III. Thermomechanical Analysis of SU8 Thermal Actuator

advertisement

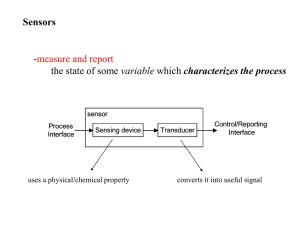

1

Fabrication and Non-linear Thermomechanical

Analysis of SU8 Thermal Actuator

Leema Rose Viannie, G. R. Jayanth, V. Radhakrishna and K. Rajanna

Abstract—SU8 based micromechanical structures are widely

used as thermal actuators in the development of compliant

micromanipulation tools. This paper reports the design, nonlinear thermomechanical analysis, fabrication, and thermal

actuation of SU8 actuators. The thermomechanical analysis of

the actuator incorporates non-linear temperature-dependent

properties of SU8 polymer to accurately model its thermal

response during actuation. The designed SU8 thermal actuators

are fabricated using surface micromachining techniques and

electrical interconnects are made to it using flip-chip bonding.

The issues due to thermal stress during fabrication are discussed

and a novel strategy is proposed to release the thermal stress in

the fabricated actuators. Subsequent characterization of the

actuator using a 3D optical profilometer reveals excellent

thermal response, good repeatability and low hysteresis. The

maximum deflection is about 10 μm for an actuation current of

about 5 mA. The experimentally obtained deflection profile and

the tip deflection at different currents are both shown to be in

good agreement with the predictions of the non-linear

thermomechanical model. This underscores the need to consider

nonlinearities when modeling the response of SU8 actuators.

Index

Terms—SU8

thermal

actuator,

nonlinearthermomechanical analysis, 3D optical profiler, residual

stress.

I. INTRODUCTION

MEMS fabrication technology has enabled dramatic

miniaturization of mechanical sensors and actuators [1], [2].

Micromanipulators developed from these miniature devices

can be used to precisely hold and assemble micro-parts such

as micro-gears [3] and micro-mirrors [4]. In biological

applications, micromanipulators are often used to capture,

immobilize and characterize individual living cells [5], [6].

Such micromanipulators or micro robotic arms are often

integrated with an actuator in order to produce controlled

mechanical motion. These actuators can be driven using

electrostatic [7], piezoelectric [8], shape memory [9] or

thermal [10] actuation techniques. Among these, thermal

actuation has the advantages of large actuation force, low

driving voltage and large mechanical deflection [11]. The

performance of thermal actuators mainly depends on the

coefficient of thermal expansion (CTE) of its constituent

materials. Most often, MEMS based thermal actuators are

fabricated from silicon [12]. Being relatively stiff and

possessing small CTE, silicon produces small mechanical

Leema Rose Viannie, G. R. Jayanth and K. Rajanna are with the Department

of Instrumentation and Applied Physics, Indian Institute of Science,

Bangalore

560012,

India(e-mail:

roseviannie@iap.iisc.ernet.in;

jayanth@isu.iisc.ernet.in; kraj@isu.iisc.ernet.in).

V. Radhakrishna is with Space Astronomy Group, ISRO Satellite Centre,

Bangalore, India. (e-mail: rkrish@isac.gov.in)

deflections. The development of micromechanical tools for

single cell manipulation and characterization; positioning and

moving of cells or parallel manipulation of large number of

biological entities require that the actuators must be

biocompatible and capable of generating large mechanical

displacement for small driving voltages at lower operating

temperatures [6]. Therefore, research groups have

investigated fabrication of thermal actuators by alternate

materials such as polymers, since they possess low Young’s

modulus and high CTE. Some commonly used polymers in

the fabrication of thermal actuators are parylene C [13],

polyimide [14], polypyrrole [15] and SU8 [16]. Among them,

SU8 polymer is particularly suited for fabricating high

aspect-ratio MEMS devices [17]. It is an epoxy based

negative photoresist which can be easily patterned using

conventional UV photolithography techniques. Fully crosslinked SU8 polymers have several desirable properties

including low Young’s modulus, better chemical resistance

and excellent biocompatibility [18]. Due to its high CTE

value, SU8 thermal actuators provide large mechanical

deflections at lower operating temperatures [6], [19]. While

the low Young’s modulus reduces the stiffness and hence the

bandwidth of actuation, SU8 polymer actuators find

applications in several areas which do not require large

bandwidth and but do require lower actuation force [5], [6],

[19], such as in the development of micro-valves [8], microextractors [20], micro-actuators [21], and micro-cages [22].

These devices find applications in areas such as

micromanipulation,

entrapment

and

electrical

characterization of biological cells and tissues. Likewise, they

can also be used as probes in Atomic Force Microscopy,

wherein they can be employed for performing quasi-static

force spectroscopy and indentation experiments [23],

especially on soft, biological samples such as macromolecules and cells.

In order to evaluate the performance of SU8 thermal

actuators at elevated operating temperatures, a precise

understanding of thermomechanical properties of SU8 is

essential. Earlier reports have investigated the mechanical

[24] and thermal [25] properties of fully cross-linked SU8

polymer for MEMS applications. These properties are used in

several studies that adopt analytical and finite element (FE)

modeling of SU8 thermal actuators [19], [25], [26], [27],

[28]. The FE modeling assumes linear thermo-elastic

behavior of the polymer, and therefore neglects the variation

of Young’s modulus and CTE at all operating temperatures.

