Energy Conservation and Optimization of Condensate Splitter

advertisement

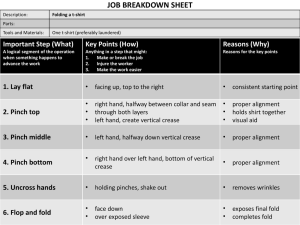

Energy Conservation and Optimization of Condensate Splitter Plant Eid M. Al-Mutairi* and Husamelden Elkawad Department of Chemical Engineering King Fahd University of Petroleum and Minerals Dhahran31261, Saudi Arabia mutairi@kfupm.edu.sa Abstract In this work, energy integration of a heat exchanger network (HEN) of the Plant Refinery was carried out using the Pinch Analysis Technology through (heat-int) software. From the operating data, the HEN data was extracted, then the heat exchanger network data were analyzed through varying the pinch temperature and the amount of hot and cold utilities were observed. Also the effects of pinch temperature on the area of heat exchangers were done. The percentages of changing in hot and cold utilizes beside the area of heat exchangers were investigated and the percentages of utilities and area changing with pinch temperature were done. The main problem of the exiting heat exchanger network came from cross pinch temperature, seven heat exchangers with total energy of 183099704.2BTU\hr crosses the pinch point that’s violated the pinch rules. Cross pinch point with different pinch temperature was found to occur, so attention must be taken with these temperatures. The area efficiency of the current heat exchangers is 0.4 comparing with the ideal area with the same amount of hot utility. Retrofitting of the current heat exchangers was done by replacing some heat exchangers and adding new units. The reduced in hot and cold utilities were 6.79% and 27.9 % respectively with 10.53% decreases in the area. 1.0Introduction Pinch technology is a methodology derived from simple scientific principles, by which it is possible to design new plants with optimum energy and capital costs. Also it’s used with existing processes to improve the performance. The condensate splitter plant produced high quality ofnaphtha,stabilized naphtha, LPG, heavy naphtha, kerosene, light and heavy diesel and atmospheric gas oil (AGO) for domestic uses and exportation. In this work we are going to extract and analyze the information data to find the quantities of hot and cold utilities required for the crude distillation unit (CDU)and theninvestigate the effects of changing the pinch temperature on the current heat exchanger network (HEN) using HEAT-INT software. 2.0Literature Review The pinch analysis technique has been used globally to target hot and cold energy requirement for crude distillation units CDU specifically and for any distillation column generally as mentioned in many several articles [1,2,3,4,5,6]. Riyami(2001) studied the effects of changing the pinch temperature of a fluid catalytic cracking plant on the hot and cold utilizes and the area of the heat exchanger networks [2] .Ajao(2009) investigated the energy integration of the crude pre heat train of kaduna refinery, from the study he found the optimum pinch temperature for the pre-heat train using pinch analysis techniques [6].Salomeh(2008) used the Hint software which is based on methods of pinch technology to design, optimize and improve the integrated heat exchanger network of crude oil preheating Process in distillation unit in Arak refinery , also he reduced the load of the furnace[7]. The above hard work has proven that using the pinch analysis technique is very helpful and powerful in optimization not only of distillation units, but also in general chemical and petrochemical industries. 3.0 Process Description The process consisting from desalting units, stabilized feed and the crude distillation units as shown in the block diagram in figure (1). Condensate Fraction Overhead& CDU Overhead Final Products Crude distillation unit Desalting unit Stabilizer Unit LPG & Light Naphtha Figure (1): The Process Block Diagram The splitter plant Refinery of the crude condensate produced a high quality ofNaphtha, stabilizedNaphtha, Liquefied Petroleum Gas (LPG), HeavyNaphtha, Kerosene, Light and Heavy dieseland atmospheric Gas Oil (AGO) for domestic uses and exporting. First, the condensate crude from storage is preheated by the resulting products from the Crude Distillation Unit (CDU), thecrudeenters the desalting unit to remove the dissolved salts. Then it’s entering the first distillation column (Flash Column). The bottom product from the flash columnis heated in two furnaces using flue fuel gases then enters a second distillation column (CDU) .Thetop product is routed as feed to the condensate fractionator, while medium naphtha sent to the fractionator top and light naphtha is routed to the fractionator’s overhead/cold condensate exchanger.The distillations products are then used to pre-heat the feedstock beforestoring in the tanks or sends to exporting ports. 