Template for Electronic Submission to ACS Journals

advertisement

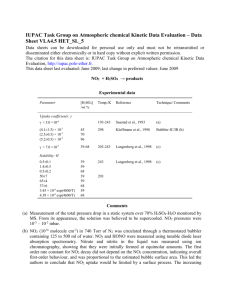

1 Supporting Information for 2 A calibrated Graphene-based chemi-sensor for sub-ppm NO2 detection operating at room 3 temperature 4 Filiberto Ricciardella,* Ettore Massera, Tiziana Polichetti, Maria Lucia Miglietta and 5 Girolamo Di Francia 6 ENEA Research Center, Piazzale E. Fermi, 1, Portici (Napoli), I-80055, Italy 7 Corresponding author: filiberto.ricciardella@enea.it 8 9 Optimization of device conductance value 10 The chemiresistor conductance value has been optimized in order to have a conductance 11 around 10-5 S by varying the volume of the dispensed suspension until the achievement of the 12 proper film conductivity: This particular conductivity range allowed to exploit at the best the 13 electronics of our experimental setup. 14 After preparing different graphene dispersions by chemical exfoliation, few microliters of 15 suspension were deposited by drop-casting onto quartz substrate and the sheet resistance was 16 measured through four-probes instrument (NNPSON RESISTAGE RG8). 17 The flake average thickness in the deposited film was estimated equal to 200 nm through 18 profilometric analysis (KLA TENCOR P-10) so that a conductivity value ranging between 19 104÷105 S/m corresponds to a sheet resistance of drop-casted films in the range of kΩ/sq. 20 1 21 22 Seebeck effect measurement 23 Exploiting the thermoelectric effect, this qualitative method allows to identify the type of the 24 carrier in semiconductors. In our case, this analysis appears to be particularly useful because the 25 interaction between graphene and analyte is strongly influenced by the majority carriers.1 26 On alumina strip (3 x 1 cm2), two pads at a distance of about 5 mm were created by spreading 27 drops of silver paste. Few microliters of graphene dispersion were deposited between the 28 metallic contacts. Once one pad was heated at 450°C, a positive voltage equal to 3mV was 29 measured between the electrodes. This behavior, typical of the p-type doped material, has been 30 inspected for each graphene dispersion, confirming the type of the material doping. 31 32 33 34 35 2 36 Alumina transducer details 37 The sketch of the transducer used as sensor substrate is depicted in Figure S1. 38 39 Figure S1. Sketch of transducer used as substrate for sensor 40 41 All the finger dimensions have been designed by ourselves and customized by 3M taking into 42 account our need and the structure of the test chamber. The graphene film covers the gold 43 interdigitated electrodes (IDE) for an area of about 49 mm2. Volt-amperometric measurements 44 were performed by applying the two probes on the larger pads of the transducer. The probes have 45 a diameter of about 500 m. 46 47 48 3 49 Gas Sensor Characterization System and test protocols towards NO2 50 51 Figure S2. Picture of Gas Sensor Characterization System (left) and corresponding circuital 52 scheme (right). 53 The device is located in a stainless steel test chamber (see fig. S2) placed in a thermostatic box. 54 The chamber is provided of an electrical grounded connector for bias and conductance measure 55 as shownon the right in fig. S2 . 56 A constant flow (500sccm) of the gas carrier, i.e., synthetic air crosses the test chamber. The 57 carrier can be properly humidified through a water bubbler placed in a thermostatic bath. In this 58 environment, characterized by controlled temperature and humidity, the conductance value of the 59 device in its equilibrium state is firstly measured (baseline); after that, an intentional disruption 60 of the equilibrium state is produced by introducing Nitrogen dioxide in a controlled amount and 61 by mixing it with the gas carrier via pneumatic valves and through programmable Mass Flow 62 Controllers. In the field of environmental monitoring, the NO2 concentrations needed to be 63 detected are lower than few parts-per-million (ppm), this poses a fundamental issue in 64 reproducing as much as possible these conditions in lab. In addition, the reproducibility of these 65 levels of concentration in the lab equipment appears no immediate since the pipes and the core of 4 66 test chamber is made of electro-polished stainless steel. This means that the NO2 molecules can 67 spread over and adhere also to the chamber walls, reducing the effective analyte concentration 68 interacting with the sensor. In order to minimize the effects of these limitations, within 30 69 minutes before the measurements, the maximum available concentration