Style: feature Strap head: filter media

advertisement

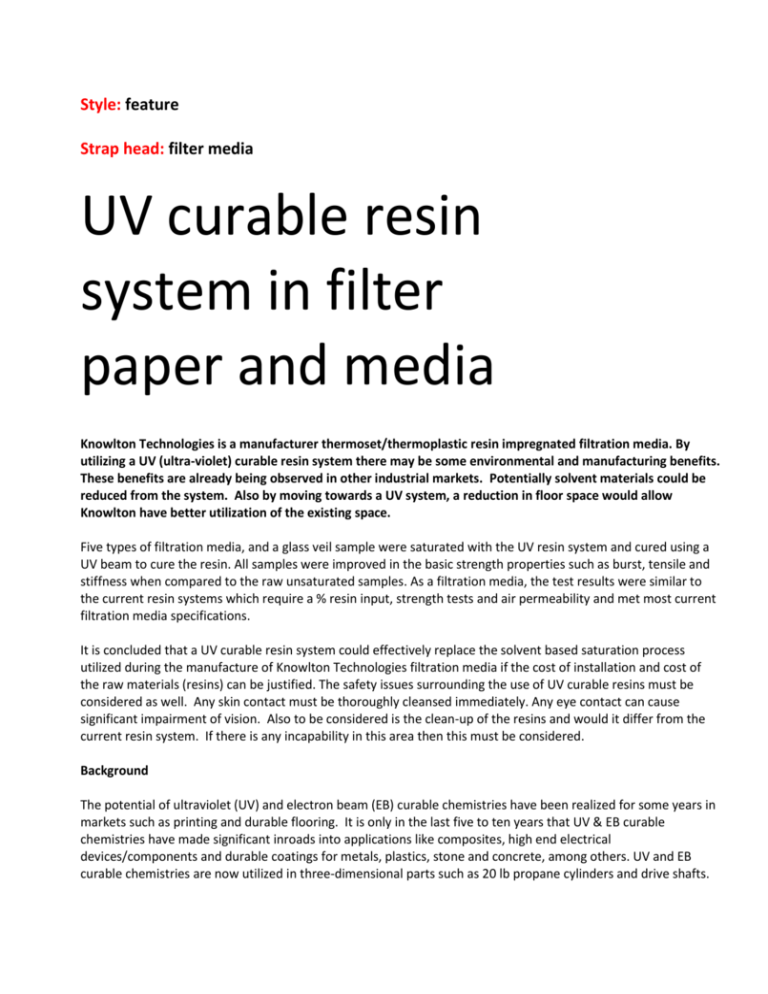

Style: feature Strap head: filter media UV curable resin system in filter paper and media Knowlton Technologies is a manufacturer thermoset/thermoplastic resin impregnated filtration media. By utilizing a UV (ultra-violet) curable resin system there may be some environmental and manufacturing benefits. These benefits are already being observed in other industrial markets. Potentially solvent materials could be reduced from the system. Also by moving towards a UV system, a reduction in floor space would allow Knowlton have better utilization of the existing space. Five types of filtration media, and a glass veil sample were saturated with the UV resin system and cured using a UV beam to cure the resin. All samples were improved in the basic strength properties such as burst, tensile and stiffness when compared to the raw unsaturated samples. As a filtration media, the test results were similar to the current resin systems which require a % resin input, strength tests and air permeability and met most current filtration media specifications. It is concluded that a UV curable resin system could effectively replace the solvent based saturation process utilized during the manufacture of Knowlton Technologies filtration media if the cost of installation and cost of the raw materials (resins) can be justified. The safety issues surrounding the use of UV curable resins must be considered as well. Any skin contact must be thoroughly cleansed immediately. Any eye contact can cause significant impairment of vision. Also to be considered is the clean-up of the resins and would it differ from the current resin system. If there is any incapability in this area then this must be considered. Background The potential of ultraviolet (UV) and electron beam (EB) curable chemistries have been realized for some years in markets such as printing and durable flooring. It is only in the last five to ten years that UV & EB curable chemistries have made significant inroads into applications like composites, high end electrical devices/components and durable coatings for metals, plastics, stone and concrete, among others. UV and EB curable chemistries are now utilized in three-dimensional parts such as 20 lb propane cylinders and drive shafts. The numerous process and environmental benefits of UV & EB curable technologies are what make them a sustainable and a technology worth looking at in today’s marketplace. Some of these benefits include reduced or near zero volatile organic compound (VOC) and potentially hazardous air pollutant emissions, significantly reduced energy consumption, high processing speeds, good finished product performance quality and less floor space. On the other hand is the cost and installation of the new equipment, increased electrical usage and developing new formulations for the wide range of products being the manufactured. Knowlton Technologies, LLC of Watertown, NY conducted a feasibility study to develop and to quantify the benefits of a 100% solids UV curable resin system(s) that would replace the standard thermally cured resin blends in a number of their specialty filter papers/media. A UV curable resin system is potentially capable of replacing Knowlton's standard thermally cured solvent based thermoset and thermoplastic resin systems in some products, may potentially provide significant environmental and processing benefits in the process of manufacturing specialty filter and filtration media. At the same time, it's projected that a UV curable resin could possibly result in an equal product that is less expensive to produce, giving Knowlton an opportunity to increase market share and business as whole. There are areas in how the final media is processed that must be answered though in order to make this a viable system. Knowlton Technologies, LLC is a privately held company that now employs over 100 people within New York State. Knowlton's history dates back over 200 years to 1808 when the company was started by John Paddock and Gurdon Caswell. The company has since undergone many transformations, but at the core of these evolutions is the paper mill capable of producing thousands of pounds of wet laid non-wovens, filter and composite