4.0 Data Extraction The source temperature (Ts), target temperature (Tt), flow –rate and heatcapacity and of each streams in the heat exchangers network were extracted. Also the areas of each heat exchanger in the network were extracted. The physical properties of the products from the crude distillation unit are shown in the table (1) below. Table (1): The Physical Properties of the Crude Distillation Unit Products Viscosity CP Specific gravity 60 oF/60oF No. Stream name Type Density lb/ft3 1. Fractionators overhead Cold 0.41 0.01 - 2. Heavy naphtha Cold 39 0.18 0.78 3. Kerosene Cold 38 0.17 0.81 4. Light diesel Cold 42 0.24 0.83 5. Heavy diesel Cold 42 0.24 0.85 6. Fraction bottom Cold 42 0.3 0.88 7. Dirty wash oil Cold 40 0.21 0.87 8. Fractional feed Hot 0.66/40 - 0.87 9. Pre flash column overhead Cold 0.63 0.01 - 10 Hot crude Hot 40 0.2 0.78 11. Crude (tank) Hot 48 0.84 0.78 5.0 Cost Data There are two types of cost data, the operating cost for utilities and the capital cost for heat exchangers. These cost data are need in the compression between different values of pinch temperatures and in retrofitting. The cost data annualized base on 86000 hours per year, a payback period of 10 years with interest rate of 8%. 5.1 Operating Cost The currently used cooling utilities are air and sea water, while the heating utilities are 150-Psig and flue gas. The cost of these utilities are shown in the table (3) below Table (3): Cost Data of Hot and Cold Utilities No. 1 2 4 5 Stream Air Cooling Type Cold Cost 6407SR (Btu /year) Cooling Water Cold 6407 SR (Btu /year) 150-Psig Hot 36120SR (Btu /year) Flue Gas Hot 1.161SR (Btu /year) 5.2 Capital Cost Data The capital cost is represented by the following relation Capital Cost = A + B(area of heat exchangers)C Where A represents the fixed cost of installation independent of area , B and C represents the cost of area per unit and they depends on the material of constructions of heat exchanger.Here we assume that the same equation is used for all types of heat exchangers in the network, process to process and utilities exchangers. 6.Existing Heat Exchangers Network The process includes 128 streams with cold streams and hot streams. Also it’s includes process to process heat exchangers and hot and cold utilities heat exchangers. The hot exchanger’s utility usessteam and flue gases and the cold utilities heat exchangers uses sea water and air as coolants.The energy consumptions of the exiting process are shown on the grand composite curve in figure (2). Figure (2): The Current Heat Exchanger Network Grand Composite Curve From the diagram, the pinch temperature of the network is 28.85 0F, the amounts of the hot and cold utilities are 329000000 BTU\hr and 429834000 BTU\hr respectively, the processes to processes heat exchanges is 893209000 BTU\hr. The percentage of the energy consumptions are as shown in Table (4) Table (4): The Current Heat Exchanger Network Data Hot utilities Flue Gases 99.998% Cold utilities Air Cooling 99.82 % 150 Psig 0.001 % Sea Water 0.178% Table (4): Existing Utilities Percentages 6.1Capital, Utilities and Total Costs of the Existing Network The costs and the area of the existing network are shown in table (4) per year below. Hot Utility Cost 4.44E+03 SR/year Cold Utility Cost 3.20E+07 SR /year Total Utility Cost 3.20E+07 SR /year Capital Cost 8.39E+06 SR /year Total Network Cost 7.24E+07 SR /year Total area 432000 ft2 Process area 290408.36 ft2 Utility area 141591.63 ft2 6.2Analyzing of Exiting Heat Exchanger Network The existing network consists from 64 heat exchangers (process to process s heat exchangers , 2 furnaces , 3 utilities and air fans cooling heat exchangers).Through analyzing the network to determine the inappropriate uses of energy consumption, either through crossing the pinch temperature or inappropriate using for utilities. Table (5) shows the heat exchangers that violated the pinch rule. Table (5): The Current Heat Exchanger Cross Pinch Energy 1. 