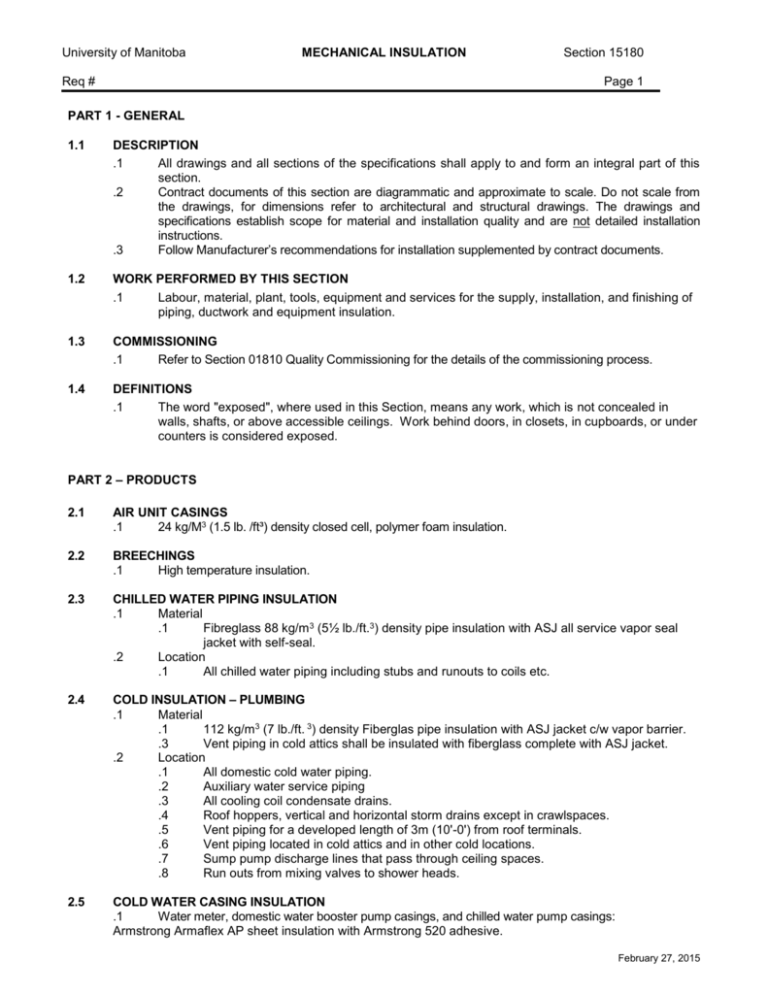

15180 Mechanical Insulation

advertisement

University of Manitoba MECHANICAL INSULATION Req # Section 15180 Page 1 PART 1 - GENERAL 1.1 DESCRIPTION .1 All drawings and all sections of the specifications shall apply to and form an integral part of this section. .2 Contract documents of this section are diagrammatic and approximate to scale. Do not scale from the drawings, for dimensions refer to architectural and structural drawings. The drawings and specifications establish scope for material and installation quality and are not detailed installation instructions. .3 Follow Manufacturer’s recommendations for installation supplemented by contract documents. 1.2 WORK PERFORMED BY THIS SECTION .1 Labour, material, plant, tools, equipment and services for the supply, installation, and finishing of piping, ductwork and equipment insulation. 1.3 COMMISSIONING .1 Refer to Section 01810 Quality Commissioning for the details of the commissioning process. 1.4 DEFINITIONS .1 The word "exposed", where used in this Section, means any work, which is not concealed in walls, shafts, or above accessible ceilings. Work behind doors, in closets, in cupboards, or under counters is considered exposed. PART 2 – PRODUCTS 2.1 AIR UNIT CASINGS .1 24 kg/M3 (1.5 lb. /ft³) density closed cell, polymer foam insulation. 2.2 BREECHINGS .1 High temperature insulation. 2.3 CHILLED WATER PIPING INSULATION .1 Material .1 Fibreglass 88 kg/m3 (5½ lb./ft.3) density pipe insulation with ASJ all service vapor seal jacket with self-seal. .2 Location .1 All chilled water piping including stubs and runouts to coils etc. 2.4 COLD INSULATION – PLUMBING .1 Material .1 112 kg/m3 (7 lb./ft. 3) density Fiberglas pipe insulation with ASJ jacket c/w vapor barrier. .3 Vent piping in cold attics shall be insulated with fiberglass complete with ASJ jacket. .2 Location .1 All domestic cold water piping. .2 Auxiliary water service piping .3 All cooling coil condensate drains. .4 Roof hoppers, vertical and horizontal storm drains except in crawlspaces. .5 Vent piping for a developed length of 3m (10'-0') from roof terminals. .6 Vent piping located in cold attics and in other cold locations. .7 Sump pump discharge lines that pass through ceiling spaces. .8 Run outs from mixing valves to shower heads. 2.5 COLD WATER CASING INSULATION .1 Water meter, domestic water booster pump casings, and chilled water pump casings: Armstrong Armaflex AP sheet insulation with Armstrong 520 adhesive. February 27, 2015 University of Manitoba Req # MECHANICAL INSULATION Section 15180 Page 2 .2 .3 Refinish with Armstrong Armaflex finish. Apply insulation to pump casings to match form of pump. Apply adhesive as per Manufacturer’s recommendations. 2.6 COMPATIBILITY OF COMPONENTS .1 All adhesives, sealers, vapour coating, mastics, laggings, and bedding compounds, shall be compatible with materials to which they are applied. They shall not soften, corrode, or otherwise attack such material in either wet or dry state. Materials shall only be those recommended by Manufacturer or insulation as suitable for application proposed and be applied within ambient temperature range recommended by the Manufacturer. 2.7 EQUIPMENT AND MISCELLANEOUS APPLICATIONS .1 Heat exchangers: Shell and tube type: 48 kg/M³ (3.0 lb. /Ft³) density fibreglass pipe and duct wrap. Insulation not required on plate type heat exchangers. .2 Refrigeration systems: closed cell Armaflex or Imcolock insulation on evaporator, suction piping, and chilled water headers. .3 Hot water storage tanks: 48 kg/M³ (3.0 lb./Ft³) density fibreglass pipe and duct wrap. Insulation not required on plate type heat exchangers. 2.8 ENGINE EXHAUST PIPING AND SILENCER INSULATION .1 Engine exhaust piping and silencer shall be covered with Thermo-12 preformed calcium silicate pipe insulation. .2 Insulate fittings with mitered sections of same insulation. 2.9 FINISHES AND PROTECTIVE COVERINGS .1 Canvas: 170 g/m2 with lagging adhesive, ULC labelled. .2 Stainless Steel: Protective covering to be equal to smooth 0.016” Childers Type 316 stainless steel covering secured with 12mm (½“) stainless steel banding at 300mm (12”) on centre. Stainless steel covering to be complete with 3 mil heat laminated Polysurlyn moisture retrarder coating. .3 Trowelled-on weather protective coating: Bakor 110-14 asphalt mastic vapour barrier coating on screen mesh. 2.10 HIGH TEMPERATURE SEALANT .1 High pressure sealant to be equal to LePage LEO40 hi-heat silicone sealant with temperature rating of 315°C (600°F) 2.11 HOT INSULATION - PLUMBING .1 Material .1 112 kg/m3 (7 lb./ft.3) density Fiberglass insulation with all service jacket (ASJ) and selfsealing lagging adhesive. .2 Location .1 All domestic hot water, tempered water supply and hot water recirculation piping. .2 Barrier free lavatory basin “P” traps. 