These models are used to estimate the temperature

distribution in a heated thermal actuator. However, a recent

report by S. Chung et al [29] revealed the effects of

temperature on the mechanical properties of SU8 polymer. It

was found that the Young’s modulus of SU8 shows strong

2

non-linear temperature dependence. Therefore, in this work

we incorporate the effect of temperature on the Young’s

Modulus, evaluate the actuator’s thermomechanical response

and verify the same experimentally.

In this paper, we present the design, nonlinear

thermomechanical analysis, fabrication and actuation of a

polymeric thermal actuator. The actuator consists of SU8

microcantilever with an integrated Au thin film resistor.

Nonlinear finite element analysis (FEA) has been used to

simulate the thermomechanical response of the actuator by

incorporating the dependence of Young’s modulus and

Poisson’s ratio on temperature. The SU8 thermal actuator is

fabricated using surface micromachining techniques.

Subsequently, the thermal actuation of the actuator has been

experimentally characterized using 3D optical profiler. A

novel strategy is proposed to release the thermal stress in a

fabricated actuator. Subsequent experiments show good

agreement between the measured deflections of the actuator

and that of the nonlinear FEA. This underscores the need to

consider the effect of temperature on the performance of SU8

based thermal actuators.

The rest of the paper is divided as follows: section II

discusses the design of SU8 thermal actuator. The analytical

model for steady state temperature distribution, finite element

analysis (FEA) of a thermally heated actuator along with the

non-linear thermomechanical analysis of the SU8 actuator is

discussed in section III. A detailed account of the actuator

fabrication and its electrical interconnection is discussed in

section IV. This section also discusses the challenges faced

during the fabrication process. The experimental set-up used

to measure the motion of the actuator is mentioned in section

V. Finally, a comprehensive discussion of the experimental

results and their comparison with finite element analysis is

presented in section VI.

When current is passed through the resistor, its temperature

rises due to Joule heating. This rise in temperature induces

internal thermal stresses within SU8-Au bimorph. Since the

thermal expansion of SU8 (α2) is greater than Au (α1) it

produces a bending moment in SU8-Au bimorph thereby

resulting in the mechanical deflection of SU8 cantilever.

Also, the direction of cantilever deflection is towards lower

CTE layer i.e. towards the Au layer. The maximum tip

deflection of the cantilever bimorph is related to the

temperature distribution within the cantilever, its physical

dimensions as well as its material properties [30]. Since the

temperature varies along the length of the cantilever, and also

the Young’s modulus of SU8 polymer changes with

temperature [29], the deformation profile for such a nonlinear thermal actuation phenomenon cannot be estimated

accurately using simple analytical models. Therefore, we

employ finite element analysis to evaluate the

thermomechanical response of SU8 thermal actuator.