2. 3. 4. 5. 6. 7. Heat exchanger no. E 231 E 101 E 201 E222 E350 E211 E 241 Total Energy Amount of Energy (BTU/hr) 1697015.12 47909491 9270976 22430081 27256375 14436456 12189819.08 183099704.2 6.3Heat Exchanger Network Area versusDifferent Pinch Temperatures The areas counter current and 1-2 shell and tube heat exchangers networks changes with pinch temperatures. Figure (4) shows the variation of network areas with different values of temperatures. 4.00E+05 3.00E+05 2.00E+05 1.00E+05 0.00E+00 0 5 10 15 20 1-2 shell and tube heat exchangers area 25 30 35 40 45 counter current heat exchanger area Figure (4): Heat Exchanger Area versus Pinch Temperature The area of process to process heat exchangers increaseswhen temperature decreases, that’s will decrease the amount energy consumption for the networks. 6.4Heat Exchanger Network Annualized Costsversus Different Pinch Temperatures The total annualized cost versus different approach temperatures are shown in figure (5&6) below for counter current and 1-2 shell and tube heat exchangers. From the graph we could select the optimum approach temperature with minimum total cost. 3.20E+10 3.00E+10 2.80E+10 2.60E+10 0 5 10 15 20 25 30 35 40 45 35 40 45 total cost Figure (5): The Total Heat Exchanger Network Cost perYear (counter current) 3.20E+10 3.00E+10 2.80E+10 2.60E+10 0 5 10 15 20 25 30 total cost Figure (6): The Total Heat Exchanger Network Cost per Year (1-2shell & tube) The area of heat exchangers decreases from190100 ft2 to 134400ft2, when the pinch temperature increases from 100F to400F, that’s will increases the cost from 8394026.42 SR/year to6369165.69 SR/year for counter current heat exchangers.For 1-2 shell and tube heat excanghers the area of heat exchangers decreases from237900 ft2 to 173200 ft2, when the pinch temperature increases from 10 0F to 40 0F, that’s will increases the cost from 10036970.24 SR/year to 7794045.78 SR/year. The cost of the cold and the hot utilities increases within the increases of the pinch temperatures as shown in figures (7). The cost increases from 29170673.10 SR/year to 33090083.20 SR/year, when the pinch temperature increases from 100F to 400F. 3.20E+10 3.00E+10 2.80E+10 2.60E+10 0 5 10 15 20 25 30 35 40 45 utility cost Figure (7): The Utilities Cost per Year for the Heat Exchanger Network 6.5Analyzing the Heat Exchangers Network at Different Pinch Temperature When applying different pinch temperatures for the exitingheat exchangers’ network, some heat exchangers violated one of the pinch rules, heat transfer across pinch. The table (6) below showed the numbers of heat exchangers that’s violated this rule and the amount of heat transfer through the pinch. Figure (8) shows the loss of energy due to cross pinchtemperaturedecreases as the pinch temperature increases. Table (6): The Current Heat Exchanger Cross Pinch Energy Pinch temperature 10 0F Pinch temperature 15 0F Pinch temperature 20 0F Heat exchanger no. Heat transferred BTU/hr Heat transferred BTU/hr Heat transferred BTU/hr E 101 32266000 12798600 16144440 E 241 18917780 16923040 14949020 E 211 4320570 3336710 2352840 E 231 19755600 18178200 16600700 E 222 7476810 7476810 7476810 E 350 17931940 14033700 10135440 E 202 2939480 2351600 1763694 103608180 84142500 69433000 150000000 100000000 50000000 0 0 5 10 15 20 25 30 35 40 45 cross pinch energy Figure (8): The Cross Pinch Temperature Energy vs different Pinch Temperatures BTU/hr 6.7 Effects of Changing the Current Pinch Temperature on both Utilities and Area of Heat Exchangers The current heat exchanger network is working at specific pinch temperature. Figure (9) below showed the percentages effects of changing the current pinch temperature on hot and cold utilities beside the area of the heat exchangers. 