media now being utilized in everything from automotive transmissions to medical filtration. Problem and solution Knowlton owns and operates two composite media manufacturing lines and one saturation line. More than half of the filter paper and composite media that is manufactured by Knowlton is impregnated with a resin to add additional value to the product and provide the customer with a product of a desired quality. The addition of a resin to a paper, filter or composite media can significantly increase the strength, heat and chemical resistance and long term durability of the product. Knowlton has identified two filter product lines as candidate products for qualification of a UV curable resin as a replacement for the traditional resin systems. B oth of which are proprietary filter formulations sold to major manufactures of fluid filter manufacturers. For these products the customer(s) are generally most concerned with cost and performance. Knowlton has secured a verbal commitment from their primary customer of these grades, who asked to remain unnamed, to evaluate and qualify any new filter products that have the potential to make Knowlton's manufacturing process ‘greener,’ while maintaining performance and ideally reducing costs. The saturation line, as currently configured and operated, requires significant floor space and energy to impregnate filter and composite media with thermally cured resins. Secondary concerns with the current system include the flammability issues associated with the resins and the solvents that they contain. F lue detection and suppression systems have been installed as the current chemistry is flammable. Also, since phenolics generally contain some amount of free phenol and formaldehyde, there is a safety factor associated with humans handling these chemicals. In certain locations, such as the room that contains the saturator bath, respirator systems must be used when interacting with these chemicals to prevent exposure to the respiratory tract. Third, as most of the phenolics currently purchased by Knowlton are supplied as 50% - 60% solids a significant weight and volume of the purchased product is material that has no function in the finished product and simply adds to shipping costs and storage space. This means that up to 50% of the volume taken up on a shipping container, commercial truck or storage tankage does not add value to the end product. Fiberglass composites have been produced at roughly 0.0500 in (50 mm) thickness and containing anywhere from 40%-60% resin based on weight. The key to UV curing is that it is a ‘line-of-sight’ curing technology. In other words, the resin must see or be directly exposed to UV light in order to cure, or crosslink. UV transmission measured through an 80 mm fiberglass veil produced by Knowlton Technologies showed more than sufficient UV energy passing through the random chopped fiber media. Table 1 shows that data obtained by measuring the UV transmission through the 80 mm glass veil of a 500 W/in microwave powered Fusion UV light fitted with an iron (D) doped bulb at roughly 2.5 in from the bottom of the irradiator housing. The data was measured with an EIT Power Puck II A2. Keep in mind that the optimum distance from Fusion focused irradiator is 2.1 in. UV Range UVB (280-320nm) UVA (320-390nm) UVA2 (375-415nm) UW (395-445nm) Peak Irradiance Total Energy mW/cm2 mJ/cm2 mW/cm2 mJ/cm2 mW/cm2 mJ/cm2 mW/cm2 mJ/cm2 Control Through Media % Transmission 865 956 2423 2836 1546 1658 2355 2726 32 20 920 817 719 589 1240 1094 4% 2% 38% 29% 47% 36% 53% 40% Table 1 – UV transmission through 80mil chopped fiber veil. In this particular application, the use of a 100% solids UV curable resin will eliminate solvents from the saturation and curing process and the need for a thermal oxidizer. From an environmental and health and safety standpoint this is a benefit to switching to a UV curable resin system. This feasibility study is not designed to research and develop a UV curable resin system(s) to replace all of Knowlton's saturation resins as some products, such as friction papers, require very high temperature resistance and the UV light source cannot penetrate this substrate. However, this feasibility study will show that a UV curable resin system can successfully be formulated to