TABLE I

DIMENSIONS AND MATERIAL PROPERTIES OF SU8 THERMAL ACTUATOR

Material

Parameters

Symbol

Values

Unit

Au

Length

Width

Thickness

Young’s Modulus

CTE

Thermal conductivity

Resistivity

L1

w1

t1

E1

α1

k1

ρ

220

5

50

70

14.2

312

2.44×10-8

μm

μm

nm

GPa

ppm/ºC

W/mK

Ω.m

SU8

Length

Width

Thickness

Young’s Modulus

CTE

Thermal conductivity

L2

w2

t2

E2

α2

k2

120

30

5

4.02

52

0.2

μm

μm

μm

GPa

ppm/ºC

W/mK

II. DESIGN OF SU8 THERMAL ACTUATOR

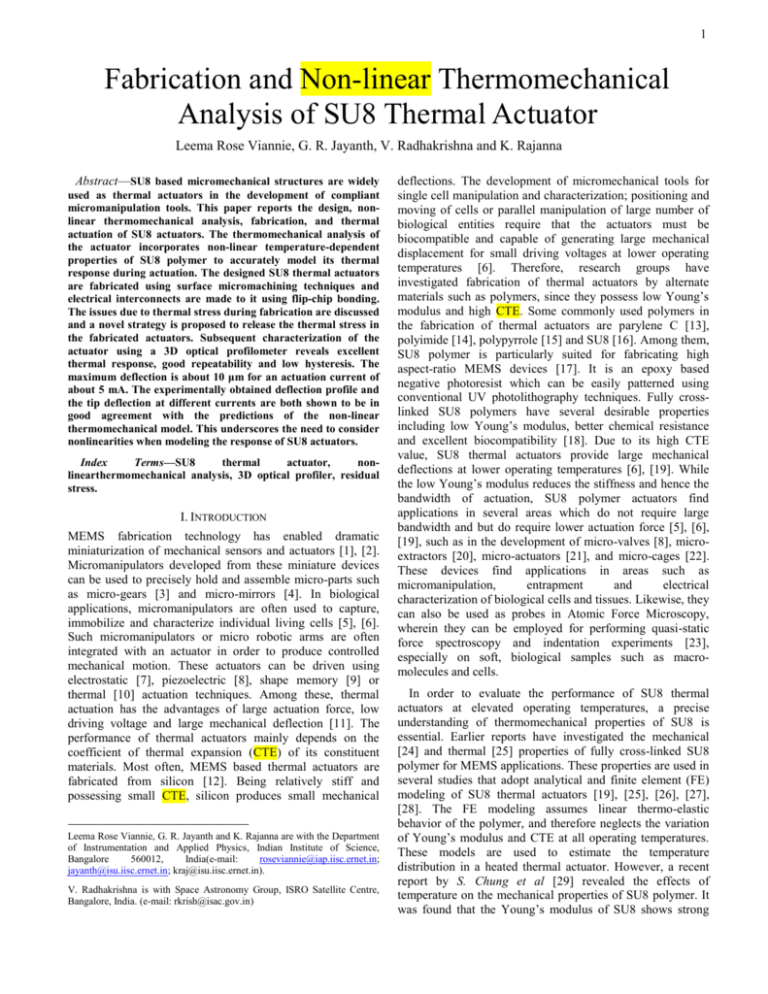

Fig. 1(a) and (b) shows the geometry of the SU8 thermal

actuator comprising of a rectangular SU8 microcantilever

with an integrated gold (Au) thin film resistor. The actuator’s

dimensions and material properties are given in Table I. In

this design, the two structural layers namely the SU8 polymer

and the Au thin film constitute a thermal bimorph. The Au

resistor, which is symmetrically patterned over the SU8

cantilever, serves as a resistive heating element.

III. THERMOMECHANICAL ANALYSIS OF SU8 THERMAL

ACTUATOR

This section discusses the temperature distribution and the

corresponding deformation profile of a SU8 thermal actuator.

Section III A proposes a simple model to obtain the

temperature distribution along the length of the cantilever,

and validates it by means of finite element analysis. Section

III B employs finite element analysis to obtain the

deformation profile of the actuator.

A. Steady-state temperature distribution on the thermal

actuator

Fig. 1. (a) Schematic cross-section of SU8 thermal actuator showing SU8-Au

bimorph structure. (b) Schematic showing the top view of rectangular SU8

microcantilever with integrated Au resistor.

In order to determine the steady-state temperature

distribution on the thermal actuator, a one dimensional (1D)

analytical model was formulated. The model assumes the

presence of conductive heat transfer [31] within the gold

layer and between the gold and polymer layers, but ignores

the effects of convective and radiative heat transfer. With

3

these assumptions, the variation of temperature Tg along the

contour of the gold resistor depends on the actuating current

I and the polymer temperature Tp as,

d 2Tg

k w

I 2

(1)

2 2 (Tg T p )

2

k

w

t

dx1

1 11

k1w1t1t2

where, x1 is a distance variable along the contour of the

resistor. The other symbol definitions are mentioned in Table

I. Likewise, by applying the steady-state heat equation, the

variation of polymer temperature Tp along the contour of the

gold resistor can be written as

d 2T p 2

(2)

(Tg T p ) 0

dx12 t22

By assuming that the ends of the Au resistor and the polymer

layer at 𝑥1 = 0 and 𝑥1 = 𝐿1 are maintained at zero, i.e.,

Tg

x 0

Tg

x L1

0 and Tp

x 0

Tp

x L1

0 , Eqn. (1) can

be solved analytically to obtain the variation of temperature

along the contour of the Au resistor. This is given by

T ( x1 )

g

q

p 1 2

me x1 ne x1

x1 r x1 m n

a

2

(3)

Where,

m

r

b

;

4a

n

b

a

4

p

;

b

2a

e

L1

L1

e

L1

1 e

L1

1

;

e

L1

e

L1

;

2

b

a

2

t2

2

The maximum temperature rise within the Au resistor occurs

𝐿

in the middle of the resistor. Hence Eqn. (3) at 𝑥1 = 21 can be

written as

Tmax

Fig. 2(a) shows the steady-state temperature distribution in

the SU8 actuator obtained from FEA. Fig. 2(b) compares the

temperature distribution in the Au resistor obtained from

finite element analysis (FEA) with that obtained analytically

by using Eqn. (3). It is seen that the maximum difference

between the two is about 0.38%. The close match between

the two reveal that Eqn. (3), obtained from the ID model,

provides simple closed-form expression for temperature

distribution that enables quickly and accurately estimating the

steady-state temperature distribution. Further, the functional

dependence on the parameters evident in Eqns. (3) and (4)

facilitates design and optimization of the actuator. Finally, the

results of FE simulation also reveal that the effect of

convective heat transfer is negligible and thus, it does not

significantly affect the temperature profile.

B. Non-linear thermomechanical analysis of the SU8 thermal

actuator using FEA

me L1 ne L1 (m n) p 1 L1

L1

2

e

Fig. 2. (a) FE simulation showing the steady state temperature distribution in

a heated SU8 thermal actuator. (b) Analytical and finite element analysis

(FEA) showing the variation of temperature along the length of the SU8

thermal actuator.

2

L1

L

q L1

p 1 L1

2

2

me ne

r 1 m n

2 4

a

2

(4)

In order to validate this model, the steady state temperature

distribution within the SU8 thermal actuator was simulated

using finite element software (COMSOL). A 3D model of the

actuator was constructed using the dimensions and material

properties as mentioned in Table I. In this simulation, the

convective heat transfer for air was assumed to be 5 W/m2K.

Also, the effect of radiation was ignored considering low

operating temperatures in polymeric devices.

