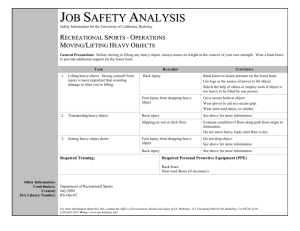

Lifting Studies (Plan)

advertisement

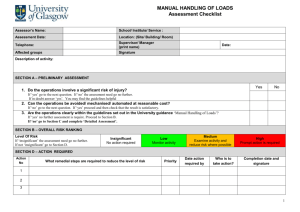

AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Scaffolding All scaffold erected during the project for use by any site personnel will be erected by a competent Al Hamra Construction scaffolders. It will be the AHCC Scaffold manager’s function to ensure that the scaffold department complies with:a) Ensuring that their workforce are competent and produce scaffold structures which comply with Regulations and British Standards. b) Supplying materials that are both of sound construction and adequate amounts. c) Nominating a scaffold inspector to inspect all erected scaffolding following initial erection and all subsequent weekly checks, formally recording details in the Register. Scaffolds will be re-inspected whenever there is any risk of change such as after adverse weather or after unauthorised interference. d) The structure complies with any Temporary Works Design criteria. Before any work is started which involves the use of scaffold platforms it is the responsibility of each respective construction supervisor to ensure the scaffold is fit for purpose. When each scaffold structure is completed the competent person will duly inspect and attach a ‘Scafftag’ in a prominent position in the vicinity of the access ladder. The ‘Scafftag’ system will be explained to operatives during induction. Only approved scaffolders are permitted to alter/dismantle any scaffold structure. Under no circumstances will any company, or sub-contractor’s operatives interfere with scaffold. Safe Working during Erection, Alteration and Dismantling of Scaffolding The company will insist that their scaffold department erects, alters and dismantles scaffolding in accordance with a safe system of work, this is to include:a) Secured ladders must be used for access up or down scaffolding. No-one is permitted to climb up or down scaffold framework. b) Ledgers, transoms, ladder beams, etc. must be used as access along scaffolds. c) Where access is needed along scaffolds or where men have to work, platforms which are at least 5 boards wide must be used, the boards must be adequately supported and secured, guard rails must be erected. d) Where work cannot be done from or where access cannot be gained using a 5 board wide platform, a full body harnesses must be worn and secured to a suitable anchor point. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions e) f) g) Harnesses must be worn and secured for any erection, alteration or dismantling of the following scaffolds where work cannot be done from a secure platform provided with guard rails, e.g. – suspended sling, cantilevered, truss out, bridging, or similar type of scaffold not of the independent or birdcage type. Scaffolds which are being erected, dismantled or altered must be barrier off and clearly signed to show which parts are unsafe for use. Adequate precautions must be taken to prevent materials falling. People unconnected with work should be kept away from the area by, for example, the erection of suitable signs and barriers. Those connected with the work must always wear safety helmets and all materials should be raised or lowered in a controlled manner. Inspection Check List for Construction Supervisors The Construction Supervisor will verify that the following checks have been conducted on the erected scaffold:a) b) c) d) e) f) g) h) Foundations firm and level with base under each standard. Ladder is sound, properly secured and at correct angle (1 in 4 rise). Good access to working platforms. Properly tied and braced. Working platform fully boarded. Toe boards and hand rails fitted and secure. No trap ends. Scafftag signed and dated. Erection of structures, working at heights Further information can be found in Section 26 covering harness/lanyard requirements and consideration on specific assessment of this protective equipment. Reference Documentation H&S Construction codes of practice Part-2 section-29 Abu-Dhabi Health and Safety at Work etc Act (1974) The Construction (Health, Safety and Welfare) Regulations 1996 BS 5973 (1993) Code of Practice for Access and Working Scaffolds and Special Structures in Steel BS 5974 (1990) Code of Practice Temporarily Installed Suspended Scaffolds and Access Equipment AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Lifting Operations Lifting Equipment and Accessories The project/construction manager and his respective engineers and discipline supervisors will ensure that all lifting operations under his control on site are carried out in a safe manner. All operations shall be in accordance with the Client site instructions and Lifting Operations and Lifting Equipment Regulations 1998 and H&S Construction codes of practice part-2 Section -19 & 20 Abu-Dhabi and Al Hamra Construction lifting procedure AHCC/HSMS/PRO/07/04 Safe use of Cranes Procedure Operations Assessment Lifting operations should be risk assessed by a competent person in order to classify the operation as a:a) Simple Lifting Operation b) Standard Lifting Operation c) Complex Lifting Operation The responsible manager shall ensure, where necessary, all lifting studies and method statements and lifting risk assessments are produced for such work in good time for review and approval by the project nominated competent person. Definitions Lifting Operations Basic lifting operations Lifting operations of a routine nature that are low hazard and low risk to operatives involved with the activity, personnel nearby or process. Where basic lifting activities are required, they may be undertaken accompanied with a job specific risk assessment that identifies the Hazards and Risks associated with that specific lifting activity. Standard Lifting operations Routine lifting operations that without suitable control methods would impose hazards and risk to personnel and plant. Where routing lifting activities are required, they may be undertaken accompanied with a job specific risk assessment and method statement that identifies the Hazards and Risks associated with that specific lifting activity. Complex Lifting operations Individual Lifting operations that is unique, having specific hazards and risks involved. Where complex lifting activities involving special circumstances, e.g. tandem Lifts, Lifting over live plant, difficult lifts, lifting personnel or requested by the client, there must be a Lifting study, Method statement and Risk Assessment undertaken. Examples AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions All Lifting activities using Lifting Appliances for loads greater than >2 Tonne must be undertaken in conjunction with approved lifting study (Plan), method statement and risk assessment. Lifting activities using Lifting Appliances for loads of <2 Tonne or less may be regarded as routine lifting activities unless special circumstances