2.12 HOT INSULATION - HEATING .1 Use Fiberglass 88 kg/m 3 (5½ lb./ft3) density pipe insulation with all service jacket (ASJ) and selfsealing lagging adhesive in the following thicknesses: .2 Location .1 Pumped condensate piping. .2 Glycol heating piping. .3 Glycol heat recovery piping. .4 Generator cooling piping. .5 Hot water heating piping. 2.13 HOT INSULATION – STEAM .1 Calcium silicate or high-temperature fiberglass shall be used in steam applications. February 27, 2015 University of Manitoba Req # MECHANICAL INSULATION Section 15180 Page 3 .2 .3 Use steam pipe insulation with all service jacket (ASJ) and self-sealing lagging adhesive in specified thicknesses. Location .1 Steam piping. .2 Condensate piping. 2.14 HOT INSULATION - EQUIPMENT .1 The following items insulated with J-M Thermo-12 calcium silicate blocks or Fibreglass AF570. .1 Domestic hot water converters. .2 Heat exchangers. .3 Domestic hot water storage tanks. .4 Condensate receivers. .5 Flash tanks. .6 Glycol heating convertors. 2.15 INSTALLATION 1. Insulation shall be applied on clean, dry surfaces and only after tests and approvals required by the specifications have been completed. 2. All insulation on piping operating below ambient temperature shall be continuous through wall and ceiling openings and sleeves. 3. Insulation on all cold surfaces must be applied with a continuous, unbroken vapor seal. Hangers, supports, anchors, etc. that are secured directly to cold surfaces shall be adequately insulated and vapor sealed to prevent condensation. 4. Specified adhesives, mastics, and coatings shall be applied at the Manufacturer's recommended minimum coverage per gallon. 5. Edges of vapor barrier insulation at valve stems, instrument wells, unions, and other raw edges shall be sealed adequately to prevent moisture from penetrating the insulation. 2.16 INSULATION .1 PREMOLDED INSULATION .1 Provide ULC Listed sectional fibreglass pipe insulation in compliance with ASTM C335-84 in pre-moulded sections 36” (900mm) long, split and ready for application with a minimum Thermal Conductivity of 0.033 W/m deg C at 75°F (24°C) mean temperature and be capable of use on service from -40°F to 500°F (-40°C to 260°C) and with factory applied vapour seal jacket of vinyl coated foil Kraft laminate with reinforcing of open mesh glass fibre. .2 Rigid board: 4.5 lbs/ft3 (72 kg/m3) density ULC listed glass fibre board with glass fibre reinforced aluminium foil vapour seal facing and minimum thermal conductivity of 0.035 W/m deg C at 75°F (24°C) mean temperature. .2 NON-PREMOLDED PIPE INSULATION .1 0.75 lb./ft³ (12g/M³) thick ULC listed fibreglass flexible blanket with glass fibre reinforced aluminium foil vapour seal facing with thermal conductivity of 0.036 W/m-°C. .3 HIGH TEMPERATURE INSULATION .1 High temperature - over 650°F (350°C): Pre-formed calcium silicate or Roxul 1200 mineral fibre piping insulation. .4 LOW TEMPERATURE INSULATION .1 Low temperatures: 7°C (40°F) to 1°C (34°F): fire retardant closed cell Armaflex in sheet form or pre-formed for piping. .5 VERY LOW TEMPERATURE INSULATION .1 Very low temperature: Below 1°C (34°F): Layers of 25mm (1“) Dow Chemical Styrofoam pipe insulation to establish the total specified thickness. All joints to be offset and overlapped with second layer. February 27, 2015 University of Manitoba Req # MECHANICAL INSULATION Section 15180 Page 4 .2 .3 .4 All surfaces to be insulated are to be cleaned and painted with two coats of Rustoleum red primer waterproof paint. All insulation joints to be sealed with Dow Chemical Saran vapour retarder tape Insulation to be covered with PVC jacket with all joints sealed vapour tight. .6 DUCT INSULATION .1 The use of duct liner as thermal insulation is not allowed. Duct liner may be considered for acoustical purposes only. Special sound attenuators shall be used wherever required to eliminate fan noise. The University representative shall be contacted for approval. .2 All duct insulation in mechanical rooms and on outside and mixed air ductwork, and also where subject to abuse or impact, shall be rigid fiberglass board, with a minimum density 3 of 3 lb/ft and be covered with canvas and lagging. All other duct insulation shall be blanket type. .7 ACOUSTIC INSULATION .1 The use of fiberglass liner is not allowed. All acoustic duct liner must be constructed of closed-cell, polymer sheet insulation materials. .2 Product must be cleanable and have a zero perm rating and zero water absorption. .3 Installation shall not include any tapes, fabrics, cements or other materials which are not cleanable or which offer opportunity for mold growth. .4 Installation shall be to Manufacturer’s standards and shall withstand air velocities of 12.7 m/s (2500 feet per minute). 