The thermal actuation of the SU8 thermal actuator was

simulated using coupled field multiphysics in COMSOL, by

combining the effects of Joule heating and thermal expansion

with mechanical deformation. Since the material properties of

a fully cross-linked SU8 polymer change with temperature,

the analysis also incorporated this effect. The dependence of

Young’s modulus and Poisson’s ratio on temperature for SU8

was obtained from S. Chung et al [29], who report their

values at four distinct temperatures, viz., 25ºC, 50ºC, 100ºC

and 150ºC. Since the SU8 material softens at 200˚C and loses

its mechanical stability [17], the Young’s modulus at 200ºC

was assumed to be zero. Subsequently a suitable nonlinear fit

was performed in order to estimate the mechanical properties

at other intermediate temperatures (Fig. 3(a) and (b)).

Accordingly, the dependence of Young’s modulus on

temperature was modeled to be

E (T ) E0 exp T

(5)

T

C

Where the constant E0 was identified to be 5.76GPa and the

temperature constant, Tc was identified to be 55.82˚C.

Likewise, the dependence of Poisson’s ratio on temperature

was modeled as

(T ) 0 1T 2T 2

(5)

4

For SU8, the constants𝜐0 , 𝜐1 and 𝜐2 which are obtained from

the experimental results were found to be 0.3116,

0.00103ºC-1and −1.99 × 10-6ºC-2respectively. The 3D CAD

model of the SU8 cantilever with Au strip over its surface is

shown in Fig. 3(c). The deformation of the actuator obtained

by incorporating the temperature effects on mechanical

properties in the finite element model is seen in Fig. 3(d). The

deflection profile as seen in Fig. 3(c) illustrates the direction

of cantilever bending towards the lower CTE layer i.e.

towards the Au layer along the positive Z-axis. The nonlinear thermomechanical model predicts the deflection profile

of the SU8 thermal actuator for actuation currents. The results

of this finite element analysis (FEA) are discussed further in

Section V(C), Fig. 13(b).

deposition, a bilayer lift-off technique was adopted which

includes lift-off resist (LOR10A) along with a positive

photoresist (S1813). By patterning and developing the bilayer

resist, an undercut is formed. Metal film deposited in such a

manner does not touch the walls of the resist and later the

resist can be easily stripped off. (d) 5µmthickSU8cantilever

layer was defined over the patterned metal resistor and the

contact pads by spinning negative photoresist SU8 2005 at

4000 rpm. Pre-exposure baking was done at 95ºC for 2 min

followed by 105 mJ/cm2of UV exposure. Post-exposure

baking was done at 95ºC for 3 min. (e) 100µm thick SU8

base layer was patterned over SU8 cantilever patterns. The

thick SU8 base serves as a supporting structure that holds

together the cantilever and electrical contact pads and also

helps in safe handling of the suspended SU8 thermal actuator.

In order to obtain 100µm thick base layer, SU8 2035 was

spun over SU8 cantilever patterns at 1000rpm followed by

pre-exposure baking at 65ºC for 5 min and 95ºC for 25min.

UV exposure of 450mJ/cm2results in SU8 base patterns. This

was followed by post exposure baking which was carried out

at 65ºC for 10 min and 95ºC for 20 min. At the end of the

photolithography process, the unexposed SU8 resist was

developed by immersing the entire silicon wafer containing

the SU8 cantilever and the base patterns in SU8 developer

(Microchem) for about 10min.

Fig. 3. (a) Variation of Young’s modulus of SU8 with temperature. (b)

Variation of Poisson’s Ratio of SU8 with temperature. (c) 3D CAD model of

the SU8 thermal actuator indicating the position of the Au resistor. (d) FE

simulation showing thermomechanical deflection of the actuator by

incorporating temperature dependent properties of SU8.

IV. FABRICATION OF SU8 THERMAL ACTUATOR

The SU8 thermal actuators were fabricated using surface

micromachining technique. Section IV A discusses the

patterning of SU8 cantilever structures along with the Au thin

film resistor. Section IV B discusses the releasing of

patterned SU8 structures while Section IV C discusses the

procedures for establishing electrical interconnection to the

fabricated actuator device.

A. SU8 thermal actuator patterning

The process steps involved in the fabrication of SU8

microcantilever is illustrated in Fig. 4(a-e). (a) The process

begins with RCA cleaning of p-type {100} silicon wafer

followed by wet thermal oxidation in order to produce 1 µm

silicon dioxide layer on the silicon wafer. This oxide layer

serves as an adhesion layer to pattern SU8 and also as a

sacrificial layer for SU8 cantilever release. (b) 5nm/50nm

thick chromium and gold (Cr/Au) films are sputter deposited

and patterned to form contact pads over the oxide layer. (c)

Cr/Au resistors of 5nm/50nm thickness were sputtered and

patterned over the Cr/Au contact pads. During Cr/Au

Fig. 4. Schematic showing the sequence of fabrication.

B. Releasing patterned SU8 thermal actuator

The patterned SU8 microcantilevers were released by

immersing the silicon wafer in 25% buffered hydrofluoric

acid (BHF) for 4-5 hours. Since SU8 and Au do not react in

BHF, only the silicon layer oxide layer between the SU8

layer and the silicon wafer gets etched, thereby releasing the

SU8 structures from the silicon wafer. The released SU8

chips with suspended microcantilevers remain floating on the

surface of the aqueous BHF. These structures were carefully

removed using polymer tweezers. Fig. 5(a) & (b) shows a

fully released SU8 microcantilever with integrated Au thin

film resistor on its surface.

