FSP 9th Meeting 06-11-12 Minutes

advertisement

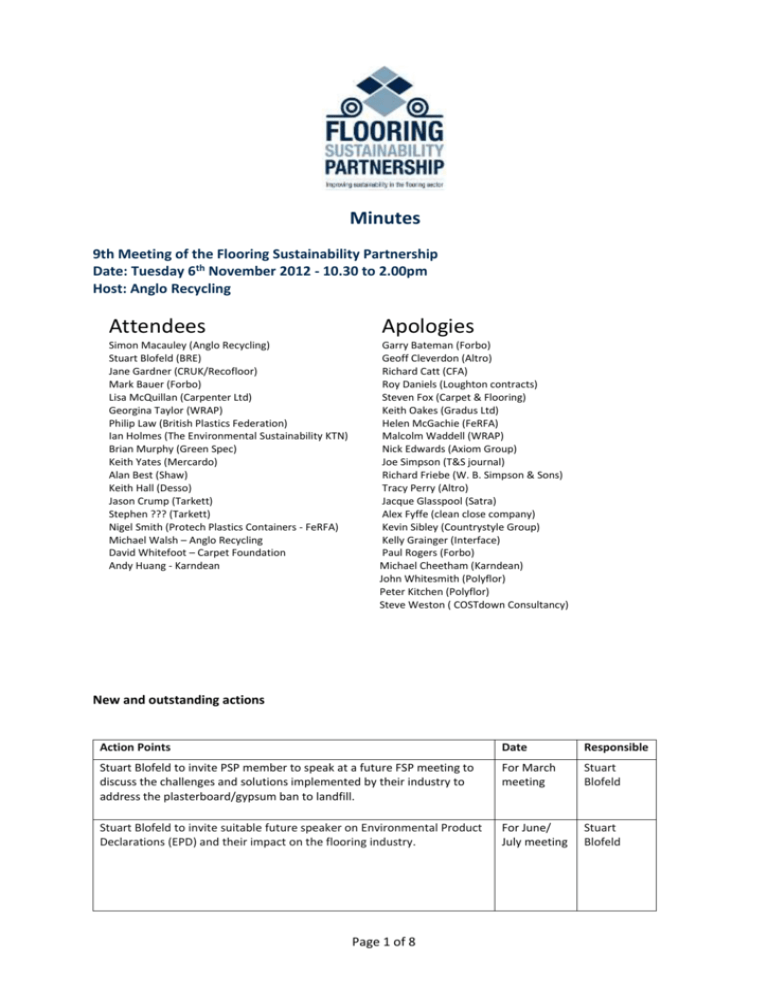

Minutes 9th Meeting of the Flooring Sustainability Partnership Date: Tuesday 6th November 2012 - 10.30 to 2.00pm Host: Anglo Recycling Attendees Apologies Simon Macauley (Anglo Recycling) Stuart Blofeld (BRE) Jane Gardner (CRUK/Recofloor) Mark Bauer (Forbo) Lisa McQuillan (Carpenter Ltd) Georgina Taylor (WRAP) Philip Law (British Plastics Federation) Ian Holmes (The Environmental Sustainability KTN) Brian Murphy (Green Spec) Keith Yates (Mercardo) Alan Best (Shaw) Keith Hall (Desso) Jason Crump (Tarkett) Stephen ??? (Tarkett) Nigel Smith (Protech Plastics Containers - FeRFA) Michael Walsh – Anglo Recycling David Whitefoot – Carpet Foundation Andy Huang - Karndean Garry Bateman (Forbo) Geoff Cleverdon (Altro) Richard Catt (CFA) Roy Daniels (Loughton contracts) Steven Fox (Carpet & Flooring) Keith Oakes (Gradus Ltd) Helen McGachie (FeRFA) Malcolm Waddell (WRAP) Nick Edwards (Axiom Group) Joe Simpson (T&S journal) Richard Friebe (W. B. Simpson & Sons) Tracy Perry (Altro) Jacque Glasspool (Satra) Alex Fyffe (clean close company) Kevin Sibley (Countrystyle Group) Kelly Grainger (Interface) Paul Rogers (Forbo) Michael Cheetham (Karndean) John Whitesmith (Polyflor) Peter Kitchen (Polyflor) Steve Weston ( COSTdown Consultancy) New and outstanding actions Action Points Date Responsible Stuart Blofeld to invite PSP member to speak at a future FSP meeting to discuss the challenges and solutions implemented by their industry to address the plasterboard/gypsum ban to landfill. For March meeting Stuart Blofeld Stuart Blofeld to invite suitable future speaker on Environmental Product Declarations (EPD) and their impact on the flooring industry. For June/ July meeting Stuart Blofeld Page 1 of 8 Page 2 of 8 Minutes from meeting Ref 1. Welcome Simon Macaulay Chairperson of the Flooring Sustainability Partnership and host welcomed all attendees to the meeting. 2. Introductions Introductions made. (Full attendance list and apologies above). Mark Bauer (Forbo) – mentioned interest in attending FSP to understand Company Sustainability Strategies. Could this be of interest to others as a future discussion topic, and or further work to assist other members in understanding all about establishing a sustainability strategy. Stuart to propose that BRE could represent on their learning in the development and implementation of BRE’s company sustainability strategy ‘ S Plan’. 3. Minutes of Previous Meeting / Matters Arising Minutes of the 8th Meeting have been approved by those present. Stuart Blofeld to invite PSP member to speak at a future FSP meeting to discuss the challenges and solutions implemented by their industry to address the plasterboard/gypsum ban to landfill. Action Points Date Responsible Stuart Blofeld to invite PSP member to speak at a future FSP meeting to discuss the challenges and solutions implemented by their industry to address the plasterboard/gypsum ban to landfill. For March meeting Stuart Blofeld Simon Macaulay to draft a position statement on behalf of the FSP re the gov consultation on flooring waste to landfill and circulate for comment. The final FSP position statement will be included in the first FSP newsletter to be distributed in September, and sent to Defra. Process has started with engagement of CRUK members on the landfill ban ONGOING Simon Macaulay Stuart Blofeld to invite suitable future speaker on Environmental Product Declarations (EPD) and their impact on the flooring industry. For Oct/ March meeting Stuart Blofeld Jason Crump to recommend a speaker (from British Plastics Federation??) that who could give FSP insights and advise us on the best route forward if the government decides to legislate on recycling. FSP members to provide content for FSP newsletter to Jane Gardner at Axion by 20th August at the very