dictate otherwise. Equipment Assessment All equipment hired or purchased for all lifting activities should be assessed for suitability purpose and operational use. This assessment shall identify that the equipment is adequate for the intended activity. The assessment shall also be applicable to lifting accessories, e.g. slings eye bolts, edge protection, timber skids/supports. Consideration should be given to location and the method of attaching lifting equipment to permanent structures and any loading imposed by the lifting activity. The location of equipment attachments should be adequate to safely support any imposed load, advice may be sought from a Structural Engineer or the client's representative. Where an assessment identifies working at heights is required, scaffolding should be provided. However, if there is a requirement for operatives to work from man-riding baskets they will be issued with full body harnesses in case, for whatever reason, the basket or platform displaces. Each employee will receive instruction on:a) How to wear the full body harness, and b) Where to attach the lanyard, (in case of a cradle or basket this would be the crane hook). This equipment assessment should be undertaken by rigging supervisors during the planning phase and prior to any work commencing onsite and reviewed as work progresses. Trained Personnel Where required, lifting plant and equipment may only be operated by certified personnel and only trained Rigger/Banksmen shall be used to direct crane movements at all times while operating on site. Only competent Riggers/Banskmen can direct the crane operator and rig loads for lifting. Competence must be proven by a training certificate from an approved training provider. Equipment Certification Mobile Lifting Equipment and Portable lifting appliances and equipment used on site, e.g. - Cranes, Hoists, chain blocks, slings etc must have documentation regarding recent Thorough Examinations and Inspection, from a competent 3rd party approved examiner, they must also be in good condition before use. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Details of equipment shall be recorded by the Appointed Person/Nominated Competent Person (Rigging supervisor) into the Al Hamra Construction site register and Project Health and Safety file where required. All certification of lifting equipment and accessories must be checked before use by either the site safety advisor, the nominated project appointed person, Rigging Supervisor with copies of certification held on file In the site register. Note: Equipment that is intended to be used for lifting personnel shall be inspected on a daily basis and findings recorded. All portable lifting appliances and equipment must be inspected by the user prior to use, by the equipment user. Defects of equipment must reported to the supervisor and the defective item placed into quarantine to prevent further use. Documentation and review All lifting study documents, method statements and risk assessments should be reviewed and approval shall be recorded by the project nominated appointed person on the front cover with the document presented to the planning supervisor for inclusion into the project Health and Safety file. Where there is a requirement for deviation from approved written method statements, lifting studies, and risk assessments all work must stop. The nominated competent person for the lifting operation shall undertake further review of the operation and record any amendments and seek approval from the appointed person prior to re-commencing work. Prior to starting work on any lifting activities, the contents of the method statements shall be fully explained to supervision and the operatives performing 'hands on' tasks. All operations relating to the lifting operation shall be in accordance with the specific lifting study and method statement and risk assessments. Any reviews or amendments to the lifting documentation should be conveyed to the operatives. Lifting Studies (Plan) Information to be included in Lifting Operation studies should comprise but not limited to: a) b) c) d) e) f) g) h) i) j) k) l) Description of Lifting Activity Weight of load SWL factors for plant and equipment Loading attachments and relative centre of gravity Origin/destination of load Seating/Setting of the load Local Environment including other process plant/services Size and suitability of lifting appliance Local ground loading Local underground services (If any) Selection of suitable lifting equipment Turning moments around C of G AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions m) n) Failure Modes Exclusion Zones Specific lifting studies and routine lifting studies may require regular review, as dictated by a change in circumstances, routine or method which may influence the lifting operation in any manner. Review of all Lifting studies shall be undertaken by the project appointed person for lifting operations. Method Statements Information to be included in lifting operation method statements should comprise, but not be limited to: a) b) c) d) e) f) g) h) Description of task Methods of execution Manpower Location of placement Position of crane and plant Safety protective equipment to be used Lifts over sensitive areas Types of slings/chains and SWL to be used. Contract Lifting The project/construction manager and his respective engineers and discipline supervisors will ensure that all Specialist Contract Lifting operations on site are undertaken in a safe manner in accordance with the site instructions and Lifting Operations and Lifting Equipment Regulations 1998 and H&S Construction codes of practice Part-2 section-29 Abu-Dhabi. The project/construction manager shall ensure that that the nominated Specialist Lifting contractor has appointed in writing to Al Hamra Construction the relevant appointed person and competent personnel for the lifting activity. Training records must be requested to ensure validation in and competency in their appointments in accordance with BS 7121. The project/construction manager shall ensure that in conjunction with all relevant Health Safety and Environmental obligations, specialist contractors have all contractual and commercial assurances in place covering the specific lifting operation. The nominated Al Hamra Construction competent person for the project, together with the Rigging Superintendent shall review and approve all lifting studies undertaken by the specialist lifting contractor by the prior to submittal to the client. All lifting study document reviews and approval shall be recorded by the project nominated competent person on the front cover, with the document presented to the planning supervisor for inclusion into the project Health and Safety file. Each subcontractor undertaking lifting operations must ensure that all their employees are suitably trained and competent to do the