display

advertisement

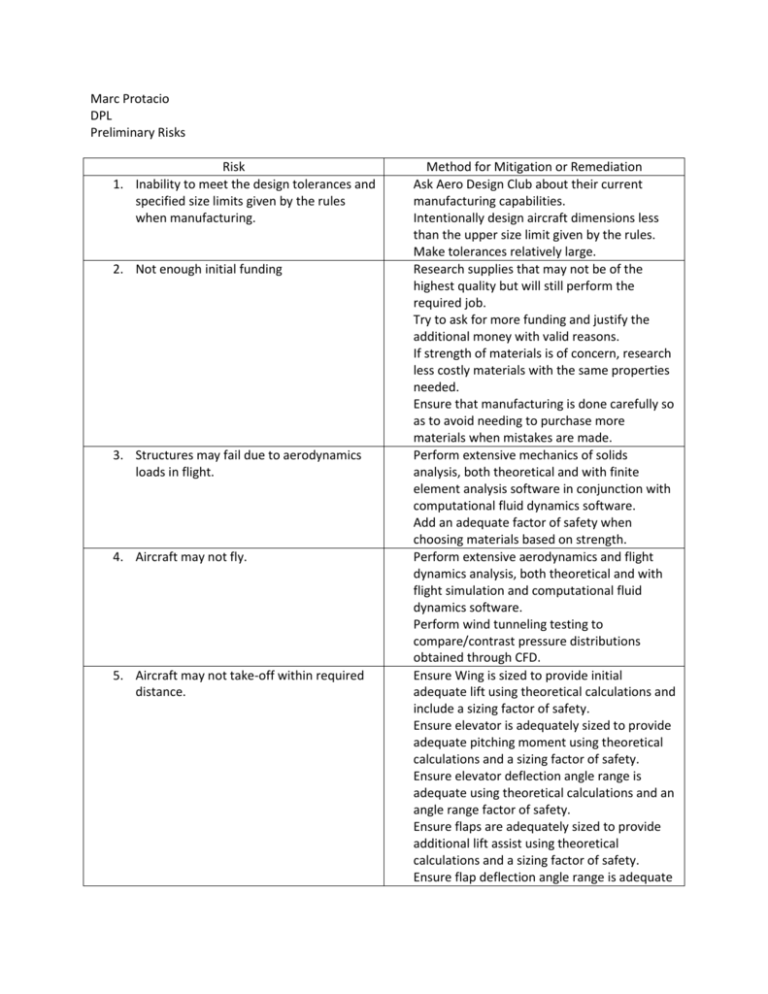

Marc Protacio DPL Preliminary Risks Risk 1. Inability to meet the design tolerances and specified size limits given by the rules when manufacturing. 2. Not enough initial funding 3. Structures may fail due to aerodynamics loads in flight. 4. Aircraft may not fly. 5. Aircraft may not take-off within required distance. Method for Mitigation or Remediation Ask Aero Design Club about their current manufacturing capabilities. Intentionally design aircraft dimensions less than the upper size limit given by the rules. Make tolerances relatively large. Research supplies that may not be of the highest quality but will still perform the required job. Try to ask for more funding and justify the additional money with valid reasons. If strength of materials is of concern, research less costly materials with the same properties needed. Ensure that manufacturing is done carefully so as to avoid needing to purchase more materials when mistakes are made. Perform extensive mechanics of solids analysis, both theoretical and with finite element analysis software in conjunction with computational fluid dynamics software. Add an adequate factor of safety when choosing materials based on strength. Perform extensive aerodynamics and flight dynamics analysis, both theoretical and with flight simulation and computational fluid dynamics software. Perform wind tunneling testing to compare/contrast pressure distributions obtained through CFD. Ensure Wing is sized to provide initial adequate lift using theoretical calculations and include a sizing factor of safety. Ensure elevator is adequately sized to provide adequate pitching moment using theoretical calculations and a sizing factor of safety. Ensure elevator deflection angle range is adequate using theoretical calculations and an angle range factor of safety. Ensure flaps are adequately sized to provide additional lift assist using theoretical calculations and a sizing factor of safety. Ensure flap deflection angle range is adequate 6. Aircraft may not land within the required distance. 7. Aircraft may not be able to carry a “competitive” payload. 8. Aircraft may not be designed and built within the required time frame. 9. Poor weather during flight demonstration may inhibit aircraft performance 10. Poor controllability of aircraft during flight. 11. Electronics may fail. 12. Lack of electronics integration experience. using theoretical calculations and an angle range factor of safety. Ensure engine provides adequate thrust to get aircraft to the required initial velocity by testing the thrust capability of the engine on a test stand. Have discussion with pilot to discuss required landing velocity and ensure that he/or she plans to obtain that requirement when approaching the land. Make sure elevator and flaps are adequately sized and have adequate angular range, as discussed previously when taking-off, to trim aircraft during landing. Make sure rudder is adequately sized and has sufficient angular deflection capability to remove any sideslip angle, using theoretical calculations and applying a factor of safety. Research previous winning aircrafts and the payloads that they were able to carry. Design the aircraft to carry more than that payload, and include a factor of safety in the lifting capability. Test aircraft to ensure the designed payload weight is carried prior to competition. Develop Gantt scheduling chart and follow it strictly. Include a scheduling factor of safety (allocate extra time for tasks) to account for problems experienced and mistakes made in the process. - Test aircraft in a variety of weather scenarios to give pilot experience flying with poor flight conditions. - Properly size control surfaces using theoretical calculations and a sizing factor of safety. - Ensure control surface deflection angle range is adequate using theoretical calculations and an angle range factor of safety. - Allow pilot adequate time to test the aircraft so that he or she is comfortable flying it. - Purchase spare electronic components. - Inspect/test electronics prior to flight. - Consult with the Aero Design Club for - 13. Engine may not be able to provide adequate thrust. - 14. Lack of aeronautical engineering knowledge amongst team members. - - common methods of electronics integration. Refer to previous SAE Aero design reports to learn about other electronics integration methods. Calculate required thrust using theoretical calculations and ensure that a thrust factor of safety is implemented. Test the thrust capability of the engine on a test stand. Consult with textbooks regarding aeronautical engineering theory as well as aircraft design methods. Refer to previous SAE Aero design reports to learn about design methods used. Assemble team members that are in the “Aero” option.