2.17 INSULATION PROTECTION SHIELDS .1 Insulation protection shields shall be installed at all pipe hangers and supports. Shields shall span an arc of 180°. .2 An 18 gauge galvanized metal shield shall be installed fully over the top ½ of all insulated piping located outdoors where exposed to potential damage. The shield shall be a minimum length of 900mm (36”) and field located to prevent damage to the insulation while walking over the piping. Stainless steel jacket to be installed over the shields on all outdoor piping. .3 All piping in Mechanical and Equipment Rooms shall have PVC insulation jacketing. Areas that need moisture protection also to be completely wrapped in PVC. Above ceilings, a standard allservice fiberglass (ASJ) jacket shall be used. 2.18 MATERIALS .1 All insulation systems shall have composite (insulation, jacket and adhesive used to adhere the jacket to the insulation) Fire and Smoke Hazard ratings as tested under procedure ASTM E 84, NFPA 225, or UL 723. .2 Asbestos in any form shall not be used for any type of insulation work. All products must be certified “asbestos free”. .3 All final pipe and duct installations including insulation, covering and adhesive shall have a flame spread rating of not greater than 25. .4 All canvas shall be treated to be fire retardant in accordance with UCL standards. .5 Wire to be 1.2mm (18 ga.) soft annealed, type 304 stainless steel. .6 U.L.C. label or satisfactory certified report from approved testing laboratory is required to demonstrate that the fire hazard ratings for materials proposed for use do not exceed those specified. .7 Flame proofing treatments subject to deterioration due to effects of high humidity are not acceptable. .8 The Consultant reserves the right to demand test samples of components of insulation systems for fire and smoke hazard ratings. .9 In general, piping systems shall be insulated with fiberglass piping insulation with an all-purpose jacket. Fittings, flanges, and valves shall be insulated with fiberglass inserts and pre-molded polyvinyl or PVC jackets. .10 Refrigerant piping systems shall be insulated with elastromeric pipe insulation. .11 Calcium silicate or high-temperature fiberglass shall be used in steam applications. February 27, 2015 University of Manitoba MECHANICAL INSULATION Section 15180 Req # Page 5 .12 Special insulation protection shall be considered for areas subject to abuse and moisture, such as outside areas, washdown areas, public areas, food preparation areas, and classrooms. 2.19 PIPE FITTINGS .1 In general, insulation for fittings shall be pre-formed and/or full thickness of the same material as the insulation on the piping. Sectional pieces of standard insulation may be used on the larger size fittings. The use of fibreglass duct wrap at fittings is not allowed. Up to 50mm (2”) pipe, use fibreglass insulation with PVC cover. 65mm (2½”) and over to be insulated with mitred rigid pipe covering with PVC cover. .2 All steam and condensate fittings to be insulated with ceramic fiber cement and canvas finish. 2.20 SERVICE TRENCH INSULATION SYSTEM .1 Provide a Class C Heat Distribution system consisting of 100 percent chemically modified calcium carbonate particles, all less than 10 microns, which is manufacturer certified to be Hydrophobic. The particles shall cohesively bond with each other to form a closed-cell compacted mass that will effectively isolate pipe surfaces from air, water, moisture, and chemicals. .2 Material shall be inert, compatible with metals and plastics, and shall not be affected by normal soil constituents. .3 Material shall be non-flammable, non-toxic, and meet OSHA safety standards. .4 Insulation manufacturer must provide documentation of completion of Corps of Engineers 10 ft. head of water test (14 days - less than 1% moisture gain). .5 Insulation must be free flowing and self-compacting. .6 Physical Properties: 1. 2 Thermal Conductivity: K = 0.58 Btu/hr.ft F/in. @ 100 F Temperature Range: Bulk Density: Load Bearing: K = 0.68 Btu/hr.ft F/in. @ 300 F Cryogenic (-273 F) to 480 F (250 C) 60 - 62 lbs. /cu. ft. Up to 12,000 lbs. / sq. ft. 2 2. 3. 4. 14 .7 .8 .9 .10 .11 5. Electrical Resistivity: R = 10 Ohms/cm/cm 6. Dielectric Constant: 2.7 7. Friction Coefficient: 0.35 plus or minus 0.04 8. Waterproof: Certified 100% Hydrophobic 9. Vapor Barrier: Closed cell insulation - vapor proof to -273 F Product to be equal to DriTherm insulation. Accessories .1 Mineral Fiber Cushion: Flexible type, 4 – 6 lb. density – mineral wool or inorganic glass. .2 Polyethylene Sheet: 6 mil thick Examination .1 Verify trenching dimension including clearances under the piping are as required to receive the work. .2 Verify the base of the trench contains un-disturbed earth. If fill dirt is required it must be compacted to resemble original trench base conditions. Sand / crushed stone / pea gravel is not allowed as trench base material or backfill. .3 Verify piping is supported, anchored and guided as specified .4 Verify piping systems have been tested and accepted. Mineral fiber cushion .1 Where expansion loops or changes in pipe direction are provided to allow for pipe expansion, wrap the piping at the point of movement with 4 to 6 lb. density mineral fiber cushion to allow free movement of the pipes within the cushion. Place the fiber cushion so as to not come in contact with earth, pipe supports, anchors, guides, or any other surface that makes direct contact