work. This will include adequate risk AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions assessments being produced prior to any lift taking place, with the control aspects identified and passed on to the employees. Al Hamra Construction will audit sub-contractors standards of training, lifting methods, risk assessments, plant and equipment to ensure compliance with legislation, Al Hamra Construction and Client standards. Reference Documentation H&S Construction codes of practice Part-2 section-19/20 Abu-Dhabi Lifting Operations and Lifting Equipment Regulations 1998 BS 7121 Parts 1 and 2 Avoidance of Danger from Overhead Electric Lines Contact with live overhead lines is the cause of fatal or serious injuries every year. In order to prevent contact with live overhead lines in the vicinity of the workplace, detailed risks assessments will be undertaken that will implement both the statutory requirement of Electricity at Work Regulations and GS 6 Avoidance of Danger from Electric Overhead Lines. Electricity company must be contacted and agree a safe system of work. Pre-planning of safe working procedures is essential. In all situations, including construction sites, specific advice will be necessary if vehicles, plant or equipment, etc. are brought in to the vicinity of overhead lines. In these cases, no part of the vehicle or plant or equipment etc. should be allowed to approach or be worked in any position where it is liable to be within 15 metres of overhead lines suspended from steel towers or 9 metres in the case of wood poles. The first essential step in complying with the regulations is to ascertain whether danger exists in the working area. Consequently, an inspection must be made to ascertain whether or not there is any overhead electric line within or immediately adjoining the work area, or access to any route to it. If work beneath the live overhead lines cannot be avoided barriers, goal posts and warning notices will be provided. However, they will not prevent danger from upward movements of cranes, excavators or other appliances, nor will they prevent direct contact by workers where buildings or structures are being erected beneath the lines. Additional precautions are therefore essential. Reference Documentation H&S Construction codes of practice Part-2 section-6 Abu-Dhabi Electricity at Work Regulations 1989 Construction (Health, safety and Welfare) Regulations HSE Guidance Note GS6 and HS(G)150 AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Erection of Structures, Working at Heights Many serious accidents and fatalities occur during the erection of structures and the principal cause is falls from heights. It is therefore essential that management exercise stringent controls in order that their employees are put to work in a safe and proper manner. To ensure that safe systems of work are implemented it is important that safe erection of pipe work, vessels, machinery, etc. is considered as early as the design stages. Design must take into account the need for, and the partiality of, safe methods of working. Supervision/Operatives Only competent personnel will be allowed to undertake any of the aforementioned tasks. They in turn will be supervised at all times by the construction supervisor working within the safe working procedures identified in the works permit to work or method statement/risk assessment documents. Fall protection Fall protection should be looked at from two aspects:a) Fall arrest looks at limiting the extent of falling after a person has lost their footing b) Fall prevention looks at restricting a person from gaining access to an area from which they could fall prior to using fall protection equipment, which should only be used when there is no other way of affording proper protection, a job specific risk assessment must be carried out with due consideration given to the following points:- c) Must be capable of automatically arresting a person who accidentally falls (fall arrest) Must prevent a person entering an area from which they could fall (fall restraint or prevention) d) e) Allow work to proceed through ergonomic, safe and secure means f) Ensure that the deceleration forces imposed upon the person falling during the arresting phase are kept to a minimum AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions g) Take into account the arrest distance through which the person falls and the risk of ground or equipment collision h) The anchorage point must be suitable and capable of sustaining the forces generated during the arrest i) Take into account subsequent rescue and recovery operations j) The person for whom protection is required k) The connecting line between anchorage and the harness. Depending on activity this may require doubling up, e.g. as a lifeline and lanyard or double lanyards being utilised by such disciplines as scaffolders l) Various connection fittings m) Horizontal lifelines and special travelling devices connected to them Safety Harnesses General purpose harnesses to EN361, which incorporate shoulder and crutch straps and fitted with double lanyard(s) no longer than 2 m. with a shock absorber incorporated into lanyard for use on site. Where appropriate the harness may be used in conjunction with inertia reels. Task Supervisors must ensure that when using safety harnesses the wearer has a suitable anchor point to fix to. Issue/Storage of Safety Harnesses Before issuing any safety harnesses they will be inspected by a competent person (discipline foreman) to ensure they are of sound construction and in good condition. Each piece of equipment will have its unique identification number recorded within register and all such inspections entered accordingly and shall be colour coded. After use, each safety harness will then be returned to the stores for proper storage. System of Work at Heights The 2 metre rule for working at height no longer exists. Any height from which a person can fall from one level to another level is considered as working at height. Where practicable scaffolding will be provided when employees are to undertake work at heights. However, if there is a requirement for operatives to work from man-riding baskets they will be issued with full body harnesses in case, for whatever reason, the basket or platform displaces. Each employee will receive instruction on:a) How to wear the full body harness, and b) Where to attach the lanyard (in case of a cradle or basket this would be the crane hook). AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Use of ladders Working off ladders must be considered as a last resort. If a ladder is required the person using the ladder must have a 3 point contact at all times, the ladder must have a 1:4 lean ratio and use should be restricted to maximum time of 10 minutes. The ladder must be tied off at the top and secured or held at the bottom. Tie offs should be attached to the