Massachusetts Institute of Technology

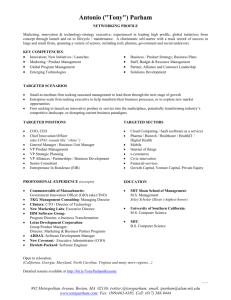

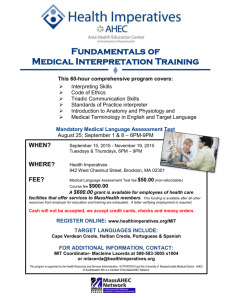

advertisement