with the surrounding soil. Tape / tie mineral fiber cushion in place. .2 Follow the insulation manufacturer's recommendations as to extent and thickness of coverage. .3 Insulation dimensions are increased in mineral fiber cushion areas except for the dimension between multiple pipes. Consult manufacturer for details. Coatings February 27, 2015 University of Manitoba Req # MECHANICAL INSULATION Section 15180 Page 6 .1 .12 Apply coatings to supports, manhole face, concrete, metal and other materials in contact with the piping system that extend through and beyond the insulation, to prevent entrance of water by capillary action. Apply coating to concrete surfaces used in conjunction with pipe supports, anchors and guides in direct contact with the insulation. Apply coating just prior to placing the insulation. Coating must be sufficiently tacky to allow the insulation to bond to it. Service trench insulation .1 Except for pipes within manholes and valve pits, encase all underground piping with specified insulation. .2 Pour the insulation within the drywall forms. Make certain no voids exist beneath closely spaced pipes – knife if necessary. Provide additional support and rigidity to the forms by placing earth backfill on the outside of the forms alternately with the placing of the insulation. .3 Once the insulation has been installed to specified dimensions, place polyethylene sheet over the top of the material. Place empty insulation bags or sacks over the polyfilm to protect the material during the backfilling operation. Leave forms in place. 2.21 UNDERGROUND STEAM AND CONDENSATE .1 Provide sectional foam glass pipe insulation in premolded sections 600mm (24") long, split, and ready for application. .2 Permeability value to be 0.00 perm-inch. .3 Thermal conductivity to be 0.32 BTU-inch/hr-sq.ft. -°F at 24°C (75°F) mean temperature and be capable of use on service from -73°C (-100°F) to 480°C (900°F). .4 Insulation to be installed with factory approved high-temperature-resistant, flexible adhesive between all horizontal and butt joints. .5 Provide cushioning material between horizontal sections and Hydrocal B11 on all slip surfaces to Manufacturer’s recommendations .6 Fasten insulation sections in place with stainless steel bands. .7 Insulation to be Pittsburgh Corning Foamglas StrataFab or approved equal. .8 Insulation thickness .1 Steam piping 75mm (3”). .2 Condensate piping 25mm (1”). .9 Foamglass insulation shall be protected with PittWrap CW Plus jacketing. Wrap to be 50 mil (1.3mm) thick self-sealing, modified bituminous membrane with a glass fabric and 1 mil (0.03mm) aluminum top film & release paper backing. .10 In general, insulation for fittings shall be pre-formed and/or full thickness of the same material as the insulation on the piping. Sectional pieces of standard insulation may be used on the larger size fittings. .11 All steam and condensate fittings to be insulated with ceramic fiber cement and canvas finish. 2.22 VAPOUR BARRIER FLEXIBLE DUCT INSULATION .1 Insulate the following ductwork externally with Fibreglas RFFRK reinforced foil-faced vapour seal duct insulation PF335, 340 g. (¾ lb./ft.3) density: .1 25mm (1") Thickness .1 All round supply air ductwork, and all rectangular supply air ductwork, 1200mm (48") wide and less. .2 50mm (2") Thickness .1 All round exhaust and relief ducts, and outside air ducts not shown acoustically lined from roof or wall back for a length of 1.8m (6'-0") or from wall or roof discharge back to damper, whichever is greater. .2 All round roof ducting to exhaust fans located on roofs to be insulated with 2” (50mm) pipe and tank wrap and stainless steel cladding. 2.23 VAPOUR BARRIER RIGID DUCT INSULATION .1 Following ducts externally insulated with Fibreglas RFFRK reinforced foil-faced vapour seal duct insulation type FF 340 g. (4.5 lb./ft.3) density: .1 25mm (1") Thickness .1 All rectangular supply air ductwork, greater than 1200mm (48") wide, on discharge of fan systems with cooling coils. February 27, 2015 University of Manitoba Req # MECHANICAL INSULATION Section 15180 Page 7 .2 50mm (2") Thickness .1 All rectangular exhaust and relief ducts, and outside air ducts not shown acoustically lined from roof or wall back for a length of 1800mm (6'-0") or from wall or roof discharge back to damper, whichever is greater. .2 All rectangular roof ducting to exhaust fans located on roofs complete with stainless steel cladding. PART 3 – EXECUTION 3.1 STANDARDS OF WORK .1 Licensed trades people shall perform work. .2 Apply insulation materials, accessories and finishes in accordance with Manufacturer’s recommendations. .3 Do not apply insulation until hydrostatic tests have been completed, surfaces are free of grease, scale, moisture, and heat tracing where required has been installed. Insulation shall be clean and dry when installed and during application of any finish. .4 Apply insulation and coverings to equipment and piping, which will operate with hot or warm fluid, while surface is hot. Provide any