stiles and not the rungs. Reference Documentation The Construction (Health, Safety and Welfare) Regulations 1996 Working At Height regulations 2005 HSE Guidance Note GS28, Parts 2 & 3 and HS(G)150 HSE Fatal Accidents Construction Hoists and Towers Competent persons who are fully aware of the legal requirements and the relevant British Standards will erect all hoists. Special attention must be given to ground conditions to ensure adequate support for the hoist. The forces imposed on its structure by workloads and inclement weather, particularly high winds, must also be taken into account. Hoist operators must be trained and competent and should be responsible for ensuring that the hoist is not overloaded or otherwise misused. Reports, records and certification must all be available for inspection on site at all reasonable times. Reference Documentation H&S Construction codes of practice Abu-Dhabi part-2 saction-19 Lifting Operations and Lifting Equipment Regulations 1998 The Construction (Health, Safety and Welfare) Regulations 1996 HSE Guidance Notes HS(G)150, PM 24 and PM 63 BS 3125, BS 4465 and BS 5973 AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Mobile Elevating Work Platforms MEWPs divide into two categories; boom-type Mobile Elevating Work Platforms (cherry pickers), and scissor lifts All mobile elevating work platforms are to be suitable for the task to be carried out. a) All operators/maintenance personnel must be trained and receive adequate information and instruction on the equipment. b) All equipment must be properly serviced/maintained and records kept. c) The safe working load must not be exceeded. d) The basket must be fitted with adequate guardrails and toe boards which are properly secured. The raising and lowering operations should be controlled solely by the person on the platform. e) f) The controls situated on the platform should be designed and positioned to prevent inadvertent operation and should be of the dead man’s handle’ type. g) No-one should be on the platform in an elevated position while travelling. h) The operational area should be cordoned off to prevent persons walking below the platform who could be struck by falling objects. i) Operatives must not stretch or lean out from the platform. Safety harnesses to be worn at all times. j) Ground conditions must be adequate – firm and reasonably level. k) Never work near overhead power lines as electricity may arc across and electrocute personnel. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions l) Under no circumstances must the SWL be exceeded. m) If outriggers are fitted they should be extended before use Reference Documentation H&S Construction codes of practice Part-2 section-29.21.2 Abu-Dhabi Health and Safety at Work etc Act 1974 HSE Guidance Notes GS6 and HS(G)150 The Provision and Use of Work Equipment Regulations 1998 Manual Handling When mechanical lifting devices cannot be utilised and manual handling cannot be avoided then an assessment of the task must be carried out in order to reduce the risk of injury. When planning, before carrying out the job, the following points must be considered:a) b) c) d) e) f) g) h) i) Decide in advance how Plan the route, free from hazards Determine the destination, will help be needed Look over the object, decide where and how to hold it Remove any grease, oil or projections from object Consider the distance to the destination. Plan rest stops. Be sure that there is enough space for handling. Use mechanical aids where possible. Ensure that personnel carrying out manual handling activities have been properly trained. Reference Documentation Manual Handling Operations Regulations 1992 AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Safe Operation of Construction Plant and Site Hoists Plant The company and our sub-contractors shall employ competent trained plant operators to operate Loadalls, Cotils, etc. Before any employee is allowed to operate any such plant they must have received adequate instruction from an authorised training provider. This will either be the Construction Industry Training Board (CITB), Certification of Training Achievement of Construction Plant Operators (CTA Scheme) or something similar. All operators of plant will be registered and copies of their competence/authority will be held by the site HSE adviser. Loading Cotil tractors and cranes are not allowed to carry loads on site roads, their respective loads must be placed on trailers for transportation. Overhanging loads on trailers will at all times be marked with flags or lights and if necessary by a banksman. Overhangs shall not exceed 2 metres. Spillages Strenuous controls shall be implemented to prevent rubbish or materials being displaced onto haul roads or public roadways. Loads shall be secured and sheeted before leaving site. Site Hoists The company will ensure that only trained and competent people operate the equipment and that all statutory registers are duly completed. Under no circumstances will any person be permitted to ride in hoists designed for materials. Hoist operators will be in possession of the valid test certificate for the hoist. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Vehicles and Mobile Plant Only drivers who hold a current driving licence appropriate to the vehicle or plant will be allowed to operate company plant or vehicles. All vehicles on site will be properly maintained in accordance with the manufacturers recommendations and always be in a safe and road-worthy condition. The site Plant and Transport foreman will keep a register of competent plant operators/ drivers’ licences/authority. No fuelling of vehicles will be done on site all fuelling and maintenance will be completed at the lay down area. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Compressed Air and Pressurised Services Suitable arrangements for pressurised systems are established within the company. All such systems used will be in accordance with the relevant Codes of Practice Abu-Dhabi. Diesel driven compressors before being allowed on site must have their certification checked to ensure that a competent person has inspected the equipment in accordance with the statutory provisions. Static air compressors and air receiver tools and equipment will be regularly inspected, maintained and records kept. Engine exhausts must not be permitted to discharge their fumes into any building. All fittings and associated equipment must be for compressed air service and suitable for the pressure to which the system operates. Hose connections must be fitted with a whiplash chain to prevent injury in the event of a failure. Reference Documentation Pressure Systems and Transportable Gas Containers Regulations 1989 Approved Code of Practice Lift Trucks AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Confined Space Entry A confined space is any enclosed space, above or below