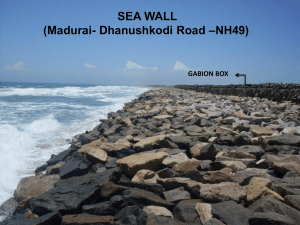

No43-PipeandGabionConstruction

advertisement

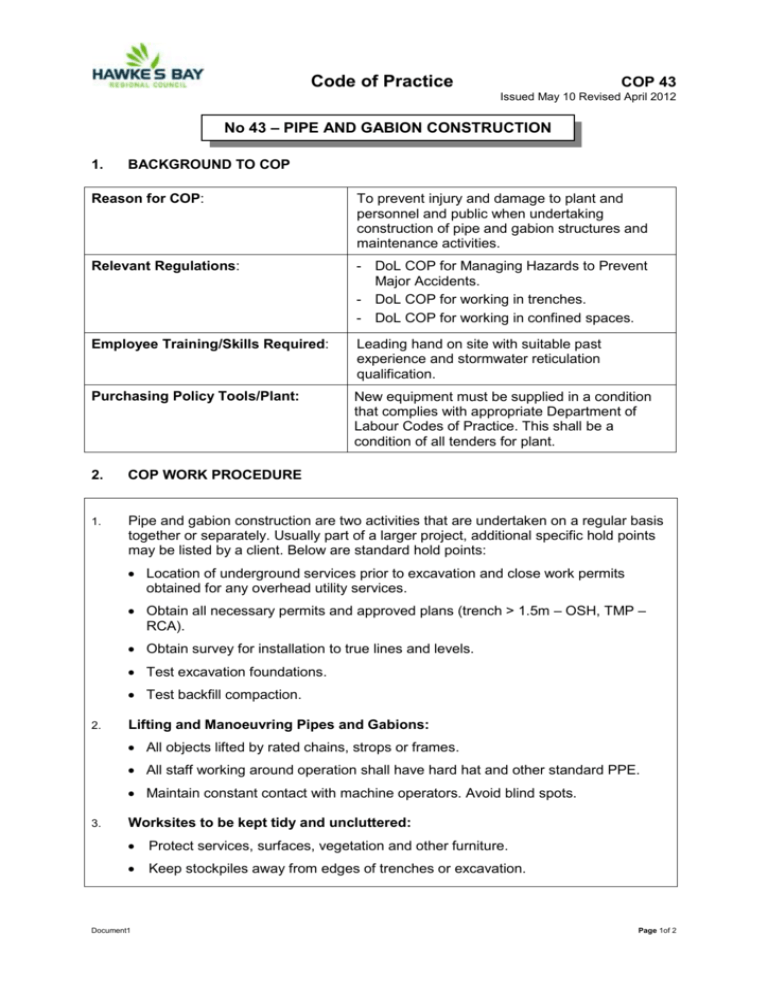

Code of Practice COP 43 Issued May 10 Revised April 2012 No 43 – PIPE AND GABION CONSTRUCTION 1. BACKGROUND TO COP Reason for COP: To prevent injury and damage to plant and personnel and public when undertaking construction of pipe and gabion structures and maintenance activities. Relevant Regulations: - DoL COP for Managing Hazards to Prevent Major Accidents. - DoL COP for working in trenches. - DoL COP for working in confined spaces. Employee Training/Skills Required: Leading hand on site with suitable past experience and stormwater reticulation qualification. Purchasing Policy Tools/Plant: New equipment must be supplied in a condition that complies with appropriate Department of Labour Codes of Practice. This shall be a condition of all tenders for plant. 2. COP WORK PROCEDURE 1. Pipe and gabion construction are two activities that are undertaken on a regular basis together or separately. Usually part of a larger project, additional specific hold points may be listed by a client. Below are standard hold points: Location of underground services prior to excavation and close work permits obtained for any overhead utility services. Obtain all necessary permits and approved plans (trench > 1.5m – OSH, TMP – RCA). Obtain survey for installation to true lines and levels. Test excavation foundations. Test backfill compaction. 2. Lifting and Manoeuvring Pipes and Gabions: All objects lifted by rated chains, strops or frames. All staff working around operation shall have hard hat and other standard PPE. Maintain constant contact with machine operators. Avoid blind spots. 3. Worksites to be kept tidy and uncluttered: Protect services, surfaces, vegetation and other furniture. Keep stockpiles away from edges of trenches or excavation. Document1 Page 1of 2 Hazard Identification & Analysis Worksheet – HBRC Work Task, Activity or Item of Equipment What can cause harm? How could potential harm situation arise? Significant Hazard Yes/No* Controls that Reduce Harm 043 – Pipe and Gabion Construction Performing job/ general duties Working outside generic hazards Impact, crush or Unstable material on trench or suffocation from excavation face trench or Top of trench or excavation overloaded excavation at edge failure Impact from fall Trip or slip down manholes Unstable manhole cover or trench Impact or crush Lifting support failure from falling lifted Gabion basket splitting open and spilling objects rocks Loss of load travelling over uneven ground Impact or crush Not visible from mechanical Poor communication with operator excavator or Vehicle rollover from unstable ground loader Date: April 2012 Y M N M Y M E M Y M I Epoxy Poisoning Using epoxy mortars N M Lifting, Installing Pipes or gabions Hand, limb, or body crush Y M Transporting pipe and gabion hardware Loss of load Parts sticking during installation Loss of control during heavy lift Poor rigging Lifting device failure Travelling too fast Insecure load Document1 Status Y M Ref COP 00 – General Fieldworker Operations Use cage or shoring in trench > 1.5m deep Batter back excavations or trenches to at least 1:1 Keep stockpile materials at least 1.5m away from top of excavations or trenches In place In place In place Maintain clean site and correct footwear. Have minimum number of covers open, ensure correct fit. 2 man job always All lifting supports (Chains) certified If lifting full gabions double stick or ring top and sides Correct PPE incl Hard hat Carry all loads within 1m of the ground. In place In place In place In place In place In place In place Wear correct PPE, hi viz and work boots. Hard hat if under working plant. Ensure continued eye contact with operator. Consider use of spotter in increased risk situations. Machinery to maintain safe working distances Use only trained/licensed people to operate plant/machinery. Wear correct PPE, long gloves. Avoid skin contact. Mask in confined space. Identify staff who have allergy to epoxy In place In place Mechanically shift parts Check weather conditions, no wind required Trained persons required (certified crane, hiab lifters) Use correct PPE, Hard hat and steel cap boots Obey Speed rules Secure at recognised tie down points Secure any potential loose components In place In place Trained operator In place In place Trained operator In place In place In place In Place In Place Page 2of 2