required temporary heat to accomplish this. .5 Cold surfaces to be dry and ferrous surfaces to be coated with rust penetrating protective paint before applying insulation and vapour barriers. .6 Vapour barriers and insulation to be complete over full length of pipe or surface, without penetration for hangers, duct or seams, and without interruption at sleeves, pipe and fittings. .7 Install insulation with smooth and even surfaces, with round shapes laid to true circular and concentric shape, shaped to blend with fitting insulation and adjacent covering; with full length section and tight to insulated object. .8 Pack solid around all pipes where they pass through sleeves in walls, floor slabs, etc. for full thickness of floor with fiberglass or rockwool. Insulated pipes having vapour barrier jacket to pass through wall, floors, etc. to accommodate full insulation thickness. Protect insulation of exposed pipes passing through floors with 1.2mm (18 ga.) galvanized iron 150mm (6") from finished floor. .9 On piping, gouge out insulation for proper fit where there is interference between weld bead and insulation. Bevel insulation away from studs and nuts to permit their removal without damage to insulation. Closely and neatly trim around extending parts of pipe saddles, supports, hangers and clamp guides. Seal with insulating cement. .10 Use insulation protection saddles at all supports unless otherwise indicated. .11 Butt joints .1 Place joints on top of duct wherever practical. Butt joints on side of duct for flexible duct insulation. .2 Adhere and seal laps of vapour barrier cover or vapour barrier strip of 100mm (4") minimum width furnished with insulation, using vapour seal adhesives. .12 Sagging of duct insulation will not be acceptable. .13 Stagger both longitudinal and horizontal joints, on duct insulation of multi-layered construction. .14 Duct insulation with vapour barrier shall be continuous, except at fire dampers. .15 Ducts acoustically lined need no external insulation, unless specifically noted otherwise. .16 Existing duct and pipe covering damaged or cut back during installation work to be made good with same insulation as specified for new work. .17 Protect insulation against elements during all stages of application. .18 Do not cover Manufacturer’s nameplates. Cut insulation on 45º angle to nameplate edge and seal. .19 Covering to be uniform in diameter, smooth in finish. Place longitudinal seams so as to be invisible. 3.2 AIR UNIT CASINGS (INTERNAL) .1 25mm (1") thick rigid board neoprene faced. Install insulation on weld pins and speed washers 300mm (12") OC. Cut pins flush with surface of insulation and cover all pins and joints with glass fab tape embedded in two coats of approved mastic compound. Use the first coat to embed the glass fab tape and the second coat as a finish. Refer to detail drawings. February 27, 2015 University of Manitoba MECHANICAL INSULATION Section 15180 Req # Page 8 3.3 ASBESTOS INSULATION REMOVAL .1 Engage a Contractor regularly employed in asbestos insulation removal. .2 Comply with requirements of the authority having jurisdiction and the provincial Clean Environment Act including disposal of this material. .3 In case of any conflict among these regulations or with these specifications, the more stringent requirements shall apply. .4 Provide all containment devices, air control devices, temporarily portioning, transportation and skilled labour. .5 Test samples of all insulation to be removed, and apply regulations relative to type and content. .6 Arrange for and include cost of inspection as required by the Authority. .7 All water piping insulation in the building is asbestos latent to some extent including the boiler. 3.4 COLD INSULATION – PLUMBING .1 Fiberglass .1 Insulate flanges, fittings and valve bodies, etc. .2 Fasten longitudinal laps with staples and seal with Swifts Adhesive #3218. .3 Butt joints wrapped with a 100mm (4") strip of ASJ. Stagger joints on multiple layers. 3.5 COLD INSULATION - CHILLED WATER PIPING .1 Application as per Clause “Cold Insulation – Plumbing”. .2 All piping, fittings, stubs, etc to be fully insulated to prevent condensation. 3.6 DUCTWORK .1 Installation .1 Exposed ductwork: Rigid Board Insulation .1 Rectangular ductwork: Impale rigid board on weld pins and speed washers 300mm (12") OC with a minimum of two rows per side on any side greater than 300mm (12"). Cut pins flush with surface of insulation and cover with foil faced tape. Cover all joints with foil faced self-adhesive tape. Finish with canvas and lagging to Manufacturer’s specifications. .2 Round ductwork: Apply flexible blanket insulation with an approved adhesive brushed on in 100mm (4") wide strips 300mm (12") OC and at all joints. Seal all joints and perforations with foil faced self-adhesive tape. Finish with canvas and lagging to Manufacturer’s specifications. .2 Concealed ductwork: .1 Blanket type insulation: Apply flexible blanket insulation with an approved adhesive brushed on in 100mm (4") wide