25 20 15 10 5 0 Hot Utility Cold Utility Heat Exchangesr Area ∆T % Figure (9): Percentage Change in Pinch Temperature versus HEN Area andUtilities 6.8Determination of area efficiency for Retrofit Design In retrofit design the area efficiency measures the performance of the exiting heat exchangers network with the ideal network. The closer the exiting heat exchangers area to the curve, best performance is given by the installed heat exchangers area.As shown in figure (10), the efficiency of exiting heat exchangers area is 0.4397, where the exiting and target areas for the energy recovery were 432100.15 and190022 ft 2 respectively. 4.00E+05 exiting HEA 3.00E+05 2.00E+05 1.00E+05 0.00E+00 2.50E+08 2.70E+08 2.90E+08 3.10E+08 3.30E+08 3.50E+08 1-2 shell and tube heat exchangers Figure (10): Energy Area Plot of the CDU Heat Exchangers Area vs. EnergyRecovery 6.9Adjusting the Current Heat Exchangers Network When pinch analysis was applied to the current heat exchangers network, seven heat exchangers (E221, E241, E231, E101, E211, E222, E 350 and E202) crossed the pinch temperature as shown in table (7). In order to avoid this situation, some arrangement for the network design is suggested as shown in figure (11) in general manners. The solutions steps are:- Determine the heat exchangers that cross the pinch temperature. Find out which streams violet the pinch rule. Move the exiting heat exchanger either below or above the pinch point, calculate the new area needed. Calculate the area for heat exchanger for the remaining energy recovery. After these steps, the expected energy saving are 6.79 and 27.9 for hot and cold respectively. Table (1): Heat Exchangers Cross Pinch Temperature Amount of energy transfer(Btu/hr) Heat exchanger Stream cross temperature pinch Hot stream Cold stream 1. E 101 hot 42833477.45 2. E 241 hot + cold 17372603.07 10744787.2 3. E 211 hot + cold 3362687.261 9622843.575 4. E 231 hot 10863454.11 5. E 222 hot 4032883.301 6. E 350 hot 41243273.4 7. E 201 hot 456147.175 In this procedure, the old heat exchangers that violated the pinch rules will be replaced by efficient heat exchangers. By this way the area will be reduced by 10.5% , as shown in the table (8) below. Table (8): Heat Exchangers retrofit of current network HE old area ft2 new area ft2 E101 5500.9 6010.134 E201 4311.83 3681.059 E231 5144.35 4081.736 E222 3621 3637.812 E241 9208 3077.186 E350 4880 10133.26 E211 7398.44 5220.855 Diff Diff % Total area 4.01E+04 3.58E+04 4.22E+03 10.5392 Capital cost 2.44E+06 2.24E+06 2.05E+05 8.401942 Solution Pinch temp. Pinch temp. Figure (11): Suggested Solution for the Current Heat Exchangers Network 7.0 Conclusion In conclusion, the heat integration of the heat exchanger network (HEN) of The Plant Refinery was carried out using the Pinch Analysis Technology by Heat-int software. Moreover, merits of integrated network are shown compared to the base case design. 8.0 References 1- Ajay Mane and Amiya K. Jana. A New intensified heat integration in distillation column. Ind. Eng. Chem. Res. 49. (2010) 9534-9541. 2- Badr A. Al-Riyami, Jiri Klemes, and Simon Perry. Heat integeration retrofit analysis of a heat exchanger network of a fluid catalytic cracking plant. Applied Thermal Engineering 21 (2001) 1449–1487. 3- M. Nakaiwa, K. Huang, T. Endo, T. Ohmori, T. Akiya, and T. Takamatsu. Internally heat integrated distillation columns: A review. National Institute of Advanced Industerial Science & Technology, Japan. And Institute of Industerial Technology, Japan. 4- K. Liebmann and V. R. Dhole.Integrated crude distillation design.Computers Chemical Engineering. Vol. 19 (1995) 119–124. 5- Patipat Promvitak, Kitipat Siemanond, Somporn Bunluesriruang, and Voratai Raghareutai. Retrofit Design of Heat Exchanger Networks of Crude Distillation Unit. Process Integration and Energy Optimization Conference. Florence, Italy (2011). 6- K.R. Ajao and H. F. Akande. Energy Integration Of Crude Distillation Unit Using Pinch Analysis. Researcher, 1(2), (2009) 54–66. 7- Salomeh Chegini , Reza Dargahi , Afshin Mahdavi , Modification of Preheating Heat Exchanger Network in Crude Distillation Unit of Arak Refinery Based on Pinch Technology, WCECS 2008, October 22 - 24, 2008, San Francisco, USA