5

Fig. 5.(a)Scanning Electron Micrograph (SEM) of released SU8

microcantilever. (b) Optical microscope image of suspended SU8

microcantilever with metal thin film resistors.

An important issue with fabricating SU8 microcantilever

by surface micromachining technique is the influence of

residual stress on the shape of the suspended microstructure.

This stress occurs due to large differences in the CTE values

of sacrificial layer(silicon dioxide, 0.56ppm/ºC) and SU8

layer(52ppm/ºC). In addition to the poor adhesion of SU8

onto Au surface, the CTE mismatch between SU8 and silicon

dioxide induces a tensile residual stress on the SU8 cantilever

surface, thereby sometimes resulting in peeling-off and

cracking of Au thin film (Fig. 6(a)). Further, the evaporation

of solvents during the processing of SU8 negative photoresist

after UV exposure results in non-uniform stress across the

thickness of SU8 layer. This stress gradient induces an

upward curvature in the SU8 cantilever as seen in Fig. 6(b).

Also, Fig. 6(c) shows the cracks on SU8 films just after post

exposure baking and development. These film cracks and the

undesirable cantilever curvature can be minimized by

controlling SU8 soft baking and post exposure baking

temperatures during lithography [32].

bonding technique was adopted by combining Au ball bump

formation along with conductive epoxy bonding methods

[33]. First, a suitable printed circuit board (PCB) was

designed such that the Au contact pads on the fabricated SU8

chip are aligned with the PCB contact pads (Fig. 7(a)). Then,

Au ball bump was formed on the surface of PCB contact pad

by ball wedge bonding. The Au ball bump ensures electrical

connectivity between the SU8 chip and the PCB. Finally,

SU8 chip was attached to the PCB pads using silver

conductive epoxy (H20E EPO-TEK, Ted Pella, Inc.). The

cross-sectional view of Au ball bump on PCB with silver

epoxy underfill is seen in Fig. 7(b). Once the SU8 chip

attached, it is slightly pressed against PCB to planarize the

silver epoxy underfill and the epoxy is cured at room

temperature for 48 hours. The optical microscope image of

SU8 chip bonded over PCB is seen in Fig. 7(c). The silver

epoxy not only provides good electrical connectivity, but also

ensures better adhesion of SU8 chip with PCB.

The average electrical resistances of Au resistors, measured

just after flip-chip bonding was found to be about 120 Ω.

After connecting wires were soldered onto PCB with SU8

chip, the overall resistance was in the range 120-130 Ω.

Fig. 7. (a) Schematic showing a SU8 chip contact pads aligned with the

PCB’s. (b) Schematic cross-section showing Au ball bump with silver epoxy

underfill.(c) Optical image showing SU8 chip attached to PCB via flip-chip

bonding.

V. EXPERIMENTAL RESULTS AND DISCUSSION

Fig. 6. (a) SEM image showing peeling off Au thin film. (b) SEM image

showing cantilever curvature due to residual stress. (c) Optical image

showing the cracks on patterned SU8 layer

C. Electrical Interconnection

After fabrication of the SU8 based thermal actuators, it is

necessary to make electrical contact with them. Conventional

wire bonding techniques used in packaging silicon based

MEMS devices fail in the case of SU8 polymer material. This

is because polymers are good thermal insulators and also

absorb ultrasonic vibrations, thereby making conventional

wire bonding difficult. In this work, therefore, flip-chip

This section discusses the results of experimental

characterization of the actuator. Section V A describes the

set-up employed for performing characterization. Section V B

discusses the release of residual stress in the actuators.

Section V C discusses the experimentally measured

deformation profile of the actuator and compares them with

analytical results. Finally, Section V D discusses the possible

improvements that can be achieved in the analytical model by

incorporating nonlinear temperature dependence of the

thermal expansion of SU8 material.

A. Experimental setup for characterization of the SU8

thermal actuator

The experimental arrangement used to determine the

thermomechanical response of a fabricated SU8 thermal

actuator is illustrated in Fig. 8(a). Keithley source-meter

6

(2440 5A) was used to supply constant DC current to the Au

resistor in order to produce thermal actuation of SU8

cantilever. The subsequent SU8 cantilever deflection was

measured using non-contact 3D optical profiler (Talysurf,

CCI). A focused optical laser light was scanned over the

actuator and reference cantilever to obtain their relative

displacements along Z-axis. Fig. 8(b) shows the optical

microscope image of the fabricated actuator cantilever anlong

with the reference cantilever when the actuation current, I = 0

mA. Also, it’s 2D surface profile is seen in Fig. 8(c). Thermal

actuation experiment was carried out in air at room

temperature and the experimental observations are discussed

in the following section.

Fig. 8. (a) Schematic showing the experimental set-up used for the

characterization ofSU8 thermal actuator. (b) Optical microscope image of the

SU8 microcantilevers when I= 0 mA. (c) Typical 2D surface profile of the

actuator and reference SU8 microcantilevers obtained using 3D optical

profiler when I= 0 mA.

B. Release of residual stress in the SU8 thermal actuator

Residual stress in the actuator arises due to mismatch

between the CTEs of SU8 and the silicon dioxide substrate.