strips 300mm (12") OC and at all joints. Seal all joints and perforations with foil faced self-adhesive tape. .3 Ductwork exposed to outdoors: Impale rigid board on weld pins and speed washers 300mm (12") OC with a minimum of two rows per side on any side greater than 300mm (12"). Cut pins flush with surface of insulation and cover pins and joints with foil faced self-adhesive tape. Finish with stainless steel jacket. .2 Application: Provide external ductwork insulation in thickness as listed below: .1 All supply air ductwork from fan discharge or unit outlet of air handling systems delivering air at temperatures as noted below. This includes supply air ductwork connected to discharge side of fan coil units, heat pumps, reheat coils and VAV terminals and air handling systems with cooling and/or heating coils and direct or indirect fired burner sections. .1 Provide 25mm (1") thick for systems up to 30°C or less air supply temperature. .2 Provide 38mm (1½") thick for systems with 30°C or greater air supply temperature. .3 Outdoor intake ductwork, ductwork conveying mixed outdoor/return air and mixed air plenums: 50mm (2”) thick. .4 Supply and return air ductwork located outdoors: 50mm (2") thick. .5 Exhaust ductwork located outdoors: 50mm (2") thick. February 27, 2015 University of Manitoba MECHANICAL INSULATION Section 15180 Req # Page 9 .6 .2 Exhaust ductwork located indoors for a minimum of 3 m (10 ft.) back from the discharge point to outdoors: 50mm (2") thick. Exceptions: external duct insulation is not required where: 1. Supply air ductwork installed exposed within conditioned space. .1 Supply air ductwork installed concealed in ceiling spaces, whether ceiling space used as return air plenum or not, is to be totally insulated. 2. Ductwork is internally insulated and located indoors. 3. Acoustic type flexible ductwork. 4. Duct silencers. 3.7 ENGINE EXHAUST PIPING AND SILENCER INSULATION .1 Insulation to be applied with edges tightly butted and joints staggered. Fasten with 18 gauge Type 304 stainless steel soft annealed wire for sizes up to 150mm (6”) and 12mm (½“) stainless steel bands on 300mm (12”) maximum centres, for 200mm (8”) and larger sizes. Where required, provide welded steel studs, clips or angle as anchors for wires and bands. .2 System insulation to be covered with stainless steel wrap and bands. .3 Insulation on [diesel exhaust piping], [engine exhaust], and [silencers] must be installed to allow for expansion. Temperature of exhaust will be 482°C (900°F). All adhesives used on this piping shall be suitable for temperatures involved. 3.8 EQUIPMENT AND MISCELLANEOUS APPLICATIONS .1 Chiller vessels: 20mm (3/4") fire retardant closed cell Armaflex on evaporator, suction piping, and chilled water headers. Apply Armaflex with suitable adhesive and seal all joints with suitable plastic tape. For chiller heads, provide one or two-piece slip-on field fabricated and fitted sections held in place with metal bands with screwdriver operated tightening devices. Cover with Armaflex finish. Do not insulate over registration and nameplates. .2 Drains and water supplies for wall hung handicapped lavatories: preformed insulation and PVC jacket. .3 Radiant Ceiling Panels: Provide 2” (50mm) thick fibreglass batt insulation over all active sections of radiant ceiling panels. .4 Test ports and areas, which must be accessed for maintenance or testing, shall be insulated using techniques that allow for easy removal and reinstallation without re-insulating. 3.9 HOT INSULATION - PLUMBING .1 Application as per Clause “Cold Insulation – Plumbing”. 3.10 HOT INSULATION - HEATING .1 Application as per Clause “Cold Insulation – Plumbing”. 3.11 HOT INSULATION - EQUIPMENT .1 Insulation to be applied with edges tightly butted and joints staggered. Fasten with 18 gauge Type 304 stainless steel soft annealed wire for sizes up to 150mm (6”) and 12mm (½“) stainless steel bands on 300mm (12”) maximum centres, for 200mm (8”) and larger sizes. Where required, provide welded steel studs, clips or angle as anchors for wires and bands. Insulation to have canvas wrap. 3.12 INSULATION THICKNESSES .1 Ductwork: .1 Air unit casings .2 Supply ductwork .3 Fresh air intake ducts to air unit, mix plenums or heat exchangers .4 Combustion air ducts .5 Air to air heat exchanger .6 Mixed air ducts from FA duct to heating coil .7 Ducts penetrating an exterior building surface .8 Exhaust ducts from heat exchanger to outlet 25 mm (1") 25 mm (1") all all 50 mm (2") 50 mm (2") 50 mm (2") 25 mm (1") 50 mm (2") 25 mm (1") all all all all for the last 3 M all February 27, 2015 University of Manitoba MECHANICAL INSULATION Section 15180 Req # Page 10 .9 .10 .11 .12 .13 .2 .3 3.13 Relief air ducts Drip pans Breeching Chimneys (single wall) Dryer vents Piping: .1 Cold Insulation – Plumbing Up to 2” 2½” and over .2 Hot Insulation – Plumbing Up to 2” 2½” and over .3 Tempered & Recirc – Plumbing Up to 2” 2½” and over .4 Hot Insulation – Heating ¾” and smaller piping 1” to 1½” piping 2” and over