latest. JGardner@axionconsulting.co.uk DONE Jason Crump DONE ALL Page 3 of 8 4. Jane Gardner to confirm method/software for producing and sending out the FSP newsletter (e.g. mailChimp or HTML etc). DONE Jane Gardner Stuart to send Jane FSP distribution list. DONE Stuart Blofeld Plastics industry packaging recycling targets presentation (Philip Law - BPF) • • • • • • • • • • EU Directive on Packaging and Packaging Waste (94/62/EC – 20th December 1994) – Aimed to limit packaging waste and promote recycling and recovery – All packaging: household, industrial, commercial – Included recycling targets by material by 2008 (weight) • 60% glass, paper, board • 50% metals • 22.5% plastics • 15% wood Producer Responsibility Obligations (packaging waste) 1997 – Collective Producer Responsibility principle – Whole chain responsibility – If over £2 million turnover AND/OR Handling >50 tonnes packaging/annum UK approach was unique in implementing this obligation - each firm has a precise responsibility to organise recycling of a specific tonnage of material based on the following: – Raw material manufacturer = 6% – Converter (packaging manufacturer) = 9% – Packer/Filler = 37% – Seller = 48% – Importer = Rolled up obligation Firms could meet their obligation by: – Buying Producer Responsibility Notes ( PRN) yourself – Getting PRN via a recycler – Go to an Open market platforms e.g. The Environment Exchange – Join a ‘Compliance Organisation’ to do it for you e.g. Valpak where an annual Membership fee (most common method) PRN costs were different per tonne based on material type Question on whether the definition of ‘Recycling’ within the Producer Responsibility Obligations are limited innovation in terms of dealing with packaging waste. – Why shouldn’t energy recovery be on a par with recycling? Big issue with operating plastics recycling processes for volume and not quality and selling to China rather than selling to UK markets for reuse (thus closing the loop) e.g. producing quality recycled plastic packaging for big UK retailers and manufacturers PRN costs fluctuates and creates uncertainty in the marketplace Questions Michael Walsh – Are the obligations forcing more innovation in plastics packaging? See more composite materials which are perhaps less recyclable rather than more. How does this fit? Comment: PL - There comes a point where minimising packaging and optimising its weight Page 4 of 8 • • • • • 5. reduces the opportunities Comments: PL - Realistically legislation is required to drive a scheme like this forward especially within packaging sector. Perhaps within Flooring it could work more on a voluntary basis e.g. via schemes like Vinyl2010/Vinyl Plus and Recofloor DW - There could be a general principle of ‘Producer Pays’ but this then effects Imports of flooring outside of the UK. So Retailers and distributors then have to …. DW - Surcharge is added to tyres so why not flooring… JD – CRUK is engaging with the whole supply chain on this issues to discuss opportunities for recycling up the supply chain KY - There are already costs within the supply chain that cover the disposal and recycling of flooring materials. These are rising and are a driving to recycling. Defra update (Jane Gardner) Meeting on 24th October with Defra to discuss potential ban of textile waste to landfill. CRUK and WRAP attended. Before meeting CRUK surveyed steering committee members. Presentation of achievements and challenges in the sector to Defra. Defra found it very useful to meet with trade associations to discuss potential ban of textile waste to landfill. Defra are also considering and consulting on ban of other materials including wood waste, and organic waste. Textile ban consultation has started. Broader than just flooring textile waste e.g. carpets. 383,000 carpet waste to landfill. 