powerful non-destructive evaluation tool for characterising industrially important single crystal specimens. Glass industry: While glasses are X-ray amorphous and do not themselves give X-ray diffraction patterns, there are still manifold uses of XRD in the glass industry. They include identification of crystalline particles which cause tiny faults in bulk glass, and measurements of crystalline coatings for texture, crystallite size and crystallinity. 4 4. Bragg’s Law English physicists Sir W.H. Bragg and his son Sir W.L. Bragg developed a relationship in 1913 to explain why the cleavage faces of crystals appear to reflect X-ray beams at certain angles of incidence (theta, q). The variable d is the distance between atomic layers in a crystal, and the variable lambda l is the wavelength of the incident X-ray beam; n is an integer. This observation is an example of X-ray wave interference(Roentgenstrahlinterferenzen), commonly known as X-ray diffraction (XRD), and was direct evidence for the periodic atomic structure of crystals postulated for several centuries. Where n is an integer, λ is the wavelength of incident wave, d is the spacing between the planes in the atomic lattice, and θ is the angle between the incident ray and the scattering planes. The Incident Beam The beam that comes strikes to the surface. and INCIDENT BEAM is used to be made of TUNGSTEN but now COPPER is used because it is easy to cool down. The Diffracted Beam When the electron beam passes through the thin crystalline sample, it is diffracted by the atomic planes in the sample when the Bragg condition is satisfied. 5 5. Micro X-ray Diffraction (µXRD) Micro X-ray diffraction (µXRD) is a structural analysis technique which allows for the examination of very small sample areas. Like conventional XRD instrumentation, µXRD relies on the dual wave/particle nature of X-rays to obtain information about the structure of crystalline materials. Unlike conventional XRF, which has a typical spatial resolution ranging in diameter from several hundred micrometers up to several millimeters, µXRD uses X-ray optics to focus the excitation beam to a small spot on the sample surface so that small features on the sample can be analyzed. Polycapillary focusing optics collect X-rays from the divergent X-ray source and direct them to a small focused beam at the sample surface with diameters as small as tens of micrometers. The resulting increased intensity delivered to the sample in a small focal spot allows for enhanced spatial resolution for small feature analysis and enhanced performance for diffraction measurement of small specimens. Unlike conventional XRD instrumentation which is bulky and has high power requirements, microdiffraction with high diffracted-beam intensity can be achieved with a very low-power source using these optics. 6. Parallel Beam Geometry for Powder X-ray Diffraction Some of the major drawbacks of traditional parafocusing XRD for diffraction measurement of powder samples are that it requires very precise source-sampledetector alignment and carefully prepared samples. Errors often result from differences in sample position, shape, roughness, flatness, and transparency. Furthermore, small diffraction intensities may result due to the small parafocusing source irradiation area as the number of crystals in a powder satisfying the Bragg condition depends on the volume irradiated by the beam and the crystallite size. Parallel beam XRD using polycapillary collimating optics can be used to enhance powder XRD experiments. Due to the insensitivity of parallel beam XRD to sample geometry and displacement errors, minimal sample preparation is required for powder samples. An additional benefit of using a collimated beam for X-ray powder diffraction is to spread the incident beam over a large region, 6 allowing many more crystals to be in diffracting condition compared to the area typically irradiated with a parafocusing instrument. 7. Parallel Beam X-ray Diffraction Some of the major drawbacks of traditional XRD are that it is often based on bulky equipment with high power requirements. Furthermore, most conventional instruments use a parafocusing Bragg-Brentano geometry, offering the advantages of high-resolution and high beam-intensity analysis at the cost of very precise alignment requirements and carefully prepared samples. Additionally, this geometry requires that the source-to-sample distance be constant and equal to the sample-to-detector distance. Ensuing errors often lead to difficulties in phase identification and improper quantification. A mis-positioned sample, a partially transparent sample, or a rough sample can lead to unacceptable specimen displacement errors. The sample flatness, roughness, and positioning constraints usually preclude in-line measurements. These constraints are removed if the incident X-ray beam is parallel. In parallel beam XRD, a polycapillary collimating optic can be used to form an intense parallel X-ray excitation beam resulting in very high X-ray intensities at the sample surface. With parallel-beam geometry, the sample position can vary and the XRD system is no longer constrained to maintain the same distance between the X-ray source and sample as between the sample and detector. The geometric flexibility can accommodate existing manufacturing conditions and can be used on a much 7 broader range of sample shapes and sizes. Parallel beam XRD is not only insensitive to errors associated with sample displacement; it virtually eliminates all of the other well-known instrument error functions, which contribute to asymmetric peak broadening, such as non-flat or rough specimens, axial divergence, and sample transparency. As a result, minimal sample preparation is required. Furthermore, through use of a polycapillary collimating optic, the target parallel beam XRD system can be combined with a low power X-ray source, reducing instrument size and power requirements. Parallel beam XRD using Xray optics has been successfully used for applications including thin film analysis, sample texture evaluation, monitoring of crystalline phase and structure, and investigation of sample stress and strain. The elimination of multiple sources of error and the potential for reducing the power, size, weight, and cost of an instrument makes parallel beam X-ray systems natural candidates for on-line diffraction systems for quality control and feedback in manufacturing and process environments. Parallel-beam XRD has been successfully used in process applications for phase distribution measurements in the pharmaceutical and steel industries, thin film texture measurements for superconductor layers and magnetic films, and structure measurements for proteins. 8. Neutron Diffraction Single crystal and powder neutron diffraction can be enhanced through the use of polycapillary focusing optics for convergent beam neutron crystallography. Using polycapillary optics, neutrons can be focused into a small spot resulting in an increased neutron current density on the sample. Polycapillary optics can also provide large gains over conventional unfocused neutron beams. Convergent beam neutron crystallography using capillary optics can be effectively used in crystal structure or phase distribution studies for small samples of small-tomedium-size molecules. This is particularly important for ultra high pressure or low temperature measurements. Enhanced thin film analysis Powder diffraction using neutron focusing optics enables the analysis of small samples or weakly diffracting polycrystalline materials such as polymers. High spatial resolution studies of strain, phase, and texture distributions in extended samples may also be possible. 8 9. REFERENCES 1. http://www.ammrf.org.au/myscope/xrd/additional/ 2. http://www.diss.fuberlin.de/diss/servlets/MCRFileNodeServlet/FUDISS_derivate_000000002 709/06_ch3.pdf?hosts= 3. http://chemwiki.ucdavis.edu/Analytical_Chemistry/Instrumental_Analysis/Di ffraction/Bragg%27s_Law 4. http://www.xos.com/techniques/xrd/ 5. http://materialsection.files.wordpress.com/2011/09/1-1-xray_diffractionbragg-law.pdf 9