piping .5 Steam Low pressure High pressure .6 Chilled Water & Glycol Piping 4” and smaller piping 6” to 10” piping 12” and over piping .7 Exhaust Piping and Silencers .8 Hot Insulation – Equipment .9 Heating Condensate piping .10 Cooling Condensate piping .11 Heat traced piping .12 Heat pump piping .13 Heat recovery piping .14 Refrigerant suction lines .15 Plumbing vents Up to 2” piping 2½” and over .16 Rain water leaders and drain bodies Equipment: .1 Expansion tanks .2 Air eliminators/separators .3 Domestic hot water tanks .4 Heat exchangers & converters .5 Domestic hot water converters .6 Engine exhausts .7 Domestic hot water storage tanks .8 Condensate receivers .9 Flash Tanks .10 Water meters 50 mm (2") 25 mm (1") 50 mm (2") 50 mm (2") 25 mm (1") all all all all all 25 mm (1”) 25 mm (1”) all all 25 mm (1”) 25 mm (1”) all all 25 mm (1”) 25 mm (1”) all all 25 mm (1") 38 mm (1½”) 50 mm (2”) all all all 50 mm (2") 75 mm (3”) all all 50 mm (1”) 38 mm (1½”) 50 mm (2”) 75 mm (3”) 50 mm (2”) 25 mm (1") 12 mm (½") 25 mm (1") 25 mm (1") 25 mm (1") 18 mm (¾") all all all all all all all all all all all 25 mm (1”) 25 mm (1”) 25 mm (1") all all all 25 mm 25 mm 50 mm 50 mm 50 mm 75 mm 50 mm 50 mm 50 mm 25 mm all all all all all all all all all all (1") (1") (2") (2") (2") (3") (2") (2") (2") (1”) PIPING .1 Insulate and finish all fittings and flanges in the same manner and same thickness as piping. Use mitred sections of the specified pipe covering. .2 Apply insulation at temperature above 18°C (65°F) over clean, dry surfaces. February 27, 2015 University of Manitoba Req # MECHANICAL INSULATION Section 15180 Page 11 .3 .4 .5 .6 .7 .8 .9 .10 .11 .12 .13 Butt adjoining sections of insulation firmly together with the longitudinal seam of the jacket located on the bottom half of the pipe. All adhesive and finishes to be fire retardant or fire resistant when dry, and acceptable to authorities having jurisdiction. Insulate and finish all valves, fittings and flanges on all piping systems in the same manner and same thickness as piping. Use PVC jacketed mitred sections of the specified pipe covering or pre-formed insulation to suit fitting. Provide canvas and lagging where PVC jackets are not used. Seal longitudinal lap joints with a suitable vapour barrier adhesive for cold and chilled water piping and suitable cement capable of withstanding service temperature on hot water piping. Cover circumferential butt joints with a strip of the same material as the jacket and cement as indicated above. Cover all joints with foil faced self-adhesive tape on chilled and cold water piping. Concealed insulated items require no further finish than provided in factory-applied jacket. Cover exposed insulation and all insulated equipment with canvas, field applied, adhered and lap sealed and finished off by a brush coat of approved sizing. Insulated piping exposed to outdoors: Apply aluminium protective covering over all insulated pipe and fittings. All joints to be weather tight. On all domestic cold and chilled water piping: .1 Oversized hangers are to be used on all cold and chilled water piping to allow for a continuous run of pipe insulation and vapour barrier. .2 For piping up to 25mm (1”), protect insulation with a sheetmetal saddle installed between the vapour barrier and the hanger. .3 For piping 38mm (1½”) and larger, provide a supporting section of rigid insulation or noncompressible material under the pipe inside the vapour barrier for the same length as the saddle - see detail drawing. .4 Where oversized hangers are not used, apply 12mm (½”) insulation with vapour seal over hanger and support rod for a distance of two pipe diameters up the rod from the attachment point at the ring, clamp or clevis. .5 Seal valves, fittings and flanges on cold and chilled water application in a manner as specified for circumferential joints. On strainers, insulate over blow-down valves and bushings or flanges required for strainer basket removal by providing a removable prefabricated Armaflex cover held in place with a stainless steel gear clamp. Do not insulate over blow-down valves and bushings or flanges for strainer basket removal on condenser water piping. .6 Seal end joints and perforations with 100mm (4") vapour barrier strips applied with the same adhesives and cements as previously specified for cold and chilled water. On all steam and hot water piping: .1 Oversized hangers are to be used on all steam and hot water piping to allow for a continuous run of pipe insulation. .2 For piping up to 38mm (1½”), protect insulation with a sheetmetal saddle installed between the insulation wrap and the hanger. .3 For piping 50mm (2”) and larger, installation will include a pipe saddle welded to the pipe. Fill void of saddle with matching pipe insulation and cut insulation covering tight to saddle to allow it to run free on pipe rollers. Apply blanket type insulation on piping using an approved adhesive and seal all longitudinal and transverse joints with foil-faced tape. Insulate pipe