385,000 tonnes of clothing textile waste to landfill. Drivers in the commercial sectors are much more developed for recycling than in the domestic carpets sector. Needs to be differentiate. DW - Domestic consumers have very little interest in environmental issues. Price remains the biggest factor. Cost per m2 of carpet. Won’t be prepared to pay extra for green issues. Carpet Foundation survey before economic downturn did show that consumer are more aware of green issues and recycling. But this has fallen away during recession. JG – This is changing with some evidence that consumers are becoming more discerning in their purchasing decisions. CRUK steering committee members support the continued increase in the Landfill Tax escalator. Official Defra consultation is expected to start in the new year on potential ban of textile waste to landfill. KY – Burden is too far up the chain on smaller independent retailers and fitters (DW estimate 4,000-6,000 retailers). This needs to come down the supply chain to larger manufacturers supplier products into the marketplace. 6. FSP newsletter All FSP members to distribute HTML email or send web link to supply chain where possible Mercardo have already sent out the FSP newsletter to 1,800 supply chain partners CRUK have sent newsletter to 74 members. 36 of these have opened newsletter (50% success rate) Tarkett have sent the newsletter internally within organisation Following members to tweet newsletter to their followers Page 5 of 8 o o o BRE (5,000 followers) WRAP (?? followers) GreenSpec (8,000 followers) The next FSP newsletter to be sent out by mid-March. Content from members to be sent to Jane Gardner (JGardner@axionconsulting.co.uk) no later than mid-February. Content can include: Actions taken across on sustainability Short case studies Links to external articles Seminars/conferences Awards NEW SECTION: FSP Members Profile (Stuart Blofeld’s idea) Would you like to appear in the next newsletter? Describe your day-to-day role within your organisation, what makes you tick, why do you do what you do, and the impact you have as a result. And why you joined the FSP. 7. FSP End of Year Reporting & Metrics (Stuart Blofeld) Simon Macauley outlined the WRAP funding that has been secured this year to enable to production of an Annual FSP Summary report, plus development of Metrics to enable the FSP to measure and report on quantifiable progress in future years. Stuart Blofeld outlined that BRE have 4-5 person days allocated to complete both these tasks. Stuart presented draft structure for the FSP Annual Summary Report. Agreed content for FSP Annual Summary Report: Foreword by the FSP Chair (Simon Macauley to write) Executive Summary (BRE to write) Intro to FSP (BRE to write) Achievements in 2012 (Broadloom, Carpet Tiles, Resilient, Resin, Hard) (ALL members to contribute content – BRE to produce template and collate content) FSP KPIs/Metrics (BRE to develop agreed Metrics) Appendix – List of FSP members (BRE to write) Stuart outlined that ‘Achievements in 2012’ section is not limited to only reporting on the original FREAP targets and milestones. This section can and should include sector, scheme, and organisational level updates on sustainability/environmental targets set, actions taken, programmes and initiatives delivered, and outputs and successes realised during the year. Wherever possible these should link to quantifiable reductions in environmental impacts realised. ACTIONS: BRE to send out template to all FSP members for contributions to the annual report by 16th November 2012 All members to provide their contributions to the first draft report by 31st December 2012 First draft FSP Annual Report will be sent to all members for comment by 20th January 2013 All members to provide feedback and any additional content for the report by 10th February 2013 BRE to disseminate final draft report for review by 24th February 2013 (for discussion and sign off at 10th FSP