Some papers [32], [34] discuss the significance of fabrication

processing conditions such as hard bake temperature and

baking time in reducing the effect of residual stress during the

fabrication of SU8 microstructures. While there are several

charaterization techniques used to measure residual stress in

conventional silicon MEMS devices [35], there are few

reportson characterizing residual stress in polymeric MEMS

structures. The effect of residual stress can be observed

during the thermal actuation process. Fig. 9(a)shows the

thermal response of SU8 thermal actuator, measured with

respect to its evaluated by passing current from 0 to 5 mA in

steps of 0.5 mA. The plot labeled ‘Trial_1’ in Fig. 9(a) shows

the deflection of the actuator before release of thermal stress.

It is seen from the plot that the actuator deflects downwards,

i.e., in a direction opposite to the expected trend. However,

upon increasing the current beyond 4mA, for which the

maximum rise in temperature is 125ºC, the actuator starts to

deflect in the expected manner, presumably due to release of

thermal stress. A similar strategy, of gradually heating the

polymer close to its softening temperature, has also been

suggested [21]. Once the stress is released, the subsequent

actuation trials do not show the initial trend, but instead

deflect as expected. Further, the deflections were found to be

repeatable over several cycles of actuation (traces Trial_2,

Trial_3, and Trial_4 in Fig. 9(a)). Figs. 9 (b) and (c) show

the optical profilometer images of the profile of the actuator

before and after release of thermal stress respectively. The

reference cantilever seen in the 3D deflection profiles is used

to compare with the actuator deformation profile after

releasing residual stress.

Fig. 9. (a) Thermal response of SU8 thermal actuator illustrating residual

stress release during actuation process. (b) The position of actuator before

releasing the residual stress when actuation current, I=0. (c) Slightly bent

position of an actuator after releasing the residual stress when actuation

current, I= 4 mA.

It is worth noting that care has to be exercised in passing

appropriate actuation current during this process, so that the

maximum temperature does not exceed the softening

temperature of SU8 (225ºC). When the current exceeds 6

mA, the corresponding tempertaure rise in the actuator is

about 200ºC. At this temperature the SU8 polymer softens,

losses mechanical stability and undergoes permanent,

irreversible curling as seen in Fig. 10(b). However, this

curling effect can be avoided by operating the actuator well

below 6 mA.

7

Fig. 10.SEM image showing (a) SU8 microcantilever before thermal

heating.(b) The irreversible curling of SU8 microcantilever after 6mA

actuation current is passed. 40º tilted view of the curled up SU8 actuator is

inset.

C. Thermomechanical actuation of the SU8 thermal actuator

The thermomechanical performance of a stress-free SU8

actuator was experimentally obtained using 3D optical

profiler. Fig. 11(a-d) shows 3D profiles of SU8 actuator

deflection for different actuation currents, while Fig. 11 (e)

shows the corresponding 1D deflection profiles of the

actuator. The actuator displayed a small deflection even when

the current I through the actuator was zero, owing to the

release of thermal stress. The deflection of the actuator at

higher currents was measured relative to this initial profile.

When the current I was increased upto 5 mA, the rise in

temperature within the SU8-Au bimorph induces

corresponding thermomechanical deflection of the actuator as

seen in Fig. 11(b-d). When the actuation current is about 6

mA the deflection of the actuator exceeds the measurement

range, of the optical profiler. Fig. 11(f) compares the

experimentally obtained deflection profile of the actuator,

relative to its initial profile, at one particular current, viz., I=4

mA, with the results of non-linear thermomechanical

analysis. It is observed that the experimental deformation

profile agrees with the non-linear FEA with a maximum

difference between the two being about 14.3%. Similar

agreement between experiment and FEA were also found at

other actuation currents.

Fig. 11.(a-d) 3D profile showing SU8 thermal actuator deflection at different

actuation currents.(e) 1D cantilever deformation profile of the SU8 actuator.

(f) 1D deformation profile of the actuator obtained experimentally is

compared with non-linear FEA for an actuation current of 4mA.

The thermal response for a single heating and cooling cycle

of a stress-free actuator is shown in Fig. 12(a). The response

indicates low hysteresis and good repeatability. In order to

compare the experimentally observed thermal response of the

SU8 thermal actuator, Fig. 12(b) plots the experimentally

observed responses from three distinct actuators along with

the results of both nonlinear and linear FEA. It can be

observed that the three actuators show maximum deflection

about 6 to 10 μm for an actuation current of 5 mA. The

nonlinear FE simulation results are seen to agree well with

the experimentally observed thermal response, but slightly

underestimate the deflection, especially at higher currents. In

contrast, the results of linear FEA, which ignores the

variation of Young’s modulus and Poisson’s ratio with

temperature, is seen to underestimate the deflection by over

70%. This underscores the need to incorporate the

dependence of mechanical properties of SU8 on temperature

when analyzing the overall mechanical deflection of a SU8

based thermal actuator.

8

chip bonding technique was employed. The thermal response

of the actuators was experimentally evaluated. The fabricated

actuators showed the effects of residual stress and resulted in

anomalous deflection in the first trial. However, it was shown

that heating the actuator adequately can alleviate the effect of

residual stress. Subsequently, the actuator was demonstrated

to show repeatability and low hysteresis in response. The

experimentally measured average actuation range, of about

8.5μm for a current of about 5mA, was found to be in good

agreement with theory. It was demonstrated that

incorporation of the nonlinear thermal expansion of SU8 in

the model can further improve the correspondence between

experiment and theory. The analysis and experimental

evaluation results presented in this paper enable precise

design of thermally actuated micromanipulation tools for

robotic microgrippers and micro tweezers. They also provide

a strategy to eliminate residual stress after fabrication.

