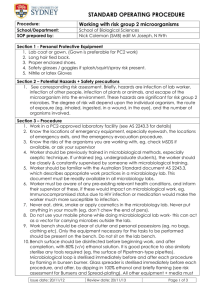

Working with risk group 1 microorganisms

advertisement

STANDARD OPERATING PROCEDURE Procedure: School/Department: SOP prepared by: Working with risk group 1 microorganisms School of Biological Sciences Nick Coleman (SMB) edit M Joseph, N Firth Section 1 - Personal Protective Equipment Lab coat or gown. Long hair tied back. Proper enclosed shoes. Safety glasses / goggles if splash/squirt/spray risk present. Gloves if hands have broken skin areas on them, or if desired. Section 2 – Potential Hazards + Safety precautions 1. See corresponding risk assessment. Briefly, hazards are infection of lab worker, infection of other people, infection of plants or animals, and escape of the microorganism into the environment. Note that these hazards are very minimal for risk group 1 microbes. Section 3 – Procedure 1. Work in a PC1-approved laboratory facility (see AS 2243.3 for details) 2. Know the locations of emergency equipment, especially eyewash, the locations of emergency exits, and the emergency evacuation procedure. 3. Know the risks of the organisms you are working with, eg. check MSDS if available, or ask your supervisor 4. Worker should be previously trained in microbiological methods, especially aseptic technique. If untrained (eg. undergraduate students), the worker should be closely & constantly supervised by someone with microbiological training. 5. Worker should be familiar with the Australian Standard document AS 2243.3, which describes appropriate work practices in a microbiology lab. This document must be readily available in all microbiology labs. 6. Worker must be aware of any pre-existing relevant health conditions, and inform their supervisor of these, if these would impact on microbiological work. eg. Immunocompromised status due to HIV infection or medication would make the worker much more susceptible to infection – in this case, risk group 1 organisms are much more dangerous. Special precautions would need to be taken (eg. work according to risk group 2 guidelines – see this SOP). 7. Never eat, drink, smoke or apply cosmetics in the microbiology lab. Never put anything in your mouth (eg. chew the end of pens). 8. Do not use your mobile phone while doing microbiological lab work- this can act as a vector for carrying microbes outside the lab. 9. Work bench should be clear of clutter and personal possessions (eg. no bags, clothing etc). Only the equipment necessary for the tasks to be performed should be present on the bench. Do not sit on the lab bench. 10. Bench surface should be disinfected before beginning work, and after completion with 80% (v/v) ethanol solution. It is good practice to also similarly sterilise any tools required (eg. the surface of Pipetman-type pipettes). Microbiological loop is sterilised immediately before each procedure, and after, by flaming in bunsen burner. Glass spreader is sterilised immediately before each procedure by dipping in 100% ethanol and briefly flaming (see risk assessment for Bunsens and Spread-plating). All other equipment + media must be sterilised by autoclaving or filtration. 11. Turn Bunsen burners off when not actively doing lab work requiring these. This helps keep the lab cool, and minimises the fire hazard. Do not leave a Bunsen Issue date: 20/11/12 Review date: 20/11/13 Page 1 of 3 flame unattended, even for a few minutes. 12. When making transfers of cultures, streaking plates etc, work close to the Bunsen flame – this minimises deposition of airborne microbes onto/into media. 13. A biosafety cabinet is not necessary for risk group 1 organisms, but could be used for manipulations demanding a high degree of sterility. 14. All cultures must be labelled with the name of the organism (species and strain), the name or initials of the worker, and the date. Cultures must be incubated in the appropriate location, and must not be taken out of the lab. 15. Upon finishing work, sterilise the bench again, and discard all unwanted cultures into the appropriate location. All microbial cultures must be destroyed by autoclaving, they cannot be put down the sink, or in the regular garbage. 16. Wash your hands with antiseptic soap before leaving the laboratory, eg. with soap containing chlorhexidine. 17. Remove your lab coat or gown before leaving the laboratory. It is OK for a PC1 lab to take the gown out of the lab, but it should be enclosed in a sealed plastic bag in this case. The coat/gown should be washed regularly. Section 4 – Spills / Incidents 1. Report all spills and other incidents to your supervisor, and if a serious incident occurs, this needs to be formally reported via the online reporting system. 2. Clean up spills immediately as follows: 3. Contain the spill by surrounding with paper towel or an absorbent ‘boom’ from the spill kit, or other absorbent material 4. Disinfect the spill by adding freshly prepared bleach solution containing 1% hypochlorite. Allow at least 10 min for the bleach to kill the microbes. 5. Soak up all the liquids with paper towels, and dispose of all the towels and any other spill containment items used into a strong plastic bag (eg. a ‘wet garbag’ or a biohazard bag). 6. This bag containing the spill materials should NOT be autoclaved, as bleach will corrode the autoclave. Instead, this should be disposed of as medical waste, or as hazardous chemical waste. Section 7 - References 1. Australian Standard document AS 2243.3 Issue date: 20/11/12 Review date: 20/11/13 Page 2 of 3 SOP Training Confirmation By signing below, these individuals confirm that they have read and understood the SOP, and agree to always follow the instructions in this SOP when performing this procedure. Position Name Signature Date Supervisor employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student employee / student WHS Committee Approval Representative: A. Prof Frank Seebacher Chair Safety Committee Signature: ........................................................ Date: ..................................... Issue date: 20/11/12 Review date: 20/11/13 Page 3 of 3