of NO2 is fluxed into 70 the chamber for 15 minutes through a protocol controlled via software. In order to check the 71 degree of agreement between the gas concentrations set in the protocols and those present into 72 the chamber, tests have been performed through an FTIR (THERMO ANTARIS IGSS) equipped 73 with a cryogenic detector and a cell having an optical path equal to 10 m. All these operations 74 guarantee the reproducibility of the condition of the test chamber. Hardware and software 75 implemented on a work station allow to control and record environmental parameters, device 76 bias and output signal, making possible to perform customizable automated tests on devices 77 (Protocols). 78 79 In Figure S2 a picture of the stainless steel testing chamber (on the left) and the circuital scheme for the electrical characterizations (on the right) are reported. 80 In the field of environmental monitoring, the NO2 concentrations needed to be detected are 81 lower than few parts-per-million (ppm), this poses a fundamental issue in reproducing as much 82 as possible these conditions in lab. In addition, the reproducibility of these levels of 83 concentration in the lab equipment appears no immediate since the pipes and the core of test 84 chamber is made of electro-polished stainless steel. This means that the NO2 molecules can 85 spread over and adhere also to the chamber walls, reducing the effective analyte concentration 86 interacting with the sensor. In order to minimize the effects of these limitations, within 30 87 minutes before the measurements, the maximum available concentration of NO2 is fluxed into 88 the chamber for 15 minutes through a protocol controlled via software. In order to check the 5 89 degree of agreement between the gas concentrations set in the protocols and those present into 90 the chamber, tests have been performed through an FTIR (THERMO ANTARIS IGSS) equipped 91 with a cryogenic detector and a cell having an optical path equal to 10 m. All these operations 92 guarantee the reproducibility of the condition of the test chamber. 93 94 An example of standard protocol for sensing measurement at fixed NO2 concentration is set as follows: 95 • 1200 seconds in carrier gas at constant relative humidity (RH) and temperature 96 • 15 seconds exposure to 4300 parts-per-billion (ppb) of NO2 97 • 225 seconds exposure to 350 parts-per-billion (ppb) of NO2 98 • 180 seconds at zero gas flow 99 • 1200 seconds of flushing with carrier gas. 100 The first step, also called baseline, is required to stabilize the conductance value and to 101 determine the starting point of the response at the gas inlet. Since the test chamber volume is 102 about 40 cl, a “double step” for the gas inlet is needed to more rapidly reach the steady state 103 conditions in terms of gas concentrations: in the first 15 sec the gas flow is set to very high 104 concentration value; in the subsequent 225 sec the gas flow is set to the target concentration. The 105 flushing step is used to recover the conductance to the initial condition. 106 107 The typical conductance dynamic response of the sensor upon the just described run is showed in Fig. 4 in the paper; in that case, the carrier gas is N2 and the RH is set at 50%. 108 The standard protocol for the sensing measurements referred to Fig. 5 in the main text consists 109 of different pulses of NO2 followed by short recovery steps, operating in conditions of humidity 110 and carrier gas similar to those reported in the last runs. For all the concentrations, except for the 111 exposure to 50 ppb, the protocol is set as follows: 6 112 2 minutes exposure to NO2 113 4 minutes flushing with carrier gas 114 115 In the case of 50 ppb, the only change regards the exposure time window that requires 4 minutes to achieve an appreciable conductance variation. 116 Likewise, for the sensor calibration, the test protocol is constituted by sequential steps at 117 different analyte concentrations: after the initial acquisition of the baseline, the device was 118 exposed to NO2 for 2 minutes and left to recover in inert gas flow for 28 minutes assisting the 119 partial desorption of the gas and avoiding the poisoning of the sensing film. 120 121 7 122 Derivative Method and calibration protocol 123 The employed method for the sensor analysis and calibration is focused on the derivative of 124 the signal output. In particular, the derivative is calculated as the average of the incremental ratio 125 according to the following relation implemented by OriginPro® software: 126 𝒇′ (𝒙𝒊 ) = 𝟏 𝒚𝒊+𝟏 − 𝒚𝒊 𝒚𝒊 − 𝒚𝒊−𝟏 [ + ] 𝟐 𝒙𝒊+𝟏 − 𝒙𝒊 𝒙𝒊 − 𝒙𝒊−𝟏 127 where xi and yi are generic time instant and value conductance, respectively. 