hanger in similar manner for a distance of two pipe diameters up the rod beyond the attachment point at the ring, clamp or clevis. Insulation on piping where Victaulic couplings are used: .1 In concealed areas provide insulation over couplings to same thickness as specified for piping. .2 In exposed areas (except mechanical and service rooms) increase insulation thickness and provide one-half specified thickness over couplings to achieve the appearance of uniform diameter of pipe and fittings. .3 Where stainless steel sheet cladding is required, increase insulation thickness as described in (2) above to achieve a standard and uniform diameter. On water-to-water heat pump circuits utilizing 50mm (2") insulation: At all ball valves, use 25mm (1") insulation to allow space for valve handle operation. February 27, 2015 University of Manitoba Req # MECHANICAL INSULATION Section 15180 Page 12 3.14 RADIANT PANELS .1 Radiant ceiling panels: lay insulation over active sections only. Co-ordinate with Section 15700 Subtrade and follow panel Manufacturer’s instructions. 3.15 REFRIGERANT PIPE INSULATION .1 Insulate fittings, valve bodies, etc. .2 All fittings shall be insulated with mitre-cut pieces of Armaflex AP pipe insulation the same size as on adjacent piping. .3 Seal joints and seams with adhesive, and refinish exposed fittings with specified finish. Refinish all exposed piping with two additional coats. .4 Where insulation comes in close contact with adjacent equipment or piping having surface temperatures above 100 deg. C, provide additional protection to ensure against deterioration of insulation by heat. .5 Allow adhesive joints of Pipe insulation to dry 24 hours to 36 hours before applying finish. Apply finish directly to clean, dry insulation in two coats. Wipe surface with cloth dampened with nonoily solvent such as alcohol to clean surface and remove powdered lubricant. Allow first coat to dry minimum of two hours before applying second coat. Before applying finish, read precautionary information on can label. .6 Finish insulation located outdoor with Armstrong WB black Armaflex finish. Do not apply over joints freshly cemented with 520 adhesive. Allow adhesive joints of Armaflex pipe insulation to dry 24 hours to 36 hours before applying finish. Apply finish directly to clean, dry Armaflex insulation in two coats. Wipe surface with cloth dampened with non-oily solvent such as alcohol to clean surface and remove powdered lubricant. Allow first coat to dry minimum of two hours before applying second coat. Before applying Armaflex WB finish, read precautionary information on can label. .7 For aluminum jacketing installation install in strict accordance with manufacturer's published recommendations. Make weathertight application. 3.16 SCHEDULE OF WORK .1 Insulation shall not be applied prior to flushing and pressure testing of pipe work. 3.17 VAPOR BARRIER FLEXIBLE DUCT INSULATION .1 Rectangular Ductwork .1 On ducts 600mm (24") wide and wider apply welded pin fasteners to bottom surface of duct by impaling on welded pins on 300mm (12") centres. Spot adhesive on 300mm (12") centres on all sides of duct. Apply insulation with edges tightly butted together and secured with 100% coverage of 3-M No. 17 or approved alternate. Staple joints and seal with 100mm (4") strips of vapor barrier foil of same quality as duct insulation membrane sealed with BF 85-15. .2 After installation of fasteners, cut pins and apply foil tape to cover completely. .3 On ducts 575mm (23") wide or less insulation applied as above but welded pins may be omitted. .2 Round Ducts .1 Adhere to duct surface applied in strips 150mm (6") wide, 300mm (12") o.c. Butt all edges of insulation, staple and seal all joints with tape adhered over the joint. Seal all breaks with vapor barrier type. .3 Exposed Ducts .1 Recover ducts exposed to view with 170 g. (6 oz.) canvas secured with Flintguard No. 120 white fire retardant lagging adhesive. Finish with brush coat of same adhesive. 3.18 VAPOUR BARRIER RIGID DUCT INSULATION .1 Insulation applied with edges tightly butted and secured by impaling on pins welded to duct. Pins to be staggered, minimum 300mm (12") o.c. in every direction. This applies to all sides. Secure insulation to pins with metal fasteners. Pins shall be long enough to bend after fasteners have been applied. Install two fasteners to all insulation on roof. Dab adhesive over pins and fasteners. February 27, 2015 University of Manitoba MECHANICAL INSULATION Req # Section 15180 Page 13 .2 .3 .4 After installation of fasteners, cut pins and apply foil tape to cover completely. Seal all joints, edges and breaks in vapor seal jacket with vapor barrier foil of the same quality as that of duct membrane 100mm (4") wide with BF 85-15 lagging adhesive. Wrap exposed ducts with fire retardant paper recovered with 170 g. (6 oz.) canvas secured with Flintguard No. 120 white fire retardant lagging. Brush coat with same adhesive. Do not use staples. END OF SECTION 15180 February 27, 2015