ground, where a hazard to health may exist due to lack of, or enrichment of, oxygen in the atmosphere, or a potentially toxic or flammable atmosphere. Places coming within this definition include, but are not limited to, excavations, culverts, manholes, sumps, drainage systems, unventilated rooms, tanks, boilers/heaters, flues, chimneys, silos, vessels and process columns. Entry into a confined space is potentially hazardous and as such will be strictly controlled through the client’s permit to work procedure or Al Futtaim Carillions AHCC/HSMS/PRO/07/05 Confined Space Entry procedure. All work undertaken in a confined space will have a risk assessment carried out which will identify and define any hazard that employees might encounter during the work or to any other person who might be affected by the operation. It will also review what hazards may be introduced in to the space by the intended work. Work Method Statements and Risk Assessments are mandatory for this type of work. No work will be permitted without a valid Confined Space entry PTW. Reference Documentation H&S Construction codes of practice Part-2 section-21 Abu-Dhabi HSE Guidance Notes HS (G) 150 and GS5 – Entry into Confined Spaces The Confined Spaces Regulations 1997 AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Excavations The project/construction manager will arrange for a competent person to supervise any excavations that may be necessary after carrying out a site survey and marking out the location of known underground services. Excavations may contain trapped gases or fumes caution needs to be exercised, any gas tests conducted in narrow service trenches. The construction/supervisor will inspect the excavation(s) daily and undertake a thorough examination within every 7 days in accordance with the Regulations which will be recorded in the register. A risk assessment should be made of ground conditions, material, etc. and where necessary the excavation must be supported or battered back to prevent materials and soil falling into the trench. A safe means of access and egress must be available into the trench and the supervisor will ensure that stop blocks are utilised where vehicles have to approach the trench edge and that adequate hard barriers are properly placed around all excavations. All activities will be undertaken under a permit to work. Machine Dig exclusion zone No machine shall operate within a 5 metre radius from the buried service. There are six main dangers associated with excavation work:a) striking underground services b) collapse of the excavation c) people falling into the excavation d) plant, etc. falling into the excavation e) gas, vapour or lack of oxygen in the excavation f) undermining nearby structures Precautions to be Taken AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Underground Services There are many different types of underground services that may be present when undertaking excavation work. They include water supplies, drains, sewers, telecommunication lines, gas lines and electrical cables. Before any work commences service drawings must be referenced to ensure every effort has been taken to identify any underground services. Service routes shall be physically marked to identify the service route to the workers an equipment operators Surveying for Cables Cable locating instruments will be used before any excavation is started. The equipment will be used only by trained and competent persons. After locating any cables, clear marked wooden pegs/marker tape shall be positioned to identify the hazard below and where necessary trial holes (which must be done by hand) will be dug to confirm the position of cables. Reference Documentation H&S Construction codes of practice Part-2 section-23 Abu-Dhabi The Construction (Health, Safety and Welfare) Regulations 1996 HSE Guidance Note HS(G)47 and HS(G)150 Electricity Electrical Work Electrical equipment taken onto the works by the company and sub-contractors will comply with all appropriate legislation and be 110v rated. Persons engaged in any work activity concerning electrical installation or maintenance must be competent and possess the necessary technical knowledge and experience to prevent possible danger and/or injury. Portable Electrical Tools a) b) c) d) e) f) Every such tool will be inspected before being issued to the site by a competent electrical engineer. Each individual item, e.g. – extension cable, grinder, transformer, etc. will then have a unique number attached to it. A formal record system is to be operated with comprehensive details appertaining to each piece of equipment filed. Within a period not exceeding 3 months a full inspection is to be conducted, where every component is visually inspected with functional tests checked on the PAD 300 system or something similar and colour coding tag will be provided in accordance with SLWP colour coding system. This equipment produces an independent print-out which will then be attached to the inspection records. All such work is to be carried out by a competent electrician. Only doubled insulated hand tools of 110v AC will be used on site. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions All persons changing grinding or abrasive wheels must have proof of current training and be familiar with ‘Provision and Use of Work Equipment Regulations 1998’. Hot Work Permits are required for use of abrasive wheels in restricted areas. All electrical leads will be fitted with an approved plug/socket in accordance with British Standards. Taped joints/breaks in cables must never be used on site. Under no circumstances should guards or handles be removed or interfered with. Defective equipment must be withdrawn immediately and returned into the stores for repair. Site Electrical Power a) A client or AHCC electrical engineer will design the site energy requirements and ensure it is installed, tested and commissioned in accordance with HSE rules and applicable statutory duties. All fixed wiring circuits will be inspected annually by an electrical engineer. A competent electrician will check temporary distribution boards at three-monthly intervals and records kept of the inspections. b) Cable routes whenever possible will be run in ducted underground cables. Should this be impractical then permission will be sought from the client. Arc Welding The plant and apparatus used for electric welding shall be in accordance with BS 638 (Parts 1-8) or equivalent standard. HSE Guidance Note PM 64 (Electric Safety in Arc Welding) must also be observed. The following precautions are to be adhered to:a) Ensure cables are correctly connected and adequately earthed. b) Keep cables clear of ladders and walkways. c) Do not allow them to pass over machinery or any process pipe work where they may make contact. d) Do not allow traffic to pass over cables. e) Disconnect from power source when not in use. f) Never use