128 When the sensor is exposed to several sequential steps at different analyte concentrations (see 129 Figure 5 in the text) for the same exposure time, the effects of the algorithm on the signal is well- 130 rendered. The linear trend of the maxima with the concentration leaps out, clearly highlighting an 131 increase of one order of magnitude upon NO2 exposure passing from 100 ppb to 1000 ppb. This 132 biunivocal corrispondance has been exploited to the aim to calibrate the sensor according to a 133 above mentioned calibration protocol. 134 The error bars in the calibration plot (Figure 6 in the paper) have been calculated by 135 considering the difference between two subsequent points in the neighborhood of the maximum 136 of each derivative peak. 137 The employed analysis method allows to compare devices fabricated starting from different 138 batches and/or having a large different parameters such as initial conductance and response to the 139 analyte. At the same time, the method reveals so versatile that it can be extended to all devices 140 affected by slow and incomplete recovery. 141 142 8 143 State of the art for the sensors operating at Room Temperature 144 A brief comparison between our sensor results gas sensor devices operating at Room 145 Temperature and based on sensing materials other than graphene, is reported herein. 146 147 - Sensitive film based on nanostructured metal oxides 148 Metal oxides are considered the best option for this kind of application and SnO2 is one of the 149 most investigated material. This oxide is a very good choice for sensors working at high 150 temperatures (>350°C), but when RT scenarios have to be considered, their performances 151 strongly get worse and different approaches (i.e. nanostructured morphologies) have to be 152 considered. For instance, Khuspe et al. show that a fairly high response (about 20%) can be 153 obtained although at much higher concentration (100 ppm).2 However, the device shows a very 154 short time of response (7s) but the operating temperature is still fairly high, around 200°C . In 155 comparison, our device is certainly slower but it is much more sensitive (10 times at least) and it 156 truly operates at RT. 157 ZnO is another widely investigated metal oxide for NO2 detection. Shishiyanu et al. report on 158 a doping process also finalized to decrease the device operating temperature. They find a 159 sensitivity around a few %/ppm at RT (therefore again our device seems more promising) with a 160 response time in the order of minutes (comparable to our device).3 161 162 - Sensitive film based on an organic material. 163 Some conjugated polymers have been investigated as possible sensitive materials exploiting 164 the “doping” effects that some chemicals can exhibit during the molecule-polymer interaction. In 165 the recent paper, Ji et al., it is for instance shown that a high change of the relative response at 9 166 RT can be observed (about 20%) but at 5 ppm of NO2, with a time of response that strictly 167 follows the gas pulse (tens of minutes).4 Also in this case our device seems to be more 168 promising, at least in terms of response time. 169 170 - Sensitive film based on Carbon Nanotubes (CNT). 171 CNTs based sensors show a very interesting response to NO2. The most widely cited papers, in 172 this respect, is the paper by L. Valentini et al. Their device shows a 6% response to 100 ppb and 173 are sensitive to the gas up to 10 ppb. However the device operates at a fairly high temperature 174 (165 °C) and, more importantly, the characterizations have been performed in dry air, that is, far 175 from normal operating conditions.5 Our device operates, on the contrary, at relative humidity 176 concentrations similar to those normally observed in urban environments. 177 178 179 180 10 181 182 183 184 185 186 REFERENCES 1. F. Schedin, A. K. Geim, S. V. Morozov, E. H. Hill, P. Blake, M. I. Katsnelson, and K. S. Novoselov, Nature Mat. 6, 652 (2007). 2. G. D. Khuspe, R. D. Sakhare, S. T. Navale, M. A. Chougule, Y. D. Kolekar, R. N. Mulik, R. C. Pawar, C. S. Lee, V. B. Patil, Ceram. Int. 39, 8673 (2013). 187 3. S. T. Shishiyanu, T. S. Shishiyanu, O. I. Lupan, Sens. Actuators B 107, 379 (2005). 188 4. S. Ji, H. Wang, T. Wang, D. Yan, Adv. Mat 25, 1755 (2013). 189 5. L. Valentini, I. Armentano, J. M. Kenny, C. Cantalini, L. Lozzi, S. Santucci, Appl. Phys. 190 Lett. 82, 961 (2003). 191 11