replace thermally cured resin systems in many filter applications as UV cured epoxy acrylates and epoxy novolac acrylates have good thermal resistance and excellent chemical and moisture resistance. Secondly, the UV curable resins will be formulated to cure almost instantaneously with the specified wavelength and energy of UV light to meet or exceed current production rates. The energy consumption of the required number of UV lights is expected to be significantly less than the energy required to run the thermal ovens to cure the thermo resin systems and power the material handling equipment. Once a formulation is developed that meets all of the performance specs and fits within the cost model it will be determined how much UV energy is required to sufficiently cure the chemistry. In this case, an EIT MicroCure will be utilized to quantify the amount of UV energy necessary to cure the resin and ultimately determine the number of UV lights to meet the processing speeds. Once this information is determined a comparative analysis of energy consumption of the two different resin systems can be thoroughly performed. A I00% solids UV curable resin system will eliminate the flammability hazard and safety equipment required for such products. 100% solids UV curable resins are not flammable and have flash points well over 200°F. From a safety and handling standpoint, UV curable resins can at worst case be considered skin irritation/sensitization hazards, and this property is generally a result of low molecular weight monomers and not higher molecular weight oligomers. Since no solvents will be present in the UV curable resins, no special respiration equipment will be required, meaning a better working environment for the employees. Lastly, 100% of the resin shipped to Knowlton will be utilized in the final product. In the big picture, this means that Knowlton could technically use 50% less volume of resin compared to the thermoset resins utilized today. This means less storage space is required and more efficient transport of raw materials to Knowlton Technologies. Project benefits This p r o j e c t is a proof of concept and the final UV curable resin formulation and UV energy requirements to cure this composition will not be established until well into the research and development process. As a result, it is difficult to project accurate estimates of cost and energy benefits at this time. However, during the latter stages of the project, after a UV curable resin has been developed and quantified, measurable energy savings, reduction in solvent usage, reduction in maintenance costs, the potential for increased market share and overall growth of Knowlton can be evaluated. Energy S a v i n g s : while difficult to quantify at this point, certain energy savings can be identified through discontinued use of the thermal oxidizer, curing ovens, material handling equipment and environmental controls in these areas. Additional quantifiable energy benefits may include reduced resin shipments and reduced storage space. Environmental benefits: the environmental benefits would be significant by reducing the use of solvent borne chemistries originating from the saturation process. Economic benefits: a UV curable resin system has the potential to allow Knowlton to manufacture the same products for less money, meaning Knowlton can improve margins or use the lower costs of manufacturing to gain market share both domestically and overseas. Either way, the company can improve the bottom line and be in a better position grow/expand, hire more employees in upstate New York and develop new products and processes that help diversify the company and keep them competitive in today's global marketplace. Cost benefit projection: once a UV curable resin formulation has been qualified, detailed comparative analysis will be performed to determine potential energy savings, actual solvent reductions and process benefits, such as reduced maintenance costs. Included in this analysis will be the difference in natural gas and electricity consumption resulting from the shutting off of larger energy sinks like the thermal oxidizer, ovens and material handling equipment. At the same time, the actual reduction in solvent consumption will be evaluated to see if savings on permitting or