ACKNOWLEDGMENT

Fig.12. (a) Thermal response of a stress-free SU8 thermal actuator obtained

experimentally. (b) Comparison of experimental and FEA results.

The authors wish to acknowledge the Centre for Nano

Science and Engineering (CeNSE), Indian Institute of

Science, Bangalore for providing microfabrication and

characterization

facilities.

Authors

also

thank

Prof.M.M.Nayak of CeNSE for his kind suggestions and help

regarding the packaging aspects of the actuators.

D. Discussion

While the results of finite element analysis generally agree

with the experimental results, the difference between the two

can be attributed primarily to errors in estimation of the TEC

and the Young’s modulus of SU8. Further, it is noticed that

the error is significant primarily for larger currents, for which

case, the operating temperature of the actuator is close to the

softening temperature of SU8. Since it is reasonable to expect

small nonlinearity in CTE in this temperature range, it is

assumed that the CTE "𝛼2 " of SU8 demonstrates a variation

with temperature as,

2 (T ) 2 (T0 ) 1 T T0

(7)

Where, the constant 𝛼2 (𝑇0 ) is identified to be 52 ppm /ºC.

Then, the dashed curve in Fig. 12(b) shows the estimated

deflection profile when the value of ε = 0.00175ºC -1. It is

evident that the new curve is closer to the experimentally

observed deflection. Thus, incorporation of nonlinearity in

CTE, based on physical considerations of the operating

temperature, is seen to result in a significantly better

agreement between the nonlinear finite element model and

the experiment.

CONCLUSION

This paper reported design, thermomechanical analysis,

fabrication and evaluation of an SU8 based thermal actuator.

Thermomechanical analysis of the response of the actuator

was performed by incorporating the temperature-dependant

mechanical properties of SU8. Subsequently the actuator was

fabricated using surface micromachining techniques. In order

to make electrical connection with the polymer actuator, flip-

REFERENCES

[1]

A. Boisen, S. Dohn, S. S. Keller, S. Schmid and M. Tenje,

“Cantilever-like micromechanical sensors,” Rep. Prog.Phys., 74,

036101, pp. 1-30, 2011.

[2] Y. P. Hsieh, C. Y. Chen, Z. H. Wei, M. F. Lai, “Magnetically actuated

micromechanical tweezers,” Sens. Actuators A-Phys., 172, pp. 471474, 2011.

[3] V. Seidemann, S. Butefisch, S. Buttgenbach, “Fabrication and

investigation of in-plane compliant SU8 structures for MEMS and

their application to microvalves and micro grippers,” Sens. Actuators

–A-Phys.,97-98, pp.457-461, 2002.

[4] L. Wang, J. K. Mills, W. L. Cleghorn, “Novel approach for

microassembly of three-dimensional rotary MOEMS mirrors,” J.

Micro/Nanolith. MEMS MOEMS., vol. 8, 043035, pp. 1-4, 2009.

[5] N. Chronis and L. P. Lee, “Electrothermally activated SU-8

microgripper for Single Cell Manipulation in Solution,” J.

Microelectromech. Syst., vol. 14, no. 4, pp. 857-863, 2005.

[6] E.W. H. Jager, O. Inganas, and I. Lundstrom, “Microrobots for

micrometer-size objects in aqueous media: Potential tools for singlecell manipulation,” Science, vol. 288, pp. 2335–2338, 2000.

[7] W. Dai, K. Lian and W. Wang, “Design and fabrication of SU8 based

electrostatic microactuator,” Microsyst. Technol., vol 13, pp. 271-277,

2007.

[8] I.Chakraborty, W.C Tang, D.P Bame and T.K Tang, “MEMS microvalve for space applications,” Sens. Actuators A-Phys., vol. 83, issues

1-3, pp. 188-193, 2000.

[9] I. Roch, P. Bidaud, D. Collard and L. Buchaillot, “Fabrication and

characterization of an SU-8 gripper actuated by a shape memory alloy

thin film,” J. Micromech. Microeng.,vol. 13, pp. 330-336, 2003.

[10] B. Mitra and A. Gaitasa, “Thermally actuated tapping mode atomic

force microscopy with polymer microcantilevers,” Rev. Sci. Instr., vol.

80, 023703, pp. 1-4, 2009.

[11] G. K. Lau, J. F. L. Goosen, F. V. Keulen, T. C. Duc, and P. M. Sarro,

“Polymeric thermal microactuator with embedded silicon skeleton:

9

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[23]

[24]

[25]

[26]

[27]

[28]

[29]

[30]

[31]

[32]

Part I—design and analysis,” J. Microelectromech. Syst.,vol. 17, no.

4, pp. 809-822, 2008.

J. Lee and W. P. King, “Microcantilever actuation via periodic internal

heating,” Rev. Sci. Instr., vol. 78, 126102, pp. 1-3, 2007.

H. Y. Chan and W. J. Li, “A thermally actuated polymer micro robotic

gripper for manipulation of biological cells,” Proc. IEEE Int. Conf. on

Robotics and Automation, Taipei, Taiwan, Sep 2003.

