Companion volume_Range of conditions V6

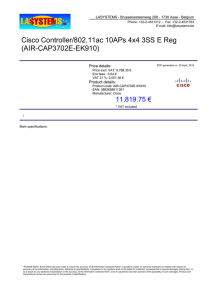

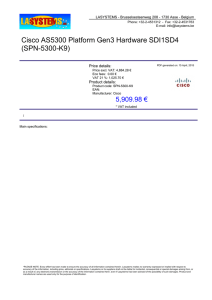

advertisement