any other emission related issues can be realized. It would be desirable from Knowlton's standpoint that this proof of concept result in a technology that can be commercialized in a relatively short period of time and have a return-on-investment (ROI) of less than three years on the capital cost to integrate such a technology into the production line. Results Knowlton Technologies chose six samples to be saturated to our standard input levels. The samples were chosen across our typical grade mix of air filtration, liquid filtration and glass veil type grades. The samples were then cured under the UV light at a speed of 10fpm to a saturated fully cured state. These samples were then tested for physical properties and compared to our current specifications for each specific grade. Based upon all testing completed the samples saturated with the UV resin were equal in all ways to the traditional phenolic saturated products and the specifications that the grades were compared against were met. INITIAL SAMPLE TESTING SAMPLE ID BsWt CAL DEN FRAZ MULLEN MD STIFF CD STIFF AVE. INPUT B TARGET 125.9 19.1 6.59 2.74 67.5 7600 4000 12.7 D HIGH 146.3 31.1 4.70 43.8 37.8 10800 7200 44.7 D TARGET 104.1 31.0 3.36 110 32.8 9600 3600 19.0 E HIGH 177.6 22.1 8.04 1.09 50.8 10800 6800 40.5 E TARGET 130.6 21.6 6.05 1.83 53.3 10400 4400 18.3 F TARGET 132.7 24.8 5.35 6.34 53.0 14400 6000 14.0 G HIGH 181.0 26.4 6.86 3.42 47.0 15200 9200 46.7 G TARGET 133.3 26.5 5.03 5.96 51.0 12400 6000 21.5 H HIGH 174.2 34.7 5.02 38.6 51.3 20000 13200 38.5 H TARGET 129.3 33.5 3.86 52.4 34.5 15200 5600 13.4 Table 2. Physical property results with UV resin. SAMPLE ID BsWt CAL DEN FRAZ MULLEN MD STIFF CD STIFF AVE. INPUT B1 142.1 19.1 7.44 1.9 99 8800 3600 20.4 B2 145.2 19.1 7.60 1.69 94.5 9600 4800 18.6 B3 145 19.7 7.36 1.85 86 9200 4000 18.3 D1 108.1 26.5 4.08 99 67.5 10000 4000 24.1 D2 107.1 26 4.12 96.2 65 9600 4800 22 D3 108.1 26.8 4.03 91.6 65.0 7600 5200 23.3 E1 141.7 21.4 6.62 1.35 66.0 9600 5600 19.7 E2 140.8 21.5 6.55 1.27 64.5 10000 4400 20.6 E3 137.5 20.6 6.68 1.3 60.5 9200 4800 20 F1 129.7 24.4 5.32 10.2 80.5 15200 6000 16.1 F2 131.5 23.6 5.57 9.77 78 14800 6400 17.9 F3 128.4 23.7 5.42 10.6 75 12800 5200 17.5 G1 126.3 26.3 4.8 4.85 42 12800 6400 23.5 G2 120.6 26.1 4.62 5 55 10400 4800 21.4 G3 123.5 26.2 4.71 4.93 58 10000 4400 21.8 H1 138.5 33.3 4.16 60.2 64 20000 8800 20 H2 138.7 34.7 3.99 55.8 61 19200 10400 18.2 H3 135.9 35.6 3.82 61.2 74.5 15200 6800 19 AIM INPUT 14.0% 23.0% 20.0% 16.0% 21.5% 19.0% Table 3. Conclusions Based upon the results obtained through this testing, it appears that the UV curable resins have a true potential for the saturation of filtration media. Properties such as tensile strength, Mullen burst, and Elmendorf stiffness were improved equal to the thermoset resin systems, while at the same time maintaining Frazier air permeability. Should Knowlton Technologies go forward with this project, an investigation of the costs associated with this technology is required. This would include the need to determine cost of the UV equipment necessary, the projected costs of the raw materials, energy consumption and how these might be incorporated into the Knowlton manufacturing plant layout. Lastly, the safety needs of handling the UV curable resin and operating the UV light systems would need to be thoroughly investigated. The UV systems would allow some reduction of solvent based resins from the operation however not all. Many of the products manufactured would still require thermoset resin systems as the UV light is not visible through 100% of the non-woven media manufactured at Knowltons. Therefore there would still be some solvent based systems in house and it may result in problems switching between the systems. Contact John Crimi Director of sales and product development Knowlton Technologies, LLC 213 Factory Street Watertown, NY 13601 Work (315)755-2640 Fax (315)782-7517 www.knowlton-co.com Caption The filters are used primarily for fuel filtration, coalescing (water removal) filtration, and lubrication oils filtration. One of Knowlton’s largest product lines is aviation fuel filtration. The company manufactures roll stock of grooved material, which its customers will typically convert into a cartridge. Picture courtesy of Ozgur Coskun/Shutterstock.com