damaged cables. g) Disconnect from power sources before joining any cables. Stray Currents It is essential to ensure there are no stray electrical currents when welding operations are being performed. Therefore, in all cases where butt welding of two items, e.g. butt ends of pipe has to be done and neither item is permanently attached to any structure both items must be connected to the welding return. This requirement is necessary to prevent stray electric currents causing sparks at a distance from the welding point. Welding Cable Inspection AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions The welding supervisor will conduct a regular formal inspection to ascertain whether all cables are without defects. Office Electrical Equipment a) b) c) d) Office and kitchen equipment which includes such items as kettles, refrigerators, microwaves, heaters, PC’s, fans, etc. will be inspected once in every 12 months and formal records will be kept of the inspections conducted by the electrical engineer. Private electrical items are not allowed on site unless authorised by the project/construction manager, who will then ensure the item conforms to the aforementioned procedure. Multi adaptor plugs must not overload electrical outputs. Under no circumstances is any employee allowed to interfere with or attempt to repair any electrical item whatsoever, unless he is the nominated electrical engineer. Reference Documentation Provision and Use of Work Equipment Regulations 1998 and Approved Code of Practice Electricity at Work Regulations 1989 AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions High Pressure Water Jetting Specialist sub-contractors will be utilised for this type of work. The work will always be carried out under a safe system of work supported by a method statement specific for the work to be undertaken. The method statement will include but not be limited to:a) The layout of the plant and equipment to be used in relationship to the site. b) The operating parameters of the equipment. c) The precautions to be taken and in particular if the work is to be carried out either in a confined space or local to the work activities being carried out by others. d) The PPE requirements. e) The type and positioning of barriers and signs. f) How waste products are to be handled and disposed of. For further information on method statements refer to section 18.0 Equipment is to be earth bonded and ‘fail safe’ devices fitted. Under no circumstances will unauthorised persons be allowed to enter the work area whilst jetting is in progress. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Fabrication/Pressure Testing of Pipelines The following represents a brief synopsis of some of the measures required for the execution of the works to pipelines. They are by no means exhaustive and proper method statements are a prerequisite of any work being carried out. All work associated with pipelines including breaking into the pipelines requires a permit to work. The following must be ensured when working on pipelines:a) b) c) d) e) f) g) h) Record the insertion and removal of spades, all spades to be clearly tagged and identified. Ensure that gaskets of the correct specification are used and that bolting is to the correct specification. Ensure that all flange faces are clean. Tighten flanges properly and to the correct tension. Ensure that the correct tools are used. Ensure that all tools are in good condition and tagged (electrical). Ensure spool is secure prior to any activities and surrounding area is safe (barrier worksite if required). Hearing protection must be worn when grinding and also the correct PPE, i.e.– Fireproof overalls, safety goggles, hard hat, safety boots. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions i) j) k) l) m) Ensure all lifting of pipe work/valves is carried out by a competent person. All large bore weld make-ups must be inspected by QC engineer prior to welding taking place. Spools/valves should be supported prior to the removal of lifting equipment and job start. All mechanical lifting devices and/or temporary supports must remain in situ until the weld is complete and great care must be taken to ensure that this is adhered to. Reference should be made to relevant risk assessments, e.g. – MMA welding, grinding, TIG welding. Pressure Testing a) There may be a requirement for two types of pressure testing:i) Strength Testing where a pressure is applied greater than the safe working pressure to prove the mechanical strength or integrity of equipment, weld or fabrication. ii) Leak Testing - normally at or below safe working pressure a system is pressurised to ascertain the integrity of reinstatement prior to service/operation. All work will be carried out under a permit to work using suitable materials and calibrated equipment under direct supervision of a person competent to carry out such tests. If high pressure testing in excess of 75 bar is required then this will be carried out under the supervision of a specialist test engineer (approved contractor) who can evaluate the stress within pipe work and/or vessels. The following procedure will be adopted:a) b) c) d) e) f) g) Verify the test pressure before starting. Ensure that the pressure gauges have been calibrated. Ensure that the spades are of the required thickness to withstand the pressure. Ensure that the supports are adequate for the weight of the test. Ensure that the area around the test is cordoned off and warning notices erected. Don’t rush the test. Increase the pressure in safe steps. The medium used for testing is to be considered carefully to take cognisance of the pipe system metallurgical properties, pressure and temperature. Remember to vent the system. If a positive displacement pump is being used to fit a relief valve, or a kickback system. The fittings used (especially screwed fittings) must be rated for the pressure employed. Don’t use air or a gas as a testing medium. Use a non-compressible fluid as agreed with the client. Pneumatic tests require the authorisation of senior management and will require a full detailed method statement. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Exercise extreme caution when de-pressurising. Working overhead – ensure the area below the pressure testing area is cordoned off, warning notices erected and the area cleared of personnel. Pressure/leak testing of instrumentation impulse pipe work and tubing may be air or gas tested after agreement with the construction authority. Reference Documentation The Pressure Systems and Transportable Gas Containers Regulations 1989 HSE Guidance Note GS4 Painting Health Hazards Associated With Painting a) b) c) d) b) Work involving solvent based paints, thinners, etc. may give rise to atmospheres which are both flammable and toxic and only approved sub-contractors will be employed to undertake the work. To ensure adequate provisions have been taken in controlling painting activities a safe system of work must be followed identified either on the permit to work or risk assessment/method statement. Over-exposure may cause irritation to the eyes and respiratory system. Excessive concentrations may produce effects on the central nervous system including drowsiness and in extreme cases loss of consciousness may result. Splashes entering the eye will cause severe discomfort and possible damage and prolonged contact with skin may have a de-fatting effect and lead to dermatitis. Only specified amounts of paint shall be taken into the work area daily and returned at the end of a shift. No open paint tins are to left on site. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Safety controls Where possible AHCC shall pursue a suitable alternative to solvent based paint. If that is not possible we shall ensure that the conditions of the Material Safety Data Sheet are stringently complied with and all necessary additional respiratory, eye and Personal protective equipment is worn at all times. Cartridge Operated Fixing Tools Cartridge operated fixing tools are very similar to firearms in both construction and operation. Operators of these tools must have been trained in their safe use, must be over 18 years of age and must be authorised (in writing) for their use. As a general principle AHCC does not allow the use of these tools on their sites, however if the tool is to be used, the company or Sub Contractor will strictly comply with 03 Safe Use of Cartridge Operated tools: Procedures for Use a) No cartridge operated tool will be allowed on site without the written permission of the project/construction manager. b) Tools must only be used in strict adherence to the makers instructions and when not in use both tools and cartridges must be kept in a secure locked storage place. c) A controlled procedure for the issue of cartridges must be established. This will require a register to be maintained by the contractor ensuring accountability of all cartridges used and unused on site. d) Wherever practicable cartridge operated fixing tools should not be used in the immediate vicinity of other works and extra care should be taken to ensure that no person is sited in line with the ‘flight of the pin’ when the tool is in use. e) Where an area cannot be completely isolated warning notices must be displayed. f) A trained operators and assistants must wear safety helmets, ear defenders and goggles/visors and tools should never be left unattended. g) No adjustments should ever be made to a loaded tool. h) Before any work can proceed a risk assessment has to be prepared and submitted to Downstream Oil, Gas and Process for approval. i) All work will be strictly controlled under permit conditions. j) Cartridges and firing pins for different types/makes of tools are not interchangeable, even though they may appear to be identical. Reference Documentation Provision of Use of Work Equipment Regulations 1998 and Approved Code of Practice The Construction (Health, Safety and Welfare) Regulations 1996 AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Highly Flammable Liquids Highly flammable liquids (HFL’s) means liquids that give off flammable vapours at less than 32°C and includes but is not limited to solvents, oil based paints, white spirit, thinners, petroleum based adhesives. For HFL’s where storage is less than 50 litres metal lockable bins may be used. The bins must not be stored in site office or welfare facilities and preferably stored in metal containers. The metal containers must be sited at least 2 metres away from any building or perimeter fence. Alternatively, when there is a significant amount of HFL materials to be stored, consideration is to be given to the erection of a purpose built storage facility. For all storage requirements the contractor is to submit their proposals to the construction manager for approval. The work site inventory of HFL’s will be kept to a minimum, the maximum being the amount required for a single work period. This is particularly important if the HFL’s are to be used in a confined space or temporary encapsulation. In general the storage of petrol on site will not be permitted. Storage of diesel will be permitted after a suitable bunded location has been approved. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions For all storage areas signs must be erected indicating the type of material stored and the precautions to be taken in and around the area. Reference Documentation Chemicals (Hazard Information and Packaging for Supply) Regulations 1994 Highly Flammable Liquids and Liquefied Petroleum Gases Regulations 1972 HSE Guidance Notes HS(G)34 Use and Storage of Gas Cylinders Propane and Butane (LPG) a) b) c) d) e) f) g) LPG cylinders in excess of 50kg total capacity must not be stored within 3 metres of any compressed gas cylinders including acetylene. They must be located in a fixed upright position. Kept away from ignition sources (including static discharges). They must be stored in a well ventilated area, protected from the elements, preferably in open air. The storage area must be identified with Highly Flammable –No Smoking signs. The storage area must be away from ducts, trenches, excavations (as both propane and butane are heavier than air), and a minimum of 2 metres away from any openings. No cylinder is to be any nearer than 1.5 metres from the fire wall if provided. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions h) Always leak check cylinders when first collected/delivered or used using an approved leak detecting fluid. i) Never roll cylinders. Milk-churning cylinders on their bases is permissible but must not be moved over long distances. Use approved bottle trolley only. j) For hydrogen, propane, acetylene and oxygen use only regulators designed for the gas. Remember the cylinder pressure and properties are different for each gas. k) Charged and discharged propane and butane cylinders may be stored together, but positively identified and segregated. l) Identification symbols: F+ extremely flammable; T – toxic, risk phase R12 m) Propane cylinders must never be laid on their side as liquid propane could be released which is extremely hazardous. Oxygen a) b) c) d) Oxygen and inert gases may be stored together but positively segregated. Charged and discharged cylinders may be stored together but positively identified. Cylinders containing oxygen or oxidising gases must be separated from cylinders containing flammable gases by a minimum of 3 metres or by a fire resistant partition. Oxygen cylinders are charged at different pressures dependant on location – always check charge pressure against regulator operating pressures, i.e. – North 230 Bar, South 200 Bar. Hose assemblies must be tested after repair in accordance with BS 1389: 1986 to 15 Bar and a register kept of repairs. Cylinders – General a) b) c) d) e) f) g) h) Oxygen equipment is at most risk from oil and grease so keep greasy hands, rags and gloves away from any part of the cylinder and fittings. Acetylene cylinders must never be used if they have been laid horizontally unless a twelve hour period has elapsed since restoring the cylinder to an upright position. Acetylene cylinders must be stored separately with a minimum distance of 3 metres from any compressible gas cylinders. There is no such thing as an empty cylinder. It is recommended that any regulator with BS 5741 need replacing with BS 7650. It is recommended to exchange units every 5 years. Separated storage areas must be clearly labelled as to their contents and with any cautionary notices. Use only correct cable and hose connections:Argon = Black – BS EN 5120 Oxygen = Blue Fuel Gas = Orange Oxygen, acetylene and propane equipment will be fitted with flashback arrestors and non-return valves in the hose connection. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions Storage Facilities a) b) c) A secure storage area will be erected at a suitable location away from site buildings. Minimum distance 100 metres. The base of the store will be level and of a suitable size to permit segregation of individual gases with a separate area for empty and full cylinders. The perimeter fence will consist of open wire mesh at least 2m. high. Particular consideration will be given to access and egress for both the operatives changing bottles and in the event of an emergency, fire vehicle. Individual notices for the classification of the gases will be attached to the wire mesh with a 3m. gap between flammable gases (LPG and acetylene) and other cylinders (oxygen and argon). Fire Precautions of Cylinder Stores Notices A number of conspicuous notices facing out over will be attached to the mesh fencing indicating ‘Warning Highly Flammable’ and ‘No Smoking’. Fire Extinguishers 2 blue (dry powder) extinguishers will be located against the exit doors. Housekeeping Under no circumstances will either combustible materials or grass be allowed to accumulate around the storage area. Training of Operatives During the induction programme, and also as a result of the risk assessment, detailed information will be passed on to each operative on how to deal with gas cylinders. In addition full cylinders should be stored separately from expended and cylinders of different gases whether full or expended should be segregated from each other. Never use any jointing compound on any cylinders including PTFE tape. Use of Gases in Confined Spaces All heating, cutting and welding torches including TIG must be removed from confined spaces, trenches or ducts to fresh air at meal times or end of shifts, alternatively disconnected at source and positively isolated. At all times whilst using cylinders a bottle key must be in place for emergency isolation! Cylinder will be kept out of confined space. Transportation of Gases Bottled gases delivered to site must be in an approved vehicle as there are road traffic requirements to be complied with when transporting such substances. Reference Documentation AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions The Pressure Systems and Transportable Gas Containers Regulations 1989 HSE Guidance Notes CS4 Asbestos If during the course of construction/maintenance operations on site where asbestos is found (or suspected) to be present (other than joint material), any operation which may cause disturbance of the material must STOP. The contaminated area must be cordoned off and screened with appropriate signs. The HSE advisor/Department must be informed as soon as possible. Only Licensed Contractors may undertake controlled removal of asbestos. When a Subcontractor is employed to remove the asbestos, the Project Manager/Site Agent is responsible for ensuring that the Subcontractor holds an Asbestos Licence (issued by Municipality) and is an approved Contractor. A copy of the Licence must be obtained and displayed on site. AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions It is the responsibility of the Subcontractor to give notice (14 days) to the HSE before work commences. Under no circumstances, should a Subcontractor to be employed to remove asbestos unless the company is in the possession of a copy of the subcontractor’s current Asbestos Licence, Breaking Joints When breaking joints and flanges, separation of flanges exposes the CAF gasket to atmosphere and the joint faces may require cleaning off residual CAF deposits. The vulcanising agent that binds the asbestos fibres in the gasket is rubber which deteriorates if exposed to high temperatures as in process operations, thus causing the formed gasket to disintegrate and release free asbestos fibres at the workface and into the environment. Preventative measures to minimise the hazard of releasing fibres would be to saturate the gasket and any residual deposits with a PVA/water solution, which would bind, and dust/fibres and [prevent them from becoming airborne. If a PVA solution is unavailable copious amounts of water will suffice, Adequate PPE must be worn at the workface, respiratory protection, disposable coveralls, gloves, all of which must be disposed of in a controlled manner as special waste after work is completed, together with any gasket and residue produced from the work activity. Correct hygiene procedures to be observed at meal/tea breaks and at the end of workshift. Disposal of gasket, residual waste and contaminated PPE to be placed in double bags sealed and identified as hazardous waste and placed in controlled waste slips for disposal by licensed waste disposal contractor. Ionising Radiation All ionising radiation work will be conducted bya specialist contractor. Clear instructions will be provided to the radiographic company performing the work as to when they may undertake the work. Details of Radiography times will be posted at strategic points on site and whenever sources are being used a controlled area must be marked off by tape, barriers and trefoil flags in compliance with the radiography company’s local rules. The area shall be patrolled to ensure that no-one inadvertently encroaches into the area and an alarm or klaxon shall be sounded to warn personnel that radiography is in progress. Personnel shall be informed of the tone to expect prior to testing as:- AL HAMRA CONSTRUCTION CO.LLC Operational Work Instructions a) Part of their induction b) Tool box talks Only ‘Classified Persons’ are allowed in the barrier area and a work permit must cover the use of sources. Sources must be returned to the shielded container in an emergency. A competent approved contractor, undertaking all activities in strict compliance with both statutory and local site rules will perform this work. Regular audits are to take place to monitor and ensure that all procedures are being adhered to.