meeting on 14th March 2013) Page 6 of 8 WRAP to design and layout report in agreed format and send to members by 27th April 2013 WRAP/FSP to publish report in May 2013 FSP KPIs / Metrics Stuart presented a proposed two-tier approach to establishing a set of agreed KPIs (Key Performance Indicators). The purpose of these KPIs is to provide a consistent and agreed approach for the collection of data from FSP members (that represent manufacturing in the UK) so that: Comparable data can be collected on a yearly basis Baseline performance established Improvement targets set Performance monitored and reported against agreed KPIs and targets Proposed LEVEL 1 KPIs KPI1 - Total Energy Use. Potential units of measurement include: kWh per m2 product produced (UK operations only) kWh per £100k company turnover (UK operations only) KPI2 - Total Water Use. Potential units of measurement include: m3 of water per m2 product produced (UK operations only) m3 of water per £100k company turnover (UK operations only) KPI3 - Total Waste Generated. Potential units of measurement include: tonnes of waste generated per m2 product produced (UK operations only) tonnes of waste generated per £100k company turnover (UK operations only) Proposed LEVEL 2 KPIs (Waste) Tonnage Material produced/collected (KPI3-1) Tonnage Material reused (KPI3-2) Tonnage Material recycled (KPI3-3) Tonnage Material incinerated with energy recovery (KPI3-4) Tonnage Material landfilled (KPI3-5) % Materials diverted from landfill (KPI3-6) It was agreed that to get started we would need to focus on the basic high level Level 1 KPIs only. That scope of the activities being covered was UK operations only, and that at this stage we are only focusing on manufacturing processes. Identified that there may be variations in the KPIs for different flooring sectors. Suggested that BRE could undertake a survey to further explore what data would be readily available from flooring sectors. However current funding for this task would not allow such a survey to be administered within the resources available. BRE will therefore issue the proposed KPIs and ask for comment from all members. ACTIONS: BRE to send proposed Level 1 KPIs to members for comment by 30th November. Potentially arrange a telephone conference thereafter to agree final KPIs for inclusion in the Annual Report. Agreement to be reached on KPIs no later than 31st December 2012 Members to start collecting KPI data for 2013 calendar year – baseline data therefore to cover period from 01/01/2013 – 31/12/2013. Page 7 of 8 8. AOB Alan Best and Brian Murphy outlined recent discussions they have had with industry about wastage rates in the installation of flooring (all types). Anecdotal evidence may suggest this figure could be as high as 30%. E.g. 30% of flooring materials purchased are wasted. This presents an opportunity to reduce this figure through a programme of education, training and awareness with tradesmen. Such a programme may attract funding via Construction Skills. Alan and Brian to follow up on this. Present at the next FSP meeting (14th March) on progress made. Ian Holmes has provided BRE with details of a TSB (Technology Strategy Board) funding opportunity entitle - Resource Efficiency: New designs for a circular economy. This could be of interest to any manufacturers interested in a part funded feasibility study looking at the redesign of flooring products, and systems to retain material within the economy over several cycles of use (e.g. closing the loop). Grants of up to £25k are available from TSB for this funding call. Deadline for applications is 12 December 2012. Email/call Ben Peace at the Environmental Sustainability KTN for further details (ben.peace@esktn.org / 0151 347 2983) 9. Date of next meeting(s) Thursday 14th March 2013 – Host: Forbo - Derby. June/July 2013 – Host: Mercardo - Chemsford, Essex Page 8 of 8