M. Ataka, A. Omodaka, N. Takeshima, and H. Fujita, “Fabrication

and operation of polyimide bimorph actuators for a ciliary motion

system,” J. Microelectromech. Syst., vol. 2, no. 4, pp. 146-150, 1993.

E. Smela, M. Kallenbach and J. Holdenried, “Electrothermally driven

polypyrrole bilayers for moving and positioning bulk micromachined

silicon plates,” J. Microelectromech.Syst., vol. 8, no. 4, pp. 373-382,

1999.

R. E. Mackay, H. R. Le and R. P. Keatch, “Design optimization and

fabrication of SU-8 based electro-thermal micro-grippers,” J. MicroNano Mech., vol.6, pp. 13–22, 2011.

A. D. Campo and C. Greiner, “SU-8: a photoresist for high-aspectratio and 3D submicron lithography,” J. Micromech. Microeng., vol.

17, pp. R81-R95, 2007.

H. Lorenz, M. Despont, N. Fahrni, N. LaBianca, P. Renaud and P.

Vettiger, “SU-8: a low-cost negative resist for MEMS,” J. Micromech.

Microeng., vol. 7, pp. 121-124, 1997.

B. Solano, S. Rolt, and D. Wood, “Thermal and mechanical analysis

of an SU8 polymeric actuator using infrared thermography,” Proc.

IMechE Vol. 222 Part C: J. Mechanical Engineering Science., pp. 7385, 2008.

B. Kim, D. Collard, M. Lagouge, F. Conseil, B. Legrand and L.

Buchaillot, “Thermally actuated probe arrays for manipulation and

characterization ofindividual bio-cell,” Proc. 12th Int. Conf. Solid

State Sensors, Actuators and Microsyst., Boston, June, 2003.

G. Lin, C.-J. Kim, S. Konishi and H. Fujita, “Design, fabrication and

testing of a c-shape actuator,” Proc.8th Int. Conf. Solid-State Sensors

and Actuators, and Eurosensors IX, Sweden, 1995.

J.K. Luo, R. Huang, J.H. He, Y.Q. Fu, A.J. Flewitt, S.M. Spearing,

N.A. Fleck, W.I. Milne, “Modelling and fabrication of low operation

temperature microcages with a polymer/metal/DLC trilayer structure,”

Sens. Actuators A-Phys., 132, pp. 346–353, 2006.

V. Lulevich, T. Zink, H. Y. Chen, F. T. Liu and G. Y. Liu,” Cell

Mechanics Using Atomic Force Microscopy-Based Single-Cell

Compression,”Langmuir, vol. 22, pp. 8151-8155, 2006.

M. Hopcroft, T. Kramer, G. Kim, K. Takashima, Y. Higo, D. Moore

and J. Brugger, “Micromechanical testing of SU-8 cantilevers,”

Fatigue. Frac.Engng.Mater.Struct, vol 28, issue 8, pp. 735–742,2005.

T. Winterstein, M. Staab, C. Nakic, H. J. Feige, J. Vogel andH. F.

Schlaak, “SU-8 Electrothermal Actuators: Optimization of Fabrication

and Excitation for Long-Term Use,”Micromachines, vol. 5, pp. 13101322, 2014.

N. T. Nguyen, S. S. Ho and C. L. N. Low, “A polymeric microgripper

with integrated thermal actuators,” J. Micromech.Microeng., vol. 14,

pp. 969-974, 2004.

X. Zhang, Y. Wu, X. Miao, C. Zhang and G. Ding, “An electrothermal

SU-8 cantilever micro actuator based on bimorph effect,” 5th IEEE

International Conference on Nano/Micro Engineered and Molecular

Systems (NEMS), pp.362-365, Jan. 2010.

R. Voicu, R. Mäuller , L. Eftime, C. Tibeica, “Design Study for An

Electro-Thermally Actuator for Micromanipulation,” Rom. J. Inf. Sci.

Tech. vol. 12, No 3, pp. 402-409, 2009.

S. Chung and S. Park, “Effects of temperature on mechanical

properties of SU-8 photoresist material,” Journal of Mechanical

Science and Technology., vol. 27, no.9, pp. 2701–2707, 2013.

Y. Zhang, Y. Zhang and R. B. Marcus,“Thermally actuated

microprobes for a new wafer probe card,” J. Microelectromech.Syst.,

vol. 8, no. 1, pp. 43-49, 1999.

F. P. Incropera and D. P. Dewitt, Fundamentals of heat and mass

transfer. New Delhi: Wiley 2009.

S. Keller, D. Haefliger and A. Boisen, “Fabrication of thin SU-8

cantilevers: initial bending, release and time stability,” J. Micromech.

Microeng.,vol. 20, 045024, pp. 1–11, 2010.

[33] A. Johansson, J.Janting, P. Schultz, K. Hoppe, I. N. Hansen and

A.Boisen, “SU-8 cantilever chip interconnection,” J. Micromech.

Microeng., vol.16, pp. 314–319, 2006.

[34] D.Sameoto, S. H. Tsang, I. G. Foulds and S. W. Lee, “Control of the

out-of-plane curvature in SU8 compliant microstructures by exposure

dose and baking times,” J. Micromech. Microeng., vol. 17, pp. 10931098, 2007.

[35] K. S. Chen, MEMS/NEMS Handbook, Techniques in residual stress

measurement for MEMS, Springer, 2006.